Expansion bolts are essential fasteners used for fastening into solid materials like concrete. An expansion anchor functions by expanding inside a pre-drilled hole. This mechanism creates a powerful frictional grip to secure objects. These expansion anchors are critical for post-construction installations on building structures. A strong anchor bolt supports significant loads, ensuring stability. For unique requirements, a custom fasteners manufacturer can supply specialized Anchor Bolts, including custom anchor bolts. These expansion bolts are fundamental to modern construction.

How Do Expansion Bolts Work?

Expansion bolts operate on a simple yet powerful mechanical principle. The design of an expansion anchor allows it to create an incredibly secure connection inside a solid material. Understanding this mechanism reveals why these fasteners are so reliable in construction.

The Principle of Mechanical Expansion

The core function relies on converting rotational force into outward pressure. This process creates a firm grip that resists being pulled out of the pre-drilled hole.

Friction and Force

When an installer tightens the nut on an expansion bolt, it pulls a threaded stud or bolt upward. This action draws a tapered cone into an expansion sleeve. The sleeve is forced to expand outward, pressing firmly against the interior walls of the hole. This immense pressure generates high levels of friction, which is the primary force that holds the anchor in place and prevents it from slipping.

Load Transfer Mechanism

The anchor bolt serves as a bridge for transferring loads. Any force applied to the secured fixture, whether it’s a downward (shear) or outward (tensile) load, travels through the bolt. The bolt then transfers this force to the expanded sleeve. Finally, the sleeve distributes the load across a wide surface area within the concrete or masonry, ensuring the base material can safely support the weight.

Key Components of an Expansion Bolt Assembly

Most expansion bolts consist of four primary parts that work together. The material composition of these components is critical for performance and durability.

The Threaded Bolt or Stud

This is the main shaft of the fastener. It features threads that engage with a nut to create the tightening force. This component bears the direct load of the item being secured.

The Expansion Sleeve or Shield

The sleeve is a metal cylinder that fits around the bolt. It is designed with splits or a specific shape that allows it to expand when the wedge is pulled into it. This is the part that makes direct contact with the walls of the drilled hole.

The Expansion Wedge or Cone

Located at the bottom of the assembly, the wedge is a small, cone-shaped piece. As the bolt is tightened, this cone is drawn up into the sleeve, acting as the catalyst for the expansion. The interaction between the wedge and sleeve is the heart of the fastening mechanism.

Materials Matter 💡 The choice of material directly impacts the strength and corrosion resistance of these anchors. Common materials include:

- Carbon Steel: A cost-effective choice suitable for dry, indoor applications.

- Stainless Steel: Grades like 304 and 316 are excellent for exterior use or in environments with high moisture and corrosive elements.

- High-Grade Alloys: For extreme conditions, manufacturers use advanced steels like duplex 2304 or specialized combinations for maximum longevity.

The Nut and Washer

The nut is threaded onto the bolt to apply the necessary tightening force. The washer sits between the nut and the fixture, distributing the clamping force evenly to prevent damage to the surface of the object being mounted.

What Are the Main Types of Expansion Bolts?

The construction industry uses several main types of expansion bolts. Each design serves a specific purpose, offering unique advantages for different base materials and load requirements. Understanding these variations is key to selecting the correct fastener for a safe and durable installation.

Wedge Anchors

Wedge anchors are renowned for their exceptional holding power in solid concrete. They are a go-to choice for many structural and heavy-duty applications.

Description and Mechanism

A wedge anchor is a one-piece fastener consisting of a threaded stud, a nut, a washer, and an expansion clip at the base. An installer first drills a hole in the concrete and cleans it thoroughly. The anchor is then hammered into the hole. Tightening the nut pulls the stud upward, forcing the expansion clip to wedge itself between the stud’s tapered end and the wall of the hole. This action creates immense outward pressure, resulting in a powerful and permanent frictional hold.

Best Use Cases

Wedge anchors excel in securing heavy loads to solid concrete. Their high tensile and shear strength make them ideal for critical connections. Installers use them for securing steel beams and columns to concrete foundations. They also anchor heavy machinery to factory floors, ensuring operational stability and safety. These anchors are the definitive choice for most heavy-duty applications requiring maximum load-bearing capacity.

