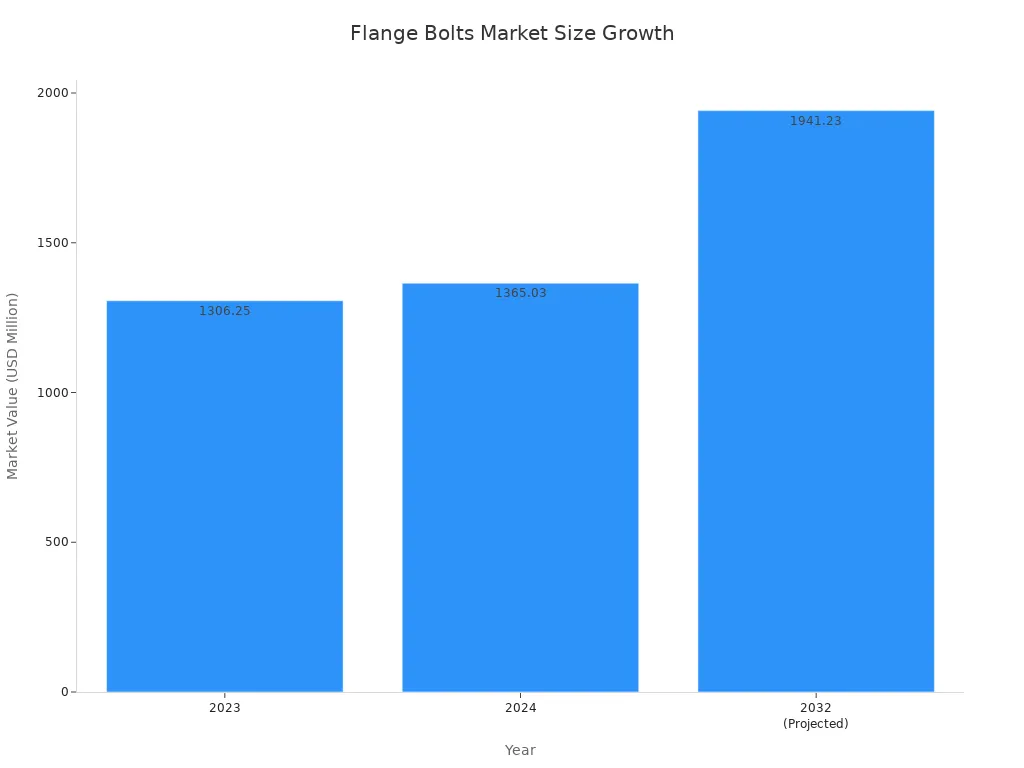

Critical industries, from Oil and Gas to manufacturing, rely heavily on the Flange Bolt for secure connections. This demand fuels a market projected for significant expansion.

Selecting the right partner is vital, whether for standard bolt casting or sourcing from a custom fasteners manufacturer. This guide reviews the top flange bolt suppliers to help you source quality custom fasteners.

- U.S. Bolt Manufacturing, Inc.

- Elgin Fastener Group (MW Components)

- Yijin Hardware Co., Ltd

- Norwood Screw Machine Parts (NSMP)

- Shanghai Hengrui Industry Co., Ltd

- Crest Industries

- Chicago Nut & Bolt, Inc.

- Monster Bolts

- EPCO

- ASMC (All-Spec Metal Corporation)

In-Depth Review of Top Flange Bolt Suppliers

Choosing a supplier requires a deeper look than a simple name-check. This section analyzes the capabilities, product offerings, and quality commitments of our top contenders to help you make an informed decision for your bulk purchasing needs.

U.S. Bolt Manufacturing, Inc.

Company Overview

U.S. Bolt Manufacturing, Inc. is a prominent Houston-based manufacturer specializing in bolts, nuts, and other fasteners. The company serves critical industries like Oil & Gas, Power Generation, and Infrastructure. It has built a strong reputation for producing high-quality, domestically made products with reliable turnaround times.

Key Strengths for Bulk Purchase

U.S. Bolt provides several key advantages for businesses placing large-volume orders. Their wholesale model is designed to support project budgets and timelines effectively.

- Reduced Costs: The company offers excellent pricing on wholesale bolts. This helps businesses manage expenses without sacrificing product quality.

- Low Minimum Orders: They provide flexible minimum order sizes. This feature allows customers to procure the precise quantity of fasteners needed for a specific job.

