An eye bolt anchor is a specialized fastener designed to create a secure attachment point on solid surfaces like concrete or masonry. This component is essential in the broader industrial fasteners market, a sector projected to grow from USD 99.63 billion in 2024 to over USD 131.45 billion by 2030. The system consists of two primary parts: the eye bolt, with its looped head for attaching ropes or cables, and an anchor mechanism. This anchor expands to grip the inside of a pre-drilled hole, forming a strong connection. Many projects rely on these Anchor Bolts, ranging from standard designs to custom anchor bolts. A custom fasteners manufacturer can produce a wide array of custom fasteners, including specialized eye bolt anchors, for unique applications. These anchors provide reliable support across various industries.

What Are Common Uses for Eye Bolt Anchors?

Eye bolt anchors are incredibly versatile, serving a wide range of functions across residential, commercial, and industrial settings. Their applications span from simple, light-duty tasks to critical, heavy-duty operations where safety is paramount. Understanding these common uses helps clarify why selecting the correct type of anchor is so important.

Light-Duty Securing and Tie-Downs

Many everyday situations call for a reliable, non-structural attachment point. In these scenarios, bent wire eye bolts combined with mechanical anchors offer a straightforward and effective solution.

Residential and DIY Projects

Homeowners and DIY enthusiasts often use eye bolt anchors for various projects around the house and yard. Common uses include:

- Creating tie-down points in a garage or on a concrete patio to secure equipment.

- Anchoring shade sails, string lights, or decorative elements to brick walls.

- Installing hooks for hammocks or hanging plants from a solid ceiling or wall.

- Setting up clotheslines or guide wires for climbing plants.

Commercial and Retail Displays

In commercial spaces, aesthetics and functionality go hand-in-hand. Eye bolts provide a clean and secure method for suspending items without obtrusive hardware. Retailers frequently use them for hanging signage and displays. An eye bolt anchor allows signs to be suspended from:

- Chains

- Cables

- Hooks

This method creates a professional appearance while ensuring the display remains safely in place.

Heavy-Duty Lifting and Rigging

Forged eye bolts paired with high-strength anchors are essential for heavy-duty lifting and rigging. These applications demand strict adherence to safety standards, as failure can have catastrophic consequences.

Industrial and Construction Sites

Construction sites rely on robust anchors for moving materials and securing structures. In these environments, eye bolts are integral components for:

- Lifting heavy machinery, concrete panels, and steel beams with cranes.

- Securing temporary structures like scaffolding to a building’s facade.

- Tensioning support cables and braces to ensure structural stability during construction.

- Serving as key connection points in complex rigging systems with pulleys and winches.

A real-world example involved a project where workers used M16 swivel eye bolts to suspend one-tonne chain blocks. These blocks lifted large beam sections into place within a basement. The eye bolts were secured into the concrete ceiling using flush-mounted resin anchors, demonstrating their critical role in complex installations.

Safety is Non-Negotiable Both OSHA and ASME provide strict guidelines for rigging hardware. For example, ASME B30.26 and B18.15 cover everything from material ductility to load capacity for forged eyebolts. Key safety practices include:

- Inspecting all rigging equipment before each use.

- Ensuring the manufacturer’s safe working load (WLL) is clearly marked and never exceeded.

- Removing any defective or unmarked equipment from service immediately.

Marine and Shipping Applications

The marine environment is exceptionally harsh due to constant exposure to saltwater and moisture. For these applications, material selection is critical. Eye bolts used for securing cargo or mooring lines must resist corrosion to maintain their strength.

| Material | Corrosion Resistance | Common Use Case |

|---|---|---|

| Galvanized Steel | Good | Economical choice for general outdoor and some marine use. |

| Type 304 Stainless Steel | High | Resists typical rusting; suitable for freshwater or less harsh areas. |

| Type 316 Stainless Steel | Excellent | Known as “marine grade,” it contains molybdenum for superior resistance to saltwater and chlorides. |

When selecting an anchor for marine use, professionals always choose an eye bolt with a Working Load Limit (WLL) that far exceeds the expected load. This safety margin accounts for dynamic forces from waves and wind.

Safety and Suspension Systems

Beyond lifting, eye bolts are crucial components in systems designed to protect lives and suspend essential building infrastructure. These anchors must meet stringent certification requirements.

Fall Protection Anchors

In construction and industrial maintenance, a fall protection anchor provides a secure attachment point for a worker’s personal fall arrest system (PFAS). These anchors are life-safety devices. The American National Standards Institute (ANSI) outlines specific requirements in standard ANSI/ASSP Z359.18-2017.

- This standard dictates design, strength testing, and installation guidelines to ensure reliability.

- It requires the connection point on these anchors to be a closed eye with a minimum internal radius of one inch.

- Any hardware used must also comply with related ANSI standards for connecting components.

