Anchor bolts are heavy-duty fasteners used to connect structural elements to a concrete base. Their primary function is to provide stability. Anchor bolts achieve this by securely transferring tension and shear forces into the foundation. The safety of buildings and machinery depends on these critical components. For unique project requirements, a custom fasteners manufacturer can supply specialized custom fasteners, including custom anchor bolts. The correct application of anchor bolts is essential for ensuring structural integrity.

The Fundamental Role of Anchor Bolts in Construction

Anchor bolts serve as the foundational connection between a structure and its concrete base. They are engineered to manage immense forces, ensuring a building or installation remains stable and secure. This stability is achieved by effectively transferring different types of loads from the structure directly into the concrete.

How Anchor Bolts Ensure Structural Stability

Engineers design connections using anchor bolts to resist forces that could otherwise cause a structure to lift, slide, or overturn. The method of load transfer depends heavily on the specific type of anchor used.

Transferring Tension Loads

Tension loads are pulling forces that try to lift a structural element away from its foundation. Anchor bolts counteract this by gripping the concrete. The mechanism for this grip varies:

- Cast-in-place anchors create a mechanical interlock with the surrounding concrete.

- Mechanical expansion anchors generate friction by expanding a sleeve against the sides of a drilled hole.

- Adhesive (bonded) anchors use high-strength epoxies or resins to create a powerful bond between the anchor and the concrete.

- Screw anchors cut their own threads into the concrete, creating a direct bearing pressure exchange.

Transferring Shear Loads

Shear loads are lateral forces that push a structure sideways, parallel to the foundation. These forces could result from wind, seismic activity, or the operation of heavy machinery. The same mechanisms that resist tension also help anchor bolts resist shear. The body of the anchor bears against the concrete, preventing the attached element from sliding. Properly selected anchor bolts provide the necessary resistance to maintain the structure’s position.

Handling Combined Forces

Most real-world applications subject anchor bolts to a combination of tension and shear forces simultaneously. For example, wind pushing against a tall building creates both a lifting force (tension) on the windward side and a lateral force (shear) across the entire base. Engineers must calculate these combined loads to select anchor bolts capable of handling complex stresses without failure.

The Importance of Proper Anchoring

Correctly selecting and installing anchor bolts is not just a best practice; it is a critical safety requirement. The consequences of improper anchoring can be severe and costly.

Preventing Structural Failure

Faulty anchoring is a direct cause of catastrophic structural failures. Inadequate anchor spacing can lead to excessive stress and premature failure, causing costly plant shutdowns for repairs. Misalignment can create gaps that compromise thermal efficiency in industrial settings.

A tragic example occurred in Boston’s Big Dig tunnel in 2006. A 26-ton concrete ceiling panel collapsed onto a vehicle, resulting in a fatality. The investigation found that the failure was caused by using the wrong type of epoxy for the adhesive anchor bolts, which could not support the sustained load.

Meeting Building Codes and Standards

Building codes and industry standards, such as those from the American Concrete Institute (ACI), provide strict guidelines for the design and installation of anchoring systems. These regulations exist to protect public safety. Compliance ensures that all anchor bolts meet proven performance criteria for load capacity, spacing, and embedment depth, creating a safe and reliable structure.

Guaranteeing Long-Term Durability

Proper anchoring guarantees the long-term performance and durability of a structure. When selected for the specific environmental conditions and installed correctly, anchor bolts resist corrosion and material degradation. This ensures they maintain their load-bearing capacity for the entire service life of the building, preventing future safety hazards and costly retrofits.

An Overview of the Main Types of Anchor Bolts

Engineers and builders select from two primary categories of anchor bolts: cast-in-place and post-installed. Each category contains multiple designs suited for specific structural demands and project constraints. A thorough understanding of the main types of anchor bolts is fundamental to ensuring a safe and durable connection to a concrete base.

Cast-in-Place Anchors

Cast-in-place anchors are set into position before workers pour fresh, wet concrete. The concrete then cures around the anchor, creating an exceptionally strong mechanical bond. Structural engineers have historically preferred this method for new construction projects. Cast-in-place anchors are typically employed when substantial embedment depths and high tensile strengths are necessary to support a given load. Common configurations include headed anchor bolts, 90-degree bent anchors, or threaded rods with an embedded nut and anchor plate.

