In 2026, hollow wall anchors serve specific, light-duty roles on standard, healthy walls. They are not appropriate for heavy, valuable, or safety-critical items. Such applications require superior fasteners, like specialized Anchor Bolts or even custom anchor bolts sourced from a custom fasteners manufacturer.

The right choice ultimately depends on the load, the wall’s integrity, and the installer’s tolerance for risk. This guide provides clear rules for any project.

Understanding Hollow Wall Anchors in the Modern Era

Before deciding on a fastener, professionals must understand the mechanics and limitations of traditional anchors. The technology has evolved, but the foundational principles and inherent weaknesses remain critical knowledge for any project in 2026.

What Are Hollow Wall Anchors and How Do They Work?

The Basic Principle: Spreading the Load

An anchor’s primary function is to distribute an object’s weight over a wider surface area. A key activated locking action transforms the anchor into a rigid, weight-distributing truss inside the hollow wall. This mechanism provides secure holding power for light and medium loads, preventing the fastener from pulling straight out of the fragile wall material.

Why You Can’t Just Use a Screw in Drywall

Drywall is essentially compressed gypsum powder between two sheets of paper. Driving a screw directly into it provides almost no holding power. The screw threads have nothing substantial to grip. Any significant weight or slight pull will cause the gypsum to crumble, creating a larger hole and a failed mounting.

The Role of Anchors When You Can’t Find a Stud

Wall studs are the vertical wood or metal framing members that form the skeleton of a wall. They offer the most secure mounting point. When an item’s placement does not align with a stud, hollow wall anchors become the necessary alternative for fastening objects to the empty space between them.

Common Types of Traditional Hollow Wall Anchors

Different anchors offer varying levels of strength. Their capacities dictate their appropriate use.

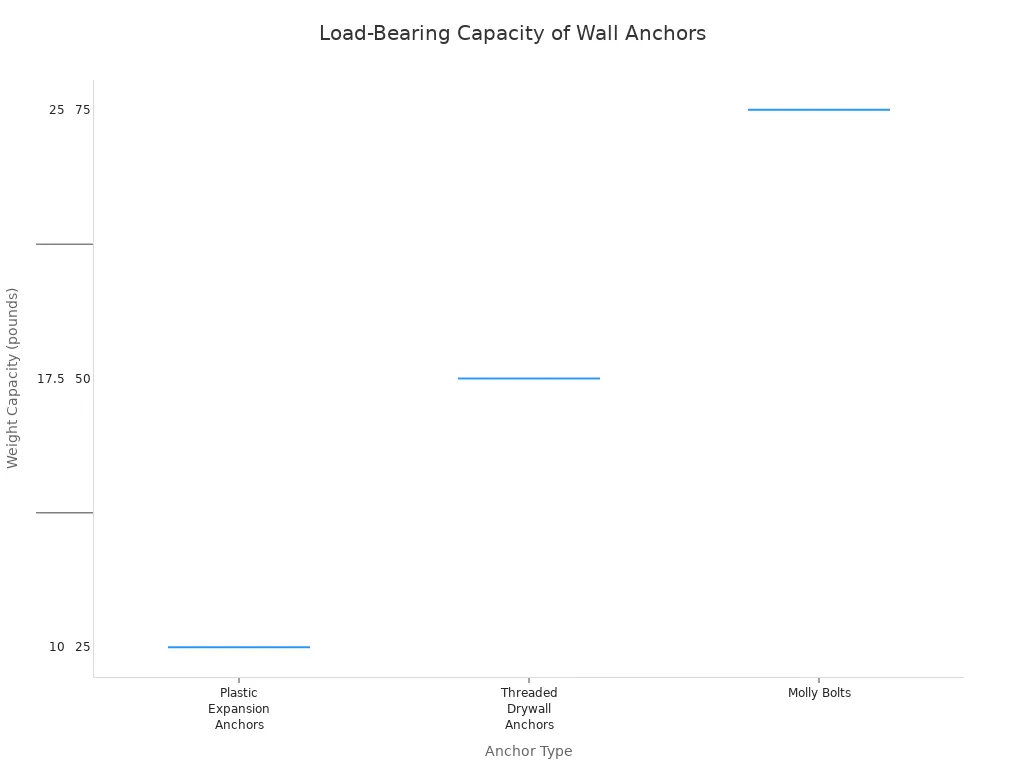

| Anchor Type | Weight Capacity (pounds) |

|---|---|

| Plastic Expansion Anchors | 10-25 |

| Threaded Drywall Anchors | 25-75 |

| Molly Bolts | 50-75 |

| Toggle Bolts | 100-200 |

Plastic Expansion Anchors

These are the most common and least robust anchors. A screw forces the plastic sleeve to expand, creating friction against the inside of the drywall. They are suitable only for the lightest, most static items.

