Drop-in anchors are a top choice for medium-duty fastening into solid concrete, prized for their flush finish and reliability. A custom fasteners manufacturer can produce various types of Anchor Bolts, including custom anchor bolts.

However, these concrete drop-in anchors present specific challenges. They demand a special setting tool and are unsuitable for brick. The holding power of drop in anchors is highly dependent on proper installation, which can be tricky.

The Pros: Key Advantages of Using Drop-In Anchors

Installers and engineers choose drop-in anchors for several key benefits. These fasteners provide reliable performance and a professional finish when used in the correct applications. Their unique design offers advantages in workflow, aesthetics, and safety.

Pro 1: A Perfectly Flush and Clean Finish

One of the most significant advantages of these anchors is their ability to sit completely flush with the concrete surface. Once the anchor is set, nothing protrudes, creating a smooth and unobtrusive fastening point.

Ideal for Removable Fixtures

The internal threading allows users to remove a bolt and the attached fixture without disturbing the anchor itself. This makes the anchor ideal for applications involving temporary or interchangeable equipment. For example, workers can unbolt machinery for maintenance or replace shelving units while leaving the strong holding points in the concrete for re-installation.

Aesthetics and Safety

The flush-mount design delivers a clean, professional appearance. In exposed applications like mounting handrails or architectural signage, the anchor remains hidden from view. This preserves the visual integrity of the finished space.

Safety First 👷♂️ A recessed anchor fastener is crucial for enhancing overall safety. By eliminating protrusions, it helps create a safer environment in commercial buildings, workshops, and public areas.

Preventing Trip Hazards

On floors and walkways, protruding hardware can create dangerous trip hazards. Because concrete drop-in anchors are set below the surface, they are an excellent choice for securing floor-mounted items like machinery guards or guide rails. The flat surface ensures a safe path for foot traffic and rolling equipment.

Pro 2: Reliable Strength for Medium-Duty Loads

These anchors provide secure fastening solutions for a wide range of medium-duty static loads. Their expansion mechanism grips the inside of the drilled hole, creating a dependable connection once set correctly.

Understanding Load Capacities

The holding power of an anchor depends on its size, embedment depth, and the quality of the concrete. Manufacturers provide performance data that specifies the ultimate pull-out (tensile) and shear loads. It is critical for engineers to consult these tables and apply appropriate safety factors for their designs.

Typical Ultimate Load Values in 3,000 PSI Concrete

| Anchor Size | Ultimate Pull-Out (lbs) | Ultimate Shear (lbs) |

|---|---|---|

| 1/4″ | 1,990 | 1,760 |

| 3/8″ | 3,640 | 3,920 |

| 1/2″ | 5,480 | 6,880 |

Note: These are ultimate loads. Always apply safety factors as required by project specifications.

Common Applications: Struts, Trays, and Supports

The overhead fastening capability of drop-in anchors makes them a top choice for mechanical, electrical, and plumbing (MEP) contractors. Common uses include:

- Suspending HVAC ductwork and strut channels

- Hanging cable trays and electrical conduit

- Supporting fire sprinkler systems and pipe runs

- Mounting lighting fixtures and junction boxes

Material Compatibility with Solid Concrete

These anchors are engineered exclusively for use in solid, dense concrete. The anchor’s expansion mechanism requires a hard, non-porous base material to function correctly. They achieve their full strength in concrete slabs, columns, and walls, making them unsuitable for brick, block, or stone.

Pro 3: Pre-Installation Capability

The design of drop-in anchors allows them to be installed before the fixture is ready to be mounted. This feature offers significant workflow advantages on a busy job site.

Streamlining Project Workflow

Contractors can drill and set all the anchors for a project phase at one time. This “pre-setting” process separates the concrete work from the fixture installation. It allows different trades to work more efficiently without waiting on each other. For example, a concrete crew can set all anchors for pipe supports long before the plumbing crew arrives.