Headed Anchor Bolts (e.g., F1554)

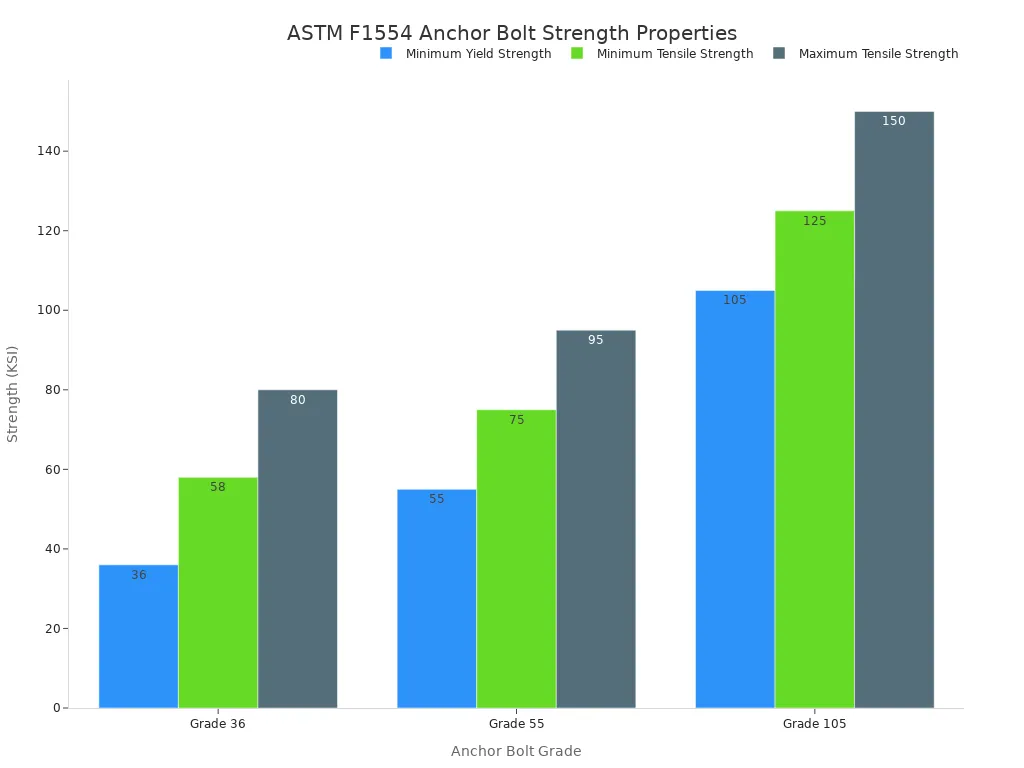

Headed anchor bolts feature a forged head on the embedded end, which provides superior pull-out resistance. The ASTM F1554 specification is the modern standard governing these critical components. The specification was developed in 1994 to create standardized guidelines for anchor bolts in complex construction projects. It defines key material properties, including:

- Tensile Strength: The maximum stress the bolt can withstand before failure.

- Yield Strength: The maximum stress a bolt can endure before permanent deformation.

- Elongation: How much the bolt can stretch before breaking.

- Chemical Composition: The precise blend of elements that determines the bolt’s characteristics.

ASTM F1554 classifies these anchor bolts into three grades based on minimum yield strength, allowing engineers to match the bolt to specific load requirements.

| Grade | Material Type | Tensile Range (KSI) | Minimum Yield Strength (KSI) |

|---|---|---|---|

| 36 | Low carbon steel | 58 to 80 | 36 |

| 55 | Medium carbon steel | 75 to 95 | 55 |

| 105 | High-strength alloy | 125 to 150 | 105 |

The different strength levels allow for precise engineering choices.

Adherence to this standard ensures predictable performance, especially in applications requiring ductility for seismic events.

Bent-Bar Anchors (L-Bolts and J-Bolts)

Bent-bar anchors, commonly known as L-bolts or J-bolts, get their name from their shape. The bent portion of the bolt creates a mechanical hook within the concrete. This hook provides resistance against tension forces. While once very common, their use in heavy structural applications has declined in favor of headed bolts. They remain a popular choice for securing lighter structural elements, such as sill plates in residential construction or light pole bases.