Self-Drilling Threaded Anchors

Often made of nylon or zinc, these anchors feature wide threads that cut directly into the drywall. They offer better holding power than simple plastic anchors but can damage the wall if over-tightened.

Classic Molly Bolts

Molly bolts are metal anchors with a sleeve that collapses and expands behind the drywall as the screw is tightened. This creates a very secure, non-removable brace.

Spring-Loaded Toggle Bolts

These provide the highest holding power among traditional anchors. A spring-loaded “wing” passes through a hole and opens flat against the back of the wall. Tightening the bolt clamps the wing securely against the interior wall surface.

Factors That Degrade Anchor Performance Over Time

An anchor’s initial strength is not permanent. Environmental factors and the wall itself can compromise its integrity over the years.

Humidity and Material Fatigue

Prolonged exposure to high humidity is detrimental to drywall.

- Material Distortion: Gypsum readily absorbs moisture, causing the drywall panel to swell, warp, and lose its structural integrity.

- Mold Growth: Humid conditions promote mold, which can weaken the paper and core of the drywall.

- Structural Instability: Over time, moisture can soften the material around an anchor, reducing its holding power significantly.

Vibrations and Dynamic Loads

Constant vibrations from appliances or frequent pulling on an object (like a towel rack) create dynamic loads. This repeated stress can slowly enlarge the hole in the drywall, causing the anchor to loosen and eventually fail.

The Aging of Drywall Itself

Drywall becomes more brittle and fragile as it ages. An old wall may not have the same strength it did when it was first installed. This makes it more susceptible to crumbling and anchor failure, even under loads it could previously support.

When You SHOULD Use Hollow Wall Anchors in 2026

Despite the rise of advanced fasteners, traditional hollow wall anchors retain a valid place in a professional’s toolkit in 2026. Their use is appropriate when the application aligns with their known strengths and limitations. Professionals should use them for specific tasks where load, wall condition, and risk are all well within acceptable parameters.

For Light-to-Medium Loads on Standard Drywall

The ideal scenario for a traditional anchor is a light-to-medium static load mounted on a standard, healthy sheet of 1/2-inch or 5/8-inch drywall.

Hanging Pictures and Artwork

This is a classic and appropriate use for wall anchors. Most picture frames and canvas art are lightweight and exert a simple, downward shear force. For heavier pieces, installers can confidently use stronger traditional options.

- Toggle bolts, for instance, can reliably support loads from 25 to 50 pounds in standard drywall. This capacity makes them suitable for large framed prints or decorative mirrors.

Mounting Small Decorative Shelves

Installers can use anchors for small shelves intended for light, decorative objects. However, caution is essential. The shelf itself adds weight, and the items placed upon it increase the load. Industry testing reveals a significant drop in capacity when relying on anchors instead of studs.

| Bracket Style | Stud-Mounted Capacity | Anchor-Mounted Capacity (Approx.) |

|---|---|---|

| Lucas L Bracket | 45 lbs | 27 lbs |

| Glimmerglass J Bracket | 60 lbs | 36 lbs |

| Jane J Style Bracket | 35 lbs | 21 lbs |

| Seneca Shelf Support | 80 lbs | 48 lbs |

As the data shows, mounting into drywall with anchors reduces a bracket’s holding power by approximately 40%. A shelf’s intended load must always fall well below this reduced capacity.

Securing Curtain Rods and Blinds

Curtain rods and blinds are generally lightweight, making anchors a viable mounting solution. This application involves a dynamic load from opening and closing the curtains, so choosing a robust anchor is critical. A simple plastic anchor may loosen over time. A Molly bolt or toggle bolt provides a much more secure hold against this repeated movement.

Installing Smoke Detectors and Thermostats

These devices are perfect candidates for simple wall anchors. They are extremely lightweight, static, and place almost no load on the fastener. In these cases, a basic plastic expansion anchor or a small threaded anchor is more than sufficient and provides a quick, effective installation.

When Cost and Availability Are Key Factors

Practical considerations like budget and accessibility often influence fastener choice. Traditional anchors excel in these areas for non-critical applications.

