A flange bolt is a one-piece fastener featuring a built-in, wide flange directly under its head. This integrated flange functions as a washer, distributing clamping pressure across a larger surface area. The bolt’s primary purpose is to forge a secure, vibration-resistant connection, eliminating the need for a separate washer. The global market for this type of bolt, including custom fasteners, was valued at over USD 1.3 billion in 2023. Projections show it reaching nearly USD 1.95 billion by 2032, reflecting its growing importance. A reliable custom fasteners manufacturer can produce the precise bolt casting required for specific applications.

The Anatomy of a Flange Bolt

Understanding the design of a flange bolt reveals why it is a superior fastener for many applications. Each component, from the head to the threads, serves a specific engineering purpose. This unique construction combines the functions of a standard bolt and a washer into a single, efficient unit.

The Head

The head of the bolt allows a tool to apply torque for tightening or loosening. The design of the head dictates the type of tool required and the amount of torque that can be applied safely.

Hex Head Design

The most common design is the hexagonal head. Standard hex flange bolts are compatible with common wrenches and sockets, making them versatile and easy to use in a wide range of environments. Their six-sided shape provides ample surface area for tool grip during installation.

12-Point Head Design

A 12-point head, also known as a double-hex head, features twelve points of contact. This design allows for more precise tool engagement, which is critical in high-torque applications. It also enables a technician to work in tighter spaces where the range of tool movement is limited.

The Integrated Flange

The defining feature of this fastener is its built-in flange. This circular ridge under the head is not just for show; it performs critical mechanical functions.

Distributing Clamping Force

The primary role of the flange is to distribute the clamping force over a wider area than a standard bolt head. This even distribution reduces stress on the mating material, creating a more secure and stable joint.

Preventing Surface Damage

By spreading the load, the flange protects the surface of the joined components. This is especially important when working with softer materials like aluminum or fastening over painted or finished surfaces. The wide flange prevents the bolt head from digging into and damaging the material.

Pro Tip: A smooth, non-serrated flange is ideal for applications involving gaskets or delicate surfaces, as it provides a secure clamp without marring the material.

The Shank and Threads

The body of the bolt, consisting of the shank and threads, determines its strength and how it engages with a nut or threaded hole.

Thread Pitch Explained

Thread pitch is a critical measurement that ensures compatibility between a bolt and a nut. The most common thread standards are Unified National Coarse (UNC), Unified National Fine (UNF), and ISO Metric. Each standard defines the number of threads per unit of length and their specific profile.

| System | Pitch | Common Sizes |

|---|---|---|

| UNC (Unified Coarse) | Fewer threads per inch (TPI), deeper thread form | 1/4-20, 5/16-18, 3/8-16 |

| UNF (Unified Fine) | More threads per inch (TPI), shallower form | 1/4-28, 5/16-24, 3/8-24 |

| Metric (ISO) | Pitch in mm (distance between threads) | M6 × 1.0, M8 × 1.25, M10 × 1.5 |

Fully Threaded vs. Partially Threaded

A fully threaded flange bolt has threads running its entire length. This design maximizes grip strength for clamping objects together. A partially threaded bolt has an unthreaded portion, or shank, below the flange. This smooth shank provides superior shear strength, making it ideal for applications where the fastener must resist sideways forces.

How a Flange Bolt Creates a Secure Connection

The unique design of a flange bolt is not just for appearance; it is engineered to create a stronger and more reliable joint than a standard bolt. Its effectiveness comes from superior force distribution, inherent vibration resistance, and streamlined assembly. These factors combine to make it a preferred choice in critical applications where failure is not an option.

The Science of Clamping Force

When a bolt is tightened, it stretches slightly, acting like a powerful spring. This tension creates a clamping force that holds the joined parts together. The flange plays a crucial role in managing this force effectively.

Load Distribution Mechanics

The primary engineering principle behind the flange is effective load distribution. A standard bolt head concentrates all the clamping force into a small ring of contact. The integrated flange, however, has a much larger diameter. This increased surface area spreads the load evenly across the mating material. This distribution reduces localized stress and prevents the material from deforming or cracking under pressure.

Key benefits of this design include:

- Wider Load Path: The flange geometry creates a broader path for the force to travel through the joint.

- Reduced Surface Pressure: Spreading the force over more area lowers the pounds per square inch (PSI) exerted on the material.