Setting Anchors in Batches

Batch installation improves consistency and saves time. An installer can move through an area, drilling all holes, cleaning them, and then setting each anchor with the proper tool. This repetitive, streamlined process reduces the chance of error compared to installing anchors one by one as fixtures are positioned.

Flexibility in Fixture Placement

With the anchors already in place, mounting the final fixture becomes a simple task of aligning it with the threaded holes and inserting the bolts. If a project timeline changes, the pre-set anchors remain ready in the concrete, offering flexibility without requiring rework.

Pro 4: Permanent and Tamper-Resistant

Once a drop-in anchor is set, it becomes a permanent part of the concrete structure. This permanence provides excellent security and long-term reliability, making it a superior choice for applications where fixtures should not be easily removed.

How the Anchor Achieves Permanence

The anchor’s permanence is a direct result of its mechanical expansion design. The installation process physically locks the anchor into the base material, creating an irreversible bond.

- An installer drills a hole to the specified diameter and depth.

- The installer inserts the anchor body into the clean hole until it is flush with the surface.

- A specific setting tool drives an internal plug downward, forcing the slotted anchor shell to expand.

Once the shell expands against the walls of the hole, the concrete drop-in anchors are permanently locked into place. The anchor cannot be removed without destroying the surrounding concrete. This creates a fixed, reliable threaded point for the life of the structure.

Security in Public and High-Traffic Spaces

The non-removable nature of the anchor body offers a high level of tamper resistance. Since the anchor itself cannot be extracted, it deters theft and vandalism of the mounted fixture.

A Secure Choice for Public Fixtures 🛡️ The flush finish and permanent installation make it difficult for unauthorized individuals to pry or tamper with the fastening point. This is a critical feature for maintaining safety and security in public spaces.

This makes them a preferred choice for securing fixtures in areas where tampering or theft is a concern:

- Benches, bike racks, and tables in public parks

- Security railings, fences, and air conditioning cages

- Public art installations and valuable plaques

- Fixtures in high-traffic areas like public bathroom stalls and cafeterias

Long-Term Structural Integrity

The permanent setting of drop-in anchors contributes directly to long-term structural integrity. Because the anchor becomes an integral part of the concrete, it resists loosening over time from minor building shifts or non-vibratory operational stresses. This reliability is essential for overhead applications like fire sprinkler systems, HVAC ducts, and cable trays, where a failed anchor could have severe consequences. Engineers and facility managers can trust that once properly installed, these drop-in anchors will maintain their holding power for years to come.

The Cons: Critical Disadvantages of Concrete Drop-In Anchors

While drop-in anchors offer distinct advantages, they also come with a rigid set of requirements and potential pitfalls. An installer must understand these drawbacks to prevent anchor failure, project delays, and safety hazards. The challenges center on specialized tooling, material limitations, and the precision required for installation.

Con 1: The Mandatory Setting Tool

Unlike many other fasteners, these anchors cannot be installed with standard tools. They require a specific, purpose-built tool to function correctly, which introduces several complications.

What is a Drop-In Anchor Setting Tool?

A drop-in anchor setting tool is a hardened steel punch designed for one job: to reliably set the anchor’s internal plug. Its shoulder is machined to rest perfectly on the top edge of the anchor body. This design ensures the setting force is applied directly and evenly to the internal plug. The anchor cannot be properly set with a screw or bolt, making this specialized tool an absolute necessity for the fast and reliable installation of drop-in anchors.

The Added Cost and Inconvenience 💸

The requirement for a special tool adds an extra layer of cost and planning. For a professional contractor, this means purchasing and tracking a set of tools for each anchor diameter. For a DIYer or someone tackling a small one-off project, it represents an inconvenient and often unexpected expense. The tool is not optional; without it, the project cannot proceed correctly.

The Risk of Using Improper Tools

Attempting to bypass the correct setting tool is a recipe for failure and a serious safety risk. Using a makeshift punch, a screwdriver, or a spare bolt can damage the anchor’s internal threads, making it impossible to insert the final fastener. Even worse, it introduces significant job site hazards.

