Concrete wedge anchors are a type of mechanical expansion anchor for solid concrete. These wedge anchors create a high-strength connection by expanding when tightened. Their reliability and high load capacities make them essential anchors for heavy-duty jobs. The market for all types of anchors, including standard Anchor Bolts and custom anchor bolts from a custom fasteners manufacturer, is robust.

Industry Growth 📈: The global Concrete Anchors/Fasteners Market reached USD 2,818.6 million in 2024. This growth reflects the demand for quality wedge anchors, including this specific wedge anchor and other similar wedge anchors.

What Are the Components of a Wedge Anchor?

A wedge anchor’s remarkable strength comes from the precise interaction of its three core components. Each part has a specific job. Together, they create a secure and reliable fastening system in solid concrete. Understanding these components is key to appreciating how these powerful anchors work.

The Threaded Stud Body

The threaded stud body is the main structural element of the anchor. It consists of a long metal rod that provides the necessary length and strength for the connection. This single piece of steel has two distinct ends, each with a critical function.

Main Shaft and Threads

The main shaft forms the backbone of the anchor. It features external threads, typically Unified National Coarse (UNC) threads, along its upper portion. These threads allow a nut and washer to attach and secure a fixture to the concrete surface. The diameter and material of the stud body directly determine the anchor’s load-bearing capacity. Larger diameter wedge anchors can handle significantly higher tension (pull-out) and shear (side-to-side) forces.

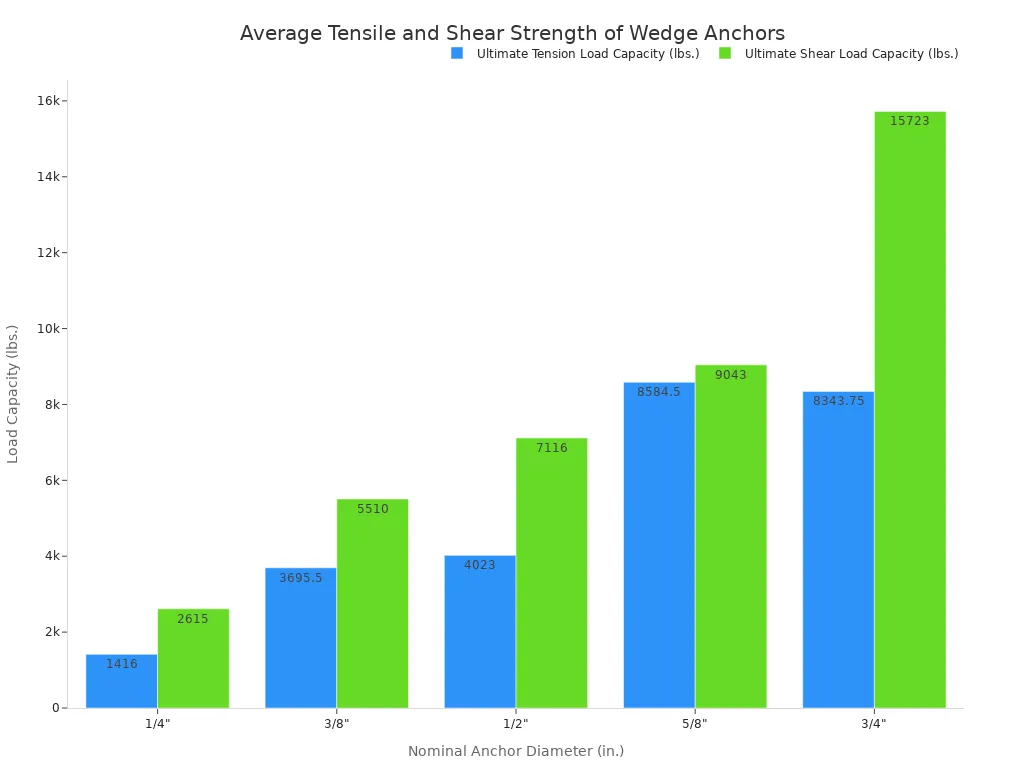

The ultimate load capacities for wedge anchors vary based on diameter, embedment depth, and the concrete’s compressive strength.