Post-Installed Anchors

Post-installed anchors offer tremendous flexibility because they are installed into concrete after it has hardened. This makes them the go-to solution for a wide range of projects. Common applications include:

- Retrofitting, renovation, and repair projects

- Connecting new steel beams or columns to existing concrete

- Non-structural uses like installing handrails, HVAC equipment, and signage

- Seismic retrofitting and facade system attachments

- Securing heavy machinery and industrial pipelines

The variety of post-installed types of anchor bolts allows for tailored solutions for nearly any anchoring challenge.

Mechanical Expansion Anchors

Mechanical expansion anchors work by creating a friction force against the wall of a drilled hole. After insertion, tightening a nut or bolt expands a sleeve or wedge at the anchor’s base. This expansion locks the anchor firmly in place. Mechanical wedge anchors are a popular subtype known for their high load capacity and reliability in solid concrete. These anchors are cost-effective and easy to install, making them a frequent choice for medium- to heavy-duty fastening. The performance of mechanical wedge anchors depends heavily on the quality of the concrete base.

Adhesive Anchors (Chemical Anchors)

Adhesive anchors, also called chemical anchors, use a high-strength resin or epoxy to bond a threaded rod to the concrete. Workers inject the adhesive into a clean, drilled hole before inserting the rod. The chemical cures to form a powerful, stress-free bond. This method is ideal for applications requiring very high load capacities or when anchoring close to edges. High-quality adhesive epoxy anchors are also suitable for use in both cracked and uncracked concrete, offering superior performance in demanding conditions. The reliability of adhesive epoxy anchors is directly tied to proper hole cleaning and cure time.

Screw Anchors

Screw anchors are specialized fasteners with heavy-duty threads that cut into concrete and masonry. Installation is fast and straightforward: a worker drills a pilot hole and then drives the screw directly into the base material. This creates a secure mechanical interlock. A key advantage of screw anchors is their removability, which makes them ideal for temporary installations like formwork or bracing.

Undercut Anchors

Undercut anchors provide the highest performance among post-installed options. Installation involves a two-step process. First, a standard hole is drilled. Then, a special tool creates an “undercut” or bell-shaped cavity at the bottom of the hole. The anchor expands into this cavity, creating a positive mechanical interlock. This design eliminates the expansion stresses associated with mechanical anchors, making them extremely reliable for dynamic loads, seismic applications, and anchoring in cracked concrete.

Common Applications for Anchor Bolts in Various Projects

Anchor bolts are indispensable in modern construction, providing the secure connections that underpin structural safety and functionality. Their versatility makes them essential across a wide spectrum of construction projects. Understanding these common applications highlights their critical role in everything from skyscrapers to residential homes.

Structural Steel and Building Frames

In steel-frame construction, anchor bolts create the vital link between the steel superstructure and the concrete foundation. This connection is fundamental to the building’s ability to stand and resist environmental forces.

Securing Steel Columns to Foundations

The primary columns of a building transfer the entire structure’s weight to the foundation. Engineers use cast-in-place anchor bolts to create an immovable connection point for these columns. The design must account for significant forces. For instance, regulations often require that each column’s anchoring system can resist an eccentric gravity load of 300 pounds applied 18 inches from the column’s outer face. To ensure stability and redundancy, a minimum of four anchor bolts must secure each primary steel column to its foundation.

Anchoring Beams and Bracing

Anchor bolts also secure secondary structural elements like beams, girders, and bracing to concrete walls or footings. These connections are especially critical in regions prone to seismic activity, where engineers face unique challenges.

Anchoring in Seismic Zones

- Challenge: Seismic uplift forces can require very large concrete footings, making excavation difficult.

- Solution: Engineers can use anchor reinforcement, such as closed-ties, to transfer the load more effectively. This technique allows for significantly narrower footings.

- Challenge: Columns can pull out or push sideways during an earthquake.

- Solution: Anchor bolts must have deep embedment or use heavy plates at the embedded end. ACI 318 standards require the concrete’s strength to exceed the anchor’s steel strength to prevent concrete failure before the anchor yields.

Infrastructure and Civil Engineering

Public infrastructure relies heavily on robust anchoring to ensure safety and longevity. From lighting highways to spanning rivers, anchor bolts provide the necessary stability for countless civil engineering applications.

Mounting Light Poles and Traffic Signals

Light poles, traffic signals, and large highway signs must withstand constant wind loads and vibration. They are typically secured to concrete bases using a pattern of long, cast-in-place anchor bolts. Common types specified by transportation authorities include:

- Straight rods threaded on both ends

- L-shaped bent anchor bolts

- Fully threaded rods

Because these anchors are exposed to the elements, they are almost always hot-dip galvanized. This protective coating prevents corrosion and ensures long-term durability. Requirements for these construction applications can vary, as each state’s department of transportation may have its own specific standards.