Suspending HVAC and Piping

In modern buildings, installers suspend heavy infrastructure like ductwork, pipes, and cable trays from ceilings. Specialized eye bolt systems, such as the Hangermate® fastening system, are designed for this purpose. These systems use an anchor to secure a threaded rod to concrete or steel structures. The eye bolt or a similar attachment then connects to the rod, providing a strong point for suspending:

- HVAC ductwork

- Fire protection sprinkler systems

- Electrical conduits and cable trays

- Overhead lighting systems

- Suspended ceilings

These engineered solutions ensure that heavy, overhead utilities remain safely and permanently in place.

Understanding the Main Types of Eye Bolts

Selecting the correct fastener requires a clear understanding of the main types of eye bolts available. The choice depends heavily on the load’s weight, the direction of the pull, and the manufacturing process. Professionals categorize these fasteners based on two key distinctions: their shoulder design and their construction method. Examining these types of eye bolts ensures project safety and reliability.

Shouldered vs. Non-Shouldered Eye Bolts

The presence or absence of a shoulder at the base of the eye is a critical design feature. This single element dictates how the eye bolt can be loaded. These two types of eye bolts have very different application rules.

Shouldered Eye Bolts for Angular Loads

A shouldered eye bolt features a machined shoulder between the eye and the threads. This shoulder must sit flush against the mounting surface. Its purpose is to brace the shank against bending forces. This design allows the fastener to handle angular loads (pulls from the side). However, angular loading significantly reduces the eye bolt’s capacity.

Important Note: A shouldered eye bolt is mandatory for any application involving an angular pull. The shoulder provides crucial support that prevents the bolt from bending or breaking under side-loaded stress.

Non-Shouldered Eye Bolts for Vertical Loads

Non-shouldered (or plain pattern) eye bolts lack this supportive collar. They are designed exclusively for vertical, in-line lifts where the force pulls straight up along the shank’s axis. Using these types of eye bolts for an angular load is extremely dangerous. The bending stress can easily cause them to fail.