- Consistent Supply: Bulk purchasing from U.S. Bolt ensures a steady inventory of fasteners. This consistency prevents costly production delays caused by part shortages.

- Versatile Options: The supplier maintains a wide variety of bolt styles. Customers can choose from options like hex bolts and carriage bolts with plain or zinc-plated finishes for corrosion resistance.

Product Range and Materials

The company’s product catalog focuses on high-demand industrial fasteners. Their primary flange bolt offerings include:

- Hex Flange Bolts

- 12 Point Flange Screws (also known as Ferry Cap Screws)

U.S. Bolt manufactures these products from a range of standard carbon, alloy, and stainless steels. They also have the capability to work with more exotic materials for specialized applications.

Note: For specific material grades or custom alloy requirements, it is best to contact their sales team directly to discuss your project’s technical specifications.

Certifications and Quality Standards

U.S. Bolt Manufacturing adheres to stringent quality control protocols to ensure every part meets industry standards. The company operates an ISO 9001:2015 certified quality management system. This commitment to quality certifications ensures that their products deliver reliable performance in demanding environments.

Elgin Fastener Group (MW Components)

Company Overview

Elgin Fastener Group (EFG) is a division of MW Components, one of North America’s largest and most diversified manufacturers of specialty components. EFG combines the capabilities of several specialized fastener manufacturers. This structure gives them an immense domestic manufacturing footprint and a deep well of technical expertise.

Key Strengths for Bulk Purchase

EFG is an ideal partner for large-scale, complex, or ongoing supply needs. Their primary strengths lie in their scale and specialization.

- Extensive Manufacturing Network: Access to multiple manufacturing sites across the U.S. ensures production redundancy and massive capacity.

- One-Stop Sourcing: Their broad capabilities allow customers to source a wide range of fasteners and custom components from a single entity, simplifying procurement.

- Engineering Support: EFG provides in-depth engineering and design support for custom fastener development, making them a valuable partner for unique applications.

Product Range and Materials

As a comprehensive supplier, EFG offers a vast portfolio of standard and custom flange bolts. They produce parts from virtually any standard or exotic material, including:

- Carbon and Alloy Steels (e.g., Grade 5, Grade 8)

- Stainless Steels (e.g., 304, 316, 410)

- Nickel Alloys (e.g., Inconel®, Monel®)

- Brass, Bronze, and Aluminum

Their production capabilities cover a wide range of sizes, thread types, and head configurations to meet ASME, ASTM, and ISO standards.

Certifications and Quality Standards

Quality is a cornerstone of the MW Components philosophy. EFG facilities hold numerous certifications tailored to the industries they serve. These often include ISO 9001, AS9100 (for aerospace), and IATF 16949 (for automotive). Their rigorous testing and inspection processes guarantee that all parts meet or exceed customer specifications.

Yijin Hardware Co., Ltd

Company Overview

Yijin Hardware Co., Ltd is a leading international manufacturer of custom fasteners with over two decades of experience. Operating from a modern 25,000-square-meter facility, the company has a monthly production capacity of over 8 million parts. Yijin has established itself as one of the premier global flange bolt suppliers, serving clients in the automotive, electronics, and aerospace sectors.

Key Strengths for Bulk Purchase

Yijin Hardware offers a compelling value proposition for international bulk purchases, combining cost-effectiveness with robust manufacturing capabilities.

- Competitive Pricing: The company provides a highly competitive pricing structure for wholesale and bulk orders, enabling significant cost savings.

- Fast Turnaround Times: Efficient manufacturing processes and a dedicated team ensure quick order fulfillment, helping clients maintain project schedules.

- Extensive Customization: Yijin excels at creating tailored solutions for unique sizes, thread pitches, or material specifications.

- Decades of Experience: With over 20 years in the industry, their team offers valuable insights to help customers make informed decisions.

Product Range and Materials

Yijin specializes in producing non-standard and custom industrial fasteners according to client specifications. They can manufacture fasteners with diameters from 1mm to 50mm and lengths up to 2 meters. Their advanced cold heading techniques allow for the precise formation of complex parts from various materials, including stainless steel, carbon steel, brass, and aluminum.