Budget-Friendly Project Solutions

Traditional anchors are exceptionally inexpensive. For large-scale projects with tight budgets, such as outfitting an office or staging a home, the cost savings can be substantial. This makes them the logical choice for hanging dozens of lightweight pictures or small bulletin boards where performance is not safety-critical.

Quick Fixes with Hardware Store Access

Urgent repairs or last-minute installations demand readily available parts. Traditional anchors are ubiquitous. A quick trip to a local hardware store provides access to a wide array of options for immediate project needs. For example, retailers like Sutherlands consistently stock a diverse inventory.

- HILLMAN® #8 Nylon Wallboard Anchors

- HILLMAN® 3/16 x 3-Inch Toggle Bolts

- HILLMAN® 1/4-Inch Long Hollow Wall Anchors

- HILLMAN® Ribbed and Conical Plastic Anchor Kits

This widespread availability makes them a reliable fallback for quick, simple jobs.

Bulk Installations for Non-Critical Items

Projects requiring many mounting points, like creating a gallery wall of small family photos, benefit from the low cost and fast installation of traditional anchors. The efficiency of using simple threaded or plastic anchors for numerous lightweight, non-essential items makes them a practical and logical choice.

For Specific, Proven Anchor Types

Not all traditional anchors are equal. Choosing the correct type for the specific job is paramount to a successful and lasting installation.

The Enduring Reliability of Toggle Bolts

For the heaviest loads appropriate for drywall, the toggle bolt remains a champion. Its design, which features a metal bar that flips open to brace against a large area of the wall’s interior, provides superior holding power compared to anchors that rely on friction or expansion within the hole itself.

Using Molly Bolts for Secure Fixtures

Molly bolts offer a permanent and very secure mounting point. Their metal sleeve expands to create a rigid, load-bearing flange behind the drywall. Proper installation is key to achieving their maximum strength.

- Drill a hole to the exact size specified for the anchor. A snug fit is crucial.

- Gently tap the anchor into the hole until its toothed flange bites into the drywall surface.

- Turn the screw to expand the anchor’s sleeve behind the wall. An installer should stop when they feel solid resistance.

- Remove the screw, position the fixture, and re-insert the screw to secure it.

Pro Tip: 💡 Professionals often use a dedicated ‘Molly Bolt Setting Tool‘. This tool pulls the screw to expand the anchor quickly and correctly, which is much easier than using a screwdriver and reduces the risk of damaging the drywall by over-tightening.

When Plastic Anchors Are Good Enough

The simple, ribbed plastic anchor has a limited but important role. It is “good enough” only for the lightest, completely static objects. Examples include hanging a wall calendar, a small key hook, or a lightweight thermostat cover. For any item with notable weight or value, an installer should select a more robust anchor.

When You SHOULD NOT Use Hollow Wall Anchors in 2026

The decision to forgo a traditional anchor is just as important as knowing when to use one. In 2026, with a clear understanding of material science and the availability of superior fasteners, professionals must recognize situations where using a standard anchor introduces unacceptable risk. These scenarios involve heavy loads, compromised walls, or the simple fact that a better solution exists.

For Heavy, Dynamic, or Safety-Critical Loads

The primary limitation of any drywall anchor is the strength of the drywall itself. For items that are heavy, subject to movement, or essential for safety, relying on drywall alone is a professional misstep.

Mounting Large Televisions

Modern televisions are lighter than their predecessors, but they remain heavy, expensive, and are often mounted in high-traffic areas. A failed anchor could result in thousands of dollars in damage and pose a significant safety hazard. The combination of high value and potential danger makes stud-mounting the only responsible option.

Hanging Heavy Kitchen Cabinets

Kitchen cabinets must support their own substantial weight plus the variable weight of dishes, food, and cookware. The total weight of the load can easily exceed the capacity of drywall. A significant problem with wall anchors is their tendency to feel secure upon initial installation. However, an anchor poorly matched to the wall material can loosen over time, leading to catastrophic failure. Toggle bolts offer high strength, but even they have limits; the wallboard itself will often fail before a heavy-duty toggle bolt does. For this reason, professionals should secure at least two screws per cabinet directly into a wall stud.

Installing Safety Grab Bars

Grab bars are life-safety devices. Their installation is not a matter of convenience; it is governed by strict building codes and common sense. Using anchors in drywall for this purpose is negligent. Building codes, like the International Residential Code, mandate specific requirements for a secure installation.