Reducing Stress Concentration

By distributing the load, the flange minimizes stress concentration at the edge of the bolt hole. This is vital for preventing material fatigue and failure over time, especially in components subjected to cyclic loads. Achieving the correct preload is essential for the bolt to function as designed. Technicians use specific torque values to stretch the bolt to a target percentage of its yield strength.

Note: While a torque wrench is a common tool, its accuracy for achieving a specific preload is approximately ±25%. For more critical applications, methods like measuring bolt elongation provide much higher accuracy (±3-5%) but at a greater cost.

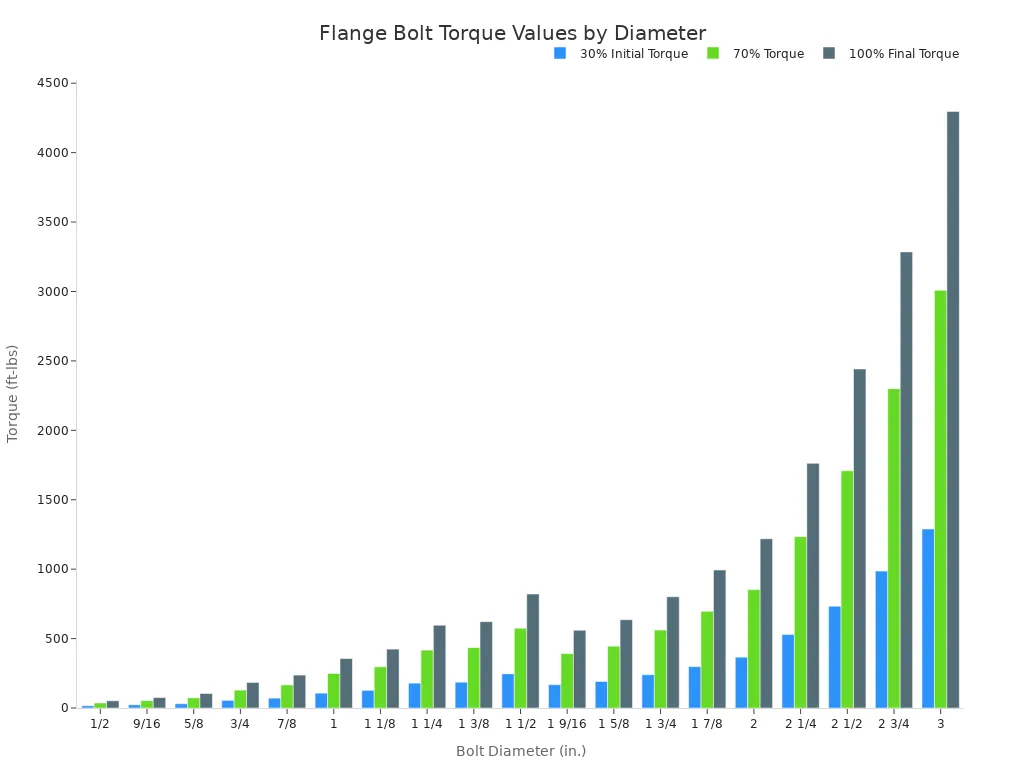

The following chart illustrates the recommended final torque values needed to achieve approximately 50% of the bolt’s yield strength for various common sizes.

These values are examples for specific stainless steel bolts and should always be verified against the manufacturer’s specifications for your particular application.

Vibration Resistance by Design

In dynamic environments like engines or industrial machinery, vibration is a constant threat that can cause standard fasteners to loosen. The flange bolt offers built-in features to combat this effect.

The Role of Serrated Flanges

Many flange bolts feature serrations, which are small, sharp ridges on the underside of the flange. As the bolt is tightened, these serrations dig into the mating surface. This action creates a mechanical lock that resists rotational loosening. The serrations are angled to grip tightly when a loosening force (counter-clockwise rotation) is applied, effectively locking the fastener in place.

Increased Surface Friction

Beyond the mechanical lock, the serrations and the larger surface area of the flange both contribute to increased static friction. A greater amount of torque is required to overcome this friction and loosen the bolt compared to a smooth, smaller bolt head. This simple yet effective design makes the connection inherently more resistant to the subtle movements caused by vibration.