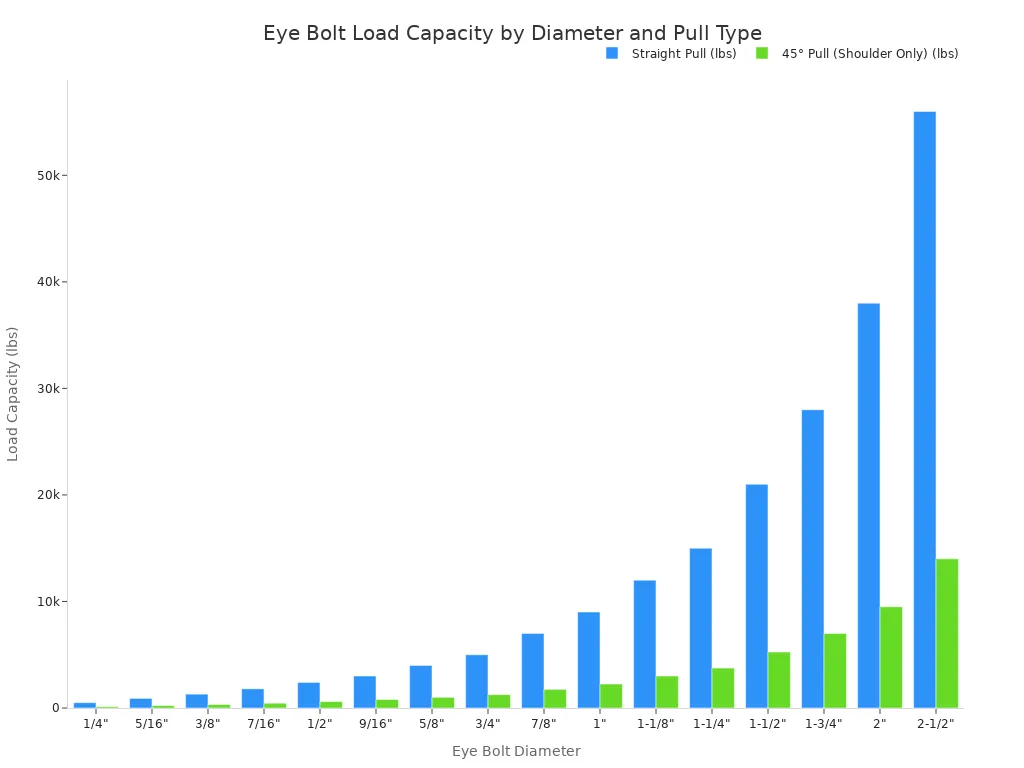

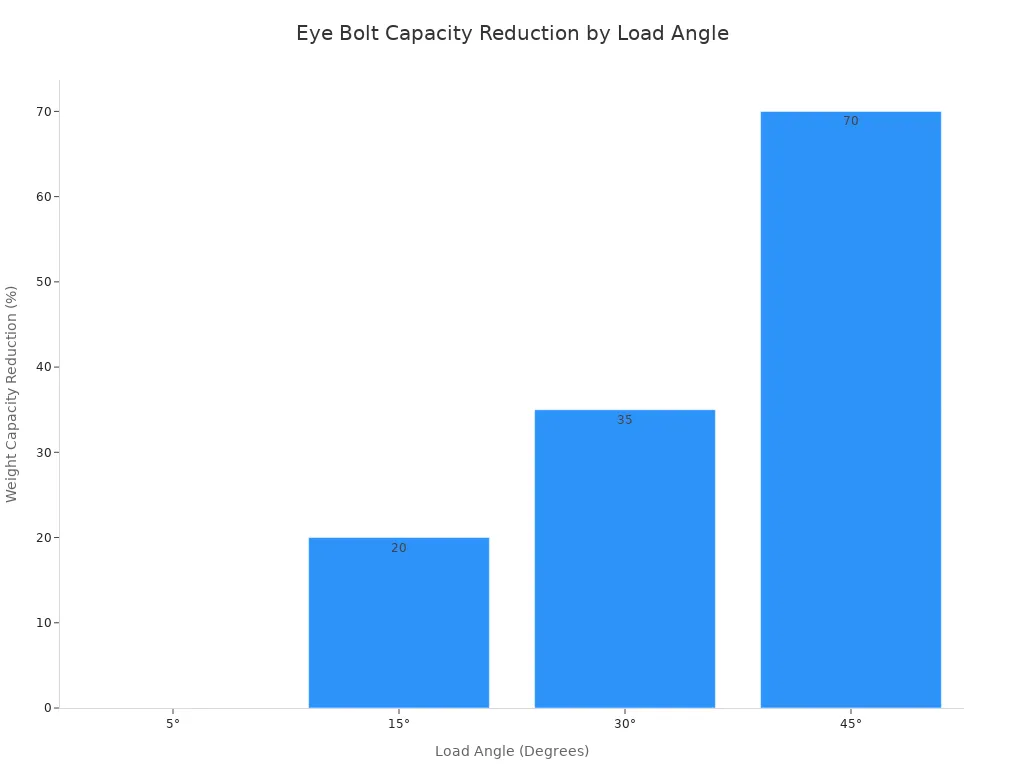

The following table and chart clearly show how load angle impacts the capacity of shouldered eye bolts. Non-shouldered types of eye bolts have no rated capacity for angular pulls.

| Diameter | Straight Pull (lbs) | 45° Pull (Shoulder Only) (lbs) |

|---|---|---|

| 1/4″ | 500 | 125 |

| 1/2″ | 2,400 | 600 |

| 1″ | 9,000 | 2,250 |

| 1-1/2″ | 21,000 | 5,250 |

Forged vs. Bent Eye Bolts

The manufacturing process directly influences an eye bolt’s strength. This creates another fundamental way to classify the types of eye bolts.

Forged Eye Bolts for Heavy Lifting

Forged eye bolts are made by shaping a single piece of steel under extreme pressure while it is hot. This process aligns the metal’s internal grain structure, resulting in superior strength and fatigue resistance.

- Manufacturing Process: Shaping metal under high pressure

- Material Structure: Improved, continuous grain structure

- Strength: Superior strength, making them the only choice for heavy-duty lifting eye bolts.

These types of eye bolts are often heat-treated to further enhance their hardness. They are the standard for industrial rigging and overhead lifting.

Bent (Wire) Eye Bolts for Light-Duty Use

Bent eye bolts are made by simply bending a steel wire or rod into a loop, which may or may not be welded closed. This method is less expensive but produces a much weaker part. The bend is a point of weakness. Under a heavy load, the eye can unbend and fail. These types of eye bolts are only suitable for light-duty, static applications like tie-downs or suspending lightweight signs.

Exploring Anchor Mechanism Types

An eye bolt is only as strong as the anchor holding it in place. The anchor mechanism creates the connection with the base material, like concrete or brick. Professionals choose between two primary categories: mechanical expansion anchors and chemical adhesive anchors. The selection depends on the load requirements, base material condition, and environmental factors.

Mechanical Expansion Anchors

Mechanical expansion anchors generate holding power through friction. Tightening the bolt or nut expands a section of the anchor, forcing it against the walls of the pre-drilled hole. These anchors offer several advantages. They are cost-effective for many standard applications and allow for immediate loading because no curing time is needed. Installers also find them less sensitive to imperfectly cleaned holes compared to chemical systems.

Sleeve Anchors

A sleeve anchor consists of a threaded stud enclosed by a metal sleeve. During installation, an installer tightens the nut. This action pulls the stud’s cone-shaped end into the sleeve. The sleeve then expands outward, pressing firmly against the surrounding concrete or masonry to create a secure hold.

Wedge Anchors

Wedge anchors are high-strength fasteners designed for solid concrete. This anchor features a threaded stud with a tapered cone at one end and a clip or expansion sleeve around it. When the nut is tightened, the clip is forced down over the cone. This wedges the anchor tightly into the hole, providing excellent tensile strength for heavy-duty applications.

