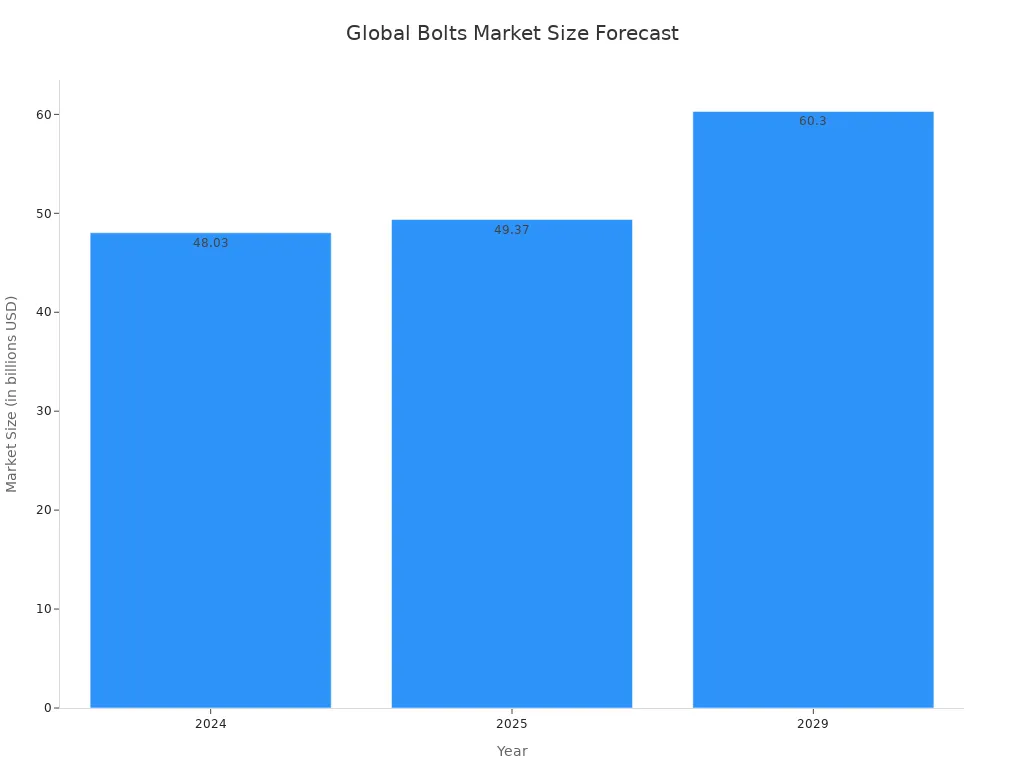

A hex bolt is a common threaded fastener defined by its six-sided head and a partially or fully threaded body. It provides strong fastening for materials like wood and steel. The global bolt market shows significant growth, reflecting its industrial importance.

This demand highlights the precision required in bolt casting. A custom fasteners manufacturer often produces specialized custom fasteners to meet project needs. This threaded bolt creates a reliable joint when paired with a nut or a tapped hole.

The Anatomy of a Hex Head Bolt

Understanding the specific parts of a hex head bolt is crucial for selecting the right fastener. Each component serves a distinct purpose, contributing to the bolt’s overall strength and function in an assembly.

The Hexagonal Head

The six-sided head is the most recognizable feature of a hexagon head bolt. This design allows for easy gripping and turning with a standard wrench or socket from multiple angles.