Improvised or damaged tools can fail or break unexpectedly. An 8-pound tool falling from a height of 200 feet can strike with an impact force of 5,540 pounds.

The consequences of a dropped, improvised tool are severe. In the U.S. alone, OSHA records show that falling objects cause nearly 116 injuries every day. These incidents not only endanger people but also damage a company’s reputation, drain financial resources through legal battles, and hurt productivity.

Con 2: Strictly for Solid Concrete Only

The name “concrete drop-in anchors” is a literal description of their only suitable base material. Their expansion mechanism is engineered exclusively for solid, dense concrete and will fail in any other substrate.

Why They Fail in Hollow or Friable Materials

The anchor works by expanding its shell to press firmly against the walls of the drilled hole. This action creates immense outward pressure.

- In hollow materials, there is no solid surface to press against. The anchor will either fail to grip or break through the thin wall.

- In friable (crumbly) materials like old or low-quality concrete, the expansion force will crush the substrate instead of gripping it, resulting in almost no holding power.

Unsuitability for Brick and CMU 🧱

Installers must never use these anchors in brick or Concrete Masonry Units (CMU), also known as cinder blocks. These materials are often hollow, contain voids, or are joined by weaker mortar lines. The anchor’s expansion force can easily crack a brick or blow out the side of a CMU block, compromising the entire fastening point.

How to Verify Your Base Material

Before drilling, an installer should confirm the base material. A simple way to check is to drill a small test hole.

- Observe the dust: Solid concrete produces a fine, light-gray powder. Brick produces reddish or brown dust, and cinder block produces a coarse, dark-gray grit.

- Feel the resistance: Drilling into solid concrete provides consistent, hard resistance. Drilling into brick or block often involves sudden drops in resistance as the bit passes through voids.

Con 3: The High Risk of Improper Installation

The holding power of a drop-in anchor is entirely dependent on the installer’s ability to execute the installation process perfectly. Unlike a simple screw, there is very little margin for error.

The Danger of Under-Setting the Plug 💥

If an installer does not strike the setting tool with enough force, the internal plug will not travel far enough to fully expand the anchor shell. The anchor may feel snug, but it will not have achieved its rated load capacity. When a load is applied, an under-set anchor can easily pull out of the hole, leading to catastrophic failure of the fixture. This is a common mistake when an installer lacks the capability to perform a proper installation.

The Problem with Over-Setting and Concrete Damage

Conversely, excessive force can be just as damaging. Striking the setting tool too hard can drive the plug too deep, which can strip the anchor’s threads or even fracture the anchor shell. More critically, this immense force can create micro-fractures in the surrounding concrete, weakening the substrate and compromising the anchor’s long-term integrity.

Why Hole Preparation is Crucial

Common installation errors often begin before the anchor even enters the hole. Flawless hole preparation is non-negotiable.

- Incorrect Hole Size: A worn drill bit can create a hole that is too small, preventing the anchor from being inserted to the correct depth. A hole that is too large will not allow the anchor to expand and grip the concrete.

- Incorrect Hole Depth: A hole that is too shallow will leave the anchor protruding, defeating its flush-mount benefit. A hole that is too deep can allow the anchor to fall in, making it impossible to set.

- Failure to Clean the Hole: This is one of the most critical and overlooked steps. Dust and debris left in the hole act as a cushion, preventing the anchor from making full contact with the concrete. This severely reduces its holding power. The hole must be thoroughly cleaned with a wire brush and compressed air or a vacuum.

Con 4: The Anchor Body is Not Removable

The permanence of a drop-in anchor is a double-edged sword. While it provides security, the inability to remove the anchor body creates significant long-term challenges and irreversible changes to the concrete substrate.

