Selecting the correct anchor is crucial for project safety and stability. Professionals choose wedge anchors for heavy-duty structural loads exclusively in solid concrete. Conversely, sleeve anchors provide versatility for medium-duty fastening in materials like concrete, brick, and block. The market for Anchor Bolts reflects this specialization, with different types serving specific needs. A custom fasteners manufacturer often produces both standard types and custom anchor bolts for unique requirements.

Industry Snapshot: Metal Anchor Market Share This data highlights the prevalence of various anchor types in construction.

| Anchor Type | Market Share |

|---|---|

| Wedge Anchors | 11.4% |

| Concrete Screws | 9.5% |

| Sleeve & Nail Anchors | 5.7% |

| Drop-in Anchors | 4.6% |

The Quick Answer: When to Use Each Anchor

Choosing the right anchor prevents project failure. The decision between wedge anchors and sleeve anchors depends entirely on the load requirements and the base material.

Use Wedge Anchors For…

Professionals select wedge anchors for the most demanding jobs where strength and permanence are non-negotiable. These fasteners are specialists, not generalists.

Heavy-Duty Structural Loads

Wedge anchors are engineered to handle substantial heavy loads. They are the standard for critical structural attachments, such as securing steel columns, support ledgers, and racking systems. Their design ensures a powerful grip for these critical applications.

Solid Concrete Only

The holding power of this anchor relies on solid, dense concrete. Installers must never use wedge anchors in softer or hollow materials like brick or cinder block. The expansion force can crack or destroy these weaker base materials, leading to a complete failure of the connection.

Permanent Installations

A wedge anchor provides a permanent structural connection. Once installed and torqued, it is not designed for removal. This makes it ideal for fixtures that will remain in place for the life of the building.

Securing Heavy Machinery

Industrial settings often require bolting down heavy equipment to concrete floors. The immense tensile and shear strength of wedge anchors makes them the only suitable choice for securing lathes, presses, and other large machinery that generate significant vibration and forces.

Use Sleeve Anchors For…

Sleeve anchors offer excellent versatility for a wide range of common projects. They provide reliable holding power in various materials where a wedge anchor would be inappropriate.

Medium-Duty Non-Structural Loads

Sleeve anchors excel in applications that do not involve primary structural support. Their capacity is suitable for many everyday needs. For example, some types like Molly Bolts handle loads of 25-50 lbs. Larger sleeve anchors offer significantly more strength.

| Anchor Bolt Type | Diameter (inches) | Tension Capacity (lbs) | Shear Capacity (lbs) |

|---|---|---|---|

| Sleeve Anchor | 1/2″ | 1,800 | 2,200 |

Note: Always consult manufacturer specifications and apply safety factors. The values above are for illustrative purposes in solid concrete.

Versatile Masonry Materials

The key benefit of this anchor is its adaptability. It functions effectively in solid concrete, brick, and hollow or grout-filled cinder block (CMU). The expanding sleeve provides a secure grip across a broad spectrum of masonry materials.

Removable or Temporary Fixtures

Unlike their permanent counterparts, sleeve anchors can be removed after use. An installer can unscrew the bolt or nut, which allows the fixture to be taken down. The sleeve itself may remain in the hole, but the attachment is not permanent.

Mounting Handrails and Shelving

Common projects like installing handrails, wall-mounted shelving, and window guards are perfect for sleeve anchors. They provide a strong, reliable hold for these medium-duty fixtures in concrete or brick walls.

Understanding the Mechanics: How They Grip

The effectiveness of an anchor depends on its mechanical design. Wedge anchors and sleeve anchors use distinct expansion methods to create a secure grip within masonry.

How Wedge Anchors Create a Secure Hold

Wedge anchors generate immense force through a simple but powerful mechanical action, making them specialists for solid concrete.

The Expansion Clip Mechanism

The anchor’s design creates a powerful wedge effect inside the concrete. The installation process follows a precise sequence:

- An installer places the anchor into a pre-drilled hole.

- Tightening the nut pulls the threaded anchor body upward.

- This upward motion forces the expansion clip down the tapered end of the anchor.

- The clip expands outward, wedging itself tightly between the anchor body and the concrete wall.

The Role of Torque and Friction

Applying the correct torque to the nut is critical. This rotational force creates the pulling action that expands the clip. The anchor’s holding power comes from the resulting friction and mechanical interlock. The clip’s teeth dig into the concrete, creating a powerful grip that resists pull-out forces.

Why They Need Solid Concrete

The intense, concentrated force from the expanding clip demands a solid, high-strength base material. This is why installers must only use wedge anchors in solid concrete. Using this anchor in softer or hollow materials like brick or block would cause the base material to crack and fail.