Securing Bridge Bearings and Guardrails

On bridges, large anchor bolts fasten steel bridge bearings to concrete piers. These bearings allow the bridge deck to expand and contract with temperature changes while transferring immense vehicle loads to the substructure. The anchors must handle these dynamic forces without fail. Similarly, highway guardrails are bolted into concrete barriers or footings to provide life-saving protection.

Industrial and Commercial Settings

In industrial and commercial environments, anchor bolts are used for both structural and non-structural purposes. They secure everything from heavy manufacturing equipment to the storage systems that organize a warehouse.

Fastening Heavy Machinery and Equipment

Large industrial machines, such as presses, lathes, and generators, produce significant vibration and dynamic forces during operation. Post-installed anchor bolts are used to fasten this equipment securely to the concrete floor. This anchoring prevents movement, reduces vibration transfer, ensures operational precision, and protects workers from accidents caused by shifting machinery.

Anchoring Racking Systems and Mezzanines

Warehouse pallet racks and mezzanines must be properly anchored to prevent catastrophic collapse. Unanchored racks are dangerously unstable and can tip from forklift impacts, shifting loads, or seismic events.

Properly anchored pallet racks are essential for preventing tipping, collapses, and catastrophic accidents that can injure workers and destroy inventory. The American National Standards Institute (ANSI) provides detailed standards for rack design and installation, including anchoring.

The anchor bolts for racking systems must resist two primary forces:

- Tension (Uplift): This occurs when a lateral force, like a forklift strike high on the rack, creates a tipping motion that tries to pull the column’s base plate up from the floor.

- Shear (Lateral): This is a sideways force, typically from a direct impact at the base, that tries to slice the anchor in half.

Installers must use the anchor type and size specified by the rack manufacturer and anchor every column to the concrete floor to ensure stability and compliance with safety standards.

Residential and Safety Uses

While often associated with massive structures, anchor bolts have equally important common applications in residential construction and safety installations. They provide the foundational strength that keeps homes secure and public spaces safe for everyone.

Attaching Sill Plates to Foundations

The sill plate is the first piece of lumber in a wood-frame structure that rests directly on the concrete foundation. Attaching it securely is the first step in building a stable house. Building codes provide strict guidelines for this connection to prevent the structure from shifting or lifting off its foundation, especially during high winds or seismic events.

A common expectation is to see bolts penetrating the sill plate into the concrete at least every six feet. However, specific codes, like the International Residential Code (IRC), detail more precise requirements.

- Builders must use steel bolts with a minimum diameter of 1/2 inch or an approved anchor of equivalent strength.

- These bolts require an embedment of at least 7 inches into the concrete.

- Installers must position the bolts in the middle third of the sill plate’s width.

- The maximum spacing between bolts is 6 feet, but this decreases to 4 feet for braced wall lines in taller structures.

- Every individual piece of sill plate needs a minimum of two bolts, with one located within 12 inches of each end.

Installers typically use cast-in-place “J” bolts for new construction, setting them before the concrete pour. For existing foundations or repairs, post-installed mechanical anchors, such as wedge anchors, are a reliable alternative.

Securing Safety Railings and Handrails

Safety railings and handrails along stairways, balconies, and walkways are critical life-safety components. Their failure can lead to serious injury. The strength of these installations depends entirely on how their posts are anchored to the concrete base.

Post-installed anchor bolts are the standard choice for this application. Installers drill into the cured concrete and use mechanical or adhesive anchors to fasten the railing post’s base plate. The chosen anchor must be capable of resisting significant lateral (shear) loads, as defined by building codes and standards like the Americans with Disabilities Act (ADA).

Safety is Non-Negotiable

A railing is only as strong as its connection to the ground. Using undersized or improperly installed anchors can create a false sense of security. Engineers and installers must select anchors that are specifically rated for the structural loads required to prevent a catastrophic failure.

Properly securing these elements ensures they can withstand the pushing and pulling forces of daily use and provide reliable protection against falls.

How to Select the Right Anchor Bolt for the Job

Selecting the correct anchor bolt is a critical engineering decision that directly impacts structural safety and longevity. A systematic, three-step approach ensures that every factor, from load forces to environmental exposure, is carefully considered. This process guarantees the selection of a fastener that is perfectly suited for its specific application.