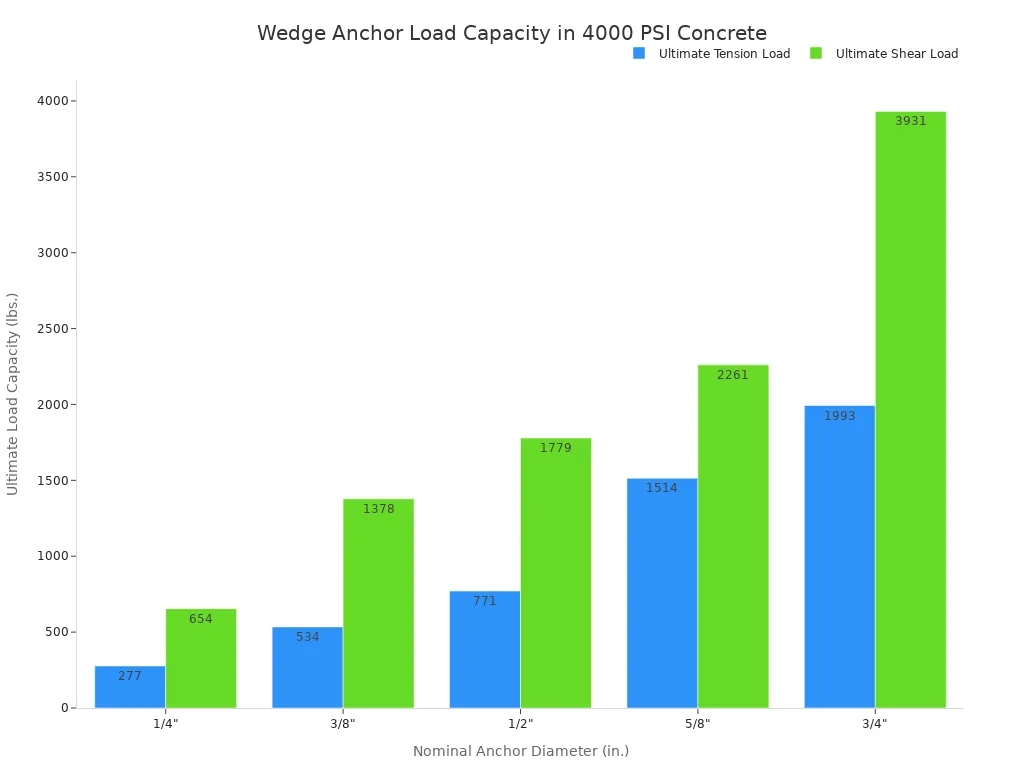

The load capacity of a wedge anchor increases significantly with its diameter. The following table illustrates the ultimate load capacities for common wedge anchor sizes in 4,000 PSI concrete.

| Nominal Anchor Diameter (in.) | Ultimate Tension Load Capacity (lbs.) | Ultimate Shear Load Capacity (lbs.) |

|---|---|---|

| 1/4″ | 277 | 654 |

| 3/8″ | 534 | 1,378 |

| 1/2″ | 771 | 1,779 |

| 5/8″ | 1,514 | 2,261 |

| 3/4″ | 1,993 | 3,931 |

Sleeve Anchors

Sleeve anchors are highly versatile fasteners known for their adaptability to a wide range of base materials, including concrete, brick, and block.

Description and Mechanism

A sleeve expansion anchor assembly includes a threaded bolt, a nut, a washer, and a full-length expansion sleeve. As the bolt is tightened, it draws a tapered cone at the bottom of the bolt up into the sleeve. This action causes the entire length of the sleeve to expand outward, creating a secure grip along the full depth of the drilled hole. This mechanism makes it suitable for materials that may be less dense than solid concrete.

Best Use Cases

The versatility of sleeve anchors makes them a popular choice for general-purpose fastening. They are suitable for light to medium-duty loads. Common residential and commercial applications include:

- Securing handrails to concrete steps or brick walls.

- Mounting large flat-screen TVs and shelving units.

- Fastening electrical boxes and conduit straps.

- Installing bathroom grab bars and other fixtures.

Their ability to work in various base materials makes them a valuable component for many renovation and construction projects.

Drop-In Anchors

Drop-in anchors are female anchors designed for medium-duty fastening in solid concrete. They are ideal for applications requiring a flush-mounted anchor point.

Description and Mechanism

A drop-in anchor is a short, cylindrical expansion anchor with internal threads. It features a pre-installed expansion plug at its base. After drilling a hole, the installer drops the anchor in until it is flush with the concrete surface. A special setting tool is then inserted into the anchor and struck with a hammer. This impact drives the internal plug downward, expanding the anchor’s base and locking it firmly into the concrete. A separate threaded bolt or rod can then be screwed into the anchor.

