An eye bolt is a fastener defined by its two main components: a threaded shank and a looped head known as the “eye”. These simple parts of an eye bolt create a secure attachment point for diverse lifting applications and rigging tasks. The eye-bolt is a fundamental piece of hardware in the industrial fastener market. This sector sees continuous innovation in areas like bolt casting, with many a custom fasteners manufacturer producing specialized solutions. The demand for custom fasteners, including the welded eye bolt, reflects strong industry growth, underscoring its importance in safe rigging. The market for this specific fastener is expanding rapidly:

| Metric | Value |

|---|---|

| Welded Eye Bolts Market CAGR (2025-2032) | 14.4% |

| Projected Welded Eye Bolts Market Size (2028) | Approx. USD 300 million |

This growth highlights the critical role the eye bolt plays in both heavy industry and everyday projects.

What Are the Different Types of Eye Bolts?

Selecting the correct eye bolt is not a one-size-fits-all decision. Safety and performance depend entirely on matching the hardware to the specific demands of the job. The different types of eye bolts are engineered with distinct features for load capacity, load direction, and installation method. Understanding these variations is the first step toward safe and effective rigging. This guide explores the most common type of eye-bolts to help users make an informed choice. The different types of eye bolts fall into three primary comparative groups.

Shouldered vs. Non-Shouldered (Plain Pattern) Eye Bolts

The most critical distinction among the different types of eye bolts is the presence or absence of a shoulder. This single feature dictates the directions a load can be safely applied.

Shouldered Eye Bolt: For Vertical and Angular Loads

A shouldered eye bolt features a distinct collar or flange between the eye and the threaded shank. Engineers specifically design this shoulder to reinforce the bolt. This added support strengthens the fastener, preventing it from bending when subjected to side loads. This structural reinforcement makes the shouldered eye bolt adaptable for applications involving non-vertical lifting angles. It can reliably support both vertical (in-line) and angular loads.

Important Note: A shouldered eye bolt must be installed completely flush with the mounting surface. Any gap between the shoulder and the surface negates its ability to handle angular loads and can lead to equipment failure.

Non-Shouldered Eye Bolt: For Vertical Loads Only

A non-shouldered eye bolt, also known as a plain pattern eye bolt, lacks the supportive collar. Its shank connects directly to the eye. This streamlined design makes it unsuitable for any type of angular pull. Applying a side load to this fastener will create leverage at the thread line, causing it to bend or break at a significantly reduced capacity. Users must only use this eye-bolt for perfectly vertical, in-line lifts.

Forged vs. Bent (Wire) Eye Bolts

The manufacturing process directly impacts an eye bolt’s strength and intended use. The two main methods produce hardware with vastly different load-bearing capabilities.

Forged Eye Bolts: For Heavy-Duty Lifting

The forging process involves hammering or pressing a piece of metal, usually heated steel, into its final shape. This intense pressure causes the steel’s internal grain structure to stretch and align with the bolt’s form. This continuous grain alignment creates an exceptionally strong and durable finished part. Forged steel is inherently harder and more resilient than other forms, making forged eye-bolts the only acceptable choice for heavy-duty lifting and critical overhead applications in construction and industry.

Bent Eye Bolts: For Light-Duty Applications

A bent or wire eye bolt is made by simply bending a steel wire or rod into a loop and threading the other end. This manufacturing method does not align the material’s grain structure, and the eye itself is often unwelded. This makes the bent screw eye-bolt significantly weaker than its forged counterpart. It is designed exclusively for light-duty, static applications. Common uses include creating tie-down points, guiding wires, or securing lightweight objects that do not involve lifting or high-stress loads.

Machinery vs. Nut Eye Bolts

The final key distinction among the types of eye bolts relates to how they are installed. The choice depends on whether the mounting surface is threaded or unthreaded.

Machinery Eye-Bolt: Threads into Tapped Holes

A machinery eye bolt has a threaded shank designed to engage with a pre-tapped (threaded) hole in a piece of equipment, an engine block, or a metal plate. The threads on the bolt match the internal threads of the receiving hole, creating a secure connection without needing a nut. This provides a clean, low-profile attachment point directly on the surface of an object.