Step 1: Analyze Load Requirements

The first step involves a thorough analysis of the forces the anchor will need to resist. These forces, or loads, determine the required strength and type of anchor needed for a secure connection.

Static vs. Dynamic Loads

Engineers must first distinguish between static and dynamic loads.

- Static loads are constant and unchanging forces, such as the dead weight of a structure or permanently installed equipment.

- Dynamic loads involve fluctuating forces from vibrations, impacts, or seismic activity. These forces are more complex and demanding.

The static load capacity of an anchor is almost always higher than its dynamic load capacity. For applications involving vibration from machinery or potential seismic events, engineers must select anchor bolts, like certain chemical or wedge anchors, that are specifically rated for dynamic performance.

Tension, Shear, and Combined Load Values

Engineers calculate the specific load values an anchor must handle.

- Tension is the pulling force that tries to extract the anchor from the concrete.

- Shear is the lateral force that tries to slice the anchor sideways.

Most connections face a combination of these forces. In such cases, engineers use a unity equation to ensure the selected anchor bolts can safely resist both tension and shear simultaneously without failure.

Step 2: Evaluate the Base Material

The condition and strength of the concrete base material are just as important as the anchor itself. A strong anchor in weak concrete will inevitably fail.

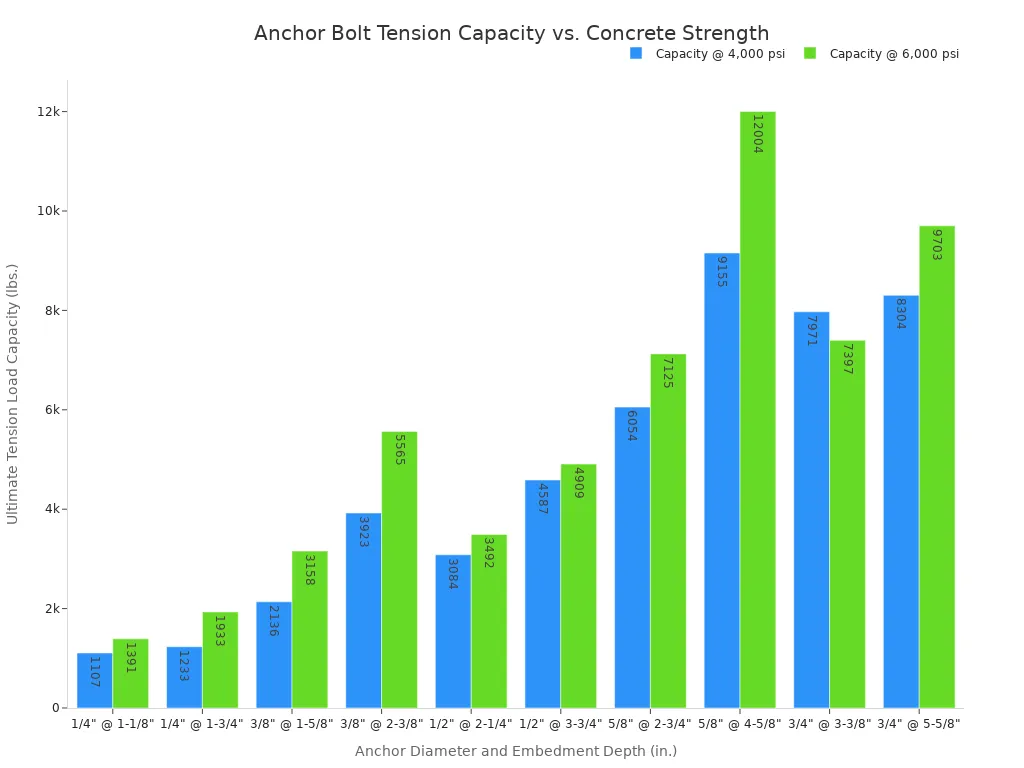

Concrete Strength and Condition

Concrete compressive strength, measured in pounds per square inch (psi), directly correlates with an anchor’s pull-out capacity. As concrete strength increases, so does the holding power of the anchor. For example, high-quality anchor bolts will exhibit significantly higher load capacities in 6,000 psi concrete compared to 4,000 psi concrete.

Cracked vs. Uncracked Concrete

Designers must determine if the concrete is likely to crack under load. Cracks can significantly reduce an anchor’s performance.