Shield Anchors

Shield anchors are versatile fasteners suitable for various base materials. Eye bolt shield anchors use an internal, tapered plug. As the eye bolt is screwed in, it pushes the plug deeper into the anchor body, or shield. This forces the shield to expand and grip the material. Installers often use eye bolt shield anchors in brick or blockwork where a wider distribution of pressure is beneficial.

Chemical and Adhesive Anchors

Chemical anchors, also known as adhesive anchors, use a resin-based agent to form a bond between the fastener and the substrate. These anchors are ideal for applications requiring the highest load capacity or when working near edges, as they introduce no expansion stress that could crack the concrete. They are also superior in resisting vibration.

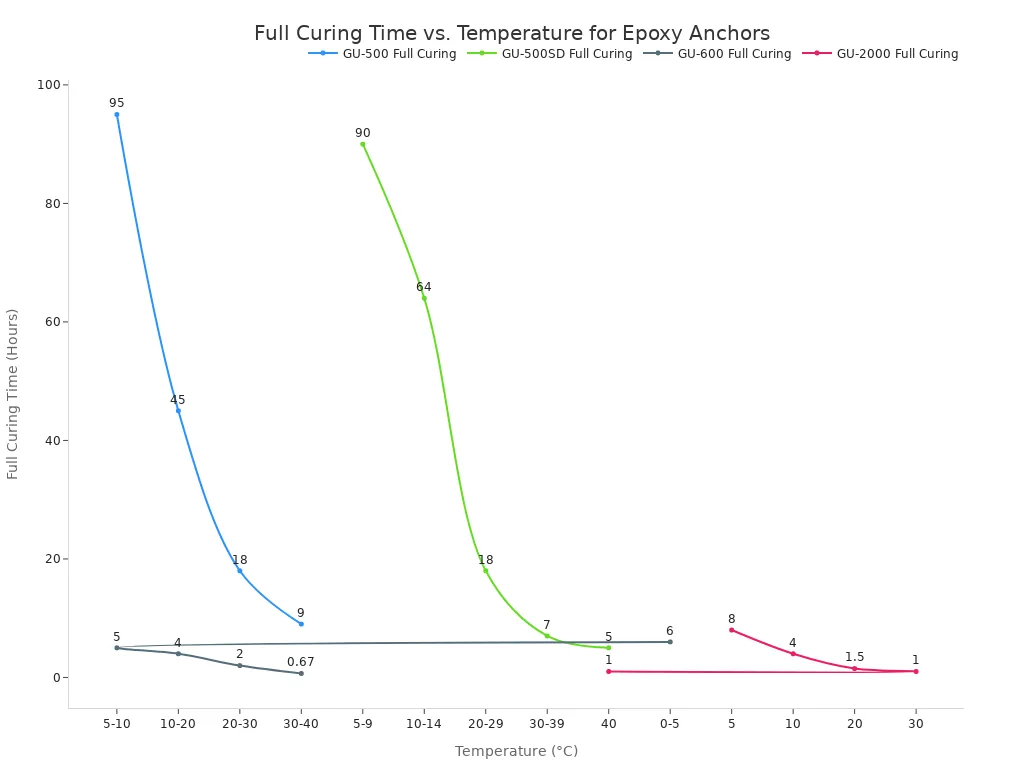

Curing Time is Critical 🌡️ The performance of chemical anchors depends heavily on temperature. The resin needs time to cure and reach full strength. Lower temperatures significantly increase this curing time. Always consult the manufacturer’s data for specific open times (the time you have to work) and full curing times.

Epoxy and Resin Anchors

These systems typically use a two-part injectable adhesive, combining a resin and a hardener. An installer dispenses the mixture into a clean hole before inserting the threaded rod or eye bolt. The chemical reaction creates an incredibly strong, waterproof bond. The curing time varies by product and ambient temperature, as shown below.

| Temperature (°C) | Open time – Tgel | Curing time – Tcur |

|---|---|---|

| +30 – +35 | 8 minutes | 4 hours |

| +20 – +25 | 18 minutes | 8 hours |

| +10 – +15 | 40 minutes | 18 hours |

| +5 – +10* | 150 minutes | 24 hours |

Adhesive Capsule Anchors

Adhesive capsule anchors provide a convenient, pre-portioned amount of resin and hardener in a glass tube. The installer places the capsule into the drilled hole. Then, they use a rotary hammer drill to spin the threaded stud into the hole. The spinning action breaks the capsule, mixes the two components, and initiates the chemical curing process.

How to Select the Right Eye Bolt Anchor

Choosing the correct eye bolt anchors involves a careful evaluation of the load and the surface material. A professional assessment of these factors ensures both safety and performance for any project. This process prevents anchor failure and guarantees a secure connection.

Assessing Load Requirements

The first step is to understand the forces the anchor will need to withstand. This involves calculating the weight and nature of the load.