Load Transfer into the Concrete

A properly installed wedge anchor creates a secure attachment by effectively transferring loads. The force from the attached fixture travels down the anchor body and is distributed into the concrete through the expanded clip, ensuring a stable and permanent connection.

How Sleeve Anchors Adapt and Expand

Sleeve anchors offer greater versatility by using a different expansion method that is suitable for a wider range of materials.

360-Degree Sleeve Expansion

The design of sleeve anchors facilitates a full 360-degree contact area inside the hole. This feature ensures an even distribution of stress against the base material. This balanced pressure is crucial for its effective grip in various types of masonry, from solid concrete to hollow block.

Gripping in Hollow or Irregular Voids

The sleeve’s ability to expand along its entire length allows it to work in hollow materials. As the sleeve expands, it can bridge voids inside a cinder block or conform to slight irregularities in a drilled hole, providing a reliable grip where other anchors would fail.

How the Tapered Bolt Works

The expansion mechanism is straightforward. As an installer tightens the head of the bolt or nut, it pulls a tapered, cone-shaped expander plug up into the sleeve. This action forces the sleeve to flare outwards, pressing it firmly against the walls of the hole.

Performance in Softer Masonry

The even pressure from the 360-degree expansion makes sleeve anchors ideal for softer or more brittle masonry. The force is spread over a larger surface area, significantly reducing the risk of cracking or damaging brick or older concrete.

Comparative Analysis: Sleeve Anchors vs. Wedge Anchors

This comparative analysis explores the key differences and selection criteria between these two popular fasteners. A professional’s choice depends on a deep understanding of each anchor’s advantages and limitations. The primary factors are holding power and load capacity, followed closely by base material compatibility.

Holding Strength and Load Capacity

The most critical distinction between these anchors lies in their ability to handle weight. The load-bearing requirements of a project will immediately narrow the selection. Examining the holding power and load capacity reveals why each anchor has a specific role.