| Nominal Anchor Diameter (in.) | Minimum Embedment Depth (in.) | Concrete Compressive Strength (psi) | Ultimate Tension Load Capacity (lbs.) | Ultimate Shear Load Capacity (lbs.) |

|---|---|---|---|---|

| 1/4″ | 1-1/8″ | 4,000 | 1,107 | 2,615 |

| 3/8″ | 1-5/8″ | 4,000 | 2,136 | 5,510 |

| 1/2″ | 2-1/4″ | 4,000 | 3,084 | 7,116 |

| 5/8″ | 2-3/4″ | 4,000 | 6,054 | 9,043 |

| 3/4″ | 3-3/8″ | 4,000 | 7,971 | 15,723 |

Important Safety Note 📝 The load values in the table are ultimate loads. Engineers must reduce these values by a safety factor (minimum of 4.0) to determine the allowable working load. Critical applications, such as overhead or life-safety installations, may require a safety factor of 10 or higher. These values apply to anchors in uncracked concrete only.

Tapered Cone End

The bottom of the stud body necks down into a cone-shaped wedge. This tapered end is the engine of the expansion mechanism. It is designed to slide underneath the expansion clip during installation. This simple yet effective design is what generates the immense outward force needed to lock the anchor into the concrete.

The Expansion Clip

The expansion clip is a small but vital component that wraps around the tapered end of the stud. It is the part that directly engages with the concrete wall, creating the friction that holds the anchor in place.

Design and Function

The expansion clip is a precisely formed piece of metal, often made from carbon steel, though some high-performance wedge anchors may use a stainless steel clip. Its design allows it to expand outward when force is applied from below. This outward radial force presses the clip firmly against the interior walls of the drilled hole. The design of the clip directly influences the anchor’s performance, dictating minimum spacing between anchors and the required distance from a concrete edge to prevent failure.

Interaction with the Tapered Cone

When an installer tightens the nut on the anchor, it pulls the threaded stud body upward. This action forces the tapered cone at the bottom of the stud up into the expansion clip. As the cone moves further into the clip, it pushes the clip’s segments outward, wedging them tightly against the surrounding concrete. This creates a powerful frictional hold, locking the anchor securely within the hole.

The Nut and Washer

The nut and washer are the final components of the assembly. They work together on the threaded end of the anchor to secure the object being fastened.

Securing the Fixture

The washer provides a larger bearing surface for the nut, distributing the clamping load evenly across the fixture’s surface. This prevents damage to the fixture and helps maintain a secure connection. The nut and washer supplied with carbon steel anchors are typically made from plated carbon steel. They must meet specific industry standards to ensure compatibility and strength.

- Nut Standards: ASTM A563 is the most common standard for nuts used with these anchors.

- Washer Standards: ASTM F436 hardened steel washers are preferred for their strength and durability.

Applying Clamping Force

Tightening the nut is the final step that activates the anchor. As the nut turns, it pulls the stud upward, engaging the expansion mechanism described earlier. Simultaneously, it creates a strong clamping force that presses the fixture firmly against the concrete surface. Applying the correct amount of torque is critical. This action ensures the anchor is properly set and the fixture is held securely in place.

The Working Principle of Concrete Wedge Anchors

The effectiveness of concrete wedge anchors lies in a straightforward yet powerful mechanical principle. The process transforms a simple steel rod into a high-strength fastener locked into solid concrete. This transformation relies on a precise sequence of actions that generate immense expansion force.

The Expansion Mechanism Explained

The entire holding power of wedge anchors originates from a four-step installation process. Each step is critical. An installer must perform them correctly to ensure the anchor achieves its full load capacity and provides a safe connection.

Step 1: Drilling the Hole

An installer first drills a hole into the solid concrete base material. The hole’s diameter must match the nominal diameter of the anchor. For example, a 1/2″ anchor requires a 1/2″ hole. The hole must also be drilled to a specific minimum depth. This depth ensures there is enough room for the anchor to expand properly and meet embedment requirements.