Understanding Working Load Limit (WLL)

The Working Load Limit (WLL) is the maximum mass an item can lift safely. Manufacturers determine the Working Load Limit by testing the bolt’s ultimate breaking strength and dividing it by a safety factor. This Working Load Limit must be clearly marked on the hardware. Several factors influence the final capacity:

- Eye Design: Forged eye bolts provide a higher Working Load Limit than bent wire eye bolts.

- Shoulder Presence: Shouldered eye bolts can handle angular loads, but this reduces the rated Working Load Limit.

- Lift Angle: The Working Load Limit decreases dramatically as the pull angle moves away from vertical. A straight pull offers the maximum Working Load Limit.

Dynamic vs. Static Loads

Professionals must distinguish between two types of loads.

- Static loads are constant and unchanging, like a suspended sign.

- Dynamic loads involve movement, shock, or vibration, such as lifting machinery or securing items on a moving vehicle.

Dynamic forces place significantly more stress on anchors. Therefore, applications with dynamic loads require a much higher safety margin and a more robust anchor system.

Matching Anchor to Base Material

The base material is just as important as the load. The right anchor creates a strong bond with the surface, while the wrong one can lead to pullout or material damage.

Concrete and Masonry

Solid materials like concrete and brick require specific types of anchors to create a secure hold. The choice of an eye bolt anchor for concrete depends on the load and material density.

| Base Material | Recommended Anchor Type |

|---|---|

| Solid Concrete | Wedge anchors (heavy loads), Sleeve anchors (light loads), Epoxy anchors (high stress) |

| Brick | Sleeve anchors |

| Hollow Block | Toggles or specialized sleeve anchors |

These mechanical and chemical anchors expand or bond within the material to provide reliable holding power.

Wood and Steel Structures

Installations in wood or steel often do not require a separate anchor mechanism. Instead, a lag thread eye bolt or a machine thread eye bolt can be installed directly into the structure. For an eye bolt anchor for wood, installers drill a pilot hole to prevent splitting. For steel, they drill and tap a hole to create matching threads for the bolt. In both cases, the installer must verify the structural member is strong enough to support the intended load.

Key Factors in Choosing Your Anchor

An eye bolt anchor’s reliability depends on more than just load calculations. A professional must also consider the environment where the anchor will be installed and the material it is made from. These key factors directly impact the anchor’s lifespan and safety. Making an informed choice prevents premature failure and ensures long-term performance.

Considering Environmental Factors

The surrounding environment plays a critical role in the longevity of eye bolt anchors. Exposure to moisture, chemicals, and temperature fluctuations can degrade materials over time.

Indoor vs. Outdoor Use

The primary environmental distinction is between indoor and outdoor applications.

- Indoor environments are generally controlled and dry. They protect anchors from rain, UV radiation, and extreme temperature swings. Basic zinc-plated anchors often suffice for these conditions.

- Outdoor environments expose hardware to harsh elements. Rain, humidity, and sunlight accelerate corrosion and material aging. Outdoor installations demand anchors with superior weather resistance.

The service life of some anchors, particularly chemical types, is significantly affected by their use environment. Continuous exposure to water in humid and rainy regions can reduce the durability of these anchors.

Corrosion Resistance

Corrosion is a major threat to the structural integrity of metal anchors. It is an electrochemical process that causes metal to rust and weaken. The risk of corrosion increases dramatically in certain settings.

- Moisture and Humidity: Moisture is a primary catalyst for rust. In humid or wet environments, using waterproof or moisture-resistant epoxy is recommended for chemical anchors. For mechanical anchors, a protective coating is essential.

- Corrosive Environments: Exposure to chemicals, road salts, or saltwater accelerates corrosion. For these applications, it is advisable to use stainless steel or galvanized anchors. Employing epoxy with enhanced chemical resistance is also crucial for adhesive systems.

Material Composition

The material of an eye bolt anchor determines its strength, cost, and resistance to corrosion. Professionals select the material based on the specific demands of the project.

Zinc-Plated Steel

Zinc-plated steel is a common and cost-effective option. A thin layer of zinc is electroplated onto the steel surface. This coating provides a basic level of corrosion protection suitable for dry, indoor use. It offers a bright, clean finish but will quickly fail when exposed to moisture.

Galvanized Steel

Galvanized steel offers more robust protection. The steel is coated with a thicker layer of zinc, usually through a hot-dip process. This creates a durable, abrasion-resistant barrier against rust. Galvanized anchors are a standard choice for outdoor construction and general industrial use where moisture is a concern.

Stainless Steel

Stainless steel provides the highest level of corrosion resistance. It is an alloy containing chromium, which forms a passive, self-healing film that prevents rust.

- Type 304 Stainless Steel: A common grade suitable for most outdoor and freshwater environments.

- Type 316 Stainless Steel: Known as “marine grade,” this type includes molybdenum. It offers superior resistance to chlorides, making it the best choice for saltwater, coastal, and chemical-processing environments.

Step-by-Step Installation Guide

Proper installation is not just a recommendation; it is a requirement for an eye bolt anchor to achieve its full rated capacity. A flawed installation can compromise the strength of even the highest quality hardware. Following a systematic process ensures a safe and reliable connection. This guide details the critical steps for installing mechanical and chemical anchors in concrete or masonry.