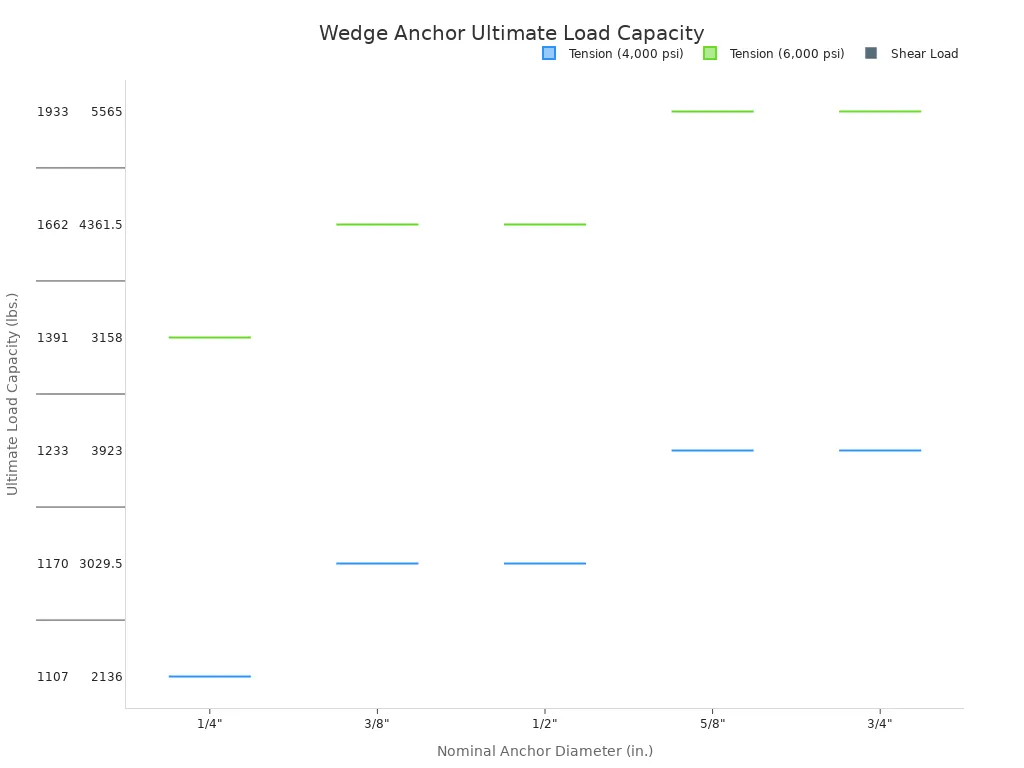

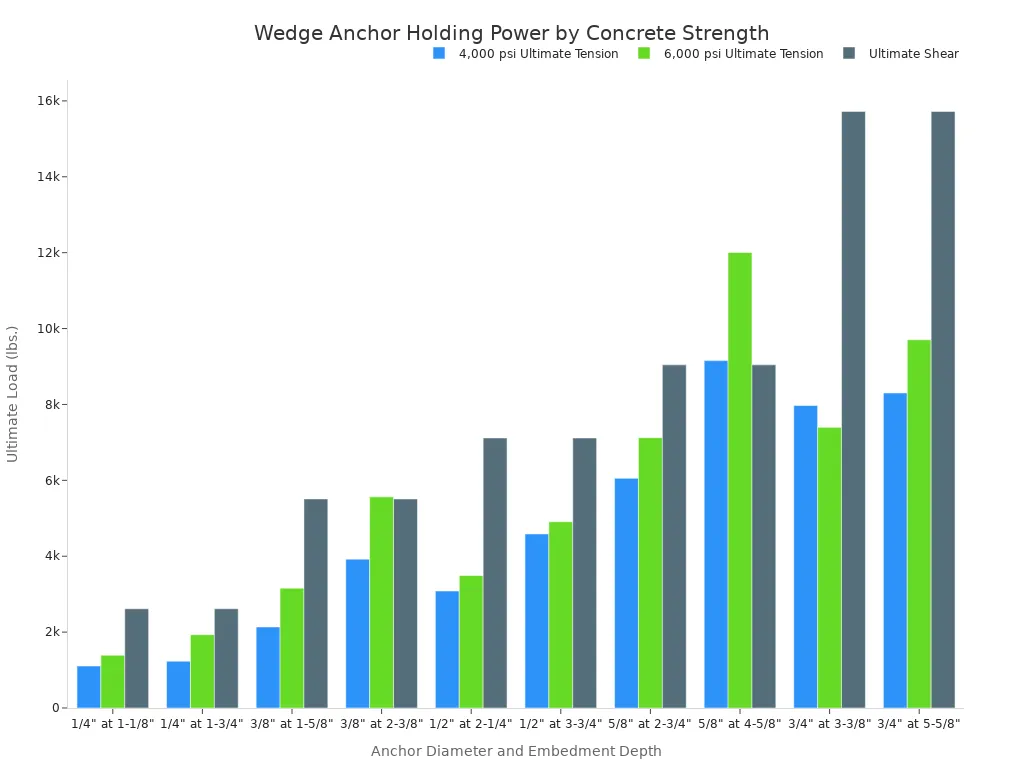

Wedge Anchor: Ultimate Tensile Strength

Wedge anchors provide the highest ultimate tensile and shear strength among common mechanical anchors. Their design is optimized for heavy structural applications where failure is not an option. The anchor’s performance is directly tied to its diameter and the strength of the concrete it is set in.

The following data illustrates the immense load capacity of wedge anchors in different concrete strengths.

| Nominal Anchor Diameter (in.) | Concrete Compressive Strength (psi) | Ultimate Tension Load Capacity (lbs.) | Ultimate Shear Load Capacity (lbs.) |

|---|---|---|---|

| 1/4″ | 4,000 | 1,107 – 1,233 | 2,615 |

| 3/8″ | 4,000 | 2,136 – 3,923 | 5,510 |

| 1/2″ | 4,000 | 3,084 – 4,587 | 7,116 |

| 5/8″ | 4,000 | 6,054 – 9,155 | 9,043 |

| 3/4″ | 4,000 | 7,971 – 8,304 | 15,723 |

Sleeve Anchor: Reliable Medium-Duty Performance

Sleeve anchors offer dependable performance for medium-duty applications. They are not intended for primary structural connections. Their holding power is more than sufficient for tasks like securing handrails, conduit, or shelving. The 360-degree expansion of the sleeve provides a consistent and reliable grip, but it cannot match the raw power of a wedge anchor’s focused expansion clip.

Understanding Shear vs. Tensile Loads

An anchor must resist two primary types of forces. Understanding these key differences is essential for proper selection.

- Tensile Load: This is a pull-out force that tries to pull the anchor straight out of the hole. Hanging a heavy object from the ceiling would apply a tensile load.

- Shear Load: This is a side-to-side force that acts perpendicular to the anchor. Attaching a ledger board to a wall creates a shear load.

An anchor’s capacity for each load type can be very different. For example, a 1/2″ wedge anchor might have an ultimate shear capacity of 7,116 lbs but a lower ultimate tension capacity of 4,587 lbs.

Applying Safety Factors

Manufacturers publish “ultimate” load values. These represent the point of failure in lab conditions. Professionals never design a connection to an anchor’s ultimate load.

Safety First: Always apply a safety factor. The industry standard is a 4:1 ratio. This means you should divide the ultimate load by four to determine the safe “working load.” For an anchor with an ultimate tension of 4,000 lbs, the safe working load is 1,000 lbs.

Base Material Compatibility

The material you are drilling into is just as important as the load you are fastening. The interaction between the anchor and the base material determines the success or failure of the installation.