Head Style and Dimensions

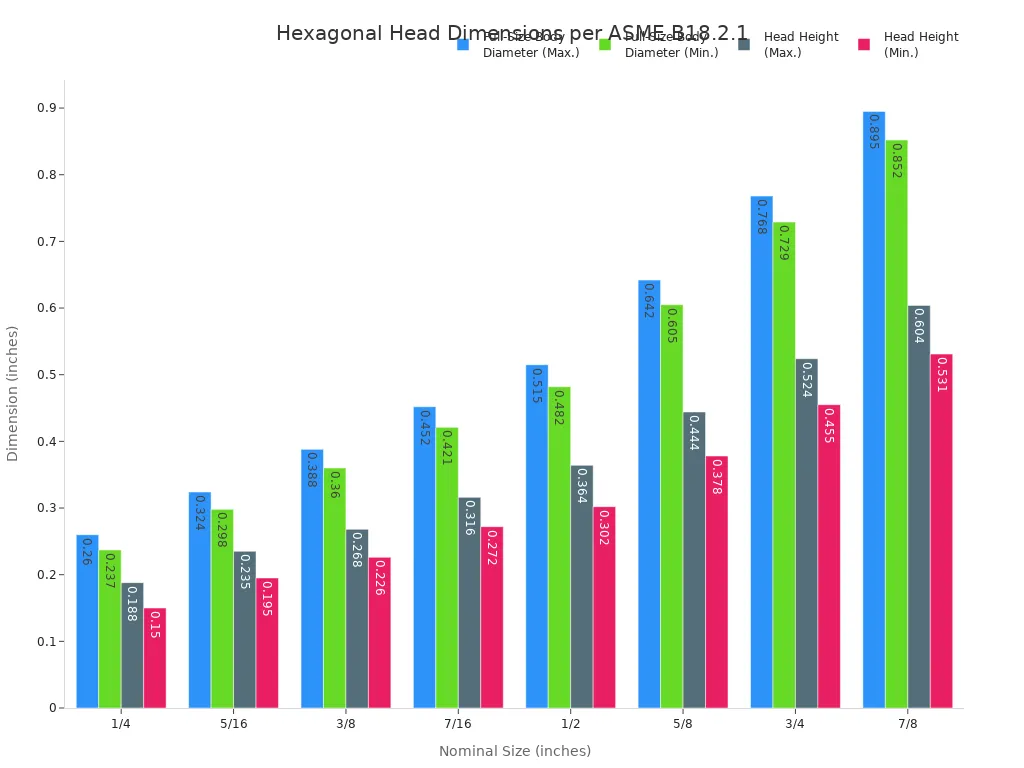

Engineers follow strict standards for head dimensions to ensure consistency and reliability. The American Society of Mechanical Engineers (ASME) B18.2.1 standard specifies these dimensions, covering head height, width across the flats, and other tolerances. These precise measurements guarantee a proper fit with installation tools.

| Nominal Size | Width Across Flats, F (Basic) | Head Height, H (Basic) |

|---|---|---|

| 1/4 | 7/16 | 11/64 |

| 5/16 | 1/2 | 7/32 |

| 3/8 | 9/16 | 1/4 |

| 1/2 | 3/4 | 11/32 |

| 5/8 | 15/16 | 27/64 |

| 3/4 | 1 1/8 | 1/2 |

The Washer Face

Pro Tip: A circular ridge is often found on the underside of the head. This feature is called a washer face. It creates a smooth, flat bearing surface that distributes the clamping load evenly and prevents the hexagonal corners from digging into the material being fastened.

The Shank (Body)

The shank is the cylindrical body of the bolt extending from beneath the head. It can be either partially or fully threaded.

Grip Length vs. Thread Length

A partially threaded bolt has two distinct sections on its shank:

- Grip Length: The smooth, unthreaded portion. This section provides superior resistance to shear forces.

- Thread Length: The threaded portion designed to engage with a nut or a tapped hole.

A fully threaded bolt has threads running its entire length, maximizing grip strength in tapped holes.

Shank Diameter

The shank diameter corresponds to the nominal size of the bolt. This dimension determines the size of the hole the fastener will pass through. A proper fit is essential for joint integrity.

The Threads

Threads are the helical ridges that spiral along the bolt’s shank. They are fundamental to creating a secure connection.

Coarse vs. Fine Thread Pitch

The spacing of the threads defines the pitch. A hex bolt can have two main types:

- Coarse (UNC): These threads are deeper and have a wider pitch. They install quickly and are more resistant to stripping or damage.

- Fine (UNF): These threads are shallower and spaced closer together. The finer threaded design provides greater tensile strength and allows for more precise adjustments.