Certifications and Quality Standards

Yijin Hardware demonstrates its commitment to global standards through its quality management systems. The company is certified to both ISO 9001:2015 and ISO 14001:2015. This dual certification ensures that their products not only meet stringent performance criteria but are also manufactured with environmental responsibility in mind.

Norwood Screw Machine Parts (NSMP)

Company Overview

Norwood Screw Machine Parts (NSMP) is a U.S.-based manufacturer with a legacy of precision engineering. The company specializes in producing custom screw machine products and CNC-turned parts. NSMP serves a diverse range of industries, including automotive, electronics, and medical. They have earned a reputation for high-quality, intricate components made to exact customer specifications.

Key Strengths for Bulk Purchase

NSMP offers distinct advantages for businesses needing custom, high-precision fasteners in large quantities. Their focus on tailored solutions sets them apart.

- Precision Customization: The company excels at manufacturing parts that meet unique and complex design requirements. This is ideal for non-standard flange bolt applications.

- Material Expertise: They possess deep knowledge in machining a wide array of materials, from common steels to challenging alloys.

- Domestic Production: All manufacturing occurs in the United States. This ensures high quality control, reliable communication, and shorter supply chains for North American clients.

- Scalable Production: NSMP has the capacity to handle both small prototype runs and large-scale production orders, offering flexibility as project needs evolve.

Product Range and Materials

NSMP’s production is primarily driven by customer blueprints. While they are not a stock supplier of standard flange bolts, they can manufacture them to any specification. Their capabilities include working with:

- Carbon and Alloy Steel

- Stainless Steel (300 and 400 series)

- Aluminum

- Brass and Copper

- Titanium

- Plastics and exotic alloys

💡 Tip: NSMP is an excellent choice when your project requires a flange bolt with unique dimensions, a proprietary head design, or is made from a non-standard material that off-the-shelf suppliers do not carry.

Certifications and Quality Standards

Quality is integral to NSMP’s manufacturing process. The company maintains a robust quality management system and is certified to ISO 9001:2015. This certification confirms their commitment to consistent production, process control, and continuous improvement, ensuring every bulk order meets the highest standards.

Shanghai Hengrui Industry Co., Ltd

Company Overview

Shanghai Hengrui Industry Co., Ltd is a major Chinese manufacturer and exporter of fasteners. With a focus on bolts, nuts, and washers, the company has established a significant global footprint. They serve customers in Europe, Asia, Africa, and North America. Their business model is built on large-scale production and adherence to international standards.

Key Strengths for Bulk Purchase

Shanghai Hengrui is one of the most competitive global flange bolt suppliers for high-volume orders, especially when cost is a primary driver. Their strengths are rooted in their massive production scale.

- Exceptional Production Capacity: The company can handle extremely large orders with impressive monthly outputs. This ensures they can meet the demands of large-scale projects.

| Product Type | Production Capacity |

|---|---|

| Non-Standard CNC Hex Flange Machining Bolts | 1000 Ton/Month |

| M5 Stainless Steel Serrated Flange Bolts | 5000 Ton/Month |

- Cost-Effectiveness: Their efficient manufacturing processes and economies of scale translate into highly competitive pricing for bulk purchases.

- Global Logistics: They have extensive experience in exporting products worldwide, managing shipping and documentation for a smooth procurement process.

The company operates on a clear principle that guides its customer interactions.

Shanghai Hengrui’s company policy prioritizes ‘Product quality > lead time > pricing‘. They welcome customers who share this belief to inquire.

Product Range and Materials

The company offers a comprehensive range of standard and semi-standard flange bolts. They produce parts conforming to DIN, ANSI, and ISO standards. Common materials include:

- Carbon Steel (Class 4.8, 8.8, 10.9, 12.9)

- Stainless Steel (A2-70, A4-80)

- Alloy Steel

They also provide various surface treatments, such as zinc plating, hot-dip galvanizing (HDG), and Dacromet finishes for enhanced corrosion resistance.

Certifications and Quality Standards

Shanghai Hengrui demonstrates its commitment to quality through internationally recognized certifications. The company is ISO 9001:2015 certified, ensuring a reliable quality management system is in place. They also hold a CE Certificate (EN 15048 & EN 14399), which is critical for construction products sold within the European Economic Area.

Crest Industries

Company Overview

Crest Industries is a vertically integrated family of companies providing goods and services to the electric utility, commercial, and industrial sectors. Their fastener division, a key part of the organization, operates as a full-line distributor and manufacturer. They leverage a massive inventory and a robust supply chain to serve customers across North America.