Wedge Anchors: The Concrete Specialist

Wedge anchors are specialists. They are engineered for one material only: solid concrete. Their expansion mechanism generates immense, localized pressure. This requires a dense, strong substrate that can withstand these forces without cracking or spalling. They are the premier choice for any heavy-duty fastening into a solid concrete slab or wall.

Sleeve Anchors: The Masonry All-Rounder

Sleeve anchors are versatile generalists. Their gentle, 360-degree expansion mechanism makes them suitable for a wide range of masonry materials. Installers can confidently use them in:

- Solid Concrete

- Brick

- Hollow Cinder Block (CMU)

- Grout-Filled Block

This adaptability makes sleeve anchors a go-to solution for many commercial and residential projects where the base material is not solid concrete.

Why Wedge Anchors Fail in Brick and Block

Using a wedge anchor in brick or hollow block is a critical mistake that leads to connection failure. The intense point pressure from the expansion clip will overwhelm the weaker material. Common failure modes include:

- Masonry Breakout: The anchor pulls out a cone-shaped chunk of the brick or block.

- Brick Edge Failure: The expansion force cracks the face shell of a hollow block or the edge of a brick.

- Masonry Crushing: The material directly under the expansion clip is crushed, eliminating the anchor’s grip.

These failure modes demonstrate why the anchor’s force must be matched to the material’s strength.

Impact of Concrete PSI Strength

The compressive strength of concrete, measured in Pounds per Square Inch (PSI), directly affects an anchor’s holding power and load capacity. Stronger concrete provides a more robust base for the anchor to grip. As the data shows, increasing concrete strength from 4,000 PSI to 6,000 PSI significantly boosts the ultimate tension capacity of a wedge anchor.

Interestingly, shear capacity is often determined by the strength of the anchor’s steel bolt itself, not the concrete. This is why shear values may remain constant even when concrete PSI increases.

Key Differences in Design and Variation

Beyond holding power, the key differences in anchor design affect installation and application suitability. Both wedge anchors and sleeve anchors come in various types, head styles, and materials. Professionals select a specific variation to match the project’s unique demands for fixture thickness, finished appearance, and environmental exposure.

Common Types of Wedge Anchors

Wedge anchors are primarily differentiated by their threading. This design choice impacts the anchor’s versatility during installation.

Fully Threaded

A fully threaded wedge anchor has threads running along most of its body. This design provides maximum flexibility. Installers can use it for a wide range of fixture thicknesses. The nut can be threaded down to any point on the anchor body to secure the material.

Partially Threaded

A partially threaded wedge anchor has a smooth, unthreaded shank between the threads and the tapered end. This design is for applications requiring a specific embedment depth. The unthreaded portion ensures the anchor is set correctly without the threads interfering with the fixture.

Common Head Styles for Sleeve Anchors

Sleeve anchors offer a variety of head styles. This allows them to secure different types of fixtures while providing a specific finished look.

Hex Head

The hex head is the most common style. It allows for easy and secure tightening with a standard wrench or socket. This style is ideal for general-purpose fastening where the head will remain exposed.

Flat Head (Countersunk)

A flat head, or countersunk, style is designed to sit flush with the surface of the material. Installers use a Phillips or slotted driver to tighten it. This creates a clean, professional finish, making it perfect for installing signs, thresholds, and door frames.

Round Head

The round head provides a low-profile, finished appearance. It is often used for attaching fixtures where a smooth, non-snagging surface is desirable. A Phillips driver is typically used for installation.

Acorn Head

The acorn head features a high-crown, dome-shaped nut. This design offers a decorative finish and protects the threads from damage or corrosion. It is an excellent choice for applications where aesthetics are important, such as installing handrails or architectural elements.

Material and Coating Options

The material and coating of an anchor determine its durability and resistance to corrosion. Choosing the correct material is critical for the long-term safety and integrity of the connection.

Zinc-Plated Steel for Indoor Use

Zinc-plated steel is the standard, most economical option. The zinc coating provides a basic level of corrosion resistance. It is suitable only for dry, indoor environments where the anchor will not be exposed to moisture or corrosive elements.

Hot-Dipped Galvanized for Outdoor Use

Hot-dipped galvanized (HDG) anchors have a thick, protective layer of zinc. This coating offers substantial corrosion resistance for outdoor use in non-marine environments. The galvanizing process is governed by strict industry standards to ensure quality and performance.

Industry Standards for Galvanizing Professionals rely on established specifications to ensure coating quality. Key standards include:

- ASTM A153/A153M: This specification covers the hot-dip zinc coating on iron and steel hardware.

- AASHTO M 232M/M 232: This standard from the American Association of State Highway and Transportation Officials also governs zinc coatings for hardware.

