A flange bolt chart is a critical reference document in industrial piping. This chart specifies the exact number, size, and length of each flange bolt needed for a specific flange. A flange’s size and pressure class determine these requirements for a secure connection.

Note: Following these guidelines for every bolt is essential for creating a safe, leak-free flange connection.

While flange bolt charts provide standard flange bolt data, some projects require custom fasteners from a custom fasteners manufacturer, especially for unique bolt casting.

What Is a Flange Bolt Chart?

A flange bolt chart is a detailed technical reference that provides the precise specifications for the fasteners required to join two pipe flanges. It acts as a universal translator, converting a flange’s size and pressure rating into an exact bill of materials for its bolting. This essential document removes ambiguity from the assembly process. Engineers and pipefitters rely on these charts to ensure every connection is built to established safety and engineering standards.

Decoding the Core Components

At first glance, a flange bolt chart might seem like a simple table of numbers. However, each column contains critical data that dictates the mechanical integrity of a bolted joint. Understanding these core components is the first step toward correct application.

Flange Size (Nominal Pipe Size)

The first piece of information is the flange size, which directly corresponds to the Nominal Pipe Size (NPS) it will connect to. This value, typically measured in inches in the United States, is the primary identifier for any given pipe. On the chart, users locate the row that matches their pipe’s NPS to find all associated bolting data.

Pressure Class Rating (e.g., 150#, 300#)

The pressure class rating indicates the maximum internal pressure a flange can safely withstand at a given temperature. Common classes include 150#, 300#, 600#, and higher. A higher pressure class rating means the flange is thicker, heavier, and requires more or larger bolts to handle the increased force. A flange bolt chart organizes data by both size and pressure class, as a 6-inch Class 150 flange uses a different bolt pattern than a 6-inch Class 600 flange.

Number and Diameter of Bolts

This component specifies the exact quantity of bolts needed for the connection and their required diameter. For example, a chart might show that a 4-inch Class 150 flange requires 8 bolts, each with a diameter of 5/8 inches. Using the correct number and diameter of bolts ensures that the clamping force is distributed evenly around the flange face, which is critical for achieving proper gasket compression and a leak-proof seal.

Required Length of Stud Bolts

The chart also dictates the correct length for each stud bolt. The specified length is calculated to be long enough to pass through both flanges and allow for full nut engagement on both ends, with a small amount of excess thread.

Pro Tip: The required flange bolt length often depends on the flange face type (e.g., Raised Face, Flat Face) and the thickness of the gasket used. Always verify these details before finalizing bolt procurement.

Understanding the Governing Standards

Flange bolt charts are not arbitrary; they are derived from rigorous, internationally recognized engineering standards. These standards ensure that components from different manufacturers are interchangeable and that assemblies meet defined safety criteria.

The Role of ASME B16.5

In North America, the most prominent standard for pipe flanges and flanged fittings is ASME B16.5. This document covers flanges from NPS 1/2 through NPS 24 and dictates dimensions, tolerances, materials, and testing. The data in most flange bolt charts used in the U.S. comes directly from this standard. ASME B16.5 also provides recommendations for flange bolt materials suitable for various service conditions, especially high-pressure and high-temperature applications.

For demanding services, the standard specifies high-strength bolting materials, including:

- ASTM A193 Grade B7

- ASTM A193 Grade B16

- ASTM A320 Grade L7A, L7B, L7C, L43

- ASTM A354

- Special alloys like ASTM B164 (Ni-Cu), ASTM B166 (Ni-Cr-Fe), and ASTM B574 (low carbon nickel)

Other International Standards (DIN, JIS)

While ASME is dominant in the U.S., global projects often involve other standards like DIN (Deutsches Institut für Normung) from Germany and JIS (Japanese Industrial Standards). These standards are not interchangeable with ASME. ASME B16.5 standards use imperial units and have standardized bolt hole patterns. In contrast, DIN standards employ metric dimensions for bolt circle diameters and hole sizes, featuring unique bolt quantities. JIS standards also present distinct bolt hole arrangements and often use different pressure rating conventions.