Nut Eye Bolt: Passes Through Holes and Secures with a Nut

A nut eye bolt features a longer, fully threaded shank. It is designed to pass completely through an unthreaded hole in a surface like a steel plate, beam, or frame. The bolt is then secured from the other side with a washer and nut. This method offers several advantages for securing loads:

- It is ideal for through-hole mounting on non-threaded objects.

- The nut and washer combination distributes the load over a wider area, preventing pull-through and ensuring a stable hold.

- The assembly is easy to remove or replace, which is beneficial for equipment requiring regular disassembly.

Other Specialized Rigging Hardware

While the different types of eye bolts cover many scenarios, some applications demand greater flexibility or different mounting solutions. Specialized hardware exists to address these complex challenges. These components are not direct replacements for eye bolts but serve as advanced alternatives when standard fasteners are unsuitable. Understanding these options is essential for comprehensive and safe rigging.

Swivel Hoist Rings

Swivel hoist rings are a superior alternative to eye bolts for complex and angular lifts. A standard eye bolt loses significant capacity when pulled at an angle. A swivel hoist ring, however, is engineered to handle these forces safely. It features a design that allows it to both swivel 360° and pivot 180°. This dynamic motion enables the lifting point to automatically align with the direction of the pull.

This capability provides several critical advantages for advanced rigging:

- Full Load Capacity at Angles: They maintain their full Working Load Limit (WLL) even at angles up to 90 degrees, unlike eye bolts.

- Enhanced Safety: The ability to rotate prevents the dangerous side-loading that can bend or break an eye bolt.

- Flexibility for Dynamic Loads: They are ideal for lifting objects that may shift, turn, or rotate during the lift, ensuring a secure connection at all times.

Professional Tip: Always use a swivel hoist ring when the lift involves multiple sling angles or when the load is likely to move, as it provides a much safer and more reliable connection point.

Rod Ends

Rod ends, also known as heim joints, are mechanical articulating joints. They are not used for lifting in the same way as the other types of eye bolts. Instead, their primary function is to connect control rods and linkages while accommodating misalignment. A rod end consists of an eye-shaped head with a spherical bearing pressed inside, attached to a threaded shank. This design allows a bolt or pin to pass through the bearing, creating a pivot point that can move freely.

They are essential components in a vast range of mechanical systems. Common applications include:

- Automotive and Motorsport: Technicians use them in steering linkages, suspension systems, and control arms on everything from race cars to lawn tractors.

- Industrial Machinery: They facilitate controlled movement in robotic arms, conveyor systems, and other automated equipment.

- Aerospace and Aviation: Engineers rely on them for flight control surfaces, landing gear assemblies, and other critical pivot points.

Pad Eyes

A pad eye is a simple, robust attachment point, typically consisting of a flat plate with a forged or bent loop welded to it. The plate is then welded or bolted directly onto a structural surface, such as a ship’s deck, a wall, or a steel beam. Unlike the different types of eye bolts that pass through a hole, a pad eye provides a fixed surface anchor.

Their simple, strong design makes them ideal for permanent or semi-permanent tie-down points. They are frequently used in marine environments for securing cargo, mooring lines, and rigging blocks. In construction and industrial settings, they serve as reliable anchor points for guy wires, chains, and shackles where a through-hole is not practical or desired.

Understanding Eye Bolt Materials and Finishes

An eye bolt‘s performance is not just about its design; the material it’s made from and the finish applied to it are equally critical. These factors determine its strength, durability, and resistance to environmental factors like moisture and chemicals. Choosing the right combination of material and finish ensures the fastener can withstand the specific stresses and conditions of its intended application, guaranteeing both safety and longevity.