Flange Bolt vs. Standard Bolt and Washer

When compared to a traditional bolt and washer combination, the flange bolt demonstrates clear advantages in efficiency, logistics, and performance.

Assembly Speed and Efficiency

A flange bolt is a single component. A standard bolt and washer are two. In any manual or automated assembly process, eliminating the need to handle and position a separate washer saves valuable time. This efficiency gain is multiplied across thousands or millions of fasteners in a production line, leading to significant cost savings.

Reduced Part Count and Inventory

Using a one-piece fastener simplifies the entire supply chain. It reduces the number of unique parts an organization must order, receive, store, and manage. This simplification lowers inventory costs and eliminates the possibility of assembly errors caused by forgetting a washer or using the wrong one.

Performance Under Torque

The torque-to-clamp force relationship differs between these two fastener types. A flange bolt generates more friction under its head due to the larger diameter of the flange. This means it may require a different torque value to achieve the same preload as a standard bolt and washer. Engineers must account for this difference to ensure the connection is tightened correctly without overloading the bolt or the joint materials.

Key Types of Flange Bolts

Flange bolts come in several variations, each engineered for specific performance requirements. The primary differences lie in the design of the flange and the head. Selecting the correct type is crucial for ensuring the safety and longevity of the assembled joint.

Serrated Flange Bolts

Serrated flange bolts are designed for maximum vibration resistance. They are a popular choice in dynamic environments where fasteners might otherwise loosen over time.

How Serrations Lock

The underside of the flange on this bolt features sharp, angled ridges called serrations. During tightening, these serrations bite into the mating surface. This action creates a powerful mechanical lock that resists counter-clockwise rotation. The angle of the serrations allows for smooth tightening but grips aggressively against any loosening force.

When to Use Serrated Bolts

Engineers specify serrated bolts for high-vibration machinery, automotive frames, and heavy equipment. The locking feature provides an extra layer of security, making them ideal for critical connections where fastener failure is not an option. Several industry standards define the specifications for serrated hex flange bolts, including:

- ASME/ANSI B 18.2.1

- DIN 6921

- IFI 111

Surface Considerations

The locking action of serrations comes at a cost. They will mar or damage the surface they are tightened against. For this reason, they are unsuitable for use on painted, finished, or soft material surfaces where cosmetic appearance or surface integrity is important.

Non-Serrated (Smooth) Flange Bolts

A non-serrated, or smooth, flange bolt offers excellent clamping force distribution without the aggressive locking feature of its serrated counterpart.

Applications for Smooth Flanges

The smooth, wide flange is perfect for securing components without damaging their surfaces. It spreads the clamping load evenly, preventing the bolt head from digging into the material. This makes it the preferred choice for fastening parts made of aluminum, plastic, or other soft materials.

Use with Gaskets and Soft Materials

Smooth flanges are essential when a gasket is part of the assembly. The even pressure creates a uniform seal without tearing or compromising the gasket material. The large bearing surface of the flange ensures a secure, leak-proof connection.

12-Point Flange Bolts

The 12-point flange bolt is a high-performance fastener designed for demanding jobs that require significant clamping force.

Benefits of the 12-Point Head

A 12-point head provides more contact points for a wrench or socket compared to a standard hex head. This design distributes the turning force more evenly across the head of the bolt. The increased contact area significantly reduces the risk of rounding off the bolt head, especially when applying high torque.

Expert Insight: The 12-point design also allows for a smaller tool swing arc. This makes it easier for technicians to tighten or loosen the fastener in confined spaces where movement is restricted.

High-Torque Applications

The ability to handle greater force makes the 12-point flange bolt ideal for high-torque scenarios. Its robust design ensures a secure grip, minimizing tool slippage and preventing damage to the fastener or surrounding components. Technicians commonly use this bolt in performance engines, aerospace assemblies, and industrial machinery.

Common Materials and Strength Grades

Choosing the right material and strength grade is critical for a flange bolt to perform correctly. The material determines its resistance to corrosion and its strength-to-weight ratio. The strength grade defines its mechanical limits, ensuring it can handle the required load without failure.

Flange Bolt Materials

Engineers select bolt materials based on the application’s environment, load requirements, and budget. Each material offers a unique combination of properties.

Alloy Steel

Alloy steel is the most common material for high-strength fasteners. Manufacturers add elements like chromium and molybdenum to carbon steel to increase its hardness and durability. This material provides excellent tensile strength at a low cost, making it a go-to choice for automotive and industrial machinery.