This table highlights some key differences between JIS and ANSI/ASME standards:

| Feature | JIS Flanges | ANSI Flanges (ASME B16.5) |

|---|---|---|

| Measurement Units | Metric (mm, kg/cm²) | Imperial (inches, PSI) |

| Bolt Hole Patterns | Different from ANSI | Standardized |

| Pressure Ratings | 5K, 10K, 16K, 20K, 30K | CL150, CL300, CL600, etc. |

| Interchangeability | Not compatible with ANSI | Not compatible with JIS |

The Critical Role of Flange Bolt Charts in Safety

Beyond logistics and efficiency, flange bolt charts are fundamentally tools for ensuring safety. In industrial environments where high pressures and hazardous materials are common, a single failed flanged connection can have devastating consequences. Adhering to these charts is a non-negotiable practice for protecting personnel, assets, and the environment.

Ensuring Mechanical Joint Integrity

The long-term reliability of a bolted joint depends on its mechanical integrity. This stability is achieved when every component works together as a system. Using the correct flange bolt specifications is the foundation for building this system correctly.

Achieving Proper Gasket Compression

A leak-proof seal depends on achieving and maintaining adequate gasket compression. The initial load applied to a bolt, known as preload, creates the compressive stress on the gasket. This stress must be high enough to seal the joint against internal pressure. Using the specified number and diameter of bolts ensures the clamping force is sufficient and evenly distributed. Accurate bolt preload is the most critical factor for reliable secure flange connections, as it allows the elastic interaction between the flange, fasteners, and gasket to compensate for relaxation over time.

Preventing Leaks of Hazardous Materials

Incorrect gasket compression directly leads to leaks. In many industrial processes, these leaks involve toxic, flammable, or corrosive substances, posing an immediate danger. Real-world incidents highlight the critical importance of using the correct components for every flange.

- CO2 Absorber Leak: In one documented case, a crew mistakenly installed a Class 150 gasket on a Class 300 flange. This error caused a major leak of a hot potassium carbonate solution, forcing a two-day plant shutdown and resulting in significant production and material loss.

- Control Valve Near-Miss: In another incident, pipefitters used a 900# ring gasket on a 1500# flange connection. An alert supervisor caught the error before startup, preventing a potential joint failure that could have led to an uncontrollable fire.

Mitigating Catastrophic Failure Risks

A simple mistake in bolt selection can escalate from a minor leak to a catastrophic failure. The forces contained within industrial piping systems are immense, and joint failure can release that energy suddenly and violently.

Preventing Joint Blowouts

A joint blowout occurs when the bolts can no longer contain the force exerted by the internal pressure, causing the flange joint to separate violently. This can happen if the bolts are too small, too few, or made of an incorrect material grade. Following the specifications on flange bolt charts ensures the connection has the mechanical strength required to withstand its designed operating pressures.

Guaranteeing Personnel and Asset Safety

Ultimately, the primary function of any engineering standard is to protect people and property. By removing guesswork from the assembly process, these charts directly contribute to a safer work environment. Every correctly assembled flange is a step toward preventing injuries, avoiding costly equipment damage, and maintaining operational integrity.

How Charts Ensure Regulatory and Standards Compliance

Using flange bolt charts is more than a best practice; it is a fundamental requirement for regulatory compliance. These documents provide a clear pathway for companies to meet stringent industry codes and create the necessary documentation for audits. Following these charts ensures that every bolted connection aligns with established safety and engineering mandates.

Adherence to Industry Codes

Major industrial projects must follow specific codes that govern design, construction, and operation. Flange bolt charts are directly tied to these codes, making them essential tools for compliance.

Meeting ASME B31.1 and B31.3 Piping Codes

The ASME B31 codes are the cornerstones of pipe engineering in North America.

- ASME B31.1 covers Power Piping, used in power plants and similar facilities.

- ASME B31.3 governs Process Piping, common in refineries and chemical plants.

Both codes mandate that components, including bolted joints, meet specific standards. Since flange bolt charts derive their data from ASME B16.5, using them ensures that every flange connection in the piping systems is assembled according to the rules set forth in these overarching codes.

Fulfilling API Specifications

The American Petroleum Institute (API) sets standards for the oil and gas industry. While there is overlap with ASME, API specifications often have unique requirements tailored to the extreme pressures and demanding environments of oil exploration and production. For example, API 6A specifies requirements for wellhead and Christmas tree equipment. The design philosophies can differ significantly.

When ASME VIII Div 1 Appendix 2 calculations are applied to standard flanges, they frequently fail the check. Specifically, ASME B16.5 flanges are often found to be ‘over bolted,’ meaning they have a bolt diameter that is too large. This suggests a potential difference in the underlying design philosophy or criteria for bolting between ASME and API 6A.

This distinction shows why project teams must use the correct chart for the governing standard (API or ASME) to ensure compliance.