- Bars must support a minimum of 250 pounds.

- Mounting hardware must be corrosion-resistant.

- Most importantly, grab bars must be anchored securely into wall studs. A non-stud installation is unreliable and dramatically increases the risk of failure when a person needs it most.

Supporting Floating Desks or Bookshelves

Floating desks and bookshelves are prime examples of dynamic, high-capacity loads. They invite users to lean on them, stack heavy books, or place dense equipment on their surface. The leverage exerted by a deep shelf multiplies the force on the fastener. Standard anchors are simply not designed to handle this combination of high static weight and unpredictable dynamic force.

On Compromised or Non-Standard Wall Materials

An anchor is only as strong as the material it is in. Using any anchor in a wall that is old, damaged, or structurally unusual is asking for trouble.

Old, Crumbly Plaster and Lath

Plaster and lath walls, common in older buildings, are fundamentally incompatible with most expansion-style anchors designed for drywall. Their physical properties create a hostile environment for these fasteners.

- Hardness & Brittleness: Plaster is hard but shatters easily. The expansive force from a typical anchor will often cause the plaster around the hole to crumble, leaving nothing for the anchor to grip.

- Internal Structure: Behind the plaster lies a grid of wood or metal lath with gaps in between. An anchor might hit a solid lath strip, but it is just as likely to land in a void where it cannot function correctly.

- Inconsistency: Plaster thickness and integrity can vary dramatically across a single wall, making anchor performance completely unpredictable.

Thin, Damaged, or Moisture-Exposed Drywall

Using anchors in compromised drywall is a recipe for failure. Any previous damage or exposure to moisture renders the wall panel structurally unsound.

- Moisture infiltration causes the gypsum core to soften and lose its integrity.

- The paper facing absorbs water, becoming mushy and prone to tearing.

- This damage leads to a warped appearance and a dramatic reduction in the material’s ability to hold a fastener. An anchor in damp drywall has virtually no holding power.

Walls with Unknown Internal Obstructions

Drilling into a wall without knowing what is behind it is a significant risk. A professional installer must always consider the possibility of hitting plumbing lines, electrical wiring, or HVAC ducts. While a stud finder can locate studs, it may not detect these other obstructions. Blindly drilling for an anchor can lead to costly repairs or dangerous electrical situations.

Double-Layer Drywall Complications

Some walls are constructed with two layers of drywall for fire resistance or soundproofing. This extra thickness, typically 1 inch to 1 1/4 inches total, is too deep for standard-length hollow wall anchors. The anchor’s expansion mechanism will deploy between the two layers of drywall instead of behind them, providing a dangerously weak hold that feels deceptively tight.

When Modern Alternatives Offer Clear Advantages

Sometimes, the reason not to use a traditional anchor is simply that a far better product is readily available. Modern fasteners have evolved to solve the classic problems of strength, installation ease, and wall damage.

For Superior Holding Power

Modern self-drilling and strap-style toggle anchors offer significantly greater strength than many traditional options. The engineering behind these products provides a more reliable hold, especially for medium-to-heavy loads. A direct comparison reveals the clear performance gap.

| Anchor Type | Shear Strength (lbs) in 1/2″ Drywall | Pull-out Strength (lbs) in 1/2″ Drywall |

|---|---|---|

| Traditional Toggle Bolt (1/8″) | ~31 | Significantly Lower |

| Cobra WallDriller (Nylon #8) | 50-80 | 23-38 |

| Toggler Strap Toggle | ~130 | ~65 |

Note: 💡 The data clearly shows that modern designs can offer more than double the holding power, making them a safer choice for valuable or heavier items.

For Ease of Installation and Removal

Many modern anchors are designed for speed and convenience. Self-drilling tips eliminate the need for a pilot hole, streamlining the installation process. Furthermore, unlike a traditional spring toggle that falls into the wall cavity if the bolt is removed, many modern strap toggles hold their position, allowing for fixture removal and re-installation.

To Minimize Wall Damage

A major drawback of the strongest traditional anchor—the spring toggle—is the massive hole required for installation. Modern designs have solved this problem, providing equal or greater strength with significantly less damage to the wall.

| Toggle Anchor Type | Required Hole Size |

|---|---|

| Traditional Metal Toggle Bolt | ~3 times the bolt diameter (e.g., >1/2″ for a 3/16″ bolt) |

| Modern Strap-Style Toggle Anchor | 1/2-inch hole |

This smaller footprint makes installation cleaner, patching easier, and preserves the structural integrity of the surrounding drywall.