Step 1: Gather Your Tools and Materials

An installer should begin by assembling all necessary equipment before starting any work. A well-organized worksite is a safe and efficient one. Having everything on hand prevents delays and reduces the risk of mistakes.

Safety Gear

Personal Protective Equipment (PPE) is non-negotiable when drilling into concrete or masonry. The process generates dust and noise, creating potential hazards.

- Eye protection: Safety glasses or goggles shield the eyes from flying debris.

- Ear protection: Earmuffs or plugs are essential when using a hammer drill.

- Dust mask: A respirator or mask prevents the inhalation of harmful silica dust.

- Gloves: Work gloves protect hands from abrasion and sharp edges.

- Hard hat: A hard hat is necessary on any active construction site.

Tools and Hardware

The specific tools depend on the type of anchor system. A typical installation requires a combination of drilling and fastening equipment.

- Drilling Equipment: A hammer drill is necessary for concrete and masonry.

- Fastening Tools: An adjustable wrench or torque wrench is needed to tighten the anchor.

- Measuring and Marking: A tape measure and a marker ensure accurate hole placement.

- Cleaning Supplies: A wire brush and compressed air source or blow-out pump are crucial.

- Hardware: The correct eye bolt anchor, nuts, and washers are required for the job.

Step 2: Drill the Pilot Hole

Drilling the hole is the first physical step in the installation. The diameter and depth of this hole must be precise. An incorrect hole size is a common cause of anchor failure.

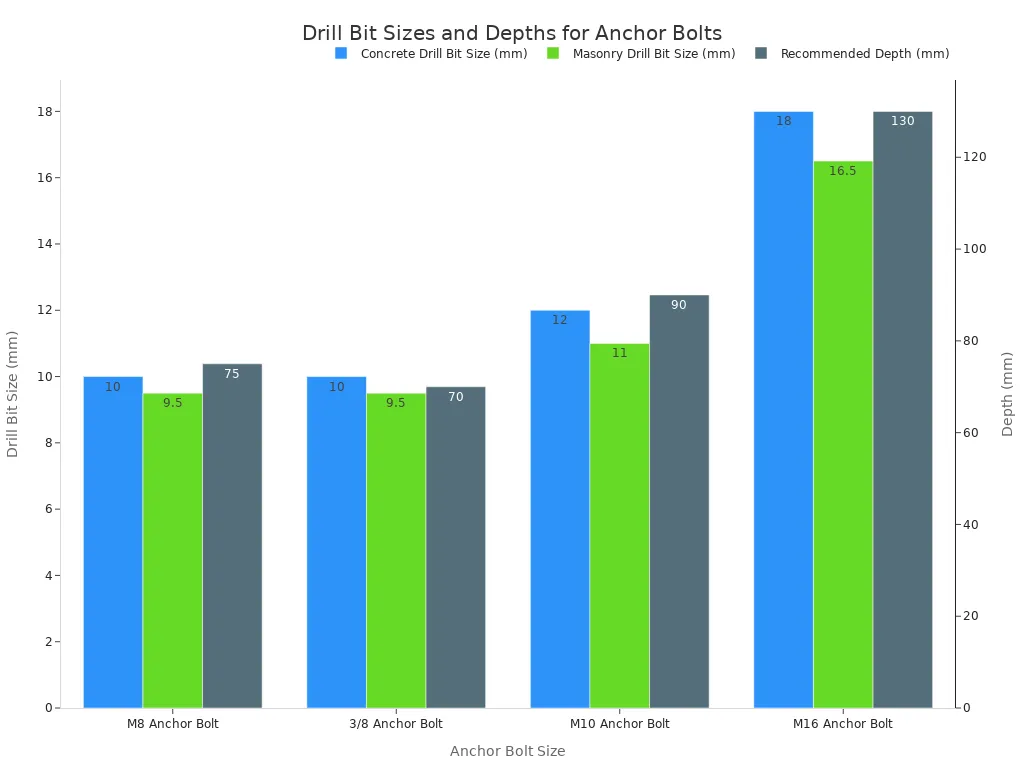

Selecting the Correct Drill Bit

The drill bit diameter must match the specifications for the chosen anchor. A hole that is too small will prevent insertion. A hole that is too large will prevent the anchor from expanding or bonding correctly. As a general rule, the drill bit size is typically 2-4 mm larger than the anchor’s diameter. For example, an M10 anchor bolt often uses a 12 mm drill bit.

Manufacturer Data is Key Always consult the manufacturer’s technical data sheet for the exact drill bit size. The requirements for different anchors can vary.