Stainless Steel (304 vs. 316)

Stainless steel contains chromium, which creates a passive, corrosion-resistant surface.

- 304 Stainless Steel: Offers good corrosion resistance for general-purpose applications.

- 316 Stainless Steel: Includes molybdenum, providing superior resistance to chlorides and acids. This makes it ideal for marine, chemical, and coastal environments.

Titanium

Titanium provides an exceptional strength-to-weight ratio. It is approximately 40% lighter than steel but offers comparable strength. Titanium also has outstanding fatigue strength and corrosion resistance, outperforming stainless steel in harsh conditions. These properties make it essential for aerospace, racing, and medical applications where weight and performance are critical.

Understanding Strength Grades

Markings on the head of a bolt indicate its strength grade. These grades specify the fastener’s mechanical properties, including its yield and tensile strength.

SAE Grades (Grade 5, Grade 8)

The Society of Automotive Engineers (SAE) system is common in the United States.

- Grade 5: A medium-strength carbon steel bolt, often identified by three radial lines on the head.

- Grade 8: A high-strength alloy steel bolt, marked with six radial lines. It offers significantly higher tensile and yield strength than Grade 5.

Metric Property Classes (8.8, 10.9)

The ISO metric system uses property classes. The numbers indicate strength.

- Class 8.8: A medium-strength bolt comparable to SAE Grade 5.

- Class 10.9: A high-strength bolt similar to SAE Grade 8. It has a minimum tensile strength of 1,040 MPa.

Coatings and Finishes

Coatings protect the base metal from corrosion and can also affect friction during tightening. The wide flange of the fastener provides a large surface for these coatings to cover.

Zinc Plating

Zinc plating is a common and cost-effective finish. The zinc creates a physical barrier and acts as a sacrificial layer, corroding before the steel bolt does. This coating extends the fastener’s life in moderately corrosive environments.

Black Oxide Finish

A black oxide finish provides minimal corrosion resistance on its own. It relies on a supplementary oil or wax coating for effective rust prevention. Its main benefit is that it adds almost no thickness to the part, making it suitable for applications with tight tolerances.

Phosphate Coating

A phosphate coating creates a crystalline conversion layer on the surface of the flange and threads. This finish provides good corrosion resistance and acts as an excellent primer for paint. It also has oil-absorbent properties that aid in lubrication.

Common Applications and Industries

The unique design of the flange bolt makes it indispensable across several key industries. Its ability to distribute load and resist vibration provides reliability in demanding environments, from moving vehicles to stationary industrial plants. This versatility makes it a go-to fastener for critical joints.

Automotive and Transportation

The automotive sector relies heavily on flange bolts to withstand constant vibration and dynamic loads. They secure vital components, ensuring vehicle safety and performance.

Engine and Transmission Mounts

Technicians use flange bolts to create a secure joint between the engine and transmission. This protects internal components from debris and ensures a durable connection. They are also essential for fastening other critical engine parts, including:

- Cylinder heads

- Oil pans

- Gearbox components

- Driveshafts

Exhaust System Connections

Exhaust systems experience extreme temperatures and vibrations. The wide bearing surface of the flange helps create a tight, gas-proof seal between pipes and components like catalytic converters and mufflers, preventing dangerous leaks.

Frame and Suspension Assemblies

Frame and suspension components are under constant stress. Flange bolts provide the necessary clamping force to hold these structural parts together securely, contributing to the vehicle’s overall integrity and handling.

Industrial Machinery and Equipment

In the industrial world, equipment failure leads to costly downtime. Flange bolts offer the robust performance needed to keep heavy machinery running smoothly and safely.

Securing Machine Frames

The structural frames of large equipment, such as manufacturing presses, must remain rigid for accurate operation. Serrated flange bolts lock frame components together, preventing any loosening that could compromise machine performance.

Mounting Heavy Components

Engineers specify these fasteners for mounting massive and high-stress components. In wind turbines, they secure blades and gearboxes. In power generation plants, they are used to install turbines and generators, ensuring stability under immense operational forces.

Conveyor System Assembly

Conveyor systems are the arteries of many production facilities. A secure flange connection is used to join conveyor sections and support structures, providing the reliability needed to prevent breakdowns and maintain productivity.