The Rise of Modern Alternatives in 2026

The fastener landscape in 2026 has evolved significantly. Modern anchors offer superior performance and solve many problems associated with traditional designs. Professionals and DIYers now have access to specialized solutions that provide greater strength, easier installation, and less wall damage for a variety of applications.

Advanced Self-Drilling Toggle Anchors

How They Combine Strength and Simplicity

Modern toggle anchors merge the brute strength of a traditional toggle with the convenience of a self-drilling tip. These fasteners often use a metal channel that flips into place behind the drywall, distributing the load over a large surface area. The installation process is streamlined, as many designs do not require a pre-drilled pilot hole.

Why They Are a Game-Changer for DIYers

These anchors eliminate much of the guesswork and potential for error. Their all-in-one design simplifies installation, and many feature a strap that keeps the toggle from falling into the wall if the bolt is removed. This allows for easy removal and re-installation of fixtures, a major improvement over classic spring toggles.

Top Brands to Look for in 2026

Installers should look for brands that have established a reputation for reliability and innovation. Companies like Toggler, Cobra, and Hillman offer advanced toggle designs that consistently outperform older anchor types in holding power and ease of use.

Specialty Anchors for Problematic Walls

Solutions for Plaster and Lath

Mounting on plaster and lath requires anchors that do not rely on simple expansion, which can crack the brittle plaster. Strap-style toggle anchors are an excellent choice. They require a small hole and brace against the solid lath or the back of the wall, providing a secure hold without shattering the surrounding material.

Anchors Designed for Metal Studs

Mounting heavy items to steel studs presents a unique challenge. Specialized fasteners provide a reliable solution. The ‘1Shot Steel Stud Anchor’, for example, is designed specifically for this purpose. It allows installers to securely mount heavy items like cabinets and TVs to interior walls in steel-framed buildings. Its design is reliable and easy to use for both homeowners and builders.

Fasteners for Thin or Double-Layer Drywall

Specialty anchors are available for non-standard wall thicknesses. For thin panels, anchors with a short grip range are necessary. For double-layer drywall, installers must use extra-long anchors or strap toggles that can accommodate the increased depth and deploy correctly behind the second layer.

A Note on Solid Walls: Types of Concrete Anchors

Fastening to solid walls like concrete or brick requires entirely different types of concrete anchors. These are not interchangeable with hollow wall solutions.

Wedge and Sleeve Anchors

The choice between a wedge anchor and a sleeve anchor depends on the load and base material. A wedge anchor offers the highest holding power and is ideal for heavy-duty applications in solid concrete. In contrast, a sleeve anchor is easier to install and works well for lighter objects in various materials, including brick and block. These two types of concrete anchors serve distinct purposes.

| Feature | Sleeve Anchors | Wedge Anchors |

|---|---|---|

| Primary Application | Lighter applications | Heavy-duty applications |

| Holding Power | Lower | Highest |

| Base Material | Brick, Block, Concrete | Solid Concrete |

Understanding these types of concrete anchors is crucial for safety. A wedge anchor provides maximum security for structural loads.

When to Use Concrete Screws

A concrete screw is often a better choice than expansion-type anchors for temporary installations. They can be removed easily, making them ideal for fixtures that might be relocated. A concrete screw also works well when fastening close to an edge, as it exerts less expansion pressure on the concrete.

Distinguishing from Hollow Wall Solutions

It is critical to recognize that these types of concrete anchors function through friction and expansion within a solid material. A wedge anchor, for instance, uses a clip that expands as the nut is tightened. These types of concrete anchors are fundamentally different from hollow wall anchors, which are designed to brace against the back of a thin, empty wall panel. Using the wrong type of anchor for the wall material is a primary cause of fastener failure.

The 2026 Verdict: A Quick Decision Guide

Navigating the world of fasteners requires clear guidelines. This guide provides a simple framework for professionals to decide when traditional anchors are appropriate and when they introduce unacceptable risk.

Use Hollow Wall Anchors If…

A professional should select a traditional anchor only when the project conditions are ideal for its limited capabilities.

The load is under 25 pounds and static

Traditional anchors perform best with lightweight, static loads. A static load is a constant force that does not move or change. These anchors can reliably support items under 25 pounds that exert a simple, downward pull on the fastener.

You are hanging a simple picture frame or small shelf

This is the classic application for standard anchors. They are perfectly suitable for hanging decorative items like picture frames, lightweight art, or small shelves intended to hold only a few trinkets. The key is ensuring the total weight remains minimal.