The Importance of Documentation for Audits

Compliance requires proof. In the event of an internal or external audit, companies must provide clear evidence that they followed all applicable standards.

Creating a Traceable Record

Flange bolt charts form a critical part of the project’s quality assurance documentation. When a technician uses a chart to select and install bolts, they create a traceable link between the physical asset and the engineering standard. This record is invaluable for:

- Verifying correct assembly during quality control checks.

- Troubleshooting joint issues during maintenance.

- Conducting root cause analysis after an incident.

Demonstrating Due Diligence

Proper documentation demonstrates a company’s commitment to safety and operational excellence. By maintaining records that show adherence to bolt chart specifications, an organization proves it has performed its due diligence. This documentation serves as a powerful defense during regulatory inspections or legal inquiries, showing that the company took deliberate, standardized steps to ensure the integrity of each pipe connection.

Using Flange Bolt Information to Boost Efficiency

Beyond their roles in safety and compliance, flange bolt charts are powerful tools for improving operational efficiency. They introduce standardization and clarity into processes that are otherwise prone to error and delay. This helps streamline workflows from the project planning stage all the way to final installation.

Standardizing Flange Assembly

Standardization is the key to repeatable success in any industrial setting. Flange bolt charts provide the foundation for creating consistent and reliable assembly procedures.

Eliminating Guesswork and Human Error

These charts serve as the single source of truth for assembly tasks. They provide technicians with clear, unambiguous data, removing the need for guesswork. This standardization ensures every worker uses the correct fasteners for a given connection, drastically reducing the risk of human error. When every team member follows the same guide for a flange, consistency and quality become standard practice.

Speeding Up Installation and Maintenance

A standardized process is an efficient one. Technicians who know the exact requirements can prepare for and complete jobs faster. This accelerated workflow is especially valuable during large-scale construction or time-sensitive maintenance shutdowns. By establishing clear, repeatable steps, companies can achieve significant improvements.

- Lower Labor Costs: Quick and accurate installation shortens project timelines and reduces overall labor expenses.

- Enhanced Reliability: Using the correct bolt specifications ensures secure connections, minimizing the chance of future leaks and costly repairs.

- Improved Efficiency: Repetition in applications allows for optimized labor, which is crucial for controlling costs on major projects.

Streamlining Project Logistics

The benefits of flange bolt data extend beyond the job site and into the realm of project management and logistics. Accurate information is essential for keeping a project on time and on budget.

Simplifying Material Procurement

Project managers and procurement teams rely on these charts to build accurate material take-offs. This simplifies the entire purchasing process. Teams can order the precise quantity, diameter, and length of fasteners required for the job. This practice prevents costly over-ordering and eliminates delays caused by material shortages. For large projects involving multiple vendors, this common reference ensures all parties procure compatible components.

Optimizing Warehouse Inventory

Effective inventory management depends on accurate data. The charts provide the detailed information needed to stock a warehouse efficiently. Planners can forecast the exact components required for upcoming maintenance or projects. This data-driven approach helps optimize stock levels, ensuring that the correct bolt is always available without tying up capital in unnecessary inventory.

A Practical Guide: How to Read and Apply a Flange Bolt Chart

Flange bolt charts translate complex engineering standards into actionable data. Technicians and engineers use this information to ensure every connection is secure and compliant. This guide provides a step-by-step process for reading and applying a flange bolt chart correctly.

Step 1: Identify Key Flange Parameters

Accurate data retrieval begins with identifying the correct flange specifications. A technician must first determine three critical parameters before consulting any chart.

Determine the Nominal Pipe Size

The first parameter is the Nominal Pipe Size (NPS). This value corresponds to the size of the pipe the flange will connect to. The NPS is typically stamped directly onto the flange body, often alongside other identifying marks. Locating this number is the initial step in finding the correct row on the chart.

Identify the Pressure Class

Next, the technician must identify the pressure class rating. This rating, such as 150#, 300#, or 600#, indicates the flange’s pressure-handling capability. Like the NPS, the pressure class is also marked on the flange. A higher pressure class signifies a more robust flange that requires a different bolt configuration.

Note the Flange Facing Type (RF, FF, RTJ)

The flange facing type dictates the gasket style and can influence the required flange bolt length. The three common types are Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ). Each has specific requirements.

- Raised Face (RF) Flanges: These feature a small raised surface where the gasket sits. They use a ring gasket that covers only this raised area, allowing the serrations to create a tight seal.