Plumbing and Pipe Systems

Plumbing and industrial piping systems require leak-proof joints, often under high pressure. The design of a flange bolt is ideal for creating and maintaining a reliable seal.

Industry Standard: The ASME B16.5 standard governs pipe flanges and flanged fittings from NPS 1/2 through NPS 24. It outlines requirements for materials, dimensions, and bolting to ensure safe and standardized connections in industrial piping.

Connecting Pipe Flanges

These bolts are the standard choice for connecting two pipe flanges. When tightened in the correct pattern, they apply even pressure across the gasket, creating a tight seal that prevents fluid or gas from escaping.

Securing Valves and Pumps

Valves and pumps must be securely mounted into a piping system. The flange bolt provides a strong, stable mounting platform, ensuring these critical components operate without shifting or leaking.

How to Select the Right Flange Bolt

Selecting the correct flange bolt is a critical step that ensures joint integrity and safety. The process involves precise measurement and a careful assessment of the operational environment. Making the right choice prevents fastener failure and equipment damage.

Measuring for the Correct Size

Accurate measurements are the foundation of a secure connection. Technicians use specific tools and methods to determine the proper flange size and bolt dimensions.

Determining Diameter

The bolt diameter is its nominal or major size. One can measure this dimension using a caliper or a ruler. The tool measures from the crest of the threads on one side to the crest on the opposite side. Precision tools like micrometers offer higher accuracy for quality control.

Measuring for Correct Length

The length of a bolt is measured from the bearing surface to the end of the threads. For a flange bolt, this means measuring from the underside of the flange to the tip of the bolt. This ensures the fastener has the correct engagement length without bottoming out or being too short.

Understanding Thread Pitch

Thread pitch defines the distance between threads and ensures compatibility with a nut or threaded hole. A thread pitch gauge is the most reliable tool for this measurement.

Pro Tip: To measure pitch, select a leaf from the gauge and press it against the threads. The correct leaf will mesh perfectly with no visible gaps. The value on the leaf indicates the pitch in millimeters (metric) or threads per inch (TPI).

Alternatively, one can use a ruler:

- Align the fastener with the ruler.

- For TPI, count the number of thread peaks within one inch.

- For metric pitch, measure the distance in millimeters between adjacent peaks.

Matching the Bolt to the Application

Beyond size, several factors dictate the ideal fastener for a specific job. Engineers must match the bolt’s material and design to the demands of the application.

Assessing Load Requirements

The bolt must be strong enough to handle the expected tensile and shear loads. This requires selecting an appropriate strength grade, such as SAE Grade 8 or Metric Class 10.9, for high-stress environments. The material’s yield strength determines its ability to clamp parts together without permanent stretching.

Environmental Factors

The operating environment greatly influences material choice. Stainless steel (304 or 316) is necessary for applications with exposure to moisture or chemicals. Protective coatings like zinc plating can provide corrosion resistance for alloy steel fasteners in less harsh conditions.

Mating Material Hardness

The hardness of the joined materials is a key consideration. A serrated flange provides excellent vibration resistance but will damage soft or finished surfaces. A smooth flange is the correct choice for fastening parts made of aluminum, plastic, or for use with gaskets where surface integrity is paramount.

Proper Installation and Usage Guide

Proper installation is paramount to leveraging the full engineering benefits of a flange bolt. A correct procedure ensures the fastener achieves the designed clamping force and maintains joint integrity over its service life. Following best practices prevents premature failure, equipment damage, and safety hazards.

Pre-Installation Checks

Before any tightening begins, a thorough inspection of the fasteners and the joint surfaces is a critical first step. This quality check prevents issues that could compromise the connection.

Inspecting Threads and Flange

Technicians must visually inspect each bolt before use. This initial check helps identify obvious defects that could affect performance. Key inspection points include:

- Checking for excessive wear on the threads or flange surface.

- Inspecting for visible cracks, which indicate material fatigue.

- Looking for signs of rust or corrosion that could weaken the bolt.

- Identifying any signs of overstressing, such as yielding (permanent stretching).

For highly critical applications, technicians may employ nondestructive testing (NDT) routines. These methods can identify hidden metallurgical defects like stress corrosion cracking, which are not visible to the naked eye and could be concealed by the flange.