Common Base Materials

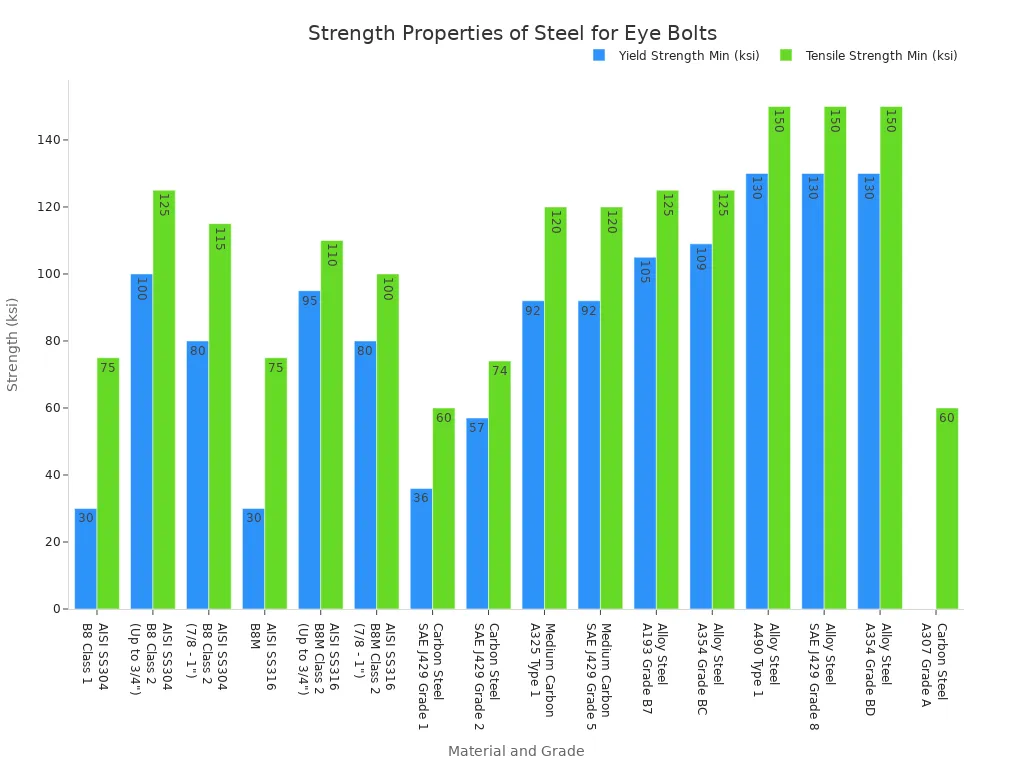

The base metal of an eye bolt dictates its fundamental mechanical properties, including its strength and ductility. The three most common materials used in their manufacturing are carbon steel, alloy steel, and stainless steel, each offering a distinct balance of performance and cost.

Carbon Steel

Carbon steel is a widely used material for general-purpose fasteners due to its good strength and affordability. It is an iron alloy with a carbon content that determines its hardness and strength. Low or medium-carbon steel grades, such as SAE J429 Grade 2 or ASTM A307, provide sufficient strength for many light to medium-duty applications. These bolts are strong but require a protective coating to prevent rust.

Alloy Steel

Alloy steel takes performance a step further. Manufacturers create it by adding elements like chromium, molybdenum, or nickel to carbon steel. This process, often combined with a quench and temper (Q&T) heat treatment, significantly enhances the material’s properties. The resulting eye bolt possesses superior hardness, tensile strength, and toughness compared to standard carbon steel. High-strength grades like SAE J429 Grade 8 or ASTM A193 Grade B7 are made from alloy steel, making them the standard for heavy-duty overhead lifting and critical rigging operations where maximum strength is non-negotiable.

Stainless Steel

Stainless steel is the premier choice for applications where corrosion resistance is the primary concern. It contains a minimum of 10.5% chromium, which forms a passive, self-healing oxide layer on the surface, protecting the steel from rust.

Did You Know? 🧐 For marine applications or environments with high chloride exposure, Grade 316 stainless steel is the superior choice. It contains molybdenum, an element that significantly enhances its resistance to saltwater and chemical corrosion, earning it the “marine grade” designation. Grade 304 is excellent for general purposes but is less resistant to pitting in salty conditions.

The chart below compares the minimum strength properties of common steel grades used for fasteners, illustrating the performance differences between carbon, alloy, and stainless steels.

Protective Finishes and Coatings

For carbon and alloy steel eye bolts, a protective finish is essential to prevent corrosion. The type of coating affects not only the bolt’s appearance but also its service life and suitability for different environments. Industry standards, such as those from ASTM International, define the requirements for these coatings to ensure consistent quality and performance.