Design Conservatively: Assume Cracks

Building codes like ACI 318 require designers to assume cracked concrete conditions in seismic zones or when analysis indicates cracking is likely. This conservative approach ensures the chosen anchor is qualified for the most demanding scenarios, providing a critical margin of safety.

Step 3: Consider Environmental Conditions

The environment where the anchor will be installed plays a crucial role in its long-term durability and performance.

Interior vs. Exterior Exposure

Interior anchors are protected from the elements. Exterior anchors, however, face constant exposure to moisture, temperature fluctuations, and ultraviolet (UV) light. This exposure accelerates material degradation if the anchor is not properly protected.

Corrosion and Chemical Resistance

For exterior or damp applications, corrosion resistance is non-negotiable. Moisture and salt can cause steel to rust, compromising its strength. Materials like hot-dip galvanized or stainless steel provide excellent corrosion resistance. In industrial settings, anchors may also be exposed to harsh chemicals, requiring a specific material or coating that offers specialized corrosion resistance to prevent premature failure. Proper corrosion resistance is essential for the service life of all anchor bolts.

Key Steps for Proper Anchor Bolt Installation

Proper installation is just as critical as selecting the right fastener. A correctly chosen anchor can fail if not installed according to precise procedures. The installation process differs significantly between cast-in-place and post-installed anchor bolts.

Installation of Cast-in-Place Anchors

The success of cast-in-place anchors depends entirely on accurate placement before the concrete is poured. There is no room for error once the concrete hardens.

Setting the Template

Installers use a template, typically made of plywood, to hold the anchor bolts in the exact position during the concrete pour. This step is crucial for aligning the bolts with the column base plates later.

- Workers fabricate the plywood template in the shop for accuracy.

- They mark the template’s alignment relative to the foundation lines.

- Each anchor rod is stabilized by securing it with a nut on both sides of the template.

- The template is often raised slightly off the formwork to prevent placement issues.

Diligence in positioning and aligning anchor bolts is essential. Relying on oversized base plate holes to fix misalignments is poor practice, as contractors rarely control those hole sizes.

Securing Bolts Before the Pour

Once the template is set, workers must ensure the entire assembly is rigid and will not shift when subjected to the immense pressure of wet concrete. Before the pour begins, a final check confirms that all anchor bolts are in their correct location and alignment. This verification prevents costly and difficult rework after the concrete cures.

Installation of Post-Installed Anchors

Post-installed anchors offer flexibility but demand a strict, multi-step installation process to achieve their specified load capacity. Skipping or rushing any step can compromise the connection’s integrity.

Drilling the Hole Correctly

The first step is to drill a hole to the correct diameter and depth. Installers commonly use rotary hammer drills for solid concrete.

- The drill bit size must comply with ANSI standards and the manufacturer’s instructions.

- The hole must be drilled to the specified embedment depth for the anchor to function correctly.

- For hollow masonry, rotary-only drilling may be necessary to avoid damaging the base material.

Cleaning the Hole Thoroughly

A clean hole is non-negotiable, especially for adhesive anchors. Debris, dust, or oil will prevent a proper bond and drastically reduce the anchor’s holding power. The industry-standard cleaning procedure is the “blow, brush, blow” method.

- Blow: Use oil-free compressed air (minimum 90 psi) to blow debris out of the hole.

- Brush: Use a stiff wire brush to scrub the inside walls of the hole.

- Blow: Blow the hole out a second time to remove the loosened dust.

Note: A vacuum cleaner cannot replace compressed air for this task. Published load values for many adhesive epoxy anchors are based on this rigorous cleaning method, sometimes called the “2x2x2” procedure (blow-brush-blow, performed twice).

Setting and Curing the Anchor

The final step is setting the anchor. For mechanical wedge anchors, this involves tapping the anchor into the hole and tightening the nut to the specified torque value. For chemical anchors, installers inject the adhesive into the clean hole before inserting the threaded rod. They must then allow the adhesive to cure for the manufacturer-recommended time before applying any load.

Common Mistakes to Avoid with Anchor Bolts

Even the most robust design can fail if common mistakes occur during anchor selection or installation. Understanding these potential pitfalls is the first step toward preventing them. Errors typically fall into two categories: mistakes made during the design phase and mistakes made during on-site installation.

Design and Selection Errors

Proper design and selection lay the groundwork for a secure connection. Overlooking key details at this stage can compromise the entire structure.