The table and chart below show common pairings for anchor bolts.

| Anchor Bolt Size | Concrete Drill Bit Size | Masonry Drill Bit Size | Recommended Depth |

|---|---|---|---|

| M8 Anchor Bolt | 10mm (3/8″) | 9.5mm | 75mm |

| 3/8 Anchor Bolt | 10mm | 9.5mm | 70mm |

| M10 Anchor Bolt | 12mm | 11mm | 90mm |

| M16 Anchor Bolt | 18mm | 16.5mm | 130mm |

Drilling to the Proper Depth

The hole must be drilled deeper than the anchor’s required embedment. This extra space accommodates any dust that cannot be removed and ensures the anchor can be fully inserted. A good practice is to drill the hole at least 1/2 inch deeper than the anchor length. An installer can mark the correct depth on the drill bit with a piece of tape to serve as a visual guide.

Step 3: Clean the Hole Thoroughly

Cleaning the hole is one of the most critical and often overlooked steps, especially for chemical anchors. Dust and debris prevent the anchor from making solid contact with the base material. This significantly reduces its holding power. The process of how to insert anchor bolts correctly always begins with a clean hole.

Using a Wire Brush

A stiff wire brush is essential for dislodging dust and debris from the sides of the hole. The brush diameter should match the hole size to ensure it scrubs the entire surface. An installer should insert the brush to the bottom of the hole and twist it while pulling it out. This action loosens fine particles that compressed air alone might miss.

Removing Debris with Compressed Air

After brushing, the loosened debris must be removed. For mechanical anchors, a simple hand blow-out pump may be sufficient. However, chemical anchors require a more rigorous approach.

- Professionals often use a “blow-brush-blow” procedure. They blow the hole out with compressed air, brush it, and then blow it out a second time.

- Some manufacturers, like Hilti, specify this procedure be performed twice (2x blow, 2x brush, 2x blow) for their injectable adhesive anchors.

- The compressed air source should deliver a minimum of 90 psi to be effective. Failure to clean the hole properly can cause chemical anchors to bond to dust instead of the concrete, leading to a catastrophic loss of strength.

Step 4: Insert and Set the Anchor

With a clean, properly sized hole, the installer can proceed to the final stage of the installation. This step involves placing the hardware and securing it. The specific actions depend entirely on whether the system uses a mechanical or chemical anchor. Each method requires a distinct technique to achieve a secure connection.

Inserting the Anchor Assembly

The method for inserting the hardware varies significantly between mechanical and chemical systems. An installer must follow the correct procedure for the chosen type of anchor.

For Mechanical Anchors: The installer inserts the complete anchor assembly—including the eye bolt, washer, nut, and expansion mechanism—into the drilled hole. A light tap with a hammer may be necessary to seat the anchor fully. The hardware should fit snugly. A loose fit indicates the hole is too large, which compromises the integrity of the connection.

For Chemical Anchors: The process begins with the adhesive. An installer dispenses the resin into the hole, starting from the bottom and slowly withdrawing the nozzle. This technique prevents air pockets from forming.

Pro Tip: Purge the Nozzle 🧪 Before injecting resin into the hole, an installer should always dispense a small amount onto a disposable surface. This action ensures the two parts of the adhesive are properly mixed in the nozzle. Most manufacturers specify the length of the initial bead to discard.

After filling the hole to the recommended level (typically about two-thirds full), the installer inserts the threaded eye bolt stud. A slow, twisting motion helps coat the threads completely and eliminates any remaining air voids. These steps are crucial for creating strong, reliable chemical anchors.

Tightening to Expand the Anchor

Setting the anchor is the final action that creates the holding power. This step solidifies the connection between the hardware and the base material.

For mechanical anchors, setting involves tightening. An installer uses a wrench to turn the nut on the eye bolt. This action pulls the stud, causing the expansion clip or sleeve to flare out and press against the walls of the hole. This friction creates the anchor’s holding strength. Using a calibrated torque wrench is essential for these anchors.

Warning: The Dangers of Improper Torque

- Under-tightening prevents the anchor from expanding fully. This results in a weak connection that cannot support the rated load.

- Over-tightening can damage the concrete base material or strip the threads of the bolt. This action can cause immediate or future failure of the anchors. Always follow the manufacturer’s specified torque value.

For chemical anchors, the “setting” process is passive. It requires no tightening. Instead, the installer must simply wait. The resin needs time to undergo its chemical reaction and cure completely. The installer must not disturb or apply any load to the eye bolt during this curing period. Touching or moving the hardware can break the bond before it reaches full strength, rendering the anchors useless.

Critical Safety and Inspection Practices

An eye bolt anchor’s strength is only reliable when combined with rigorous safety and inspection protocols. Professionals understand that even the best hardware can fail without proper oversight. Adhering to established practices for inspection, load management, and installation is essential for preventing accidents and ensuring the long-term integrity of any anchoring system.

Pre-Use Inspection Checklist

A thorough pre-use inspection is a non-negotiable safety step. Before any load is applied, an installer must carefully examine the hardware for any signs of wear or damage. This routine check helps identify potential failures before they happen.