Key Strengths for Bulk Purchase

Crest Industries is a powerhouse for businesses that need a reliable, one-stop shop for a wide range of components. Their model is built on service and availability.

- Vast Inventory: They maintain an enormous stock of fasteners, including a wide variety of flange bolts. This allows for rapid fulfillment of large orders.

- Vendor-Managed Inventory (VMI): Crest offers sophisticated VMI programs. They manage inventory levels at the customer’s site, ensuring parts are always available and reducing the customer’s carrying costs.

- Integrated Supply Chain: As a multi-faceted company, they offer streamlined logistics, packaging, and delivery services, simplifying the procurement process from start to finish.

- Technical Support: Their experienced team provides valuable technical assistance, helping customers select the right fasteners for their specific applications.

Product Range and Materials

Crest Industries supplies a broad catalog of industrial fasteners. Their flange bolt offerings cover standard specifications used in construction and utility work. The product range includes:

- Standard Hex Flange Bolts

- Serrated Flange Bolts

- Materials such as Carbon Steel and Stainless Steel

- Finishes including Plain, Zinc Plated, and Hot-Dip Galvanized

Certifications and Quality Standards

Crest Industries places a strong emphasis on quality assurance to serve its critical infrastructure clients. Their quality management system is ISO 9001:2015 certified. This certification underscores their dedication to providing high-quality products and services, ensuring that all fasteners meet rigorous industry and customer requirements.

Chicago Nut & Bolt, Inc.

Company Overview

Chicago Nut & Bolt, Inc. is a well-established distributor of fasteners with a history dating back to 1989. Operating from a central location in the Midwest, the company serves a national customer base across various industries. They have built a reputation for reliability, extensive inventory, and responsive customer service.

Key Strengths for Bulk Purchase

The company’s model is optimized for businesses that require dependable access to a wide range of standard fasteners. Their strategic location and large stock provide significant advantages.

- Rapid Fulfillment: Their Chicago-based warehouse allows for fast shipping to most locations in the United States, reducing project lead times.

- Extensive Inventory: They maintain a deep stock of common and semi-specialty fasteners, ensuring high availability for bulk orders.

- Sourcing Expertise: The team excels at locating hard-to-find items, acting as a valuable procurement partner beyond their stocked inventory.

- No Minimum Order: They offer flexibility for purchases of all sizes, which is beneficial for customers needing to supplement a large order with smaller quantities of specific parts.

Product Range and Materials

Chicago Nut & Bolt supplies a comprehensive catalog of standard industrial fasteners. Their flange bolt offerings typically include serrated and non-serrated hex flange bolts. They stock these products in common materials and grades suitable for general construction and manufacturing.

💡 Tip: Chicago Nut & Bolt is an excellent resource when you need fast delivery of standard, domestically sourced flange bolts and other common fasteners for your project.

Certifications and Quality Standards

Chicago Nut & Bolt is committed to providing quality parts. The company implements a thorough quality control process to inspect incoming and outgoing products. While they primarily operate as a distributor, they source from manufacturers who adhere to recognized industry standards like ASTM and ASME, ensuring customers receive reliable components.

Monster Bolts

Company Overview

Monster Bolts is a modern, e-commerce-driven supplier of fasteners. The company focuses on providing a straightforward and accessible purchasing experience for individuals and businesses alike. They are known for their user-friendly website, clear pricing, and fast shipping on a wide range of common bolts, nuts, and screws.

Key Strengths for Bulk Purchase

Monster Bolts simplifies the procurement process, making it an ideal choice for businesses that value convenience and speed for standard bulk orders.

- Online Convenience: Their entire catalog is available online, allowing for easy browsing, price comparison, and ordering 24/7.

- Transparent Pricing: Bulk discounts are often clearly listed, removing the need for a lengthy quotation process for standard items.

- Fast Shipping: The company is structured for quick order processing and shipping, helping customers get parts on-site without delay.

- Broad Selection of Standard Parts: They carry a massive selection of everyday fasteners, making them a one-stop shop for many project needs.

Product Range and Materials

Monster Bolts offers a focused but deep inventory of the most frequently used flange bolts. Their product range is organized for easy selection, catering to both domestic and international specifications.