- Flat Face (FF) Flanges: These have a uniform mating surface across the entire face. They are used in lower-pressure applications and require a full-face gasket that covers the entire surface from the inner to the outer diameter of the flange.

Important: The bolt length specified in many flange bolt charts is calculated for a standard Raised Face flange. Using a different facing type may require a length adjustment.

Step 2: Locate the Correct Bolt Data

With the key parameters identified, the user can now locate the precise bolting information on the reference chart.

Cross-Reference Size and Class on the Chart

The user first finds the row corresponding to the Nominal Pipe Size. Then, they scan across that row to the columns associated with the correct pressure class. For example, to find data for a 6-inch pipe, the user locates the “6” in the size column and then looks under the “150 LB” or “300 LB” heading.

Read Bolt Quantity, Diameter, and Length

Once the correct row and columns are located, the chart provides the exact specifications. The user reads the required number of bolts, the diameter of each bolt, and the necessary length for the stud bolt.

Here is a sample from an ASME B16.5 chart for Class 150 and Class 300 pipe flanges:

| Nominal Pipe Size | 150 LB. Flanges – # Bolts or Studs | 150 LB. Flanges – Dia of Bolts or Studs | 150 LB. Flanges – Length of Stud (1/16 RF) | 300 LB. Flanges – # Bolts or Studs | 300 LB. Flanges – Dia of Bolts or Studs | 300 LB. Flanges – Length of Stud (1/16 RF) |

|---|---|---|---|---|---|---|

| 4 | 8 | 0.63 | 3-1/2 | 8 | 0.75 | 4-1/2 |

| 5 | 8 | 0.75 | 3-3/4 | 8 | 0.75 | 4-3/4 |

| 6 | 8 | 0.75 | 4 | 12 | 0.75 | 4-3/4 |

The number of bolts increases significantly with the pressure class, as shown below.

Step 3: Application Example

Applying this data in a real-world scenario demonstrates its practical importance. The process ensures the correct materials are procured and installed.

Scenario: Bolting a 10-inch Class 300 RF Flange

Imagine a pipefitter needs to connect a 10-inch Class 300 Raised Face flange. The first step is to consult the appropriate ASME B16.5 flange bolt chart. The pipefitter locates the row for NPS “10” and then moves to the columns for “Class 300”.

Applying Chart Data to Procure and Install

The chart would specify the following for a 10-inch Class 300 flange:

- Number of Bolts: 16

- Diameter of Bolts: 1-1/8 inches

- Length of Stud Bolts: 6-1/2 inches

The specified length is not arbitrary. It is calculated to accommodate all components of the joint. The theoretical length (L) of a stud flange bolt can be expressed with a formula:

L = 2 (s + n + h + rf) + g

In this formula:

his the flange thickness.gis the gasket thickness.rfis the height of the raised face.nis the nut height (usually equal to the bolt diameter).sis an allowance for free threads (typically 1/3 of the bolt diameter).

Using this data, the procurement team orders exactly 16 stud bolts with a 1-1/8″ diameter and 6-1/2″ length. The installation crew then uses these components, confident they are following the correct engineering standard for this specific connection.

Common Mistakes When Using Flange Bolt Data

Even with a detailed flange bolt chart, errors can occur during assembly. These mistakes often compromise joint integrity and can lead to significant safety hazards. Understanding these common pitfalls is the first step toward preventing them.

Misinterpreting Flange Face Requirements

The type of flange face directly impacts bolt selection, yet technicians sometimes overlook this detail. A simple misinterpretation can render a connection unsafe.

Raised Face (RF) vs. Flat Face (FF) Bolt Lengths

Standard bolt lengths listed on a chart are typically calculated for Raised Face (RF) flanges. Flat Face (FF) flanges use a full-face gasket that extends to the outer edge of the flange. This requires a longer flange bolt to accommodate the gasket’s width. Using a standard RF bolt on an FF flange may not allow for proper nut engagement, creating a weak and dangerous connection.

Special Considerations for Ring Type Joint (RTJ)

Ring Type Joint (RTJ) flanges are designed for high-pressure and high-temperature services. They feature a groove that holds a metal ring gasket. The dimensions of this joint are unique, and the required bolt length can differ from RF flanges. Technicians must always verify the specific requirements for an RTJ flange, as a standard length may be insufficient.

Selecting the Incorrect Flange Bolt Material

The material grade of a flange bolt is just as critical as its dimensions. Choosing the wrong material can lead to premature failure, especially in demanding service conditions.