Understanding Thread Classes

Thread classes define the tolerance or “fit” between a threaded bolt (external thread) and a nut (internal thread). For a hex head bolt, the most common class is 2A. This classification indicates a standard fit that balances performance with manufacturing efficiency, making it suitable for most commercial and industrial applications.

Key Differences: Hex Bolt vs. Hex Cap Screw

While they appear similar, a hex bolt and a hex cap screw are distinct fasteners with different manufacturing standards and applications. The primary distinctions lie in their dimensional precision, under-head surface, and intended use. Understanding these differences is essential for selecting the correct component for a project.

Manufacturing Tolerances and Precision

The most significant difference between these two fasteners is the level of precision achieved during manufacturing. This tolerance directly impacts their performance in an assembly.

Tighter Tolerances of Cap Screws

Hex cap screws are manufactured to much stricter dimensional tolerances. They feature a flat washer face under the head and a tightly controlled body diameter. For example, a 1.5-inch diameter cap screw has a body tolerance of only 12 thousandths of an inch under its nominal size. This precision makes them ideal for applications requiring an exact fit.

General Tolerances of Hex Bolts

A hex head bolt is produced with more general tolerances. The manufacturing process, often hot-forging, allows for greater variation. A die seam across the bearing surface is permissible, and the body diameter can vary more widely. This type of bolt is designed for strength over precision.

| Feature | Hex Bolt (1.5 inch) | Hex Cap Screw (1.5 inch) |

|---|---|---|

| Body Diameter Tolerance | 1.470 to 1.531 inches | 1.488 to 1.500 inches |

| Washer Face | Not required | Required |

| Under-Head Surface | Die seam permissible | Smooth, flat surface |

Under-Head Bearing Surface

The surface directly beneath the head plays a crucial role in how the fastener distributes its load.

Washer Face on Cap Screws

A key feature of a hex cap screw is its washer face. This is a smooth, circular surface on the underside of the head. It provides a flat, consistent bearing area that distributes the clamping force evenly and protects the mating surface from damage.

As-Forged Surface on Bolts

In contrast, a standard bolt may have an “as-forged” surface under its head. This surface is not machined to be perfectly flat and may contain a die seam from the forging process. This is acceptable for many structural uses where a perfect bearing surface is not the primary concern.

When to Use Each Fastener

Choosing between these two depends entirely on the application’s requirements for precision and strength.

Precision Applications for Cap Screws

Use Case: Cap screws are the fastener of choice for machinery and automotive engines. Their tight tolerances ensure proper alignment and fit within tapped holes, which is critical for high-performance equipment.

Structural Applications for Bolts

The robust design of a bolt makes it suitable for heavy-duty construction and structural applications. They are used to connect steel beams in buildings and bridges, where their high tensile strength is more important than their dimensional precision.

Main Types of Hexagonal Head Bolts

Hexagonal head bolts are primarily available in two main configurations: fully threaded and partially threaded. The choice between them depends entirely on the specific forces the joint must withstand. Both fully and partially threaded designs are available as common sized hex bolts for various projects.

Fully Threaded Hex Bolts

A fully threaded hex head bolt has threads running the entire length of its shank, from under the head to the tip. This design maximizes thread engagement.

Function in Tapped Holes

The continuous threaded shaft makes this hexagon head bolt ideal for use in tapped holes. The bolt screws directly into a pre-threaded hole, and the full thread engagement provides a secure and tight fit. This eliminates the need for a nut in many situations, simplifying the assembly process.

Advantages for Clamping Force

Application Insight: Fully threaded bolts excel at creating strong clamping force. When tightened, the force is distributed across all the engaged threads. This makes them the superior choice for tension-loaded joints, where the primary goal is to pull two or more components tightly together.

Partially Threaded Hex Bolts

A partially threaded hex bolt features a smooth, unthreaded shank section beneath the head, followed by a threaded portion at the end. This dual-section design offers unique mechanical advantages.

The Role of the Unthreaded Shank

The unthreaded portion of the shank is known as the grip length. This solid cylinder provides a precise alignment surface when passing through holes in multiple materials. Its primary function is to resist sideways forces, also known as shear forces. The smooth surface ensures a snug fit within the bolt hole.