- Hex Cap / Hex Flange Bolts (US/Inch measurements)

- Hex Cap / Hex Flange Bolts (Metric measurements)

These bolts are typically available in popular materials like Grade 5 and Grade 8 alloy steel, as well as 18-8 stainless steel, with finishes such as black oxide and zinc plating.

Certifications and Quality Standards

Monster Bolts sources its products from reputable manufacturers that follow established quality guidelines. The company ensures that its fasteners meet the dimensional and material specifications required by industry standards. Customers can generally expect parts that conform to standard ASME/ANSI requirements for fit and function.

EPCO

Company Overview

EPCO (Electric Products Company) is a prominent industrial fastener supplier with a strong focus on customer service and inventory management. They position themselves as a supply chain partner, offering more than just parts. Their expertise and extensive product line make them a go-to source for businesses with complex or ongoing fastener needs.

Key Strengths for Bulk Purchase

EPCO provides personalized service plans, fast delivery, and quick response times. Their skilled sales staff assists customers in locating needed fasteners, ensuring on-time deliveries, and offering strong customer support. This focus on service is crucial for customers needing large quantities, as it ensures a consistent supply chain. Among other flange bolt suppliers, their dedication to partnership sets them apart.

Product Range and Materials

EPCO is an industrial fastener supplier that carries over 7,000 different parts in their fastener line, including a wide variety of flange bolts. They offer fasteners in both imperial and metric sizes. Their inventory includes a range of materials and coatings such as various alloys, stainless steel, and aluminum. This extensive stock demonstrates a strong capability to meet diverse customer needs, including those requiring specialized flange bolts for bulk orders.

Certifications and Quality Standards

Quality and reliability are central to EPCO’s business model. The company is ISO 9001:2015 certified, which validates its commitment to a robust quality management system. This certification ensures that all processes, from sourcing and inspection to packaging and delivery, are managed to a high standard, providing customers with confidence in every order.

ASMC (All-Spec Metal Corporation)

Company Overview

ASMC (All-Spec Metal Corporation) operates as a comprehensive distributor of specialty metals and industrial fasteners. The company has carved out a niche by providing a vast selection of materials and products from a single source. They serve a wide array of industries, including aerospace, defense, and manufacturing, with a focus on supplying both standard and hard-to-find items.

Key Strengths for Bulk Purchase

ASMC presents a strong case for businesses seeking a versatile and reliable supply chain partner. Their model is built around selection and service.

- Unmatched Material Selection: The company stocks an exceptionally broad range of metals and alloys. This gives customers immense flexibility when specifying materials for their flange bolts.

- Sourcing Expertise: ASMC excels at locating non-standard or exotic materials. This capability is invaluable for projects with unique performance requirements.

- Value-Added Services: They offer services like custom kitting and just-in-time (JIT) delivery. These options help customers streamline their assembly lines and manage inventory more effectively.

- One-Stop Procurement: Their extensive catalog allows businesses to consolidate purchases for various metals and fasteners, simplifying the procurement process.

Product Range and Materials

ASMC provides a wide variety of flange bolts to meet diverse engineering needs. Their primary advantage lies in the sheer breadth of materials they offer. Customers can source flange bolts made from numerous standard and specialty metals.

💡 Pro Tip: ASMC is an ideal supplier when your bill of materials includes flange bolts made from several different and specific metal alloys.

Their material options include:

- Stainless Steel (15-7, 18-8, 303, 304, 316, 410, 420)

- Grade 2 Low Carbon Steel

- Grade 5 Steel

- Grade 8 Steel

- 170 KSI / 12.9 Alloy Steel

- Metric Class 8.8 and 10.9 Steel

- Aluminum

- Brass

Certifications and Quality Standards

ASMC maintains a strong commitment to quality assurance, a critical factor for all reputable flange bolt suppliers. The company’s quality management system is certified to ISO 9001:2015. This certification ensures they have documented processes for sourcing, inspection, and traceability. For bulk purchasers, ASMC provides peace of mind by offering full material certifications and certificates of conformance upon request, verifying that every part meets the required specifications.

Quick Comparison of Leading Suppliers

Navigating the supplier landscape requires a clear understanding of each company’s core strengths. This quick comparison breaks down their specializations, material offerings, and quality commitments to simplify your selection process.