Ensuring a Clean Mating Surface

The surfaces where the flange and nut will sit must be completely clean. Technicians should remove all dirt, grease, rust, and old gasket material. A clean mating surface is essential for two reasons: it allows the clamping force to be distributed evenly, and it ensures that the applied torque reading is accurate. Debris can create false torque values, leading to an under-tightened joint.

Tightening Procedures

The tightening process is a science. It involves applying a precise amount of rotational force (torque) to stretch the bolt, creating the clamping force that holds the joint together.

Using a Torque Wrench

A calibrated torque wrench is the essential tool for proper installation. It allows a technician to apply a specific, measured amount of torque to the fastener. This precision prevents both under-tightening, which can lead to loosening, and over-tightening, which can stretch the bolt beyond its yield point or damage the joined components.

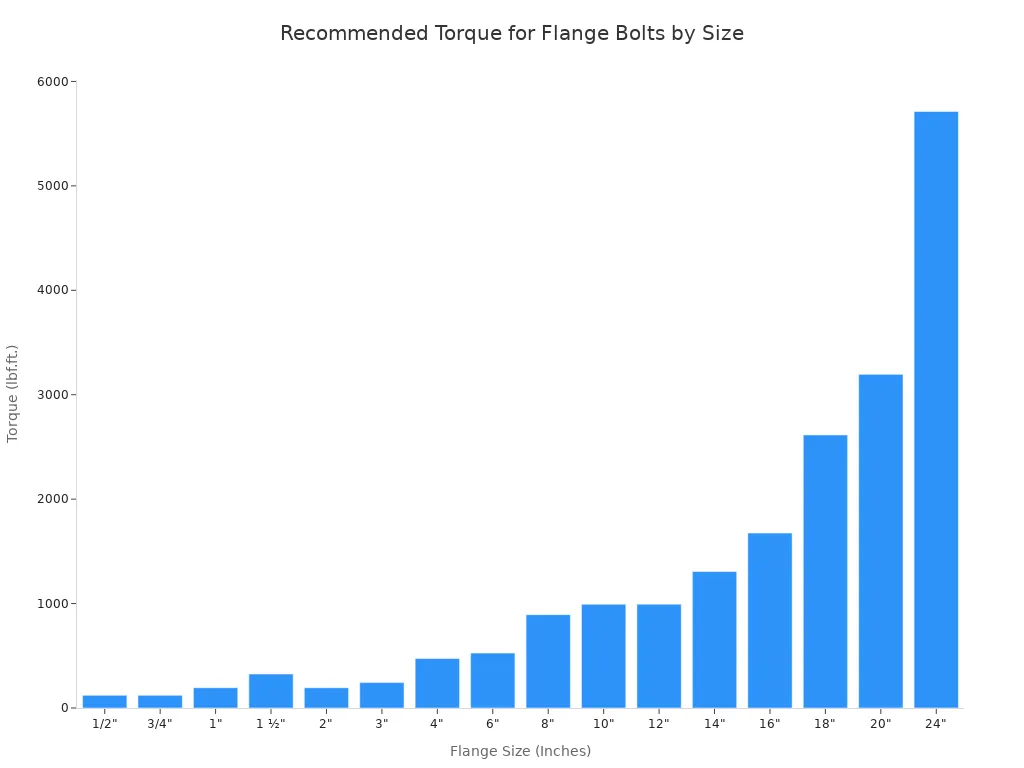

Understanding Torque Specifications

Engineers provide torque specifications based on the bolt’s material, diameter, and the application’s requirements. These values are calculated to achieve the optimal preload. The following table provides example torque values for various flange sizes using specific high-strength bolting materials and lubricants.

| Size in Inch | Size in mm | Bolt Dia. | Bolt Stress (lb/in²) | Torque (lbf.ft.) | Torque (Nm) |

|---|---|---|---|---|---|

| 1/2 | 15 | ½” | 40,000 | 121 | 165 |

| 1 | 35 | ½” | 40,000 | 194 | 263 |

| 2 | 50 | 5/8” | 40,000 | 194 | 263 |

| 4 | 100 | 5/8” | 45,000 | 474 | 642 |

| 6 | 150 | ¾” | 50,000 | 526 | 714 |

| 8 | 200 | ¾” | 45,000 | 894 | 1213 |

| 10 | 250 | 7/8” | 50,000 | 994 | 1347 |

| 12 | 300 | 7/8” | 50,000 | 994 | 1347 |

| 14 | 350 | 1” | 50,000 | 1306 | 1770 |

| 18 | 450 | 1 1/8” | 50,000 | 2615 | 3545 |

| 24 | 600 | 1 ¼” | 45,000 | 5713 | 7746 |

These specifications are applicable for flange materials like ASTM A105 and bolting materials such as ASTM A193 Grade B7, when used with specific gaskets and a Molykote 1000 lubricant. Technicians must always consult the manufacturer’s documentation for the exact torque values relevant to their specific bolt and application.