Superior Shear Strength in Joints

The unthreaded shank of a partially threaded bolt enhances its performance in shear-loaded joints. This design provides a larger cross-sectional area and eliminates the stress concentration points found in threaded sections. This feature significantly increases the bolt’s resistance to shear forces. To maximize this benefit, designers ensure the shear plane of the joint passes through the unthreaded shank rather than the threaded portion. This makes the bolt exceptionally strong against forces that try to slice it.

Standard vs. Heavy Hex Bolts

Beyond thread type, hex bolts are also categorized by their head dimensions into two primary classes: standard and heavy. The selection between a standard hex bolt and heavy hex bolts depends almost entirely on the load requirements of the connection. While they may look similar, their structural capabilities are significantly different.

Comparing Head Size and Bearing Surface

The most visible distinction between these two types is the size of the head. This difference directly impacts how clamping force is distributed onto the joint surface.

Standard Hex Bolt Dimensions

A standard hex bolt features a smaller head and is considered the default for a wide range of general-purpose fastening jobs. Its dimensions are suitable for applications where extreme loads are not a factor. The head provides an adequate bearing surface for most common materials and assemblies.

Larger Head of Heavy Hex Bolts

Heavy hex bolts are defined by a larger, thicker head. This increased size creates a wider bearing surface. The primary difference is in the width across the flats and corners, not the height. This design distributes the clamping load over a greater area, reducing stress on the fastened material. The robust nature of heavy hex bolts makes them a necessity in demanding environments.

| Dimension | Standard Hex Bolt | Heavy Hex Bolt |

|---|---|---|

| Head Height | Same | Same |

| Width Across Flats | F | F + 1/8″ |

| Width Across Corners | G | G + 0.144″ |

Load-Bearing Capabilities

The head size directly correlates with the bolt’s ability to handle stress, making the choice between standard and heavy hex bolts critical for structural integrity.

General Purpose Use

Standard bolts are the workhorses for everyday construction, automotive repairs, and machinery assembly. Their design provides sufficient strength for typical clamping and fastening needs.

💡 Pro Tip: Always select a standard bolt for your project unless the engineering specifications explicitly call for a high-strength, high-load fastener. They are more common and cost-effective for non-structural tasks.

High-Load Structural Applications

Engineers specify heavy hex bolts for high-load and high-stress structural connections. Their larger heads provide superior resistance to strain, making them ideal for steel-to-steel fastening in projects like bridges, buildings, and large industrial machinery. The design of heavy hex bolts ensures safety and durability under extreme tension and shear forces. For critical infrastructure, heavy hex bolts are the industry standard. The enhanced bearing surface of heavy hex bolts prevents material failure under intense pressure. Using heavy hex bolts is non-negotiable in these high-strength applications.

Common Materials and Finishes for a Hex Bolt

The material and finish of a hex bolt determine its strength, corrosion resistance, and suitability for a specific environment. Manufacturers select from various metals and apply protective coatings to meet demanding application requirements.

Steel and Stainless Steel

Steel is the most common material for bolts due to its strength and cost-effectiveness. Stainless steel offers superior corrosion resistance for specialized applications.

Carbon Steel Grades (2, 5, 8)

Carbon steel bolts are categorized by grades, which indicate their tensile strength. Grade markings on the bolt head identify its strength level.

- Grade 2: A standard, low-carbon steel bolt for general-purpose, low-stress applications. It often conforms to ASTM A307 standards.

- Grade 5: A medium-carbon steel that is heat-treated for increased strength. It conforms to ASTM A449 or SAE J429 standards and is common in automotive and machinery uses.

- Grade 8: A high-strength, heat-treated alloy steel for demanding applications like vehicle suspensions and heavy equipment. It meets ASTM A354 or SAE J429 specifications.

18-8 and 316 Stainless Steel

Stainless steel provides excellent corrosion resistance without needing a protective coating.

- 18-8 Stainless Steel: This common grade contains approximately 18% chromium and 8% nickel. It resists rust in most normal environments.

- 316 Stainless Steel: This grade includes molybdenum, giving it superior resistance to chlorides and acids. It is the ideal choice for marine, coastal, and chemical processing environments.

