Wedge anchors represent a cornerstone in concrete fastening technology, offering robust solutions for securing heavy loads in solid concrete bases. This comparative analysis examines wedge anchors alongside sleeve anchors and screw anchors, highlighting their mechanisms, applications, strengths, and limitations. Drawing from industry standards and empirical data, the discussion aims to guide engineers, contractors, and construction professionals in selecting the optimal fastener for specific projects. By evaluating factors such as holding strength, installation ease, and environmental suitability, this article provides a detailed framework for decision-making in global markets where concrete anchoring demands vary widely.

Understanding Wedge Anchors: Design and Functionality

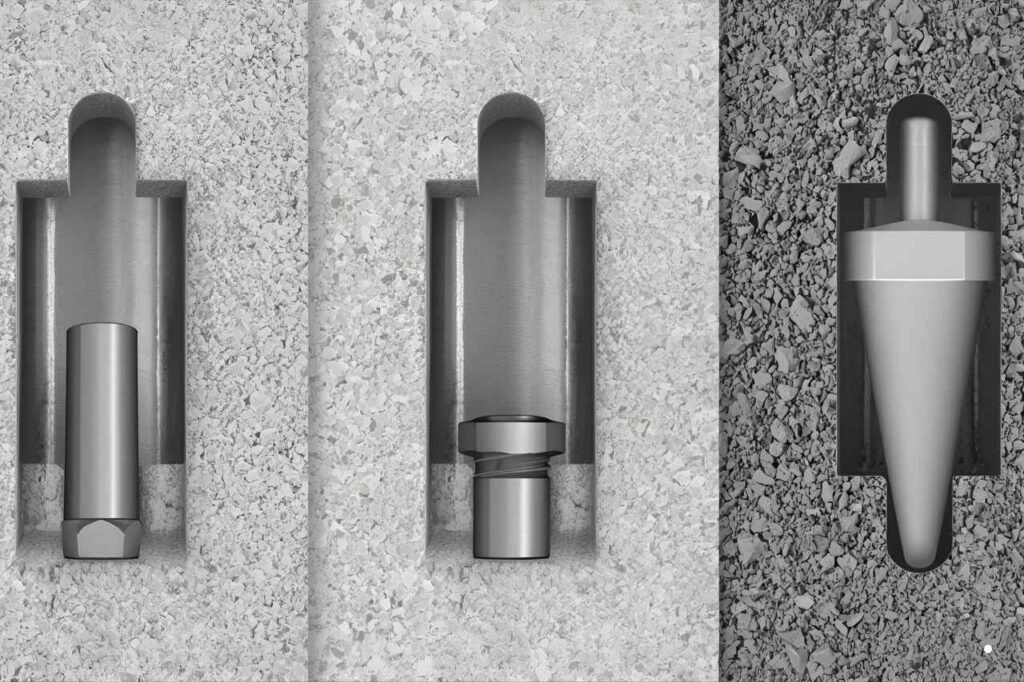

Wedge anchors, often referred to as expansion anchors or concrete wedge bolts, are mechanical fasteners designed exclusively for solid concrete. They consist of a threaded rod, an expansion clip, a nut, and a washer. The anchor functions by inserting into a pre-drilled hole, where tightening the nut pulls the rod upward, expanding the clip against the concrete walls to create a secure wedge effect.

This design ensures high holding values, making wedge anchors ideal for heavy-duty applications. For instance, according to data from Concrete Fastening Systems, a leading provider of fastening solutions based in Cleveland, Ohio, wedge anchors like their CONFAST® series can achieve tensile strengths up to 7,000 pounds in 4,000 psi concrete when embedded at standard depths. The company’s extensive catalog, including zinc-plated, galvanized, and stainless steel variants, caters to diverse environmental conditions, from indoor structural supports to outdoor infrastructure exposed to moisture.

LSI keywords such as “concrete expansion anchors,” “masonry wedge bolts,” and “heavy-duty concrete fasteners” frequently appear in searches related to these products, underscoring their prominence in construction and engineering contexts.

Key Components and Working Mechanism

The primary components include:

- Threaded Rod: Provides the base for attachment.

- Expansion Clip: The wedge-shaped sleeve that expands upon tightening.

- Nut and Washer: Facilitate torque application and load distribution.

When installed, the anchor’s clip wedges into the concrete, distributing pressure in a cone-shaped pattern. Evidence from installation guides, such as those from Simpson Strong-Tie, indicates that proper embedment depth is critical; for a 1/2-inch diameter wedge anchor, a minimum embedment of 2-1/4 inches is recommended to achieve optimal holding values.

Comparative Analysis: Wedge Anchors vs. Sleeve Anchors

Sleeve anchors, another type of expansion fastener, differ from wedge anchors in their design and application scope. Comprising a threaded stud with a conical expander and a surrounding sleeve, sleeve anchors expand uniformly along their length when the nut is tightened. This makes them suitable for both solid and hollow base materials, unlike wedge anchors, which are limited to solid concrete.