Differentiating the Removable Bolt and Permanent Anchor

A common misunderstanding surrounds the removability of concrete drop-in anchors. An installer can easily unthread and remove the machine bolt or threaded rod from the anchor. This allows for the removal of the attached fixture for maintenance or replacement. However, the anchor body itself remains permanently expanded within the concrete. Once set, there is no practical way to extract the anchor shell without causing significant damage to the surrounding base material.

The Challenge of “Dead Holes” in Concrete

When an anchor is abandoned or a fixture is permanently removed, its removal leaves behind a “dead hole.” These voids are more than just cosmetic flaws; they can compromise the structural integrity of the concrete surface.

These abandoned holes present a complex problem for future installations. Engineers must consider the effects of these voids on newly installed fasteners, particularly when using different anchor types. Laboratory tests have provided crucial guidelines for design professionals, showing that a nearby abandoned hole can negatively impact the performance of a new anchor. This requires careful assessment and design adjustments to account for these imperfect field conditions.

Caution ⚠️ Drilling a new hole too close to an abandoned one without proper remediation can significantly reduce the new anchor’s load capacity, creating a potential safety hazard.

A primary challenge is determining the minimum safe distance to drill a new hole without affecting its pull-out or shear strength. Research has explored this very issue, including methods to reinforce an abandoned hole. Filling the void with high-strength materials like non-shrink grout or drypack mortar can help restore structural integrity, which is critical if a new hole must be drilled closer than the ideal minimum distance.

Planning for Future Layout Changes

The issue of dead holes forces project managers and facility owners to plan far into the future. This limitation makes drop-in anchors a poor choice for applications requiring frequent or anticipated layout changes.

Consider a manufacturing plant or workshop that may need to rearrange its machinery layout in a few years. The old anchor points become permanent, useless voids in the floor, complicating the new installation and creating potential weak spots. Planners must commit to a fixture’s location for the long term when selecting these permanent drop-in anchors. If flexibility is a priority, alternative removable anchors should be considered.

Technical Specifications and Performance Factors

Selecting the correct anchor requires a deep understanding of its technical specifications. These factors dictate how the anchor will perform under specific loads and in different environments. Engineers and installers must review manufacturer data sheets to ensure safety and reliability.

Understanding Load Types

An anchor’s strength is measured against two primary forces: tensile and shear loads. The type of load an application will exert is a critical factor in anchor selection.

Tensile vs. Shear Loads

Technicians measure an anchor’s performance against different forces. A tensile load, or pull-out force, acts parallel to the anchor, trying to pull it straight out of the concrete. A shear load acts perpendicular to the anchor, trying to cut it off. Manufacturers determine these capacities through rigorous testing.

Testing Methods ⚙️ A ‘Pull Out Test’ uses a hydraulic system to measure the ultimate tensile strength. A ‘Shearing Test’ applies a perpendicular force to find the shear capacity. These tests verify an anchor’s load-carrying ability.

Not Recommended for Vibratory or Shock Loads

Standard concrete drop-in anchors are designed for static loads, which are constant and unchanging. They are not suitable for applications involving dynamic forces like vibration or sudden shocks. Vibratory loads, such as those from heavy machinery, can cause the anchor’s expansion mechanism to loosen over time, leading to failure.

Material Composition and Finishes

The anchor’s material determines its resistance to corrosion and its suitability for different environments. Choosing the right finish is essential for long-term performance.

Zinc-Plated Carbon Steel for Dry, Indoor Use

The most common and affordable option is the zinc-plated carbon steel anchor. The zinc plating provides a moderate level of corrosion resistance. This makes it an excellent choice for dry, indoor environments where the anchor will not be exposed to moisture or corrosive elements.

304/316 Stainless Steel for Corrosive Environments

For more demanding conditions, stainless steel is the superior choice.

- 304 Stainless Steel offers excellent protection in high-moisture or corrosive settings, such as outdoor applications or damp basements.

- 316 Stainless Steel provides the highest level of corrosion resistance. It is specified for harsh environments with exposure to chemicals or saltwater, like coastal areas and industrial plants.