Stainless Steel for Corrosive Environments

Stainless steel offers the highest level of corrosion protection. It is the required material for applications involving exposure to chemicals, salt water, or other highly corrosive agents. While more expensive, stainless steel ensures maximum longevity and safety in harsh conditions.

Installation Guide: Step-by-Step Instructions

Proper installation is just as critical as selecting the right fastener. Following the correct installation procedures ensures the anchor achieves its specified load capacity and provides a secure connection. A flawed installation process can compromise even the strongest anchor.

How to Install Wedge Anchors Correctly

The installation of wedge anchors demands precision. Each step is crucial for creating the immense holding power required for heavy-duty applications.

Step 1: Select the Right Carbide Bit

An installer must use a hammer drill and a carbide-tipped drill bit that meets ANSI standards. The diameter of the bit must match the diameter of the anchor.

Rule of Thumb: For a 1/2″ wedge anchor, use a 1/2″ carbide bit. There is no exception to this rule.

Step 2: Drill a Precise Hole

Drill a hole into the solid concrete to the specified depth. The hole must be at least 1/2″ deeper than the anchor’s required embedment. This extra space allows room for dust and debris that may settle at the bottom.

Step 3: Clean the Hole Thoroughly

Cleaning the hole is a non-negotiable step. An installer removes all concrete dust and debris using a wire brush and compressed air. This action ensures the expansion clip makes direct contact with the solid concrete, which is essential for achieving ultimate holding power.

Step 4: Drive and Torque the Anchor

Place the nut on the end of the anchor to protect the threads. Drive the anchor into the clean hole until the nut and washer are snug against the fixture. Use a torque wrench to tighten the nut to the manufacturer’s specified value. For proprietary post-installed anchors, it is necessary to refer to the manufacturer’s specific recommendations for torque values. For a 3/4″ wedge anchor, this value is often between 150 – 175 ft./lbs.

| Diameter (inches) | Torque (Ft/Lbs) |

|---|---|

| 1/4 | 5-10 |

| 5/16 | 5-10 |

How to Install Sleeve Anchors Properly

The installation procedures for sleeve anchors are more forgiving, reflecting their versatility across different masonry materials.

Step 1: Choose the Correct Bit Size

Select a carbide-tipped bit with a diameter that matches the sleeve anchor’s diameter. For example, a 3/8″ anchor requires a 3/8″ bit. Using a slightly larger bit, such as a 5/8″ bit for a 1/2″ anchor, can sometimes help with alignment.

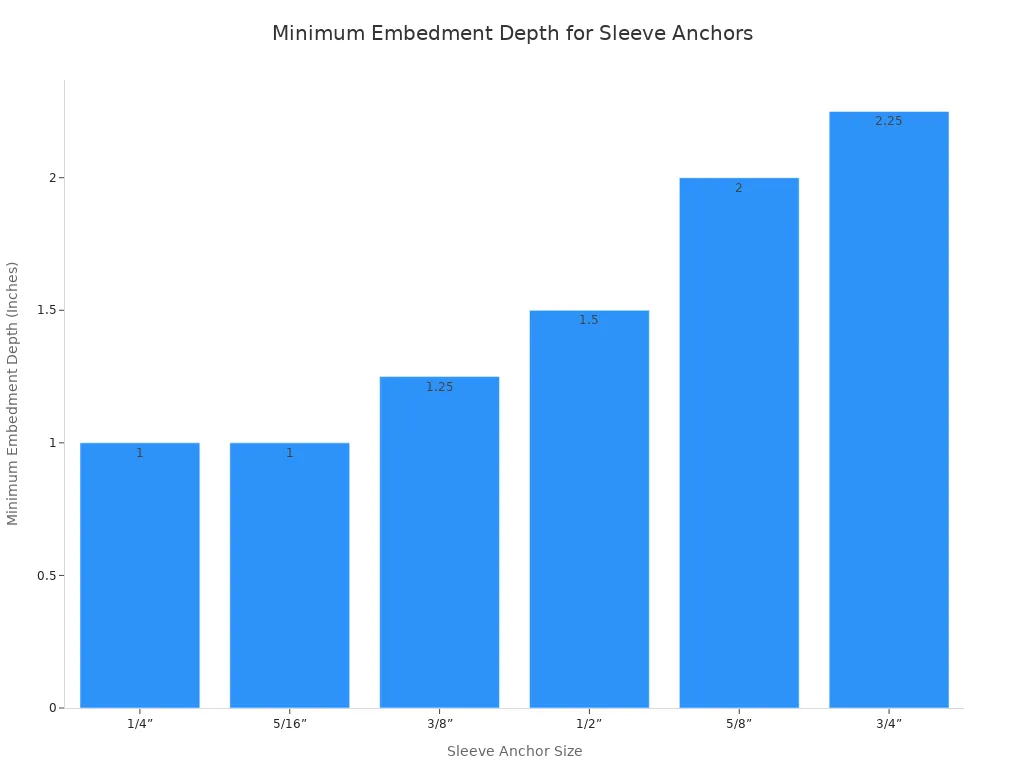

Step 2: Drill to the Required Depth

Drill a hole to the required minimum embedment depth. Professionals recommend drilling the hole at least 1/2″ deeper than the anchor’s embedment to accommodate any remaining dust. The hole depth should be at least the length of the anchor minus the thickness of the material being fastened.