Zinc Plating

Zinc plating, or electroplating, involves applying a thin layer of zinc to the steel’s surface through an electrochemical process. This finish provides a bright, shiny appearance and offers minimal corrosion protection. It is suitable for indoor, dry environments where the primary goal is to prevent surface rust during storage and light use. A zinc-plated bolt will rust quickly if exposed to rain or moisture.

Hot-Dip Galvanization

Hot-dip galvanization provides far superior corrosion resistance. This process involves immersing the fastener in a bath of molten zinc. The result is a much thicker, more durable, and metallurgically bonded coating. A galvanized eye bolt can withstand harsh outdoor and industrial environments for years without significant rust, making it a long-lasting solution for demanding conditions. Its robust, matte gray finish is a hallmark of its durability.

Self-Colored (Plain Finish)

A self-colored or plain finish means the bolt has no protective coating. It is essentially bare steel, often with a light oil coating from the manufacturing process to prevent immediate rusting. These fasteners are the most economical but also the most susceptible to corrosion. They are only suitable for indoor applications where they will be painted or otherwise protected, or in environments where corrosion is not a concern.

How to Select the Right Eye Bolt for Your Application

Choosing the correct eye bolt is a critical decision that directly impacts the safety and success of any lifting or securing operation. A systematic approach ensures the selected hardware matches the load, environment, and application. This involves evaluating the forces at play, the conditions of use, and the fundamental design of the fastener itself.

Assessing the Load Requirements

The first step is to understand the weight and direction of the force the eye bolt must withstand. Load requirements are divided into two primary categories: vertical and angular.

Vertical (In-Line) Lifts

A vertical lift applies tension directly in line with the shank of the eye bolt. This is the simplest and most efficient loading scenario. The entire capacity of the fastener is available because the force pulls straight up, minimizing stress on the threads and eye. Technicians must ensure the pull remains perfectly vertical (0 degrees from the shank) to utilize the bolt’s full rated strength.

Angular (Angled) Lifts

Angular lifts occur when the lifting force is applied at an angle to the bolt’s shank. This introduces side-loading, which significantly increases the tension on the hardware. As the angle increases, the effective strength of the eye bolt decreases dramatically. The tension in each sling of a multi-leg rigging setup can be calculated to understand these forces.

Understanding Sling Tension The formula

Tension = Load / (2 × cos(θ))shows how tension increases as the sling angle (θ) from vertical grows. A lower angle results in much higher tension on the rigging components.

Matching the Bolt to the Environment

The operational environment dictates the necessary material and finish for longevity and safety. A bolt that performs well indoors may fail quickly when exposed to the elements.

Indoor and Dry Conditions

For indoor applications free from moisture and chemicals, cost-effectiveness is often a key factor.

- Zinc-plated carbon steel bolts offer adequate strength and minimal rust protection for dry storage and use.

- Stainless Steel 304 is another excellent choice, providing superior corrosion resistance for general applications and structural support in mild environments.

Outdoor and Corrosive Environments

Harsh conditions demand robust materials and finishes to prevent failure from corrosion.

- Hot-dip galvanized steel bolts are coated in a thick layer of zinc, making them highly resistant to rust in outdoor and industrial settings.

- Stainless Steel 316, known as marine grade, is the premier choice for chemical plants and coastal areas. Its molybdenum content provides superior protection against chlorides and harsh chemicals.

Choosing Between the Key Types of Eye Bolts

Finally, the choice between a shouldered and non-shouldered eye-bolt depends entirely on the direction of the pull.

When to Use a Shouldered Eye Bolt

A shouldered eye bolt is mandatory for any lift involving an angle. The shoulder is specifically engineered to brace against the mounting surface, distributing side-load forces and preventing the shank from bending. Industrial rigging scenarios that involve angled pulls or multi-leg slings absolutely require a shouldered eye bolt to prevent catastrophic failure.