Step 2: Cleaning the Hole

After drilling, the hole contains concrete dust and debris. This debris must be removed completely. An installer typically uses a wire brush and compressed air to clean the hole thoroughly. A clean hole allows the expansion clip to make direct contact with the solid concrete wall. This contact is essential for generating maximum frictional force.

Pro Tip 💡: Failing to clean the hole is a common installation error. Debris can prevent the anchor from setting correctly, significantly reducing its holding power and potentially leading to connection failure.

Step 3: Anchor Insertion

The installer then places the fixture over the hole. The wedge anchor, with its nut and washer attached, is inserted through the fixture’s hole and into the drilled hole in the concrete. A hammer is used to gently tap the top of the anchor. This action drives the anchor down until the washer and nut are snug against the surface of the fixture.

Step 4: Tightening and Expansion

The final step activates the anchor. An installer uses a torque wrench to tighten the nut. This tightening action pulls the threaded stud body upward. As the stud moves up, its tapered cone end is forced into the expansion clip. The cone’s upward movement pushes the segments of the clip outward, wedging them firmly against the walls of the concrete hole. This creates the secure lock that gives these anchors their name.

How Frictional Force Creates a Secure Hold

The expansion of the clip generates a powerful frictional force between the anchor and the concrete. This force is the source of the anchor’s pull-out resistance. The design of the clip and the properties of the concrete work together to create an incredibly strong bond.

Grip Against the Concrete Wall

The grip is more complex than simple friction. The expansion clip is engineered to create a mechanical interlock with the concrete. This enhances the holding capacity of the wedge anchors.

- Wedge anchors achieve their holding power through a combination of friction and interlocking forces.

- The expansion clip often features angled grooves, ribs, or teeth on its outer surface.

- As the clip expands, these design features dig into the microscopic pores and irregularities of the concrete wall.

- This interlocking mechanism provides an enhanced grip, preventing the anchor from pulling out or loosening when a load is applied.

Load Transfer and Distribution

Once the anchor is set, it becomes part of a complete fastening system. When a load is applied to the fixture (either a tension or shear load), the force travels through the fixture into the anchor’s stud body. The anchor then transfers this load outward through the expanded clip and into the surrounding concrete base material. The large surface area of the expanded clip distributes the stress over a wide section of the concrete, allowing the connection to handle heavy loads safely. This efficient load distribution is why these anchors are trusted for critical applications.

Different Types of Wedge Anchors by Material

Selecting the correct material is a critical decision for any project involving concrete fasteners. The environment where the anchor will be installed directly impacts its performance, safety, and lifespan. The main types of concrete anchors are distinguished by their material composition, each offering a different level of corrosion resistance.

Carbon Steel (Zinc-Plated)

Carbon steel wedge anchors are the most common and economical choice. A thin layer of zinc plating gives them a bright, shiny finish and provides a basic level of rust protection.

Best for Dry, Indoor Environments

These anchors perform reliably in controlled, dry, indoor settings. Installers use them for applications like fastening shelving in a warehouse or securing equipment inside a climate-controlled building. They are not intended for use in damp or corrosive conditions.

Corrosion Resistance Level

Zinc-plated anchors have a shorter service life compared to other materials. The thin zinc coating can degrade over time, exposing the carbon steel underneath to rust. For this reason, they are best suited for indoor applications with minimal corrosion risk. These anchors may require regular upkeep or eventual replacement to maintain their performance over an extended period.

Hot-Dipped Galvanized Steel

Hot-dipped galvanized (HDG) anchors offer a significant upgrade in corrosion protection. This process involves dipping the anchor in molten zinc, which creates a much thicker and more durable coating than standard zinc plating.

Suited for Outdoor and Damp Conditions

The robust coating makes HDG anchors ideal for many outdoor projects and for use in damp environments. Common applications include securing fence posts, decking ledgers, and equipment in unheated garages or basements where moisture is present.

Enhanced Corrosion Protection

The thick zinc layer provides excellent defense against rust. In standardized salt spray tests (ASTM B117), hot-dip galvanized anchors are generally expected to withstand over 240 hours before showing significant corrosion. Some specific name-brand fasteners have demonstrated superior performance, enduring 642 hours in the same test, proving their enhanced durability.