Special Tool Required ⚙️ Drop-in anchors require a specific setting tool for proper installation. This tool is a piece of tempered carbon steel precisely matched to the anchor’s internal diameter. Using a standard hammer, it ensures the internal plug is driven to the correct depth for full expansion without damaging the anchor’s threads.

Best Use Cases

Drop-in anchors are primarily used for overhead applications where threaded rods are needed to suspend items from a concrete ceiling. Their flush-mount design creates a clean and unobtrusive anchor point. Common uses for these anchors include:

- Hanging pipe supports and sprinkler systems.

- Suspending overhead cable trays and electrical conduit.

- Attaching light fixtures and ceiling fans.

This design allows for easy removal of the bolted fixture without leaving a protruding stud.

Strike Anchors (Hammer-Set)

Among the various types of expansion bolts, the strike anchor stands out for its simplicity and speed. It is a single-piece expansion anchor designed for fast, permanent installations in solid concrete.

Description and Mechanism

A strike anchor, also known as a hammer-set anchor, consists of a cylindrical body and an internal nail-like pin. The body is inserted into a pre-drilled hole. An installer then uses a hammer to drive the pin into the anchor body. The pin’s downward force expands the base of the anchor, creating a secure wedge against the concrete. This straightforward mechanism requires no special setting tools or torque wrenches, making it one of the quickest anchoring solutions available.

Best Use Cases

Strike anchors are an excellent choice for light to medium-duty static load applications where installation speed is a priority. Their design is particularly effective for attaching thin materials or fixtures directly to concrete. Installers often prefer them for overhead work where a flush, finished head is desirable. Common applications include:

- Fastening metal track, brackets, and furring strips

- Securing electrical boxes, conduit straps, and HVAC hangers

- Mounting signage and security fixtures

- Anchoring concrete formwork and bicycle racks

The anchor’s ease of use also makes it suitable for certain DIY projects. For example, a family can use strike anchors to permanently install a picnic table on a concrete patio, ensuring stability and safety.

Lag Shield Anchors

Lag shield anchors are a two-piece fastening system designed for use with lag screws. They provide reliable anchoring in a variety of masonry materials, including those that are softer or more brittle than solid concrete.

Description and Mechanism

A lag shield anchor is a cylindrical shield with external ribs and internal threads. These anchors are typically made from a corrosion-resistant zinc alloy, commonly known as Zamac, which makes them rust-proof and suitable for damp environments. An installer first places the shield into a pre-drilled hole. A lag screw is then inserted through the fixture and threaded into the shield. As the installer tightens the screw, it draws the shield’s sides outward, causing the external ribs to bite firmly into the base material. This creates a strong frictional hold along the entire length of the shield.

Torque is Key ⚙️ Proper installation requires careful tightening. Over-tightening can strip the anchor or damage the base material. For example, the maximum recommended torque for a 3/8″ long lag shield anchor is just 10 ft./lbs. Always follow manufacturer specifications.

Best Use Cases

The design of lag shield expansion bolts makes them ideal for anchoring into base materials like brick, mortar joints, and block. The shield distributes the load over a larger surface area, reducing the risk of cracking brittle materials. They are a dependable choice for light to medium-duty applications. Installers use them for:

- Mounting signs and satellite dishes to brick walls.

- Securing downspouts and window guards.

- Fastening handrails and shelving to block or brick.

- Attaching heavy wall decor and fixtures.

Their ability to work with common lag screws adds to their versatility in both commercial and residential settings.

Step-by-Step Guide to Installing Expansion Bolts

Proper installation is not just a recommendation; it is a requirement for ensuring the safety and load-bearing capacity of any expansion anchor. A meticulous approach at each stage prevents anchor failure and guarantees a long-lasting, secure connection. This step-by-step guide details the professional standard for installing these critical fasteners.

Step 1: Gather Your Tools and Materials

Preparation is the first step toward a successful installation. An installer must assemble all necessary tools and materials before beginning work. This ensures the workflow is efficient and that every component is correct for the specific application.

Selecting the Correct Anchor

The selection process involves more than just picking a fastener. An installer must evaluate the base material (e.g., solid concrete, brick), the load requirements (tensile and shear), and the environmental conditions (interior vs. exterior). For example, a heavy structural beam requires a high-capacity wedge anchor made of stainless steel for outdoor use. A lighter-duty handrail on a brick wall might only need a versatile sleeve anchor. Consulting manufacturer load charts is essential for making an informed decision that aligns with project specifications.