Supplier Specialization

Each supplier occupies a specific niche in the market. Understanding these specializations helps you align your purchasing needs with the right partner. Some focus on custom manufacturing, while others excel at large-scale distribution.

| Supplier Type | Key Characteristics | Example Companies |

|---|---|---|

| Custom Manufacturer | Excels at producing parts to specific blueprints; ideal for unique designs and materials. | Yijin Hardware, NSMP |

| Broadline Distributor | Maintains a vast inventory of standard parts for rapid fulfillment; often offers VMI. | Crest Industries, Chicago Nut & Bolt |

| Specialty Manufacturer | Focuses on high-performance or industry-specific fasteners (e.g., aerospace, oil & gas). | U.S. Bolt, Elgin Fastener Group |

| Global Producer | Offers massive production capacity and competitive pricing for high-volume orders. | Shanghai Hengrui |

| E-commerce Supplier | Provides a convenient online platform for purchasing standard fasteners with fast shipping. | Monster Bolts |

Available Material Options

The application and environment determine the material choice for industrial fasteners. Carbon steel offers a cost-effective solution but has limited corrosion resistance. Stainless steel provides excellent protection in marine or chemical settings. Bronze delivers strong corrosion and wear resistance for demanding jobs in industries like oil and gas.

Suppliers often specialize in certain material categories:

- Some, like ASMC, stock a massive range of metals, including various stainless steel grades (304L, 316L) and high-nickel alloys for corrosive environments.

- Others focus on carbon steel, alloy steel, and chrome-moly for high-temperature and high-pressure service.

- Specialty manufacturers may focus on precision-engineered flanges from specific stainless steel grades like 304L for controlled vacuum environments.

Key Industry Certifications

Certifications provide objective proof of a supplier’s commitment to quality and safety. While ISO 9001:2015 is a foundational standard for quality management, many suppliers hold additional certifications tailored to specific industries.

Pro Tip: Always request material test reports and certificates of conformance with your bulk order. Reputable suppliers readily provide documentation like EN 10204 3.1B to verify chemical and mechanical properties.

Look for suppliers who can provide parts compliant with standards relevant to your project, such as:

- API (American Petroleum Institute) for oil and gas applications.

- NACE (National Association of Corrosion Engineers) for materials in corrosive services.

- MIL-SPEC (Military Specification) for defense and aerospace projects.

- ASTM, ASME, and DIN for general engineering and construction requirements.

Suppliers like Shanghai Hengrui and Elgin Fastener Group often list these compliances to demonstrate their ability to serve critical sectors.

Best For (e.g., Price, Customization)

Selecting the ideal supplier often comes down to a project’s primary driver. Some projects prioritize cost-effectiveness for standard parts. Others demand intricate customization and specialized engineering. Understanding a supplier’s core strength helps businesses align their needs with the right partner, ensuring a successful procurement strategy.

The choice between a standard and a custom flange bolt involves clear trade-offs. Standard bolts offer immediate availability and lower costs from mass production. Custom bolts provide tailored engineering, specific materials, and optimized performance, though at a higher price and with longer lead times.

The following table breaks down these key differences:

| Feature | Standard Flanges | Custom Flanges |

|---|---|---|

| Cost-Effectiveness | More affordable due to mass production; ideal for tight budgets. | Higher costs due to customization and specialized materials. |

| Availability/Lead Time | Immediate availability; reduced lead times. | Longer lead times for manufacturing and delivery. |

| Engineering Solutions | Suitable for projects with standard specifications; interchangeable. | Tailored to specific dimensions and requirements; offers project-specific fit and material flexibility. |

| Reliability | Certified and tested; compliance certificates. | Increased reliability due to tailor-made solutions; fewer failures. |

| Support | N/A | Often includes engineering consultation for optimization. |

| Best For | Small-to-medium projects, immediate supply, standard needs. | High-spec industrial projects, harsh conditions, unique performance requirements. |

With these factors in mind, the top suppliers can be categorized by what they do best for bulk purchasers.

- Price and High-Volume Production: Shanghai Hengrui Industry Co., Ltd stands out for its massive production capacity and competitive global pricing. It is an excellent choice for large-scale projects where cost is a primary consideration.

- Precision Customization: Yijin Hardware and Norwood Screw Machine Parts (NSMP) excel at manufacturing flange bolts to exact customer blueprints. They are the go-to partners for unique designs or non-standard dimensions.