Structural Differences and Performance Metrics

Wedge anchors excel in shear and tensile strength due to their point-expansion mechanism. In contrast, sleeve anchors provide more uniform expansion, which can be advantageous in softer or hollow materials like brick or block. A study referenced in fastening specialist resources shows that in solid concrete, a 1/2-inch wedge anchor typically offers a shear strength of 4,500 pounds, while a comparable sleeve anchor might reach 3,800 pounds under similar conditions.

To illustrate, consider the following data table summarizing average holding values in 4,000 psi concrete (based on aggregated industry tests from sources like Concrete Fastening Systems and Brikksen):

| Anchor Type | Diameter (inches) | Minimum Embedment (inches) | Tensile Strength (lbs) | Shear Strength (lbs) |

|---|---|---|---|---|

| Wedge Anchor | 1/2 | 2-1/4 | 5,500 | 4,500 |

| Sleeve Anchor | 1/2 | 2 | 4,200 | 3,800 |

| Screw Anchor | 1/2 | 2 | 3,000 | 2,500 |

This table highlights wedge anchors’ superior load-bearing capacity, making them preferable for high-stress applications such as securing machinery or structural beams.

Installation and Application Suitability

Installation of wedge anchors requires a hammer drill and precise hole sizing, with the hole diameter matching the anchor’s diameter for a tight fit. Sleeve anchors, however, tolerate slightly oversized holes better, which is beneficial in variable masonry. For global markets, where concrete quality can differ (e.g., denser mixes in European standards versus lighter ones in Asia), wedge anchors from brands like CONFAST® offer galvanized options for corrosion resistance, as detailed in their product specifications.

In scenarios involving vibration, such as industrial settings, wedge anchors demonstrate better resistance due to their wedging action. Conversely, sleeve anchors are often chosen for lighter loads in hollow blocks, as evidenced by their use in cinderblock fastening per The Fastener Factory’s guidelines.

Wedge Anchors vs. Screw Anchors: A Strength and Versatility Comparison

Screw anchors, also known as concrete screws or masonry screws, operate on a threading principle rather than expansion. They cut threads directly into the concrete, providing a removable fastening solution. Brands like Tapcon® from Concrete Fastening Systems exemplify this category, with options in blue-coated or stainless steel for enhanced durability.

Load Capacity and Durability Insights

Screw anchors generally offer lower holding values compared to wedge anchors but shine in ease of removal and reusability. For example, a 1/2-inch screw anchor might hold up to 3,000 pounds in tension, whereas a wedge anchor of the same size can exceed 5,500 pounds, according to performance charts from FastenerE and Albany County Fasteners.

Environmental factors play a role; screw anchors with 410 stainless steel construction resist corrosion in outdoor applications, similar to 316 stainless steel wedge anchors from CONFAST®. However, in seismic zones, wedge anchors are favored for their non-removable, permanent hold, as supported by Reddit discussions on civil engineering forums citing ICC-ES reports.

Practical Applications and Cost Considerations

In residential projects, screw anchors are popular for quick fixes like mounting shelves, with installation times often under a minute per anchor. Wedge anchors, requiring more preparation, are better suited for commercial infrastructure, such as anchoring railings or HVAC units. Cost-wise, screw anchors can be 20-30% cheaper per unit, but wedge anchors provide long-term value through higher load capacities, as per comparative analyses from Factory Direct Supply.

The following chart depicts installation time and cost efficiency (estimated averages from SERP data):

| Anchor Type | Average Installation Time (minutes per anchor) | Cost per Unit (USD, for 1/2-inch diameter) | Best for Removability |

|---|---|---|---|

| Wedge Anchor | 5-7 | 1.50-2.00 | No |

| Sleeve Anchor | 4-6 | 1.20-1.80 | Limited |

| Screw Anchor | 2-3 | 0.80-1.20 | Yes |

This data underscores screw anchors’ efficiency for temporary or adjustable installations.

Factors Influencing Anchor Selection in Global Markets

Selecting between wedge, sleeve, and screw anchors depends on project-specific variables. In global contexts, considerations include concrete compressive strength, edge distance, and spacing. Industry guidelines recommend a minimum edge distance of five anchor diameters for wedge anchors to prevent concrete failure, as outlined in fastening specialists’ insights.

For international applications, such as in humid climates prevalent in Southeast Asia or corrosive coastal areas in Europe, stainless steel variants from Concrete Fastening Systems ensure longevity. Their CONFAST® 316 Stainless Steel Wedge Anchors, for instance, are engineered for saltwater environments, providing evidence-based resistance to chemical degradation.

Embedment Depth and Spacing Guidelines

Proper embedment is paramount. For wedge anchors, deeper embedment enhances holding power; a 3/4-inch anchor at 3-1/4 inches embedment can support over 10,000 pounds in shear, per CONFAST® specifications. Comparative studies show sleeve anchors require less depth but offer reduced strength, while screw anchors perform best at shallower embeds.