Required Tools

Having the right equipment on hand is crucial for a safe and effective installation. A professional setup ensures precision from drilling to final tightening. The standard toolkit for installing anchors includes a mix of drilling equipment, fastening tools, and essential safety gear.

- Drilling and Cleaning Equipment:

- A hammer drill or rotary hammer provides the necessary impact and rotation for drilling into masonry.

- Carbide-tipped masonry drill bits matched to the anchor diameter are required.

- A wire brush and a compressed air blower or vacuum cleaner are needed for hole cleaning.

- Fastening and Measurement Tools:

- A torque wrench is essential for applying the correct tightening force.

- A standard wrench or socket set can be used for initial tightening.

- A hammer is needed for setting certain anchor types, like wedge and strike anchors.

- A tape measure ensures correct hole depth and anchor spacing.

- Personal Protective Equipment (PPE):

- Safety glasses or goggles protect the eyes from dust and debris.

- A dust mask prevents the inhalation of harmful concrete dust.

- Gloves protect the hands during drilling and handling.

- Ear protection is necessary when operating a loud hammer drill.

Step 2: Drill the Hole

Drilling the hole is the most critical physical step in the installation process. The hole’s dimensions and angle directly influence the anchor’s ability to expand correctly and bear its intended load.

Matching Drill Bit to Anchor Size

Precision is paramount. The drill bit diameter must exactly match the specified diameter for the anchor. A hole that is too small will prevent the anchor from being inserted. A hole that is too large will prevent the expansion mechanism from making firm contact with the base material, severely compromising its holding power.

ANSI Standards for Precision ⚙️ Always use an ANSI-compliant carbide drill bit. These bits are manufactured to strict tolerances, ensuring the drilled hole size is accurate. The nominal size of the anchor (e.g., 1/2″) corresponds to the required drill bit size.

Achieving Correct Depth and Angle

The hole must be drilled to the correct depth and angle. The depth should be slightly deeper than the anchor’s embedment length to provide space for any residual dust. Most hammer drills have an adjustable depth gauge for this purpose.

The installation angle is equally critical. An installer must drill the hole perpendicular (90 degrees) to the concrete surface. An incorrect angle creates uneven load distribution, placing excessive stress on one side of the anchor. This misalignment can lead to premature failure, especially in applications with significant shear or tensile forces. Maintaining a perpendicular angle ensures the load is transferred evenly into the base material, optimizing the anchor’s performance and structural integrity.

Step 3: Clean the Drilled Hole

A clean hole is a strong hole. Failing to remove dust and debris from the drilled hole is one of the most common and critical installation errors. This simple step has a massive impact on the anchor’s ultimate holding capacity.

Why Cleaning is Critical

Concrete dust and debris act as a lubricant. When an anchor expands, this fine powder prevents the sleeve or wedges from achieving a direct, high-friction grip on the solid concrete walls. The result is a significant reduction in holding power—in some cases, by more than 50%. The anchor may feel tight during installation but can slip or pull out under a much lower load than specified.

Methods for Debris Removal

Effective cleaning is a multi-step process that requires mechanical and pneumatic action. The professional standard for cleaning a drilled hole is the “brush-blow-brush-blow” method.

- Initial Blow: Use a compressed air blower or a manual hand pump to blow out the loose dust from the hole.

- Mechanical Brushing: Insert a stiff wire brush, sized correctly for the hole diameter, and scrub the interior walls vigorously. This action dislodges any compacted dust.

- Final Blow: Use the compressed air blower again to remove all the dislodged particles.

- Visual Inspection: Look into the hole with a flashlight to confirm it is completely free of dust and debris before inserting the anchor.

Step 4: Insert and Set the Anchor

With a clean hole prepared, the next phase of the installation process involves correctly inserting and setting the anchor. This step varies depending on the anchor type, but precision remains essential for a secure outcome.

Proper Insertion Technique

The method for inserting an anchor depends on its design. For through-fixture fastening, common with wedge and sleeve anchors, an installer drills the hole through the object being mounted. The anchor is then inserted through the fixture and into the hole. This technique ensures perfect alignment.

For other types, like drop-in anchors, the anchor is installed first, creating a threaded socket that sits flush with the concrete surface. An installer gently taps the anchor into the hole with a hammer until it is properly seated. The anchor bolt is then threaded in after the fixture is positioned.

Insertion Tip 💡 An anchor should fit snugly into the drilled hole. If it requires excessive force, the hole may be too small or have remaining debris. If it is too loose, the hole is oversized, and the installer must re-drill in a new location.