| Sleeve Anchor Size | Recommended Drill Bit Diameter | Minimum Embedment Depth |

|---|---|---|

| 1/4” | 1/4” | 1/2” or 1” |

| 3/8” | 3/8” | 1-1/4” |

| 1/2” | 1/2” | 1-1/2” |

| 3/4” | 3/4” | 2-1/4” |

Step 3: Clean the Hole (Recommended)

While not as critical as with wedge anchors, cleaning the hole of excess debris is still a good practice. This ensures the sleeve can expand evenly against the walls of the base material.

Step 4: Insert and Tighten the Anchor

Insert the sleeve anchor through the fixture and into the pre-drilled hole. Tighten the head of the bolt or nut. This action pulls the cone-shaped expander into the sleeve, forcing it to expand and grip the base material securely.

Critical Installation Mistakes to Avoid

Even the best anchor can fail if installed incorrectly. An installer’s attention to detail is paramount for ensuring a safe and durable connection. Avoiding common errors is the key to unlocking an anchor’s full performance potential.

Common Errors with Wedge Anchors

Precision is mandatory when installing wedge anchors. Small mistakes can lead to significant failures due to the high forces involved.

Over-Torquing or Under-Torquing

Applying the correct torque is a critical final step. Over-torquing an expansion anchor can damage the concrete, the anchor itself, or the fixture being fastened. Conversely, under-tightening results in a loose connection. The item may rattle or become misaligned, as the anchor has not achieved its required tension. Adhering to manufacturer-specified torque values is essential for reliable performance.

Incorrect Hole Depth or Diameter

An installer must use a carbide bit with a diameter that exactly matches the anchor diameter. A hole that is too large will prevent the expansion clip from gripping. A hole that is too shallow will prevent the anchor from reaching its required embedment depth, severely compromising its load capacity.

Failure to Clean Debris from the Hole

Drilling creates a significant amount of concrete dust. If an installer fails to clean the hole thoroughly with a wire brush and compressed air, this debris will prevent the expansion clip from making solid contact with the concrete. This oversight dramatically reduces the anchor’s holding power.

Installing Too Close to an Edge

Wedge anchors exert immense outward pressure. Installing one too close to an unsupported edge or too near another anchor will cause the concrete to crack and fail.

Spacing and Edge Distance Rules Inadequate edge distance is a primary cause of anchor failure. Professionals follow strict guidelines:

- Minimum Spacing: Ten anchor diameters center-to-center.

- Minimum Edge Distance: Five anchor diameters from an unsupported edge. For a 1/2-inch anchor, this means a minimum spacing of 5 inches and an edge distance of 2.5 inches.

Common Errors with Sleeve Anchors

While more forgiving, sleeve anchors also have critical installation requirements that installers must respect.

Drilling a Hole That is Too Loose

The 360-degree expansion of a sleeve anchor requires a snug fit. If the drilled hole is too wide or becomes oblong, the sleeve cannot expand properly to grip the base material. This results in a spinning anchor that will never tighten.

Not Engaging the Threads Properly

An installer must tighten the bolt or nut sufficiently to pull the cone into the sleeve, causing expansion. If the threads are not engaged enough, the sleeve will not flare, and the anchor will provide little to no holding power.

Using in Weak or Crumbly Material

Sleeve anchors are versatile, but they have limits. Using them in very soft, old, or crumbly brick or block is a mistake. The base material must be solid enough to withstand the sleeve’s expansion pressure without crumbling away.

Underestimating Load Requirements

These fasteners are for medium-duty applications. An installer commits a serious error by using sleeve anchors for heavy structural loads that demand the strength of wedge anchors. Always match the anchor to the project’s specific weight demands.

Project-Specific Recommendations and Benefits

Applying theoretical knowledge to real-world scenarios clarifies the distinct advantages of each fastener. The choice of anchor directly impacts the safety and longevity of any installation. This section provides specific recommendations for common projects, highlighting the benefits of selecting the correct hardware for the job.

Best Anchor for Solid Concrete Projects

Solid concrete provides the ideal base for heavy-duty fastening. For these critical applications, the unparalleled strength of wedge anchors is the professional standard. The benefits of their use in this material are unmatched strength and permanence.