When a Non-Shouldered Eye Bolt is Sufficient

A non-shouldered (plain pattern) eye bolt is only suitable for perfectly vertical, in-line loads. Its use is appropriate for light-duty applications where side-loading is not a risk. Examples include simple home improvement projects, creating tie-down points for securing items during transport, or using lag-threaded versions in wood for static suspension.

Working Load Limits and Safety Ratings Explained

Understanding the ratings on an eye bolt is not just a best practice; it is a fundamental safety requirement. These ratings communicate the maximum force the hardware can safely handle. Misinterpreting or ignoring them can lead to equipment failure, property damage, and serious injury. This section explains the critical concepts of Working Load Limit, the effects of load angle, and the dangers of shock loading.

What is Working Load Limit (WLL)?

The Working Load Limit is the most important safety rating for any piece of lifting hardware.

Definition and Importance

The Working Load Limit (WLL) is the maximum mass or force that a piece of lifting equipment is certified by the manufacturer to sustain under normal use. It is not a suggestion but a mandatory limit that must never be exceeded. Regulatory bodies like OSHA require that this information be clearly and permanently marked on the hardware.

According to OSHA standard 1926.251(a)(2), rigging equipment must:

- Have permanently affixed and legible identification markings that indicate the recommended safe working load.

- Not be loaded in excess of its recommended safe working load.

- Not be used if these markings are missing or illegible.

This ensures that any user can immediately identify the capacity of the hardware before beginning a lift.

WLL vs. Breaking Strength

The WLL is often confused with breaking strength, but they are very different. Breaking strength is the absolute force at which a component will fail. The WLL is a much lower, safer value derived from the breaking strength using a safety factor. For lifting hardware, this factor is typically 5:1.

- Breaking Strength: The point of catastrophic failure.

- Safety Factor: A multiplier (e.g., 5) that provides a margin of safety.

- WLL Calculation:

Breaking Strength / Safety Factor = WLL

For example, an eye bolt with a breaking strength of 10,000 lbs and a 5:1 safety factor has a WLL of 2,000 lbs.

How Load Angle Affects Capacity

Applying a load at an angle drastically reduces an eye bolt’s effective WLL. This is a critical concept in safe rigging.

The Impact of Angular Loading on WLL

When a load is pulled at an angle, it introduces a combination of tension and shear forces on the fastener. A shouldered eye bolt is designed to handle some angular force, but its capacity diminishes rapidly as the angle from vertical increases. The table below illustrates this significant reduction.

| Angle of Pull (from vertical) | % of Rated WLL |

|---|---|

| 0° (Vertical) | 100% |

| 45° | 30% |

| 60° | 25% |

| 90° (Horizontal) | 20% |

The 45-Degree Rule for Capacity Reduction

A common rule of thumb in rigging is to recognize the severe capacity loss at 45 degrees. At this angle, a shouldered fastener retains only about 30% of its vertical WLL. This means a bolt rated for 1,000 lbs vertically can only safely handle 300 lbs when pulled at a 45-degree angle.

Understanding Shock Loading

Shock loading occurs when a force is applied suddenly and is one of the most dangerous situations in any lifting operation.

What Constitutes Shock Loading

Shock loading is the result of rapid changes in velocity, such as jerking, swinging, or dropping a load. Instead of a gradual application of force, the hardware experiences a sudden, dynamic impact. This instantaneous force can be many times greater than the static weight of the object being lifted.

Why It Must Be Avoided

Shock loads must always be avoided because they can cause immediate and catastrophic failure, even if the static load is well below the WLL. The sudden impact bypasses the equipment’s built-in safety factor. This can lead to:

- Breakage of the eye bolt or other hardware.

- Deformation of structural components.

- Complete failure of the lifting assembly.

Always lift, move, and lower loads smoothly and slowly to prevent these dangerous dynamic forces.

A Step-by-Step Guide to Safe Eye Bolt Installation

Proper installation is as crucial as selecting the right hardware. A correctly installed eye bolt provides a secure anchor point, while an improperly installed one creates a significant safety hazard. Following a systematic process for preparation, installation, and inspection ensures the integrity of any rigging assembly.

Preparing the Receiving Hole

The foundation of a secure connection is a properly prepared receiving hole. The method differs depending on the type of eye bolt used.