Tightening Patterns

When securing a component with multiple bolts, such as a pipe flange, the tightening sequence is crucial. Technicians use a star or crisscross pattern to apply pressure evenly across the surface. This method prevents warping the flange and ensures the gasket is compressed uniformly, creating a leak-proof seal. The process typically involves multiple passes:

- Tighten all bolts to approximately 30% of the final torque.

- Repeat the pattern, tightening to 60% of the final torque.

- Perform a final pass at 100% of the specified torque.

Using Flange Nuts for a Complete System

For maximum performance, a flange bolt is often paired with a flange nut. This creates a matched system where both components have an integrated flange, enhancing the security and reliability of the joint.

Pairing Bolts with Flange Nuts

A flange nut is a nut with a wide flange at one end that functions like a built-in washer. Pairing a flange bolt with a flange nut of the same size, material, and strength grade creates a balanced connection. This combination distributes the clamping load on both sides of the joint.

Benefits of a Matched Assembly

A complete flange assembly offers superior performance, especially in high-vibration environments.

- Enhanced Locking: Serrated flange nuts have teeth that grip the mating surface, providing powerful resistance to loosening. Some designs increase surface contact by up to 40% for exceptional torque retention.

- Improved Load Distribution: The dual-flange system distributes pressure evenly on both sides of the joint, protecting the materials from damage.

- Simplified Installation: Using a flange nut eliminates the need for a separate washer on the nut side, further streamlining the assembly process and reducing part counts.

Advanced systems even use precision-matched thread profiles between the bolt and nut to optimize preload distribution, ensuring an incredibly reliable connection.

A flange bolt is a superior one-piece fastener that uses its integrated flange to distribute load and resist loosening. Its design simplifies assembly and provides a more secure connection than traditional options. Selecting the correct type, material, and size is essential for safety, as improper fastener selection has led to critical failures.

- In 2010, connector bolts on a ship’s blowout preventer failed during testing, prompting a recall of 11,000 fasteners.

- Ford recalled over 240,000 vehicles because improperly secured seat belt bolts compromised occupant restraint systems.

These examples underscore why matching the flange and material to the application is vital for performance.

FAQ

Can a flange bolt replace a standard bolt and washer?

A flange bolt can replace a standard bolt and washer if there is enough clearance for the flange. Technicians must use the correct torque specification for the flange bolt, as it differs from a standard bolt due to increased friction.

Are flange bolts reusable?

Engineers generally discourage reusing high-strength flange bolts. Tightening stretches the bolt, and re-torquing a stretched fastener can cause inaccurate clamping or failure. Always consult the manufacturer’s specifications for guidance on reuse.

Do serrated flange bolts require a lock washer?

No, a serrated flange bolt does not require a lock washer. The serrations on the flange’s underside perform the locking function by biting into the mating surface. Adding a lock washer is redundant and not recommended.

What happens if you over-torque a flange bolt?

Over-torquing a flange bolt can stretch it beyond its yield strength, causing permanent damage and reducing its clamping ability. This can also damage the threads or crack the joined components, leading to joint failure.

How do you choose between a hex head and a 12-point head?

Technicians choose a hex head for general-purpose use with standard tools. They select a 12-point head for high-torque applications or for use in tight spaces, as it allows for better tool engagement with a smaller swing arc.

Is lubrication necessary when installing flange bolts?

Yes, lubrication is often critical. It reduces friction, ensuring the applied torque translates into accurate bolt tension (preload). Always follow the manufacturer’s specific lubricant and torque recommendations for the application.

Why is the tightening pattern so important?

A specific tightening pattern, like a star sequence, ensures even pressure across the joint. This prevents flange warping and guarantees uniform gasket compression, which is essential for creating a reliable, leak-proof seal in piping systems.