Protective Coatings

Coatings enhance the corrosion resistance and lifespan of steel fasteners. The choice of finish depends on the level of protection needed.

Zinc Plating

Zinc plating is a common and economical finish where a thin layer of zinc is electroplated onto the steel. While standard zinc plating offers minimal protection, advanced passivation and sealants can improve performance, with some zinc-alloy coatings like Zinc-Nickel withstanding over 1200 hours of salt spray testing.

Hot-Dip Galvanization

Hot-dip galvanization (HDG) involves dipping the fastener into molten zinc, creating a thick, durable, and metallurgically bonded coating. This process provides far superior corrosion protection compared to standard zinc plating.

Important Note: Salt spray tests are not a reliable method for comparing HDG to other zinc coatings. The test environment prevents the formation of the stable, protective patina that gives HDG its long-term durability in real-world conditions.

Black Oxide Finish

A black oxide finish is a chemical conversion coating that provides mild corrosion resistance and a distinct black appearance. It is often used for aesthetic purposes and to reduce light reflection. However, its effectiveness relies heavily on a supplementary oil or wax treatment.

- Benefits: Minimal dimensional change, good lubricity, and resistance to chipping or peeling.

- Limitations: The finish offers only modest corrosion protection on its own and is not suitable for harsh exterior environments. The protective oil can wear off, requiring reapplication to maintain its appearance and rust prevention.

Common Applications for Hex Bolts Across Industries

The hex bolt is a cornerstone of modern engineering and construction due to its strength and adaptability. Its widespread use spans from massive infrastructure to precision machinery. These common applications demonstrate the fastener’s essential role in ensuring safety and reliability across various sectors.

Structural and Construction

In the construction industry, hex bolts create the robust joints necessary for building stable and long-lasting structures. They are fundamental components in projects of all sizes.

Building Frames and Bridges

Hex bolts are indispensable for creating strong structural steel connections. Engineers specify particular high-strength bolts for assembling the steel skeletons of buildings and bridges, where joint integrity is paramount.

- ASTM A325: This bolt is a common choice for general structural applications, providing reliable strength for many steel-to-steel connections.

- ASTM A490 (F3125): Engineers select this higher-strength heavy hex bolt for connections under extreme stress, such as those in major bridges or tall buildings.

The selection depends entirely on the load requirements of the specific application.

| Property | A325 | A490 (F3125) |

|---|---|---|

| Typical Use Case | General structural bolts | Heavy structural connections, infrastructure |

| Strength | High Strength | Higher Strength |

Infrastructure Projects

Beyond buildings, hex bolts are critical for a wide range of large-scale infrastructure projects. They fasten components in everything from communication towers and power transmission structures to wind turbine towers. In these applications, the bolts must withstand significant environmental stresses, including high winds and temperature fluctuations.

Heavy Machinery and Equipment

The assembly of heavy machinery and equipment relies on high-strength fasteners that can endure constant vibration and heavy loads. Hex bolts provide the necessary clamping force to hold these powerful machines together.

Manufacturing Assembly Lines

On manufacturing floors, hex bolts are used to assemble everything from CNC mills to industrial presses. Their six-sided head allows for high torque application, ensuring components remain secure during operation.

- Hex Head Bolts: These are the most prevalent fasteners, valued for their strength and ease of installation in machine assembly.

- Flange Bolts: A variation with a built-in washer, these bolts distribute clamping pressure over a wider area. This design is ideal for hydraulic equipment and machinery prone to intense vibration.

Agricultural and Construction Vehicles

Vehicles like tractors, excavators, and bulldozers operate under extreme conditions. Manufacturers use high-strength hex bolts to assemble their frames, attachments, and engine components. The fasteners must resist constant shock and shear forces to ensure operational safety and equipment longevity.

Automotive and Transportation

From passenger cars to massive railway networks, the transportation industry depends on high-quality hex bolts for safety and performance.