Stainless Steel Anchors

Stainless steel offers the highest level of corrosion resistance, making it the premium choice for harsh conditions and critical applications. The two most common types are 304 and 316 stainless steel. Their primary differences lie in their chemical composition.

| Element | Type 304 (%) | Type 316 (%) |

|---|---|---|

| Chromium | 18 | 16 |

| Nickel | 8 | 11 |

| Molybdenum | Absent | 2-3 |

Type 304 for General Outdoor Use

Type 304 stainless steel is an excellent material for most outdoor applications. It provides superior rust protection against atmospheric corrosion, making it suitable for projects in areas with rain and humidity.

Type 316 for Harsh, Corrosive Environments

Type 316 stainless steel contains molybdenum, an element that dramatically increases its resistance to chlorides and other harsh chemicals. This makes it the mandatory choice for the most demanding environments.

Application Note 📝 Use Type 316 stainless steel wedge anchors in the following situations:

- Marine and coastal areas with saltwater spray.

- Chemical plants and wastewater treatment facilities.

- Caustic environments for superior rust resistance and lowered maintenance costs.

Common Applications for Concrete Wedge Anchors

The high strength and reliability of concrete wedge anchors make them suitable for a wide range of demanding applications. From foundational structural connections to critical safety installations, these fasteners provide robust and permanent fastening solutions. Their performance in solid concrete is trusted across construction, industrial, and infrastructure sectors.

Structural and Heavy-Duty Fastening

In structural engineering, wedge anchors are essential for transferring significant loads to a concrete base. Their holding power ensures the stability and integrity of building components.

Securing Steel Columns and Beams

Engineers frequently specify these anchors for securing the base plates of steel columns and support beams. This connection is critical for distributing structural loads evenly into the foundation. The reliability of wedge anchors makes them ideal for these high-stakes tasks.

- In one automotive facility, installers used wedge anchor bolts to secure numerous station mounts for a large automated assembly line, ensuring stability against heavy loads.

- In another project, expansion anchors with a wedge design secured a large digital LED billboard, providing exceptional resistance against strong wind forces.

Anchoring Sill Plates

Anchoring sill plates is a fundamental step in wood-frame construction. Installers use wedge anchors to fasten the bottom plate of a wall directly to the concrete foundation. This creates a strong, rigid connection that prevents the structure from shifting or lifting.

Industrial and Commercial Installations

Industrial environments require fasteners that can withstand vibration, heavy loads, and constant use. Wedge anchors are a go-to choice for mounting equipment and storage systems securely.

Mounting Heavy Machinery

The proper mounting of heavy machinery is crucial for operational safety and precision. Installers use wedge anchors to bolt down equipment like CNC machines, industrial presses, and large motors. This firm connection prevents movement and vibration that could damage the equipment or create a hazardous work environment.

Installing Pallet Racking and Shelving

Warehouse safety standards require that pallet racking systems be securely anchored to the floor. This prevents tipping under heavy or unbalanced loads. Building codes often dictate specific requirements for these anchors, which can vary by region.

Code Compliance Note 📝 Permit requirements for pallet racking often depend on the rack’s height and the building’s location. The table below summarizes common triggers and inspection points across different regions in the United States.

Region Building Permit Trigger Documentation Required Inspection Focus Notable Restrictions / Notes West Commonly ≥8 ft; CA may require anchorage-only permits PE-sealed structural plans, anchorage details, seismic calcs Anchor connection, flue clearance, sprinkler coverage Storing product before permit finalization can result in fines. Midwest 5′–9″ for most fixed racks PE-sealed plans, rack layout, aisle widths Sprinkler clearances, egress, exit lights Seismic calculations may be required near specific zones. South Thresholds vary by city (many ≥8′) PE-stamped calculations, anchorage details, load calculations Egress, signage, anchor connections Coastal states require wind load and anchor review. Northeast Commonly ≥8′ (varies by municipality) PE-sealed rack drawings, sprinkler layout, anchor details Egress, lighting, anchor connections, smoke vents (MA) Seismic anchoring is required in certain areas like MA.

Safety and Infrastructure Projects

For public safety and infrastructure projects, fastener failure is not an option. The proven performance of wedge anchors makes them a trusted component for securing critical elements.