- Domestic Manufacturing & Specialty: U.S. Bolt Manufacturing and Elgin Fastener Group are leaders in producing high-quality, domestically made fasteners for critical industries like Oil & Gas and Aerospace.

- Speed and Broad Inventory: Crest Industries and Chicago Nut & Bolt operate as powerful distributors. Their vast inventories and efficient logistics make them ideal for rapid fulfillment of standard parts.

- Material Variety: ASMC (All-Spec Metal Corporation) offers an unparalleled range of metal alloys. It is the best choice when a project requires flange bolts made from multiple or exotic materials.

- Online Convenience: Monster Bolts provides a simple, e-commerce-driven experience. It is perfect for businesses that need a straightforward way to order standard fasteners online with fast shipping.

💡 Key Takeaway: Match your project’s most critical need—be it cost, speed, or a unique technical requirement—to a supplier’s specialization. This targeted approach streamlines the selection process and mitigates supply chain risks.

How to Choose the Right Supplier for Your Bulk Purchase

Selecting the right supplier is a systematic process. Following a structured approach ensures you partner with a company that meets your technical, operational, and commercial needs.

Step 1: Define Your Technical Requirements

A clear technical specification is the foundation of a successful bulk purchase. It eliminates ambiguity and guarantees you receive the correct parts.

Material and Grade Specifications

The material and grade determine a bolt’s strength and durability. Purchasers must specify these details precisely. Common options include:

- Grade 5 and Grade 8 Steel for high-strength applications.

- 18-8 Stainless Steel for general corrosion resistance.

- Plain finish or zinc-plated steel for different levels of protection.

Required Dimensional Standards

Every dimension matters for proper fit and function. A detailed specification sheet prevents errors.

| Feature | Example Specification |

|---|---|

| Diameter | 7/8″ |

| Thread Size | 9 TPI (Coarse) |

| Length | 8″ |

| Head Style | 12 Point Flange |

| Standard | ASTM A307 |

Coating and Finish Needs

Coatings protect bolts from corrosion. Hot-dip galvanizing offers superior, low-maintenance rust protection for outdoor use by applying a thick zinc layer. However, this process adds to the initial cost and lead time. In contrast, standard zinc plating is more affordable but less effective in harsh environments.

Performance in Environment

The operational environment dictates the ideal material and coating. A bolt used in a marine setting requires different specifications than one used in a dry, indoor application. Define the environmental challenges to select the right industrial fasteners for long-term performance.

Step 2: Evaluate Supplier Capabilities

Once you know what you need, you must verify that a supplier can deliver it.

Verify Certifications and Compliance

Reputable suppliers hold key certifications. An ISO 9001:2015 certificate demonstrates a commitment to quality management. Purchasers should also confirm the supplier can meet industry-specific standards like ASTM or API.

Assess Production Capacity

A supplier must have the capacity to fulfill large orders without sacrificing quality. Inquire about their monthly output and typical lead times for bulk quantities to avoid production bottlenecks.

Inquire About Customization

If your project requires non-standard parts, confirm the supplier offers custom manufacturing. Ask about their engineering support and capabilities for producing parts to your specific blueprints.

Check Quality Control Processes

A strong quality control (QC) process is non-negotiable. Ask potential suppliers about their inspection procedures, from raw material verification to final dimensional and mechanical testing.

Step 3: Analyze Commercial and Logistical Factors

The final step involves evaluating the business aspects of the partnership.

Request and Compare Bulk Quotes

Obtain detailed quotes from several shortlisted suppliers. Compare pricing, but also consider the value offered in terms of quality, support, and reliability.

Clarify Minimum Order Quantity (MOQ)

Suppliers often have a Minimum Order Quantity for bulk pricing. Ensure their MOQ aligns with your project’s scale and budget.

Confirm Lead Times and Shipping

Project timelines depend on reliable delivery. Get firm commitments on production lead times and shipping schedules to prevent costly delays.

Review Customer Support

Effective communication is key. A responsive and knowledgeable customer support team can resolve issues quickly and provide valuable technical assistance throughout the procurement process.

Distinguishing General vs. Specialty Bolt Suppliers

The fastener market includes two primary types of vendors: general distributors and specialty manufacturers. Understanding their distinct roles is crucial for making an effective procurement decision. One type focuses on volume and variety, while the other provides deep expertise and custom solutions. Choosing the right partner depends entirely on your project’s specific requirements.