Engine and Frame Assembly

In the automotive world, specific grades of hex bolts are required for critical connections where failure is not an option. High-strength SAE Grade 8 bolts are often used for their superior tensile strength and resistance to fatigue. Key uses include:

- Engine mount bolts

- Suspension mounting points

- Chassis reinforcement points

- Critical drivetrain components

Railway Track Fastening

Railway systems require specialized hex bolts to secure rails and ensure track integrity. These fasteners are subject to immense, repetitive loads from passing trains.

💡 Safety First: Railway safety standards prohibit operations over tracks with missing or ineffective bolts. Proper installation is crucial for preventing derailments.

Installers must follow strict procedures, including cleaning joint areas, using spring washers, and tightening the fasteners to precise torque values—often 400 foot-pounds—to generate up to 30,000 pounds of tension. This ensures the entire track system remains stable and secure.

Woodworking and General Repairs

Hex bolts are not just for industrial-scale projects; they are also essential fasteners in woodworking and general repairs. Their strength and reliability make them a top choice for creating durable connections in wood structures and for joining wood to other materials.

Deck and Dock Construction

Constructing decks and docks requires fasteners that can withstand moisture, environmental stress, and heavy loads. A hex bolt provides the necessary clamping force and structural integrity for these demanding outdoor applications. The choice of material is critical for ensuring longevity and safety, especially in marine environments.

The following table outlines the recommended materials for fasteners in deck and dock construction:

| Environment | Recommended Material/Finish | Key Considerations |

|---|---|---|

| Saltwater | 316 Stainless Steel | Its molybdenum content offers superior corrosion resistance against chlorides. |

| Freshwater (Preferred) | 304 Stainless Steel | Provides excellent, long-term service in freshwater and mild environments. |

| Freshwater (Minimum) | Hot-Dip Galvanized (HDG) | The minimum standard for durability; electro-galvanized options will fail quickly. |

| Pressure-Treated Lumber | Stainless Steel or HDG | Required to resist the corrosive copper compounds (like ACQ) in modern treated wood. |

Best Practices for Marine Construction:

- Use Through-Bolts: For critical connections where failure could cause a collapse, always use a through-bolt with large washers on both sides.

- Pre-Drill Holes: Always pre-drill pilot holes to prevent the wood from splitting and to ensure proper alignment.

- Apply Sealant: Use a marine-grade sealant around fasteners to create a moisture barrier and prevent water intrusion.

- Inspect Regularly: Periodically check all connections for signs of corrosion or loosening and tighten or replace fasteners as needed.

Wood-to-Metal Connections

Many projects require fastening wood components to metal frames or supports. A hex bolt is the ideal fastener for creating a strong, rigid joint between these two dissimilar materials. Common examples include:

- Attaching wooden stair treads to a steel stringer.

- Mounting a wooden workbench top to a metal frame.

- Securing wooden beams to steel support posts in a post-and-beam structure.

In these applications, the bolt passes through both materials and is secured with a nut and washer. Using a large-diameter washer under both the bolt head and the nut is crucial. The washer distributes the clamping pressure over a wider surface area, preventing the fastener from crushing the wood fibers and ensuring a secure, long-lasting connection.

How to Properly Install and Tighten a Hex Bolt

An installer’s ability to properly install and tighten a hex bolt ensures a secure and reliable joint. This process requires the right tools and a systematic approach to achieve the correct clamping force without damaging the fastener or the connected materials.

Essential Installation Tools

Selecting the appropriate tool is the first step toward a successful installation. Each tool offers specific advantages for different situations.

Wrenches (Adjustable, Combination)

Wrenches are fundamental for turning hex bolts. A combination wrench provides two options: a closed-loop box-end for a secure grip during initial tightening and a U-shaped open-end for faster turning. An adjustable wrench, with its movable jaw, can fit various bolt sizes, making it a versatile choice for general tasks. However, it offers less stability than a fixed-size wrench and can damage the fastener if not used carefully.

Socket and Ratchet Sets

Socket and ratchet sets offer superior speed and efficiency. The ratchet mechanism allows for continuous tightening or loosening without repositioning the tool. Sockets fit snugly over the bolt head, reducing the risk of slippage and rounding the corners. This makes them ideal for applications with numerous fasteners or limited access.