Setting the Anchor Before Tightening

Certain anchors require a “setting” action before the final tightening. This step pre-expands the anchor to lock it into the base material. Drop-in anchors are a prime example of this procedure. The proper installation and use of these anchors relies on a specific setting tool.

An installer follows a precise sequence to set a drop-in expansion anchor:

- The installer drops the anchor into the cleaned hole with the open, threaded end facing up.

- They insert the correct drop-in anchor setting tool into the anchor body.

- Using a hammer, the installer strikes the end of the setting tool firmly.

- They continue hammering until the shoulder of the tool makes contact with the top of the anchor. This confirms the internal plug has been driven down, fully expanding the anchor’s base.

This action firmly wedges the anchor into the concrete, preparing it to accept a threaded bolt or rod.

Step 5: Tighten to the Correct Torque

The final step is to tighten the fastener. Applying the correct amount of rotational force, or torque, is what activates the expansion mechanism and creates the final holding power. This is arguably the most critical step for ensuring the safety and reliability of the connection.

The Role of a Torque Wrench

A torque wrench is a specialized tool that measures and applies a specific amount of tightening force. Using one is not optional in professional settings; it is a requirement for a correct installation. Each anchor manufacturer specifies a required torque value for their products. This value is calculated to achieve optimal expansion without damaging the anchor or the base material.

- Under-torquing fails to expand the anchor sufficiently, resulting in poor holding values and potential slippage under load.

- Over-torquing can be catastrophic. It can strip the threads, break the bolt, or generate excessive stress that cracks the surrounding concrete.

Using a standard wrench provides no feedback on the force applied, making it easy to over or under-tighten the anchors. A torque wrench provides the necessary precision for a safe and reliable installation.

Verifying a Secure Connection

After tightening to the specified torque, an installer should perform a final check. The nut should be snug, and the mounted fixture should show no signs of movement or looseness. When using a torque wrench, the tool will typically click or signal when the target torque is reached. The nut should not continue to turn without an increase in resistance, as this could indicate a problem like a stripped thread or a failing base material. A properly installed anchor creates a solid, unyielding connection between the fixture and the masonry.

Key Factors for Choosing the Right Expansion Bolt

Selecting the correct fastener is a critical decision that directly impacts the safety and integrity of building structures. An installer must weigh several factors to ensure the chosen anchor performs reliably under its intended service conditions.

Assessing the Base Material

The material an anchor is fastened into is the foundation of the connection. Its properties dictate which type of anchor is appropriate.

Solid Concrete vs. Hollow Block

Solid concrete provides the strongest base for an expansion anchor. The compressive strength of the concrete significantly affects the load capacity an anchor bolt can handle. Higher-strength concrete allows for greater holding power. However, a key limitation is the risk of cracking if the concrete’s strength is low. For hollow block or materials with voids, an installer should choose a sleeve-type anchor that expands along its length to bridge the hollow sections.

Brick, Stone, and Other Masonry

Brick and stone are more brittle than concrete. They are susceptible to cracking under the high point-of-contact stress created by wedge anchors. For these materials, sleeve anchors or lag shield anchors are better choices. They distribute the expansion force over a larger surface area, reducing the risk of damaging the base material.

Calculating Load Requirements

An installer must understand the forces the anchor will need to resist. This involves calculating both the type and magnitude of the load.

Understanding Tensile vs. Shear Loads

Loads are generally categorized into two types:

- Tensile Load: This is a pull-out force that tries to pull the anchor straight out of the hole. An example is a suspended light fixture.

- Shear Load: This is a side-to-side force that acts perpendicular to the anchor. An example is a sign mounted on a wall.

Many connections experience a combination of both forces.

How to Read Manufacturer Load Charts

Manufacturers provide detailed charts that list the allowable load capacities for their products. These charts are essential for safe design. They show how performance changes with factors like embedment depth and concrete strength. For heavy-duty applications, deeper embedment in stronger concrete yields higher load values.

Safety First ⚠️ The listed allowable loads on charts already include a safety factor. However, installers may need to apply a higher safety factor for critical situations like overhead installations or life-safety equipment.

Considering Environmental Conditions

The environment where the anchor is installed plays a major role in its long-term durability. Moisture and corrosive elements can degrade an anchor over time.

Interior vs. Exterior Applications

Interior applications in dry, climate-controlled environments can typically use standard carbon steel anchors. Exterior applications expose fasteners to rain, humidity, and temperature fluctuations, which accelerate corrosion.