Fastening Guardrails and Handrails

Installers rely on these anchors to secure guardrails, handrails, and safety barriers along roadways, bridges, and within buildings. The high shear and tension strength of the anchors ensures these safety systems remain firmly in place.

Securing Signage and Equipment

The mounting of large road signs, communication towers, and other public equipment requires a fastener that can withstand environmental forces like wind and weather. Wedge anchors provide the durable, long-lasting hold needed for these important infrastructure elements.

How to Select the Right Wedge Anchor for Your Project

Choosing the correct wedge anchor is essential for ensuring a safe and durable connection. An installer must consider the anchor’s diameter and length, as well as the properties of the concrete and the surrounding environment. A careful evaluation of these factors guarantees optimal performance.

Choosing the Correct Anchor Diameter

The diameter of the anchor directly influences its holding power and compatibility with the fixture.

Based on Fixture Hole Size

The most basic rule for selection is that the anchor’s diameter must match the diameter of the hole in the fixture. A 1/2″ anchor requires a 1/2″ hole in the item being fastened. This ensures a snug fit and proper load transfer from the fixture to the anchor.

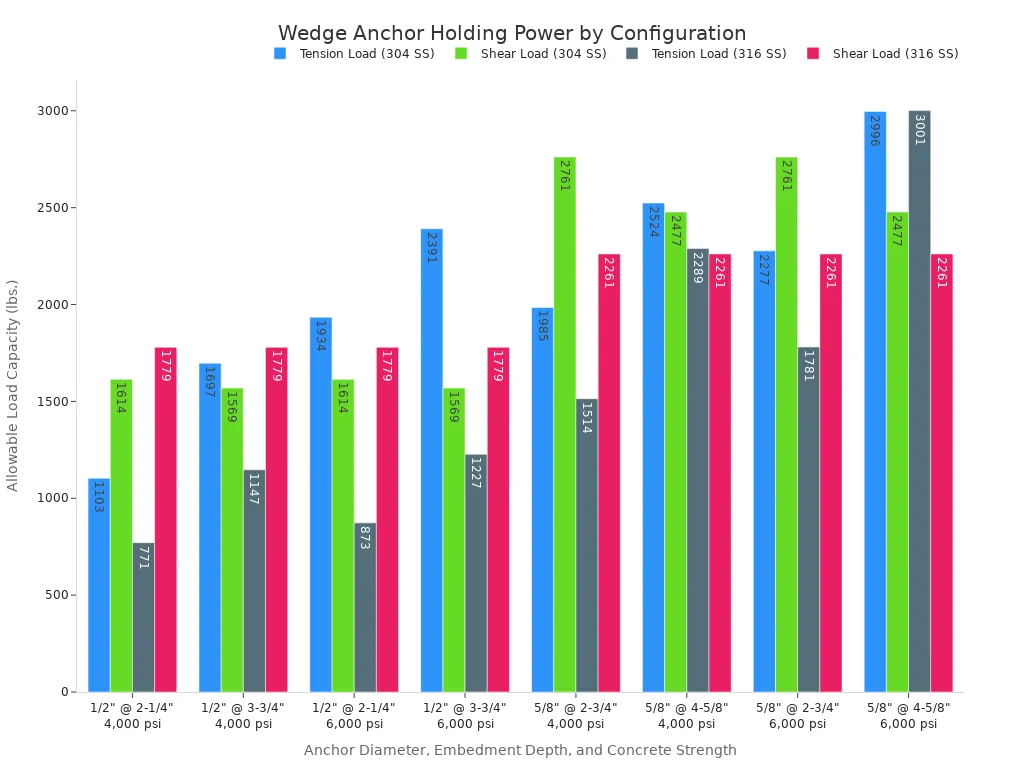

Based on Required Holding Power

Engineers determine the necessary holding power based on the project’s specific load requirements. Generally, a larger anchor diameter provides greater tension (pull-out) and shear (side-to-side) capacity. The material of the wedge anchors also plays a significant role in their ultimate strength. The chart below shows the allowable load capacities for stainless steel anchors in different configurations.