Environmental and Spacing Considerations

The condition of the concrete and the anchor’s placement within it significantly impact holding power. Installers must adhere to strict spacing guidelines to prevent anchor failure.

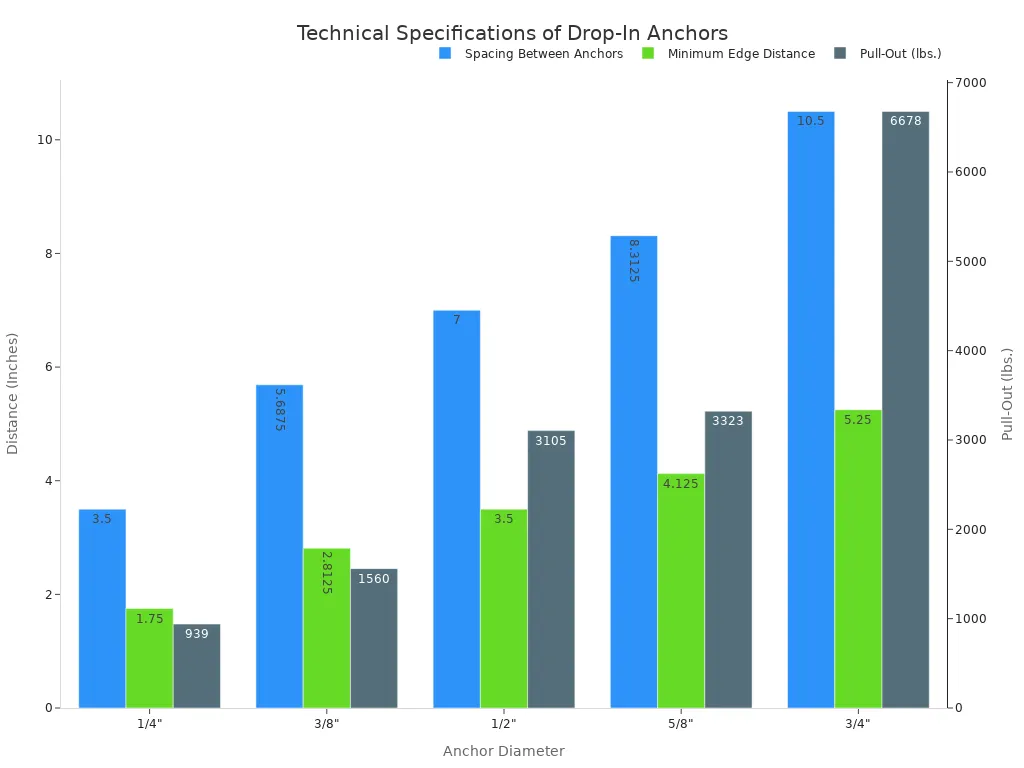

Minimum Edge and Spacing Distances

Anchors installed too close to each other or to an unsupported concrete edge can fail. The expansion force from one anchor can weaken the concrete around a neighboring anchor. Manufacturers specify minimum edge and spacing distances to prevent this.

| Anchor Diameter | Spacing Between Anchors | Minimum Edge Distance |

|---|---|---|

| 1/4″ | 3-1/2″ | 1-3/4″ |

| 3/8″ | 5-11/16″ | 2-13/16″ |

| 1/2″ | 7″ | 3-1/2″ |

Performance in Cracked vs. Uncracked Concrete

Concrete under tension can develop fine cracks. Standard anchors perform well in uncracked concrete but lose significant holding power in cracked concrete. If a crack forms near an anchor, the hole effectively widens, reducing the anchor’s grip. Anchors designed for cracked concrete have a “follow-up expansion” capability to compensate for this, but standard drop-in anchors do not.

A Deeper Dive: Installation and Best Practices for Drop-In Anchors

Proper installation is not just a recommendation; it is the only way to guarantee the safety and performance of concrete drop-in anchors. Following a precise procedure and understanding common pitfalls are essential for a successful and secure fastening.