You are working with standard 1/2″ or 5/8″ drywall

An anchor’s performance depends entirely on the wall’s integrity. Installers should only use them in healthy, standard-thickness drywall. The material should be firm, dry, and free of any signs of damage or moisture exposure for a predictable and secure hold.

Budget is your primary concern for a non-critical item

For large-scale projects involving many non-critical items, cost becomes a major factor. Traditional anchors offer a budget-friendly solution for hanging dozens of lightweight, low-value objects where a failure would not result in significant loss or danger.

Do NOT Use Hollow Wall Anchors If…

Recognizing when to avoid a traditional anchor is a mark of professional responsibility. Certain situations demand a more robust solution.

The item is heavy, expensive, or a safety feature

Installers must never use standard hollow wall anchors for high-stakes applications. This includes mounting heavy televisions, kitchen cabinets, or safety devices like grab bars. The potential for property damage, financial loss, or serious injury is too great.

The item can be pulled on or moved (dynamic load)

A dynamic load is a force that changes over time, varying in direction, position, or magnitude. This movement exerts much greater stress than a static load due to rapid acceleration. Items like curtain rods, towel bars, or floating shelves are subject to these forces, which can wiggle an anchor loose and lead to eventual failure.

Professional Insight: 💡 A dynamic load can cause the drywall around an anchor to crumble, creating a larger hole and a complete loss of holding power.

Your wall feels soft, crumbly, or is old plaster

A compromised wall cannot support any fastener reliably. An installer should never drill into a wall that feels soft, shows water damage, or is made of old, brittle plaster and lath. Expansion-style anchors will shatter the plaster, providing no grip.

A modern, stronger alternative is affordable and available

In 2026, superior fasteners are widely accessible. When a modern strap toggle or self-drilling anchor is available and affordable, it is the smarter choice. The small additional cost is a worthwhile investment for securing valuable items and ensuring peace of mind.

In 2026, hollow wall anchors remain a useful tool, but their role is specialized and limited. For safety and reliability, professionals must assess the load, inspect the wall’s condition, and seriously consider modern alternatives. Consumer safety reports highlight the risks, showing that:

- Mounting into wood studs is vastly superior to using drywall anchors.

- Many anchor kits fail under forces simulating a child’s weight.

- Product cost does not always correlate with performance.

The smartest approach is to choose a fastener based on the application’s specific demands, not just habit or convenience.

FAQ

Can an installer reuse a hollow wall anchor?

Most traditional anchors, like plastic expansion types, are single-use items. However, an installer can reuse certain Molly bolts and modern strap toggles. These designs allow for screw removal and re-insertion without the anchor falling into the wall cavity.

What is the strongest type of hollow wall anchor?

Toggle bolts provide the highest holding power. Both traditional spring toggles and modern strap-style toggles distribute weight over a large area. They brace against the back of the drywall, offering superior strength for heavier loads compared to expansion-style anchors.

How does a professional choose the right drill bit size?

Professionals always check the anchor’s packaging for the manufacturer’s recommendation. Using the correct drill bit size is critical for a secure installation.

- A hole that is too small prevents proper insertion.

- A hole that is too large prevents the anchor from gripping securely.

Why did my anchor pull out of the wall?

Anchor failure usually results from a few common errors. The load may have exceeded the anchor’s weight rating, or the wall material itself was compromised.

Dynamic loads from pulling or vibration can also wiggle an anchor loose over time, causing it to fail.

Are metal anchors always better than plastic ones?

Not necessarily. An anchor’s design determines its strength more than its material. A metal toggle bolt is much stronger than a simple plastic expansion anchor. However, a high-quality engineered nylon anchor can easily outperform a poorly designed, low-grade metal anchor.

What should an installer do if they hit a stud? 💡

Hitting a stud is good news. The installer should abandon the plan to use an anchor. They can drive a screw directly into the wood stud. This provides a far more secure mounting point than any hollow wall anchor can offer.

Can hollow wall anchors be used in a ceiling?

Using standard wall anchors in a ceiling is extremely risky due to direct pull-out force. Professionals must use fasteners specifically rated for overhead loads and always attempt to anchor directly into a ceiling joist for safety.

| Mounting Location | Recommended Action |

|---|---|

| Wall | Use appropriate anchor for load. |

| Ceiling | Anchor into a joist; avoid drywall-only. |