Choosing Corrosion-Resistant Coatings

For outdoor or damp environments, a protective coating is necessary. Hot-dip galvanizing provides a thick, durable layer of zinc that offers excellent corrosion protection. Standard zinc plating is much thinner and is not suitable for exterior use.

| Feature | Hot-Dip Galvanizing | Zinc Plating (Electroplated) |

|---|---|---|

| Coating Thickness | 2-5 mil (0.002″ to 0.005″) | Less than 1 mil (0.0001″) |

| Exterior Suitability | Excellent | Unsuitable |

| Nut Compatibility | Requires oversize tapped nuts | Standard nuts |

For the highest level of protection, especially in coastal or industrial areas, stainless steel anchors are the superior choice.

Anchor Spacing and Edge Distance

An installer must consider the placement of an expansion bolt relative to other fasteners and to the edges of the concrete. Proper spacing and edge distance are crucial for preventing the base material from cracking and ensuring each anchor achieves its full load-bearing capacity. These parameters are not arbitrary; they are based on engineering principles that account for how stress is distributed within the concrete.

Minimum Distance Between Anchors

When an expansion bolt is tightened, it creates a cone-shaped zone of stress in the concrete below it. If two anchors are installed too close to each other, their stress cones will overlap. This overlap concentrates the force in a small area, which can lead to a blowout failure where a chunk of concrete breaks away between the two fasteners. This significantly weakens the connection for both anchors.

To prevent this, manufacturers specify a minimum spacing distance. This distance is typically expressed as a multiple of the anchor’s diameter or its embedment depth.

Rule of Thumb 📏 A common guideline for minimum spacing is 10 times the anchor diameter (10d). For a 1/2-inch anchor, this means maintaining at least 5 inches between the centers of adjacent fasteners. Always consult the manufacturer’s technical data sheet for the precise requirement, as it can vary based on the anchor type and load conditions.

Following these spacing guidelines ensures that each anchor’s stress cone can fully develop without interference, allowing the system to support the intended design load safely.

Minimum Distance from Edges

Placing an anchor too close to an unsupported edge of a concrete slab or wall is a frequent cause of installation failure. The expansion force of the anchor has nowhere to go but outward, which can easily crack or break off the edge of the concrete. This is known as a side-face blowout failure. A compromised edge dramatically reduces the anchor’s tensile and shear capacity.

Manufacturers provide minimum edge distance requirements to prevent this issue. Similar to spacing, this distance is often calculated based on the anchor’s diameter or embedment depth.

- Critical Edge Distance: The minimum distance required to prevent blowout during installation.

- Full Load Edge Distance: The distance needed for the anchor to achieve its full published load capacity. This is often greater than the critical edge distance.

For example, a 1/2-inch wedge anchor might require a minimum edge distance of 2.5 inches (5 times the diameter) but may need to be 5 inches from the edge to develop its maximum strength. An installer must always prioritize the larger of the two values for critical applications. Adhering to these distances preserves the integrity of the concrete and ensures a secure, reliable fastening point.

Common Installation Mistakes and How to Avoid Them

Even the highest quality expansion bolt will fail if installed incorrectly. An installer’s attention to detail is paramount for creating a safe and reliable connection. Avoiding a few common pitfalls ensures the fastener performs exactly as the manufacturer intended.

Using an Incorrect Drill Bit Size

The relationship between the drill bit and the anchor diameter is non-negotiable. Using the wrong size bit is a fundamental error with severe consequences. A hole drilled too large prevents the expansion sleeve from making firm contact with the concrete, resulting in virtually no holding power. Conversely, a hole that is too small will prevent the anchor’s insertion or require excessive force, which can damage the fastener or the base material.

Precision is Mandatory ⚙️ An installer must always use an ANSI-standard carbide-tipped masonry bit that exactly matches the anchor’s required diameter. For a 1/2-inch anchor, a 1/2-inch bit is required. There is no room for substitution.

Failing to Properly Clean the Hole

A clean hole is essential for achieving maximum friction. Many installation failures can be traced back to leftover concrete dust and debris. This fine powder acts as a lubricant, preventing the anchor’s expansion mechanism from gripping the interior walls of the hole. This oversight can reduce the anchor’s load capacity by 50% or more, creating a dangerously weak connection that may fail unexpectedly under load. The professional solution is a simple but thorough cleaning process. An installer should use a wire brush and compressed air to remove all loose particles before inserting the fastener.