Choosing the Wrong Anchor Type

Selecting an anchor incompatible with the base material or site conditions is a frequent error. For example, installers might use a standard wedge anchor in soft materials like brick. This choice can lead to an insecure hold and significantly reduced load capacity. The anchor must be specifically designed for the material.

A critical distinction is whether the concrete is cracked or uncracked. If an anchor not rated for cracked concrete is installed in a cracked zone, it could lose up to 80% of its performance. This massive drop in capacity highlights the danger of a mismatch.

Ignoring Edge and Spacing Requirements

Every anchor creates a cone-shaped zone of stress in the concrete. If these stress cones overlap or are too close to an edge, the concrete can break out before the anchor reaches its full strength. A general rule suggests maintaining a minimum distance of 12 times the anchor diameter between anchors and from any unsupported edge.

Specific requirements vary by anchor type.

| Anchor Type | Minimum Spacing (Center to Center) | Minimum Edge Distance |

|---|---|---|

| Wedge Anchors | 10 diameters | 5 diameters |

| General Concrete Anchors | N/A | 10 diameters |

Critical Installation Mistakes

Flawless installation is essential for performance. Even high-quality anchor bolts will fail if workers do not follow precise installation procedures.

Improper Hole Preparation

A dirty hole is a primary cause of anchor failure, especially for adhesive types. Debris and dust prevent the anchor from making proper contact with the concrete. This contamination drastically reduces the fastener’s holding power. Installers must always follow the “blow, brush, blow” cleaning method to ensure a pristine hole.

Incorrect Embedment Depth

The depth at which an anchor is set directly controls its capacity. A seemingly small reduction in embedment can have a major effect on performance. The failure mode of anchor bolts also changes with depth.

- Shallow embedment often leads to concrete breakout failure.

- Deeper embedment can shift the failure to the steel bolt itself, which is often preferred.

- Smooth bolts are more likely to pull out entirely.

Installers must drill the hole to the exact depth specified by the manufacturer to guarantee the connection performs as designed.

Applying the Wrong Torque

For mechanical anchors, torque is critical. Under-torquing means the anchor is not properly set and will not achieve its load capacity. Over-torquing is equally dangerous; it can damage the concrete, break the bolt, or create excessive stress in the base material, leading to premature failure. Workers must use a calibrated torque wrench to apply the exact torque value specified in the installation instructions.

Anchor bolts are essential fasteners, providing the critical link in modern construction projects. A clear understanding of the different types of anchor bolts is fundamental for their correct application. Engineers must select the right fastener based on load, base material, and environment to ensure structural safety. Ultimately, correct installation is just as crucial. Industry standards confirm that anchor strength relies on comprehensive testing. This underscores why following procedures for all types of anchor bolts is non-negotiable for guaranteeing performance and preventing failure.

FAQ

What is the main difference between cast-in-place and post-installed anchors?

Cast-in-place anchors are set into wet concrete before it cures, creating a very strong bond. Installers place post-installed anchors into hardened concrete. This method offers more flexibility for renovations and retrofitting projects.

Can installers reuse anchor bolts?

Generally, no. Mechanical expansion anchors and adhesive anchors are single-use fasteners. Removing them damages the anchor or the concrete base. Screw anchors are an exception, as their design allows for removal and reuse in temporary applications like formwork.

Why is cleaning a drilled hole so important?

Debris and dust prevent the anchor from making full contact with the concrete. This contamination severely reduces the holding power, especially for adhesive anchors. Proper cleaning ensures the anchor achieves its specified load capacity and prevents connection failure.

What happens if you apply the wrong torque to an anchor?

Applying incorrect torque compromises the connection.

- Under-torquing means the anchor is not fully engaged and will not hold its rated load.

- Over-torquing can damage the concrete, break the bolt, or cause premature failure under stress.

How close to a concrete edge can an anchor be installed?

Edge distance is critical to prevent concrete breakout. A general rule suggests a minimum distance of 10 to 12 times the anchor’s diameter from any unsupported edge. Installers must always consult the manufacturer’s specific instructions for exact requirements.

What does “cracked concrete” mean for anchoring?

Cracked concrete refers to concrete that has or may develop fine cracks under tension loads. These cracks can significantly reduce an anchor’s holding power. Engineers must select anchors specifically tested and qualified for use in cracked concrete for these applications.