Determining the Necessary Anchor Length

The correct anchor length is calculated by combining three critical measurements. An anchor that is too short will not engage the concrete properly, while one that is too long can be wasteful and may interfere with rebar.

Accounting for Fixture Thickness

First, an installer must measure the thickness of the material being fastened. The anchor must be long enough to pass completely through the fixture.

Meeting Minimum Embedment Depth

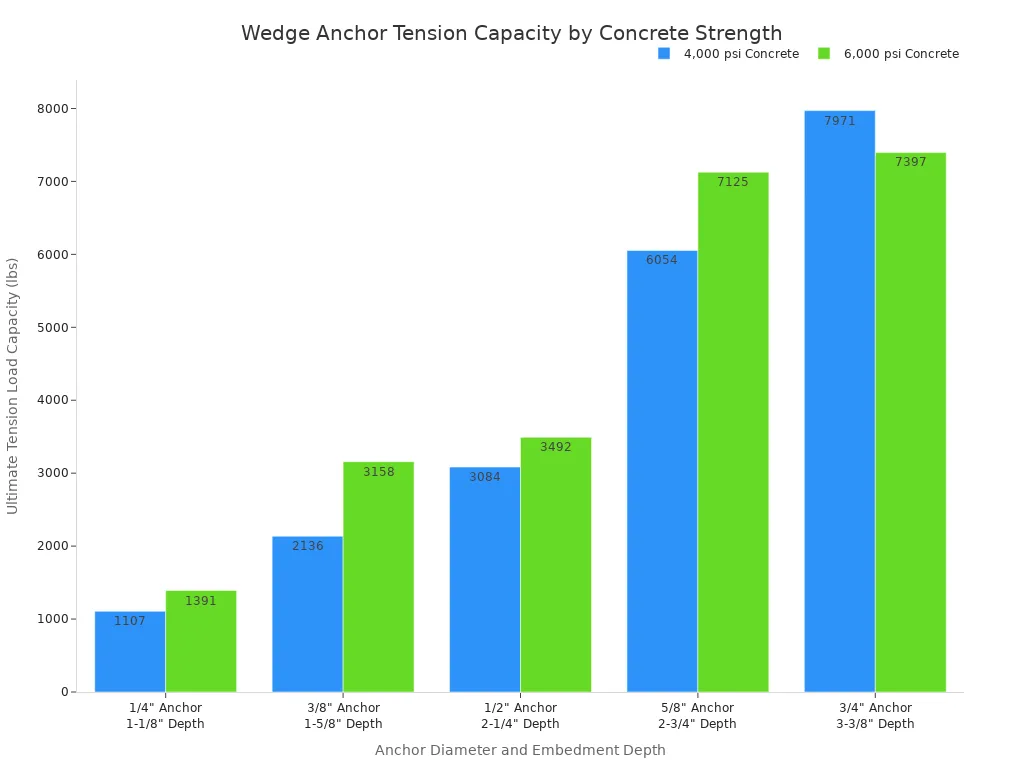

Each anchor diameter has a specific minimum embedment depth required to achieve its rated holding values. Installing anchors at a shallower depth will compromise their performance. Deeper embedment can often increase holding power.

| Anchor Diameter | Minimum Embedment Depth |

|---|---|

| 1/4” | 1-1/8” |

| 3/8” | 1-1/2” |

| 1/2” | 2-1/4” |

| 5/8” | 2-3/4” |

| 3/4” | 3-1/4” |

Including Nut and Washer Height

Finally, the calculation must include space for the nut and washer. The total minimum length is found using a simple formula.

Calculation Formula ⚙️ The formula for calculating the minimum length of a wedge anchor (MLWA) is:

Fixture Thickness (FT) + Minimum Embedment (ME) + Nut & Washer Height (NW) = MLWA

Assessing the Concrete and Environment

The condition of the base material and the installation environment are final, crucial considerations.

Concrete Compressive Strength

The compressive strength of the concrete, measured in pounds per square inch (PSI), directly affects the anchor’s holding power. Stronger concrete provides a more robust base for the anchor’s expansion clip to grip. As shown in the chart, higher PSI concrete generally yields higher load capacities. For applications in cracked concrete, installers must use specially designed icc-es approved cracked concrete anchors.