Drilling and Tapping for a Machinery Eye Bolt

Creating a threaded hole for a machinery eye bolt requires precision. Technicians must use quality High-Speed Steel (HSS) taps and a high-grade cutting oil. The process involves several steps:

- Drill the correct pilot hole size for the tap.

- Start threading with a taper tap, then finish with a bottoming tap for blind holes.

- Turn the tap a quarter-turn forward, then back it out slightly to break metal chips.

- Ensure the final thread engagement is at least 1.5 times the bolt’s diameter in steel.

Drilling a Through-Hole for a Nut Eye Bolt

Preparing for a nut eye bolt is simpler. A user drills a clean, unthreaded hole straight through the mounting surface. The hole should be just large enough for the bolt’s shank to pass through without excessive play. This allows the bolt to be secured from the opposite side with a washer and nut.

Correct Installation Techniques

Once the hole is ready, the installation technique must guarantee a secure fit and proper alignment for the load.

Seating a Shouldered Eye Bolt Flush

The shoulder of an eye bolt must sit completely flush against the mounting surface. Any gap compromises its ability to handle angular loads.

Critical Safety Check: The shoulder must make full, firm contact. If the eye is not aligned with the pull direction when tightened, users must add precision shims or washers between the shoulder and the surface to correct the orientation.

Aligning the Eye for the Pull Direction

The plane of the eye-bolt must align with the direction of the pull. This prevents side loading on the eye itself, which can bend or break it. Using shims is the correct method to achieve this alignment without backing the bolt out and creating a dangerous gap. This step is vital for safe rigging.

Properly Tightening a Nut Eye Bolt

For a nut eye bolt, the nut must be tightened securely against the mounting surface. A flat washer should always be used under the nut. This distributes the clamping force over a wider area, preventing pull-through and ensuring the entire rigging assembly remains stable under load.

Pre-Use Inspection Checklist

Before every use, a quick but thorough inspection is mandatory. Never use a damaged or questionable screw eye-bolt.

Checking for Bends, Cracks, or Corrosion

Visually inspect the entire fastener for any signs of damage. Look for bent shanks, cracks in the eye or shoulder, and significant rust or corrosion. Any of these issues can severely weaken the hardware.

Verifying Legible WLL Markings

The Working Load Limit (WLL) must be clearly stamped and legible on the fastener. If the markings are missing, worn, or unreadable, the eye bolt must be removed from service immediately.

Inspecting Thread Integrity

Check the threads for signs of stripping, galling, or other damage. Damaged threads can prevent proper engagement and tightening, leading to a failed connection.

Critical Safety Rules and Common Mistakes to Avoid

Adherence to safety protocols is non-negotiable in any lifting operation. A single mistake can lead to catastrophic failure. Understanding both correct procedures and common errors is essential for ensuring a safe work environment. This section outlines the most critical rules for using an eye bolt and the dangerous mistakes that users must always avoid.

Proper Rigging Practices

Proper rigging involves more than just connecting a hook to a load. It requires a thoughtful approach to how forces are applied and distributed across all hardware components. Following best practices minimizes risk and maximizes the efficiency of the lift.

Attaching Slings and Shackles Correctly

The connection between the lifting sling and the eye bolt is a critical point of transfer. Users must ensure all components fit together properly without force. Forcing oversized hooks or shackles into the eye can deform the hardware and lead to failure.

Critical Rule: Never attach a lifting hook directly into an eye bolt unless the hook seats fully and the load is supported by the strong base (saddle) of the hook. If only the tip of the hook fits, the connection is unsafe. The correct procedure is to use a properly rated shackle to connect the sling’s hook to the eye bolt.

This practice ensures the load is distributed correctly within the hook’s strongest point. Running a sling from one eye bolt directly to another is also a dangerous practice, as it creates a severe angular pull on both fasteners.

Using Spreader Bars for Multi-Point Lifts

Multi-point lifts present a complex challenge for load distribution. A spreader bar is a crucial piece of equipment for these scenarios. A spreader bar, or spreader frame, distributes a load evenly across multiple lifting points. It works by transferring the vertical lifting force from the crane through the bar to several connection points on the load. This process effectively spreads the forces, which reduces stress and prevents the load from deforming under its own weight. The even distribution ensures no single lifting point exceeds its maximum working load limit. A successful lift also depends on correct sling angles and an accurate assessment of the load’s center of gravity.