Over-Torquing or Under-Torquing the Bolt

Applying the correct rotational force, or torque, is what properly sets the anchor. Both too little and too much torque create problems. Under-torquing leaves the connection loose because the anchor is not fully expanded. Over-torquing is even more dangerous; it can strip the threads, snap the bolt, or generate enough stress to crack the surrounding concrete.

The only way to guarantee correct force is by using a calibrated torque wrench set to the manufacturer’s specifications. For added verification, some modern fastening systems provide visual cues.

- Traditional Direct Tension Indicators (DTIs) have small bumps on a specialized washer that flatten when the correct tension is reached.

- Advanced DTI Squirters® release a bright, colored silicone from the washer, offering an unmistakable visual signal that proper tension has been achieved.

These tools and indicators help an installer confirm a secure and correctly loaded connection every time.

Installing Too Close to an Edge

Placing an anchor too near an unsupported concrete edge is a critical error that often leads to immediate failure. The outward force from the expansion mechanism has nowhere to go but sideways. This pressure easily cracks or breaks off the edge of the concrete, a failure known as a side-face blowout. This mistake compromises the structural integrity of the base material itself. The anchor loses a significant portion of its tensile and shear load capacity, creating an unstable and dangerous connection.

The 5D Rule: A Simple Guideline 📏 A professional installer often follows a simple rule of thumb to avoid this issue. They maintain a minimum edge distance of five times the anchor’s diameter (5D). For a 1/2-inch anchor, this means installing it at least 2.5 inches from any unsupported edge. While this is a good general practice, an installer must always consult the manufacturer’s technical data sheet for the precise minimum edge distance, as it can vary.

Choosing the Wrong Anchor for the Base Material

The effectiveness of an expansion anchor is entirely dependent on the material it is installed into. A high-strength wedge anchor designed for solid concrete will perform poorly in a softer material like brick or hollow block. The intense, focused pressure from the wedge can easily crack or shatter these more brittle materials. This mismatch between the anchor and the base material results in a weak connection that cannot support its intended load.

An installer must carefully match the fastener to the application.

- For Solid Concrete: Wedge anchors provide the highest load capacity.

- For Brick or Block: Sleeve anchors or lag shield anchors are superior choices. They distribute the expansion force over a larger surface area, reducing the risk of cracking the base material.

- For Hollow Materials: A sleeve-type anchor is necessary to span the internal voids and create a secure grip on both sides of the hollow section.

Selecting the correct fastener is not about choosing the strongest one available. It is about choosing the one engineered to work harmoniously with the specific base material on the job site.

Safety Protocols and Best Practices

An installer’s work with expansion bolts is not complete until all safety measures are addressed. Following established protocols and best practices is essential for protecting workers and ensuring the long-term stability of the installation. These guidelines cover personal safety, regulatory compliance, and ongoing maintenance.

Wearing Personal Protective Equipment (PPE)

Safety on the job site begins with the individual. An installer must wear appropriate Personal Protective Equipment (PPE) during every phase of the installation process. This equipment shields them from common hazards associated with drilling into masonry and handling fasteners.

- Eye Protection: Safety glasses or goggles are mandatory. They protect the eyes from flying concrete dust, chips, and other debris generated by the hammer drill.

- Respiratory Protection: A dust mask or respirator prevents the inhalation of fine silica dust, which can cause serious long-term lung damage.

- Hand Protection: Heavy-duty gloves protect the hands from cuts, abrasions, and the vibrations of power tools.

- Hearing Protection: The loud noise from a hammer drill can damage hearing over time. Earplugs or earmuffs are necessary to reduce this risk.

Adhering to Building Codes and Standards

Professional installations must comply with all relevant building codes and industry standards. These regulations provide a legal framework for ensuring the safety and structural integrity of building structures. For projects in seismic zones, the International Building Code (IBC) provides specific requirements. The IBC references standards like ACI 318, which outlines detailed seismic anchoring provisions for structures in high-risk areas. These codes mandate that post-installed anchors used in such conditions must be qualified through testing in cracked concrete to handle seismic loads. An installer must always verify local amendments and adhere to the specified codes for their jurisdiction to ensure full compliance.

Performing Regular Inspections on Anchored Fixtures

The responsibility for an anchor does not end after tightening the nut. Regular inspections are critical for verifying the ongoing safety and performance of the connection, especially for fixtures supporting critical loads or life-safety systems. A structured inspection schedule helps identify potential issues like corrosion, wear, or loosening before they lead to failure.

Inspection Frequency 🗓️ The required interval between inspections depends on the application:

- Temporary Anchor Points: Must be inspected before each use.