Environmental Exposure (Indoor vs. Outdoor)

The environment dictates the required material. An installer uses zinc-plated carbon steel wedge anchors for dry, indoor applications. For outdoor or damp locations, hot-dipped galvanized or stainless steel anchors provide the necessary corrosion resistance to ensure a long service life.

Best Practices for Installing Wedge Anchors

Proper installation is paramount for achieving the full holding capacity of wedge anchors. Following correct procedures ensures a safe, reliable, and long-lasting connection. These professional installation techniques begin with careful preparation before drilling even starts.

Pre-Installation Checks

An installer must perform two critical checks before beginning the installation. These preliminary steps prevent common failures and guarantee the anchor has a suitable foundation.

Verifying Concrete Integrity

First, an installer inspects the concrete base material. The concrete must be solid, fully cured, and free of significant cracks, spalls, or damage. Wedge anchors rely on the strength of the surrounding concrete to function, so a compromised base will not provide adequate support.

Using the Correct ANSI-Standard Drill Bit

The installer must use a carbide-tipped drill bit that meets ANSI Standard B212.15. This standard ensures that the bit’s diameter falls within a specific tolerance range, creating a hole that is perfectly sized for the anchor. The nominal diameter of the bit must match the nominal diameter of the anchor.

Industry Standard ⚙️ The ANSI B212.15 standard was created to ensure consistency between anchor and bit manufacturers. A correctly sized hole allows the anchor’s clip to engage the concrete wall with optimal friction.

The table below shows the required diameter tolerances for common bit sizes.

| Nominal Drill Bit | Minimum Diameter | Maximum Diameter |

|---|---|---|

| 1/4” | .260” | .268” |

| 3/8” | .390” | .398” |

| 1/2” | .520” | .530” |

| 5/8” | .650” | .660” |

| 3/4” | .775” | .787” |

The Step-by-Step Installation Process

A precise step-by-step installation sequence activates the anchor’s expansion mechanism. Each action builds upon the last to create a powerful and permanent hold.

Drilling to the Correct Depth

An installer drills a hole to a depth that exceeds the anchor’s minimum embedment requirement. This extra space, typically 1/2″ deeper, allows room for any fine dust that may settle at the bottom of the hole after cleaning.

Cleaning Debris from the Hole

After drilling, the installer thoroughly cleans the hole. This involves using a wire brush to loosen debris from the walls, followed by blowing the hole clean with compressed air. This step is critical, as it ensures the expansion clip makes direct contact with solid concrete.

Setting the Anchor and Fixture

The installer places the fixture over the clean hole. Next, they insert the wedge anchor through the fixture and into the concrete. A hammer is used to gently tap the top of the anchor until the washer rests snugly against the fixture’s surface.

Applying the Recommended Torque

The final step is to tighten the nut with a calibrated torque wrench. Applying the manufacturer’s recommended torque pulls the stud upward, engages the expansion clip, and secures the fixture. This action properly sets the anchors without causing stress fractures in the concrete.

Torque Specifications 📝 Applying the correct torque is essential for all wedge anchors. Below are common torque values for smaller diameter anchors.

Anchor Diameter Recommended Torque (ft-lbs) 1/4″ 5-10 5/16″ 5-10

Following these best practices for anchors ensures a secure and dependable installation every time.

Common Installation Mistakes and How to Avoid Them

Even high-quality wedge anchors can fail if not installed correctly. An installer’s attention to detail is crucial for a secure connection. Avoiding a few common installation mistakes ensures that the anchor performs to its full potential and maintains structural integrity.

Drilling and Hole Preparation Errors

The initial preparation of the hole is the foundation for a successful installation. Errors at this stage are difficult to correct and will compromise the anchor’s strength.

Using an Incorrect Hole Diameter

An installer must use a drill bit that matches the anchor’s nominal diameter. A hole that is too large will prevent the expansion clip from making firm contact with the concrete wall. This results in a weak grip and low pull-out resistance. A hole that is too small will prevent the anchor from being inserted at all.