Securing Structural Beams

Installers must use wedge anchors for securing structural steel or wood beams to concrete footings or walls. These connections are fundamental to a building’s integrity. The immense tensile and shear capacity of a wedge anchor ensures it can handle these permanent, heavy structural loads without fail.

Anchoring Heavy Equipment

Industrial settings require machinery to be anchored securely. The benefits of using the right fastener include operator safety and equipment stability. Professionals choose wedge anchors for this task. Key considerations include:

- Understanding all forces the anchor must resist, including tensile, shear, and dynamic vibration.

- Applying correct safety factors and adhering to design codes like AISC or ASTM standards.

- Consulting a structural engineer for complex or high-risk installations.

While wedge anchors are a top choice, other heavy-duty fasteners for these critical applications include:

- ACME thread rods for systems requiring fine adjustments.

- Foundation bolts embedded directly into fresh concrete.

- Heavy hex bolts for high-stress industrial fastening.

Mounting a Workbench

A heavy-duty workbench in a garage or workshop must be completely stable. A professional secures the legs to the concrete floor using wedge anchors. This prevents any movement, rocking, or shifting, even under heavy hammering or vise work, providing significant safety benefits.

Installing Garage Lifts

Automotive lifts are a prime example of a heavy, dynamic load. The anchor connection must be flawless. Wedge anchors provide the necessary holding power to safely support the weight of a vehicle. Their performance in solid concrete offers peace of mind for such a high-stakes application.

Best Anchor for Brick Wall Projects

Brick requires an anchor that distributes pressure evenly to avoid cracking the material. Sleeve anchors are the superior choice for these applications, offering versatile and reliable performance.

Mounting Shelves or Cabinets

Sleeve anchors provide a secure hold in solid brick for medium-duty shelving and cabinets. Their 360-degree expansion distributes the load, a key feature for preventing pull-out. For a successful project, an installer should:

- Drill directly into the brick face, not the weaker mortar joints.

- Use a hammer drill with a proper masonry bit.

- Clean all dust from the hole before inserting the anchor.

Load Matching is Key Professionals match the anchor to the weight of the fixture. While sleeve anchors are excellent for many items, lighter or heavier loads may require different solutions. For items over 50 pounds, toggle bolts used in hollow walls or studs are often recommended.

Securing Window Guards

Window guards add a layer of security to a building. An installer uses sleeve anchors to attach the guard’s frame firmly to the surrounding brick facade. The anchor provides a strong connection that resists tampering or pull-out forces.

Attaching Conduit Straps

Electricians frequently run electrical conduit along the surface of brick walls. They use sleeve anchors to secure the conduit straps. This method is fast, reliable, and provides a sturdy hold for both interior and exterior applications.

Why Not to Use a Wedge Anchor in Brick

An installer must never use a wedge anchor in brick. The intense, focused pressure from its expansion clip will crack the brick, causing a catastrophic failure known as “breakout.” The material is simply not strong enough to handle the force, eliminating all benefits of the anchor.

Best Anchor for Cinder Block (CMU) Walls

Cinder block walls, whether hollow or grout-filled, present a unique challenge. The versatile design of sleeve anchors makes them the ideal solution for securing fixtures to CMU.

Mounting a TV

Mounting a heavy television onto a cinder block wall requires careful planning. A sleeve anchor provides a dependable grip in both hollow and solid block. An installer must:

- Select a TV mount rated for the television’s weight and size.

- Use a hammer drill with a sharp masonry bit.

- Verify VESA compatibility between the mount and the TV.

- Always use the correct type and number of anchors specified by the mount manufacturer.

Securing a Gate Hinge

A gate attached to a CMU wall post exerts significant dynamic shear and tensile loads. Using sleeve anchors to mount the hinges provides a robust connection. The sleeve’s broad expansion creates a stable base that can withstand the repeated stress of the gate opening and closing.

Anchoring Electrical Boxes

Attaching electrical junction boxes to a cinder block wall is a common task. Sleeve anchors offer a quick and secure method. The benefits include a flush mount and a solid connection that will not loosen over time.

Hollow vs. Grout-Filled Block Factors

The performance of a sleeve anchor changes depending on the type of block. Understanding this difference is crucial for ensuring a secure hold.

Sleeve anchors are mechanical expansion bolts for fastening to concrete, masonry, hollow block or grout-filled block.

In a grout-filled block, the anchor functions much like it does in solid concrete. In a hollow block, the mechanism adapts to grip the material differently, providing unique benefits.

| Feature | Hollow Cinder Block | Grout-Filled Cinder Block |

|---|---|---|

| Mechanism | Collapsing sleeve mechanism | Expansion forces and friction |

| Bearing Point | Bears against the back end of the face shell | Bears against the walls of the drilled hole |

| Function | Utilizes the collapsing sleeve to grip the face shell | Similar to other expansion anchors, creating friction |

Cost, Availability, and Removability

Beyond performance, practical factors like cost, availability, and removability are important considerations. These key differences can influence the final decision for a project, affecting both the budget and future flexibility.