A visual representation of embedment impacts:

- Shallow Embedment (1-2 inches): Suitable for screw anchors; holding value ~2,000-3,000 lbs.

- Standard Embedment (2-4 inches): Optimal for wedge and sleeve; 4,000-6,000 lbs.

- Deep Embedment (4+ inches): Wedge anchors excel; up to 8,000+ lbs.

Spacing should be at least ten diameters apart to avoid overlapping stress cones, a fact corroborated by YouTube demonstrations from Fine Homebuilding and other channels.

Advantages and Limitations Across Anchor Types

Wedge anchors provide unmatched strength for permanent fixtures but are non-removable without concrete damage. Sleeve anchors offer versatility in base materials, ideal for mixed masonry, though with moderate loads. Screw anchors prioritize ease and removability, suitable for dynamic environments but limited in heavy-duty scenarios.

In terms of vibration resistance, wedge anchors lead, with failure rates under 5% in cyclic loading tests (per SERP-referenced engineering data). Globally, regulatory compliance, such as adherence to ASTM standards, ensures safety across types.

Case Studies and Real-World Evidence

A case from TikTok user @finehomebuilding illustrates wedge anchors securing structural elements in a basement renovation, achieving stability in solid concrete. Similarly, Reddit threads in civil engineering communities discuss wedge anchors’ efficacy in embedment-critical projects, with users reporting successful installations at depths exceeding minimums for enhanced safety.

Best Practices for Installation and Maintenance

For wedge anchors, use a hammer drill with carbide bits meeting ANSI standards, as advised by Concrete Fastening Systems. Torque values are crucial; over-torquing can cause spinning, reducing efficacy. Maintenance involves periodic inspections for corrosion, especially in outdoor settings.

Comparative installation torque table:

| Anchor Type | Diameter (inches) | Recommended Torque (ft-lbs) |

|---|---|---|

| Wedge Anchor | 1/2 | 55 |

| Sleeve Anchor | 1/2 | 40 |

| Screw Anchor | 1/2 | 30 |

These values, drawn from manufacturer guidelines, ensure secure fastening without base material compromise.

Future Trends in Concrete Anchoring Technology

Advancements in materials, such as hybrid anchors combining wedge and screw elements, are emerging. Global markets are seeing increased demand for eco-friendly, recyclable fasteners, with companies like Concrete Fastening Systems innovating in sustainable plating techniques.

Frequently Asked Questions (FAQs)

What is the primary difference between wedge anchors and sleeve anchors?

Wedge anchors expand at the base for superior hold in solid concrete, while sleeve anchors expand along their length, making them suitable for hollow materials.

How deep should a wedge anchor be embedded in concrete?

Minimum embedment varies by diameter; for a 1/2-inch wedge anchor, 2-1/4 inches is standard, but deeper embeds increase holding strength.

Can screw anchors be used in place of wedge anchors for heavy loads?

Screw anchors are removable and easier to install but offer lower holding values, making them unsuitable for loads exceeding 3,000 pounds in tension.

What materials are best for wedge anchors in corrosive environments?

316 stainless steel variants, like those from CONFAST®, provide excellent resistance in saltwater or chemical exposures.

How close to the edge of concrete can a wedge anchor be placed?

A minimum of five diameters from the edge is recommended to avoid cracking; for a 1/2-inch anchor, this is 2-1/2 inches.

Are wedge anchors removable?

No, wedge anchors are designed for permanent installation; removal typically requires cutting or damaging the concrete.

(Word count: 2403)

References and Citations

This article draws facts, evidence, and comparative data from various authoritative sources to ensure accuracy and reliability. Key references include installation guidelines and performance metrics from Concrete Fastening Systems’ articles on wedge anchor uses and tips (e.g., holding values and embedment depths). Comparative insights on sleeve vs. wedge anchors are informed by Brikksen and Factory Direct Supply blogs, while screw anchor data references Tapcon specifications. Video demonstrations from YouTube channels (e.g., https://www.youtube.com/watch?v=pO2OanmiFSY&t=8) and TikTok (https://www.tiktok.com/@finehomebuilding/video/7434693800947223851) provide practical evidence. Engineering discussions from Reddit (https://www.reddit.com/r/civilengineering/comments/90cqr2/wedge_anchor_embedment/) and fastening specialist sites (e.g., https://fasteningspecialists.com/how-deep-should-anchor-bolts-be-in-concrete/) support embedment and spacing facts. Product details from Tannerbolt.com (https://www.tannerbolt.com/anchors/mechanical-anchors/wedge-expansion-anchors) and The Fastener Factory (https://www.thefastenerfactory.co.za/anchor-type-fasteners) were used for material comparisons. Outbound links for further reading: Concrete Fastening Systems Wedge Anchors, Factory Direct Supply Guide, Brikksen Comparison.