Drilling an Insufficient Hole Depth

Each anchor requires a specific minimum embedment depth to achieve its rated load capacity. Drilling a hole that is too shallow prevents the anchor from being set deep enough. This significantly reduces its holding power and can lead to connection failure under load.

Failing to Properly Clean the Hole

Concrete dust and debris left in the hole can severely compromise the anchor’s performance. This material acts as a barrier between the expansion clip and the solid concrete wall.

Critical Warning ⚠️ Failure to clean the hole is a leading cause of anchor failure. Debris prevents the clip from properly gripping the concrete, which can reduce holding power by over 50%. An installer must use a wire brush and compressed air to remove all loose particles.

Tightening and Torqueing Issues

Applying the correct amount of torque activates the anchor. Both too much and too little torque can lead to problems.

Over-Torquing the Anchor

Applying excessive torque can create high stress in the concrete base material. This can cause the concrete to crack or spall, especially near an edge. Over-tightening can also damage the threads or stud of the anchor itself, leading to a sudden failure.

Under-Torquing the Anchor

Insufficient torque fails to pull the cone up into the expansion clip fully. The clip does not expand enough to create the necessary frictional force against the concrete wall. This results in a loose fixture and a drastically reduced load capacity for the anchors.

Placement and Spacing Problems

The location of the anchors is just as important as the installation technique. Improper placement can create weak points in the concrete.

Installing Too Close to a Concrete Edge

Placing an anchor too close to an unsupported edge is a critical error. The outward force from the expanding clip can cause the concrete edge to break away, a failure known as spalling.

- A general rule is to maintain a minimum edge distance of 5 anchor diameters.

- For a 1/2″ anchor, this means installing it at least 2-1/2″ from the edge.

Insufficient Spacing Between Anchors

Installers must maintain adequate spacing between individual anchors. When anchors are too close, their expansion forces create overlapping stress cones in the concrete. This weakens the base material and reduces the holding power of the entire group.

- A minimum spacing of 10 anchor diameters between anchors is recommended to prevent load capacity reduction.

- Some codes allow for reduced spacing, but only if the installer also reduces the anchor’s allowable load values accordingly.

A concrete wedge anchor is a fundamental mechanical fastener. It provides a powerful and permanent bond with solid concrete through its expansion mechanism. The anchor’s impressive strength and reliability make it an essential component for heavy-duty construction and industrial projects. An installer ensures a safe, secure, and long-lasting connection by selecting the correct material and size. Following proper installation procedures for concrete wedge anchors is critical for achieving this outcome.

FAQ

Can an installer reuse a wedge anchor?

No. Wedge anchors are designed for single-use applications. The expansion clip deforms permanently during the initial installation. Removing and reinstalling the anchor compromises its holding power and creates a significant safety hazard. A new anchor must always be used for a new connection.

What is the difference between a wedge anchor and a sleeve anchor?

Wedge anchors provide superior holding power in solid concrete only. Sleeve anchors are more versatile and function in concrete, brick, and block. However, sleeve anchors generally have lower load capacities compared to the high-strength connection of a wedge anchor in solid concrete.

Can wedge anchors be installed in brick or block?

No. An installer must use wedge anchors exclusively in solid, cured concrete. Softer base materials like brick, block, or asphalt lack the compressive strength to support the anchor’s expansion forces. Using them in these materials will result in a weak and unsafe connection.

How long do wedge anchors last?

The anchor’s lifespan depends on its material and the environment. Zinc-plated anchors perform well in dry, indoor settings. For outdoor or corrosive conditions, hot-dipped galvanized or stainless steel anchors offer superior rust protection and a much longer service life.

What should an installer do if they hit rebar?

An installer must stop drilling immediately upon hitting rebar. They should abandon that hole and drill a new one. The new hole must be located far enough away to meet the minimum spacing requirements specified for the anchor diameter.

Safety First 👷 Never attempt to cut or drill through rebar. Doing so can compromise the structural integrity of the concrete itself.

Why is applying the correct torque so important?

Applying the manufacturer’s recommended torque is a critical step. It ensures the anchor’s expansion clip engages the concrete with the correct force. Under-torquing results in a weak hold, while over-torquing can crack the concrete or damage the anchor, leading to failure.