A Look at the Costs

An installer must balance upfront expenses with long-term performance when selecting hardware. The initial cost of an anchor does not always reflect its total value.

Per-Unit Price Comparison

Generally, sleeve anchors have a lower per-unit cost than wedge anchors of a comparable size. This makes them an economical choice for medium-duty projects with numerous fastening points. The price difference becomes more significant when selecting specialized materials.

Long-Term Value vs. Upfront Cost

The choice between materials highlights the trade-off between initial cost and long-term value. Galvanized steel anchors offer an attractive upfront cost, often nearly half the price of stainless steel. However, stainless steel provides superior durability and rust protection. Its higher initial cost is often offset by minimal maintenance and a longer service life, especially in harsh environments. The lower upfront cost of a galvanized anchor may lead to future replacement expenses if its protective coating wears away.

| Characteristic | Stainless Steel | Galvanized Steel |

|---|---|---|

| Cost | Higher upfront but low maintenance | Cheaper initially but may require re-coating |

Where to Find Them

Both anchor types are readily accessible to professionals and DIY enthusiasts. Their widespread use ensures they are stocked by most hardware suppliers.

Availability of Wedge Anchors

Installers can find wedge anchors at any major home improvement store, electrical supply house, or industrial fastener distributor. They are a standard stock item for any retailer catering to concrete construction.

Availability of Sleeve Anchors

Sleeve anchors are equally common. Their versatility makes them a staple in hardware stores and building supply centers. A wide range of sizes and head styles is typically available on the shelf.

The Challenge of Anchor Removal

The ability to remove an anchor is a critical distinction. One type offers flexibility, while the other provides permanence.

How to Remove a Sleeve Anchor

An installer can remove sleeve anchors if a fixture needs to be relocated. The process requires some effort but is not destructive.

- Penetrating Oil: Spray a product like WD-40 to loosen any rust. An installer can then use a hammer and a strong bolt to tap the anchor’s cone back into the hole, releasing the sleeve’s grip for removal with pliers.

- Drilling: Use a cobalt drill bit slightly smaller than the sleeve to drill out the bolt. This weakens the sleeve, allowing it to be crumpled inward with a screwdriver and removed.

Why Wedge Anchors Are Permanent

Properly installed wedge anchors are not designed for removal. Their mechanism tightens further when pulled, making extraction nearly impossible without damaging the concrete. Attempting to forcibly remove the anchor will likely cause the base material to fail, pulling out a large, cone-shaped chunk of concrete. This destructive outcome confirms their role as a permanent fastening solution.

Professionals choose wedge anchors for maximum strength in solid concrete. A reliable solution for versatile, medium-duty work in brick or block is the sleeve anchor. The Construction Fixings Association (CFA) highlights that failures often stem from incorrect selection. Therefore, matching the anchor to the base material and load is the most critical step for a safe project. This correct choice ensures a durable and secure installation.

Case Study Insights: The CFA has documented instances of fixing failures, underscoring the real-world consequences of improper anchor use.

- CFA Case Study 1: Fixing Failures

- CFA Case Study 2: Fixing Failures

FAQ

Can an installer use a wedge anchor in brick?

No. An installer must never use a wedge anchor in brick or block. The anchor’s intense expansion force will crack the weaker masonry material. This causes a complete connection failure. Sleeve anchors are the correct choice for brick.

Which anchor is better for temporary installations?

Sleeve anchors are the better choice for temporary fixtures. An installer can remove the bolt or nut, allowing the fixture to be taken down. Wedge anchors create a permanent connection and are not designed for removal.

Do I really need to clean the drilled hole?

Yes, cleaning the hole is a critical step. An installer must remove all dust and debris, especially for wedge anchors. A clean hole ensures the anchor’s expansion mechanism makes direct contact with the base material, achieving its full holding power.

What happens if an anchor is installed too close to an edge?

Installing an anchor too close to an unsupported concrete edge is a serious error. The anchor’s expansion force can cause the concrete to crack and break away. This failure is known as “spalling” or “breakout” and compromises the entire installation.

Can a sleeve anchor be reused after removal?

Reusing a sleeve anchor is not recommended. While the bolt can be removed, the sleeve itself is often damaged or left behind in the hole during the removal process. For a new installation, professionals always use a new anchor assembly.

Why is concrete PSI important for wedge anchors?

Concrete’s compressive strength (PSI) directly impacts a wedge anchor’s performance. Higher PSI concrete provides a stronger, denser base. This allows the anchor’s expansion clip to grip more securely, significantly increasing its ultimate pull-out (tensile) load capacity.