Torque Wrenches for Precision

A torque wrench is an essential tool for any application where fastener tightness is critical. It allows an installer to apply a precise amount of rotational force (torque), preventing the risks associated with over-tightening or under-tightening. Using one is non-negotiable for structural, automotive, and machinery assembly.

The Step-by-Step Installation Process

Following a consistent installation procedure guarantees that each connection meets its design specifications for strength and safety.

Aligning Holes and Inserting the Bolt

First, ensure the holes in the components are clean and perfectly aligned. Insert the bolt through the holes. For a clean installation, the fastener threads should be free of debris. Applying a thin layer of oil to the threads and under the bolt head can ensure a smoother and more accurate tightening process.

Threading the Nut

Once the bolt is in place, thread the nut onto the end by hand until it is snug. This is known as “finger-tight.” This step ensures the threads are properly engaged before applying mechanical force, which prevents cross-threading and damage.

Achieving Proper Torque

Achieving the correct torque is the most critical step. Improper torque can lead to catastrophic failures.

- Under-tightening can cause joints to loosen from vibration, leading to uneven load distribution or leaks in sealed systems.

- Over-tightening can strip threads, break the fastener head, or crack the materials being joined.

Torque Wrench Procedure:

- Identify the required torque value from the project specifications.

- Set the torque wrench to this value.

- Place the socket squarely on the fastener.

- Apply slow, steady force to the handle until the wrench indicates the target torque is reached, often with an audible click. Do not apply further force.

For assemblies with multiple fasteners, tighten them incrementally in a star or crisscross pattern. This method ensures the clamping force is distributed evenly across the joint.

The hex bolt is a fundamental fastener, valued for its strength and versatile threaded design. Proper installation of this threaded bolt is critical across industries for any application, from home repairs to major engineering projects. Choosing the right fully threaded or partially threaded type ensures performance.

Future innovations focus on enhancing this threaded fastener. Trends include smart heavy hex bolts, sustainable heavy hex bolts, and lightweight heavy hex bolts. The industry also sees more custom heavy hex bolts, advanced heavy hex bolts, digitized heavy hex bolts, automated heavy hex bolts, specialized heavy hex bolts, and eco-friendly heavy hex bolts.

FAQ

What do the markings on a hex bolt head mean?

The markings on a bolt head indicate its grade and manufacturer. The grade specifies the bolt’s tensile strength. For example, three radial lines signify a Grade 5 bolt, while six lines denote a high-strength Grade 8 bolt. These markings help installers identify the fastener’s load-bearing capacity.

How does an installer measure a hex bolt?

An installer measures a hex bolt by its diameter, length, and thread pitch.

- Diameter: The width of the shank.

- Length: The distance from under the head to the end of the bolt.

- Thread Pitch: The number of threads per inch (TPI).

When should someone use a washer with a hex bolt?

Washers are essential for distributing the clamping load over a wider surface area. An installer should always use a washer to prevent the bolt head or nut from damaging the material, especially with softer materials like wood or aluminum. They also help prevent the fastener from loosening.

What is the main difference between a bolt and a screw?

A bolt is designed to be used with a nut to clamp materials together. It is tightened by turning the nut. A screw, conversely, is designed to thread directly into a material or a pre-tapped hole. It is tightened by turning its head.

Why is torque important when tightening a hex bolt?

Proper torque ensures the bolt achieves the correct clamping force, or preload.

⚠️ Caution:

- Under-tightening can cause the joint to loosen under vibration.

- Over-tightening can strip the threads or break the bolt.

Using a torque wrench is critical for safety in structural applications.

Can a hex bolt be reused?

General-purpose hex bolts can often be reused if they show no signs of damage, stretching, or corrosion. However, high-strength structural bolts, especially torque-to-yield (TTY) bolts used in engines, are designed for one-time use and must be replaced after being removed.

Which thread type is better: coarse or fine?

The choice depends on the application. | Thread Type | Best Use Case | Advantages | | :— | :— | :— | | Coarse (UNC) | General construction | Installs quickly, less prone to stripping. | | Fine (UNF) | Precision machinery | Offers higher tensile strength and finer adjustment. |