Dangerous Mistakes in Eye Bolt Usage

Many accidents are caused by a handful of repeated, preventable mistakes. Recognizing and avoiding these common errors is a fundamental part of safe rigging.

Never Use Non-Shouldered Bolts for Angled Lifts

This is one of the most important rules in rigging. A non-shouldered (plain pattern) eye bolt is designed for vertical loads only. Applying a load at any angle will introduce bending forces that the shank cannot withstand, leading to a high risk of breakage. This type of fastener lacks the supportive shoulder needed to brace against side-loading forces.

Never Exceed the Rated Working Load Limit

The Working Load Limit (WLL) is the absolute maximum force the hardware can safely handle. Overloading an eye bolt, even for a moment, can cause it to fail. Users must remember that angular loads significantly reduce the vertical WLL. A pull at a 45-degree angle can reduce a bolt’s capacity by 70%. Shock loading, which occurs from sudden jerks or drops, creates dynamic forces far greater than the static load and must always be avoided.

Never Use a Damaged, Bent, or Modified Bolt

A visual inspection before every use is mandatory. Any sign of damage compromises the fastener’s integrity and makes it unsafe. Users must immediately remove a bolt from service if it shows any of the following issues:

- Visible Wear or Damage: Look for bent shanks, cracks, nicks, or significant corrosion. These defects dramatically reduce load capacity.

- Unauthorized Modifications: Never machine, grind, or shorten an eye bolt. Any alteration reduces its WLL and increases the risk of failure.

- Paint: A thick coat of paint can hide dangerous cracks or signs of wear, making a proper inspection impossible. Use stainless steel or galvanized finishes for corrosion resistance instead.

Never Fail to Seat the Shoulder Completely Flush

The shoulder on a shouldered eye-bolt must make full and firm contact with the mounting surface. A gap between the shoulder and the surface renders its angular load rating void. If the eye is not aligned with the pull direction when fully tightened, users must add precision shims to correct the orientation. Allowing the load to rotate or twist can damage the eye and fittings, creating a dangerous situation. Proper alignment and seating help prevent this.

Safe rigging operations depend on the correct hardware selection. Users must choose the right eye bolt for the job, such as forged eye-bolts for heavy loads. Adherence to the Working Load Limit is mandatory, as angular pulls significantly reduce an eye bolt’s capacity. Proper installation ensures a secure connection and prevents failure.

Final Safety Reminder ⚠️ When any doubt exists about the load, angle, or condition of an eye bolt, always consult manufacturer specifications or a qualified rigging professional.

FAQ

Can users reuse eye bolts?

Technicians can reuse eye bolts after a thorough inspection. They must check for wear, corrosion, or deformation. Any damaged bolt requires immediate removal from service. Proper inspection ensures continued safety for lifting operations.

Is it safe to paint an eye bolt?

Users should avoid painting eye bolts. Paint can hide dangerous cracks, corrosion, or wear, making a proper safety inspection impossible. Galvanized or stainless steel finishes provide better, safer corrosion protection for the hardware.

What is a 5:1 safety factor?

A 5:1 safety factor means the bolt’s minimum breaking strength is five times its rated Working Load Limit (WLL). This built-in margin provides protection against unexpected stresses. It is a standard safety measure for lifting hardware.

What is the main difference between a machinery and nut eye bolt?

A machinery eye bolt threads into a pre-tapped hole. A nut eye bolt passes through an unthreaded hole and secures with a nut. The choice depends on the mounting surface and application requirements.

Why is 316 stainless steel called “marine grade”?

Grade 316 stainless steel contains molybdenum. This element gives it superior resistance to corrosion from saltwater and chlorides. This property makes it the ideal material for marine and coastal environments where rust is a major concern.

What should a user do with a damaged eye bolt?

A user must immediately discard any damaged eye bolt. Bends, cracks, or stripped threads compromise its strength. Attempting to repair or use a damaged bolt creates a severe risk of catastrophic failure during a lift.