Step-by-Step Installation Guide

A successful installation follows four non-negotiable steps. Executing each one correctly ensures the anchor achieves its full rated load capacity.

Step 1: Drilling the Hole to Spec

An installer uses a carbide-tipped masonry drill bit matching the anchor’s specified diameter. The hole must be drilled to the correct minimum depth, ensuring the anchor will sit flush or slightly below the concrete surface.

Step 2: Cleaning the Hole Thoroughly

After drilling, the installer must remove all dust and debris. This is typically done with a wire brush to loosen particles, followed by compressed air or a high-powered vacuum to clear the hole completely.

Step 3: Setting the Anchor with the Correct Tool

The installer drops the anchor into the clean hole. Then, they insert the corresponding setting tool and strike it firmly with a hammer until the tool’s shoulder meets the top of the anchor. This action drives the internal plug down, fully expanding the anchor.

Step 4: Threading and Tightening the Bolt

With the anchor set, the installer can position the fixture. They then thread the correct-sized machine bolt or threaded rod into the anchor and tighten it to the specified torque.

Common Installation Mistakes to Avoid

Several frequent errors can lead to anchor failure. Installers must be vigilant to avoid these common issues.

Incorrect Hole Depth or Diameter

Using a worn drill bit can result in an undersized hole, preventing the anchor from being inserted properly. A hole that is too shallow leaves the anchor protruding, while one that is too deep can cause the anchor to be lost.

Insufficient Hole Cleaning

Critical Warning ⚠️ Failure to clean the hole is a primary cause of anchor failure. Compacted dust at the bottom of the hole prevents the anchor from being fully seated and expanding correctly, severely reducing its holding power.

Misjudging the Setting Force

Under-setting an anchor by not hitting the tool hard enough results in partial expansion and a drastically reduced load capacity. Conversely, over-setting it with excessive force can damage the anchor’s threads or fracture the surrounding concrete.

Bolt Spinning: Causes and Prevention

A spinning bolt is a clear sign of a failed installation. This happens when the anchor body is not set firmly enough to grip the concrete. The cause is rarely over-torquing; it is almost always an improperly set anchor where the wedge did not expand. To prevent this, installers must ensure the anchor is fully set before attempting to tighten the bolt.

Comparing Drop-In Anchors to Alternatives

Choosing the right anchor depends on the specific application. Drop-in anchors excel in certain scenarios but are less suitable in others.

Drop-In Anchors vs. Wedge Anchors

Wedge anchors are a heavy-duty alternative. An installer inserts them through a fixture, and tightening an external nut pulls a clip up, expanding the anchor. They offer exceptional strength for structural columns and heavy machinery but protrude from the surface. Drop-ins are better for medium-duty loads where a flush finish is required.

Drop-In Anchors vs. Sleeve Anchors

Sleeve anchors are more versatile for different base materials. Their long expansion sleeve makes them suitable for weaker substrates like brick and block, where a drop-in would fail. However, they offer lower holding power in solid concrete compared to other anchor types.

Drop-In Anchors vs. Concrete Screw Anchors

Concrete screws offer speed and removability. An installer drives them directly into a pilot hole, and they cut their own threads. They require no setting tool and are easily removed, making them ideal for temporary fixtures. However, they provide a less clean finish and are generally for light to medium-duty applications.

Summary: When to Use (and Not Use) Drop-In Anchors

Choosing the right fastener is critical for project safety and success. This summary provides a clear guide to help installers and project managers decide when concrete drop-in anchors are the best choice and when an alternative is necessary.

Quick-Reference Checklist

Use this simple checklist to determine if a drop-in anchor fits your application’s requirements.

Use Drop-In Anchors For…

- Fastening into solid concrete exclusively.

- Applications requiring a perfectly flush and clean surface finish.

- Securing medium-duty static loads, like overhead pipes or cable trays.

- Permanent installations where the anchor body will not need to be removed.