Checking for Cracks and Deformation

Visual inspection is the first line of defense. An installer should look for any physical damage that could compromise the anchor’s strength. Key points to check include:

- Identification Markings: Verify that the manufacturer’s name, rated load (WLL), and material grade are clearly legible. Illegible markings mean the anchor must be removed from service.

- Physical Damage: Examine the eye bolt for any bends, cracks, elongation, or nicks. Look for signs of heat damage, weld spatter, or unauthorized modifications.

- Corrosion: Check for severe rust, pitting, or corrosion that could weaken the metal. Any significant degradation is cause for immediate replacement of the anchors.

Verifying Thread Integrity

The threads are a critical component for both the eye bolt and the receiving hole. A secure connection depends on clean, well-formed threads.

- Thread Condition: Inspect the threads on the eye bolt and in the tapped hole for damage, burrs, or excessive wear.

- Cleanliness: Ensure the receiving hole is free of dirt, grease, or other contaminants that could prevent proper seating.

- Thread Match: Always confirm that the eye bolt threads match the receiving hole’s threads in size and pitch. Never mix imperial and metric fasteners, as this creates a weak and dangerous connection for the anchors.

Understanding Load Angles

The direction of the pull has a dramatic effect on an eye bolt’s capacity. An angular load introduces bending forces that the hardware may not be designed to handle. Understanding these dynamics is crucial for safe rigging.

The Impact of Angular Loading on Capacity

A shouldered eye bolt’s capacity decreases significantly as the load angle increases from vertical. A straight, in-line pull provides 100% of the rated capacity. Any angle reduces this value. For example, a pull at a 45-degree angle can reduce the Working Load Limit (WLL) by as much as 70%. Using an eye bolt at an angle greater than 45 degrees is not recommended and is considered unsafe.

Proper Orientation of Shouldered Eye Bolts

When an angular lift is unavoidable, a professional must use a shouldered eye bolt and orient it correctly. The load must always be applied in the plane of the eye. Pulling at an angle to the plane of the eye can cause it to bend or break. The shoulder must be seated flush against the load surface to provide maximum support against the bending force.

Common Installation Mistakes to Avoid

Installation errors are a frequent cause of anchor failure. Even with the correct hardware, a mistake during setup can compromise the entire system. Avoiding these common pitfalls is key to a secure installation.

Over-Torquing or Under-Torquing

Applying the correct torque is critical for mechanical anchors.

Warning: Both over-tightening and under-tightening are dangerous.

- Over-torquing can stretch the bolt beyond its elastic limit, causing permanent damage. It can also crack the concrete or strip the threads, leading to a sudden failure of the anchor.

- Under-torquing results in a loose connection. The anchor will not expand properly and cannot achieve its rated load capacity, creating a significant safety risk.

Using the Wrong Anchor for the Material

The choice of anchor must match the base material. Using a fastener designed for solid concrete in a hollow block wall will result in a weak connection. Each material has unique properties that require a specific type of anchor to create a secure hold. Always verify that the selected anchors are appropriate for the substrate to ensure a safe and reliable installation.

Professionals recognize that eye bolt anchors are essential fasteners for a wide range of applications. Their successful use depends on a few critical principles. A safe and reliable outcome requires careful attention to these key takeaways.

- Correct Selection: Choosing the right eye bolt and anchor mechanism for the specific load and base material is fundamental for safety.

- Proper Installation: Following precise installation steps, including drilling, cleaning, and setting, is non-negotiable for achieving the anchor’s full strength.

- Systematic Inspection: Regular inspection and adherence to load angle limits prevent failures and ensure long-term reliability.

FAQ

What is the difference between WLL and breaking strength?

Breaking strength is the absolute force at which an anchor fails. The Working Load Limit (WLL) is the maximum safe force. Manufacturers calculate the WLL by dividing the breaking strength by a safety factor. This calculation ensures a margin for safety during use.

Why is cleaning the hole so important?

Debris prevents an anchor from making full contact with the base material. For mechanical anchors, this reduces friction. For chemical anchors, the resin bonds to dust instead of concrete. Both situations severely compromise the anchor’s holding power and safety.

Can you reuse an eye bolt anchor?

Professionals do not reuse expansion or chemical anchors. The removal process can damage the anchor or the base material. The initial installation also stresses the components. For maximum safety, an installer should always use a new anchor for each new installation.

What happens if you use a non-shouldered eye bolt for an angular lift?

A non-shouldered eye bolt lacks support against side forces. Applying an angular load creates a bending force on the shank. This stress can easily bend or snap the bolt, leading to sudden failure. Installers must use these bolts only for vertical lifts.

Which material is best for marine environments?

Type 316 stainless steel is the superior choice for marine applications. It contains molybdenum, which provides excellent resistance to corrosion from saltwater and chlorides. This material ensures the anchor maintains its structural integrity in harsh coastal or shipping environments.

What is the main advantage of a chemical anchor?

The primary advantage of chemical anchors is their high load capacity without expansion stress. The adhesive bonds to the material, making them ideal for use near edges or in weaker substrates. They also offer superior resistance to vibration and dynamic loads.