Matching Material Grade to Service Conditions

The operating environment dictates the correct bolt material. Factors like temperature, pressure, and corrosive media must be considered. For example, a standard carbon steel bolt will fail in a highly corrosive chemical pipe. Technicians must match the material to the application.

| Service Environment | Recommended Bolt & Nut Material |

|---|---|

| Carbon Steel | A193 Gr.B7 / A194 Gr.2H |

| Austenitic Stainless Steel | A193 Gr.B8 / A194 Gr.8 |

| Duplex Stainless Steel | A193 Gr.B7 / A194 Gr.7 |

| Super Duplex Stainless Steel | A193 Gr.B8M / A194 Gr.8M |

For offshore and chemical processing, materials like Duplex, Super Duplex, and Nickel Alloys (Inconel, Monel) offer superior corrosion resistance.

The Dangers of Unapproved Substitution

Substituting a specified bolt with an unapproved one is a critical error. A lower-grade bolt lacks the tensile strength to handle the required preload and operating forces. This can result in bolt stretching, loss of gasket compression, and eventual joint failure.

Ignoring the Flange Bolt Torque Sequence

Applying the correct torque is essential, but the sequence of tightening is equally important. An improper flange bolt torque sequence creates uneven gasket stress, which is a primary cause of leaks.

Why a Star Pattern is Critical

The industry-standard flange bolt torque sequence is the star pattern. This method involves tightening bolts in an alternating sequence across the flange diameter. This technique applies pressure evenly, ensuring uniform gasket compression. The star pattern is suitable for all gasket and flange types, including RTJ, making it the most reliable and recommended method. Other methods, like a circular pattern, are not recommended for most applications.

Risks of Uneven Gasket Loading

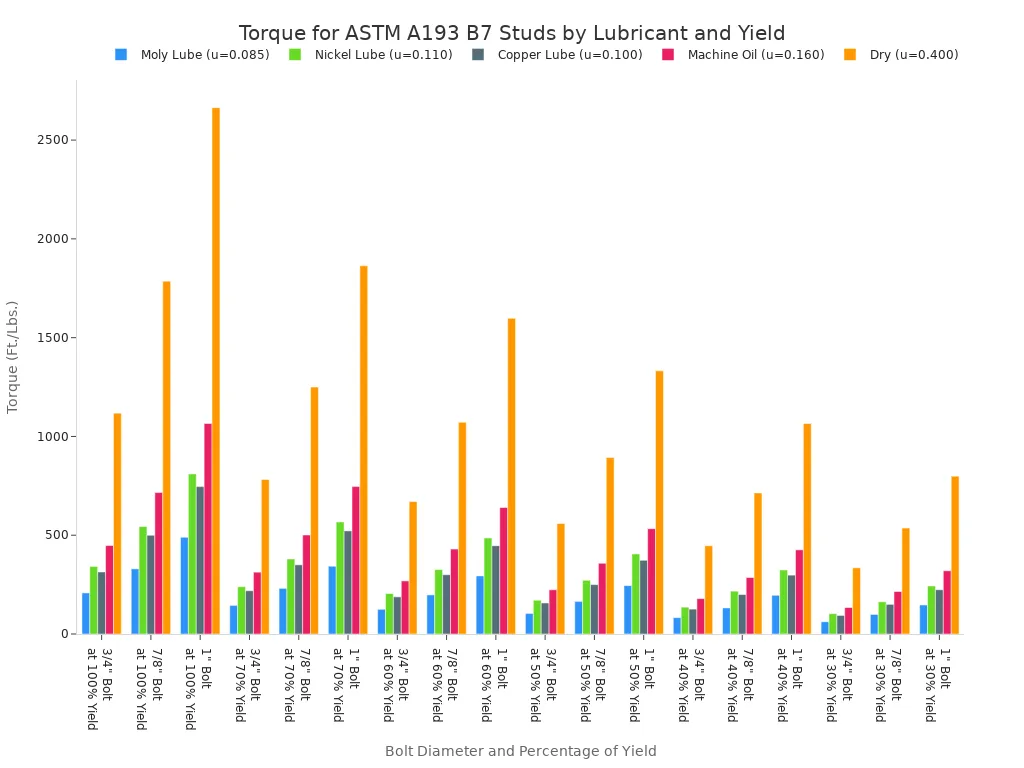

Ignoring the correct torque sequence leads to uneven loading. One side of the gasket becomes over-compressed while the other remains loose, creating a path for leaks. Achieving the recommended torque is impossible without a proper flange bolt torque sequence. The amount of torque also depends heavily on the lubricant used, as different lubricants have different friction coefficients (u). For instance, applying the recommended torque with a moly lube (u=0.085) is very different from applying it dry (u=0.400). Following the common flange bolt torque sequence ensures the final torque value effectively seals the pipe connection.