What Defines Specialty Bolt Suppliers?

Specialty bolt suppliers are manufacturers, not just resellers. They focus on producing fasteners that are not readily available on the open market. These companies operate with specialized equipment for cutting, threading, and forging steel to create custom-engineered parts. They manufacture products in-house to meet precise customer specifications.

The table below highlights the key differences between these suppliers and general distributors.

| Feature | General Fastener Distributors | Specialty Flange Bolt Manufacturers |

|---|---|---|

| Primary Role | Buy and resell mass-produced fasteners. | Specialize in producing fasteners not readily available. |

| Product Type | Smaller, standard fasteners and construction supplies. | Large, nonstandard anchor bolts and custom fasteners. |

| Product Origin | Mostly imported; some from domestic companies. | Manufactured in-house; not mass-produced. |

| Availability | Stock items for repetitive sales. | Produce custom bolts to meet specific properties. |

| Services | Filling small orders and managing bolt bins. | Engineering and manufacturing custom fasteners. |

When to Choose a Specialist

Businesses should turn to specialty bolt suppliers when a project demands more than a standard, off-the-shelf part. These situations often involve unique engineering challenges.

💡 Key Scenarios:

- Projects requiring large-diameter or nonstandard anchor bolts.

- Applications needing fasteners with specific mechanical or chemical properties.

- Designs that call for custom head styles, thread lengths, or material grades.

In essence, if a standard bolt cannot meet the performance, size, or material requirements, specialty bolt suppliers provide the necessary engineering and manufacturing capabilities.

Benefits of Working with a Broadline Distributor

While specialty bolt suppliers fill a critical niche, broadline distributors offer compelling advantages for different needs. Their primary strength lies in inventory and logistics. These distributors maintain massive stock, often holding over 100,000 different part numbers for immediate fulfillment. This vast selection ensures high availability for standard parts.

Distributors excel at simplifying the supply chain. They offer value-added services like Vendor-Managed Inventory (VMI), which helps customers minimize on-site stock and boost productivity. Their expertise in global sourcing and logistics allows them to fulfill large orders efficiently. They can also tag and configure inventory to meet specific client needs, such as government specifications. For companies needing a reliable supply of standard components without the customization offered by specialty bolt suppliers, a broadline distributor is an excellent partner.

Selecting the right bulk supplier requires balancing technical specifications, quality assurance, and commercial viability. The 10 companies listed represent a strong market cross-section. A strategic partnership with the right supplier mitigates risk and ensures project success.

For example, positive outcomes include:

- An oil refinery reduced its downtime by 20% by upgrading flange bolt options.

- A manufacturing plant achieved a 30% decrease in assembly time with pre-tensioned bolts.

Choosing poorly, however, introduces significant financial risks, including supply chain disruptions and quality issues. Businesses should use the provided criteria to systematically vet potential partners and secure a reliable supply chain.

FAQ

What is a flange bolt?

A flange bolt is a one-piece fastener with a built-in washer, or flange, under its head. This design distributes clamping pressure over a wider surface area. It simplifies assembly by eliminating the need for a separate washer.

Why choose serrated flange bolts?

Serrated flange bolts feature ridges under the flange that grip the mating surface. This design provides excellent resistance against loosening from vibration. It creates a secure, locked connection, making them ideal for dynamic applications.

What does ISO 9001 certification mean for a supplier?

ISO 9001:2015 certification indicates a supplier has a documented and audited quality management system. It demonstrates a commitment to consistent production, process control, and customer satisfaction, ensuring reliable product quality for bulk orders.

How do I get a bulk purchase quote?

Purchasers should contact a supplier’s sales team directly. Providing detailed technical specifications is essential for an accurate quote.

Key details to include:

- Material and grade

- Dimensions (diameter, length, thread pitch)

- Required quantity

- Coating or finish

What is a Minimum Order Quantity (MOQ)?

A Minimum Order Quantity (MOQ) is the smallest number of units a supplier requires for a single purchase. Suppliers use MOQs for bulk pricing to ensure production runs are efficient and cost-effective.

Can I get material test reports with my order? 📄

Yes. Reputable suppliers provide Material Test Reports (MTRs) or Certificates of Conformance upon request. These documents verify the fastener’s chemical and mechanical properties, ensuring they meet the specified standards for your project.