- Projects where you have the correct specialized setting tool.

Avoid Drop-In Anchors For…

- Any base material other than solid concrete, such as brick, block, or stone.

- Fixtures subject to heavy vibration or shock loads.

- Temporary installations or areas where layouts may change.

- Projects where you cannot guarantee perfect hole cleaning and preparation.

- Fastening close to an unsupported concrete edge without consulting spacing guidelines.

Real-World Project Scenarios

Understanding practical examples helps illustrate the correct and incorrect uses of these fasteners.

Ideal Use Case: Overhead Pipe and Strut Support

An electrical contractor needs to suspend threaded rods from a concrete ceiling to support heavy cable trays. They choose drop-in anchors because the flush finish creates a clean look. The anchors provide reliable strength for the static overhead load. The contractor can also pre-install all the anchors at once, streamlining the workflow before hanging the strut channels.

Good Use Case: Mounting Machinery to a Concrete Floor

A workshop manager needs to secure a new piece of stationary equipment to the concrete floor. The anchor’s ability to sit flush prevents a trip hazard. The bolt can be removed for machine maintenance, while the anchor body remains permanently in the floor. This is a good use, but the manager must be certain the machine’s location is permanent, as the anchor cannot be removed later.

Caution ⚠️ This application is only suitable for machinery that does not produce significant vibration. Dynamic loads can cause the anchor to loosen over time.

Incorrect Use Case: Attaching Railings to a Brick Patio

A homeowner wants to install a new safety railing on their brick paver patio. Using this type of anchor here would be a critical mistake. The expansion force would crack the bricks or fail in the weak mortar joints. The anchor would have almost no holding power, creating a severe safety hazard. A sleeve anchor would be a much more appropriate choice for this base material.

The decision to use drop-in anchors involves a clear trade-off. An installer gains a clean, permanent, medium-duty fastener for solid concrete. This benefit, however, requires a special setting tool and a precise installation process.

Final Verdict ⚖️ These anchors are an excellent choice for projects in solid concrete needing a flush finish. Success depends on using the correct ANSI-standard carbide bit and understanding the procedure. For other materials like brick, or for temporary needs, installers should consider alternatives like wedge or sleeve anchors.

FAQ

What happens if an installer loses the setting tool?

An installer must acquire the correct setting tool for the specific anchor size. Attempting to use a substitute like a bolt or punch will damage the anchor’s threads and lead to an unsafe installation. The anchor cannot function without its designated tool.

Can an installer reuse a drop-in anchor?

No, the anchor body is a permanent fastener. Once set, it cannot be removed without destroying the surrounding concrete. An installer can only remove and reuse the machine bolt or threaded rod that is screwed into the anchor.

How does an installer know the anchor is set correctly?

A properly set anchor provides clear feedback. The shoulder of the setting tool will make solid contact with the top of the anchor body. The installer will feel a distinct change in resistance, indicating the internal plug is fully driven.

What is the main difference between a drop-in and a wedge anchor?

Key Distinction 💡 Drop-in anchors sit flush with the concrete for a clean finish in medium-duty jobs. Wedge anchors protrude from the surface but provide superior strength for heavy-duty structural applications.

Why is cleaning the drilled hole so important?

Concrete dust and debris prevent the anchor from expanding properly. This cushion-like effect severely reduces the anchor’s grip and holding power. A clean hole is essential for a safe and reliable installation, preventing potential anchor failure under load.

Are drop-in anchors suitable for ceiling installations?

Yes, they are an excellent choice for overhead applications in solid concrete ceilings. Contractors frequently use them to suspend threaded rods for supporting:

- HVAC ductwork

- Cable trays and conduit

- Fire sprinkler systems

What should an installer do with an abandoned anchor hole?

An installer should fill “dead holes” with a high-strength, non-shrink grout or epoxy. This process restores the concrete’s structural integrity. It also prevents the void from creating a weak spot that could compromise a new, nearby anchor installation.