Advanced Topics Beyond Basic Flange Bolt Charts

Standard flange bolt charts provide an excellent foundation, but real-world applications often introduce complexities. Engineers and technicians must look beyond basic charts to handle specialized components and extreme service conditions. These advanced topics ensure joint integrity when standard assumptions do not apply.

The Impact of Gasket Selection

The gasket is a critical component that directly influences bolt requirements. Its material, design, and thickness all play a role in the final assembly.

How Gasket Thickness Affects Bolt Length

Standard charts often calculate bolt lengths based on a thin, 1/16-inch gasket. However, many applications require thicker gaskets to ensure a proper seal. A thicker gasket increases the distance between the two flange faces. This requires a longer bolt to ensure sufficient thread protrudes through the nut for full engagement. Using a standard-length bolt with a thick gasket can lead to inadequate clamping force and a potential leak path.

Spiral Wound vs. Ring Type Joint (RTJ) Gaskets

Different gasket types have unique sealing mechanisms that affect the required bolt load.

- Spiral Wound Gaskets: Used with Raised Face flanges, these composite gaskets require a specific seating stress to create a seal. The applied torque compresses the gasket into the serrations on the flange face.

- Ring Type Joint (RTJ) Gaskets: These solid metal rings sit in a groove and require a much higher initial bolt load. The high torque forces the soft metal gasket to deform and create an extremely tight metal-to-metal seal, ideal for high-pressure services. This means the required torque for an RTJ is significantly higher than for a spiral wound gasket in a similar pipe.

Considerations for Extreme Service Conditions

Operating environments with extreme temperatures or pressures demand special attention. The materials for every component, including the flange bolt, must be selected carefully.

High-Temperature and Cryogenic Applications

Extreme temperatures affect material properties. In high-temperature services, bolts can lose their preload over time due to a phenomenon called “creep,” which can lead to leaks. In cryogenic (very low temperature) applications, standard carbon steel can become brittle and fail.

Important: For these conditions, engineers must select specialized materials. For example, ASTM A193 Grade B8 bolts are often used for cryogenic pipe applications due to their toughness at low temperatures.

Adjustments for Thermal Expansion

Different materials expand and contract at different rates when heated or cooled. A pipe system may use a carbon steel flange with stainless steel bolts. During temperature changes, the bolt and flange will expand differently. This differential expansion can either increase bolt stress to dangerous levels or decrease it enough to cause a loss of gasket compression. Advanced engineering analysis is often necessary to calculate the correct initial torque to account for these thermal effects.

Flange bolt charts are non-negotiable tools for industrial piping integrity. Professionals use a flange bolt chart to guarantee safety and reliability in complex piping systems. Mastery of this chart is a core competency for every flanged connection. Technicians must always reference the appropriate chart to ensure each piping connection is secure and prevents failure.

FAQ

What happens if someone uses the wrong bolt size?

Using the wrong bolt size compromises joint integrity. It leads to uneven gasket compression, leaks, and potential catastrophic failure. The connection will not meet its designed pressure rating, creating a significant safety risk.

Where can technicians find official flange bolt charts?

Technicians find official charts in engineering handbooks, manufacturer catalogs, and directly within standards like ASME B16.5. Many suppliers also provide digital charts on their websites for quick reference and procurement.

Why is bolt material grade so important?

The bolt material determines a joint’s strength and corrosion resistance. An incorrect material grade can fail under specific service conditions like high temperature or pressure, leading to a dangerous system breach.

Can flange bolts be reused?

General industry practice advises against reusing flange bolts, especially in critical services. Bolts can stretch or suffer from fatigue during initial torquing. Using new, certified bolts for each installation ensures maximum reliability and safety.

What are the most critical steps in bolting?

Three steps are essential for a secure joint:

- Verifying the correct bolt size, length, and material from the chart.

- Applying the specified lubricant to threads and nut faces.

- Tightening bolts to the correct torque value using a star pattern.

Does every project require a different chart?

No. A technician uses the same standard chart (e.g., ASME B16.5) for all projects governed by that standard. They only need to confirm the chart matches the project’s specified flange standard (ASME, DIN, etc.).