- Permanent Anchor Points: Require annual checks, with more frequent re-testing in harsh environments.

- Post-Incident: An anchor that has sustained a significant impact, such as a fall arrest event, requires immediate inspection by a competent person.

A thorough inspection involves several key steps. An inspector performs a visual examination for any signs of damage or corrosion. They may also conduct mechanical tests, applying a specific load to verify the anchor’s strength. Finally, the inspector reviews all documentation to ensure maintenance records are current and the installation remains compliant with safety standards.

Understanding Anchor Failure Modes

A secure connection depends on understanding how an installation can fail. Engineers and installers recognize several distinct failure modes. Knowing these potential outcomes is the first step toward preventing them and ensuring structural safety. The three primary failure categories involve the concrete base, the steel fastener itself, or the interaction between the two.

One of the most critical failure types is concrete cone failure. This happens when the load exceeds the tensile strength of the concrete, causing a cone-shaped piece of the base material to break away. This failure is particularly dangerous because it is sudden and catastrophic.

- The failure surface typically forms a cone at an angle of approximately 35 degrees from the fastener’s axis.

- It is a fracture-dominated failure that provides minimal warning before a complete loss of capacity.

- This mechanism exhibits a pronounced size effect, where the nominal stress at failure decreases as the overall structure size increases.

Another potential issue is steel failure. This mode occurs when the load exceeds the strength of the steel bolt itself, causing it to stretch (yield) or snap (fracture). Building codes treat this failure mode differently from concrete-controlled failures. For example, ACI 318-19 assigns different seismic reduction factors for steel failure, reflecting its more predictable and ductile behavior compared to the brittle nature of a concrete blowout.

Finally, pull-out failure occurs when the fastener pulls out of the drilled hole without breaking the steel or the concrete. This typically happens when the expansion mechanism does not create enough friction to resist the tensile load. The holding power is directly related to the fastener’s design and its embedment depth.

- The pull-out strength of anchors is highly dependent on the embedment depth and the diameter of the expansion mechanism.

- Experimental data shows that doubling the embedment depth can increase the pull-out capacity by approximately 1.85 times.

- When pull-out does lead to concrete breakout, the failure cone often forms at a shallower angle, typically between 22 and 26 degrees.

Preventing these failures requires strict adherence to engineering specifications, including correct embedment depth, proper spacing, and accurate load calculations.

Expansion bolts are fundamental fasteners that create a reliable anchor in concrete and masonry. An installer must choose the correct type for the job. A heavy-duty wedge anchor is ideal for structural loads, while a versatile sleeve anchor works well for general use. Proper installation is essential to secure objects safely.

Key Takeaway 💡 The entire process, from precise drilling and thorough hole cleaning to applying the correct torque, guarantees the connection’s safety, stability, and durability.

FAQ

Can an installer reuse an expansion bolt?

No, an installer should never reuse an expansion bolt. The expansion mechanism deforms permanently during the initial installation. Removing and reinstalling the anchor compromises its holding power, creating a significant safety risk. Always use a new anchor for every installation.

Which is better: a wedge anchor or a sleeve anchor?

The choice depends on the base material. A wedge anchor offers superior strength in solid concrete. A sleeve anchor is more versatile, providing a secure hold in softer or hollow materials like brick and block by distributing the load over a larger area.

Can expansion bolts be installed in wet concrete?

An installer must wait for the concrete to fully cure before installing any mechanical expansion bolt. Drilling into wet or “green” concrete will not provide a solid base for the anchor to grip, leading to immediate connection failure.

Curing Time is Critical ⏱️ Most concrete requires a minimum of 28 days to reach its designed compressive strength. Installing an anchor before this period can compromise the entire structure.

What happens if I don’t use a torque wrench?

Without a torque wrench, an installer risks over-tightening or under-tightening the anchor. Over-torquing can crack the concrete or break the bolt. Under-torquing prevents the anchor from expanding fully, resulting in a weak connection that could fail under load.

How do I choose the right size expansion bolt?

An installer selects the anchor size based on the load requirements and the fixture’s hole size. Heavier loads require larger diameter anchors. The manufacturer’s technical data provides specific load capacities to help make the correct choice for a safe installation.

Why is cleaning the hole so important?

Concrete dust inside a drilled hole acts as a lubricant. It prevents the anchor from achieving a firm grip on the base material. This oversight can reduce the anchor’s holding power by over 50%, creating a dangerously weak and unreliable connection.