An installer’s expertise is crucial for structural integrity. The concrete anchors and fasteners market, valued at USD 2.86 Billion in 2022, is projected to reach USD 11.93 Billion by 2030. This growth highlights the importance of correct installation, as research shows nearly 30% of construction failures stem from improper anchor bolt installations. A skilled custom fasteners manufacturer can produce reliable custom anchor bolts, but the final security depends on the installer. To correctly install wedge anchor, one must follow a precise five-step process.

- Drill a hole to the correct diameter and depth.

- Clean the hole of all debris.

- Insert the wedge anchor through the fixture and into the hole.

- Tap the anchor into place.

- Tighten the nut to the required torque to set the anchor.

Tools and Materials for Installing a Wedge Anchor

Proper preparation is the foundation of a secure installation. An installer must gather the correct tools and select the appropriate wedge anchor for the job. This ensures both safety and structural integrity.

Essential Installation Tools

Having the right equipment on hand streamlines the process. It prevents delays and guarantees each step is performed to professional standards.

Power and Hand Tools

An installer needs a specific set of tools to drill the hole and set the anchor. The primary power tool is a hammer drill. It provides the necessary impact and rotation to bore into concrete efficiently.

- Hammer Drill: This power tool is essential for drilling into hard materials like concrete.

- Carbide-Tipped Masonry Drill Bit: The bit must meet ANSI standards and match the diameter of the anchor.

- Hammer: A standard hammer is used to tap the anchor into the hole.

- Torque Wrench: This precision tool is critical for tightening the nut to the manufacturer’s exact specification, ensuring the anchor sets correctly.

Hole Cleaning Tools

A clean hole is non-negotiable for a strong hold. Debris can prevent the anchor from setting properly and reduce its load capacity. Installers use simple but effective tools for this task. These include a wire brush to scrub the interior walls of the hole and a blow-out bulb or compressed air to remove all loose dust and particles.

Measurement and Safety Gear

Safety and accuracy are paramount when working with concrete. A tape measure is necessary for marking anchor locations and verifying hole depth. Personal Protective Equipment (PPE) is also mandatory.

OSHA Safety Alert: Regulations require that all work areas are inspected for embedded utilities before drilling. To manage silica dust, installers must use a dust collection system, a fit-tested dust mask (APF 10 or higher), and a HEPA-filter-equipped vacuum for cleanup.

Choosing the Right Wedge Anchors in Concrete

The selection of the anchor itself is just as important as the tools used. Factors like diameter, length, and material composition directly impact the performance and longevity of the anchors.

Understanding Anchor Diameter and Length

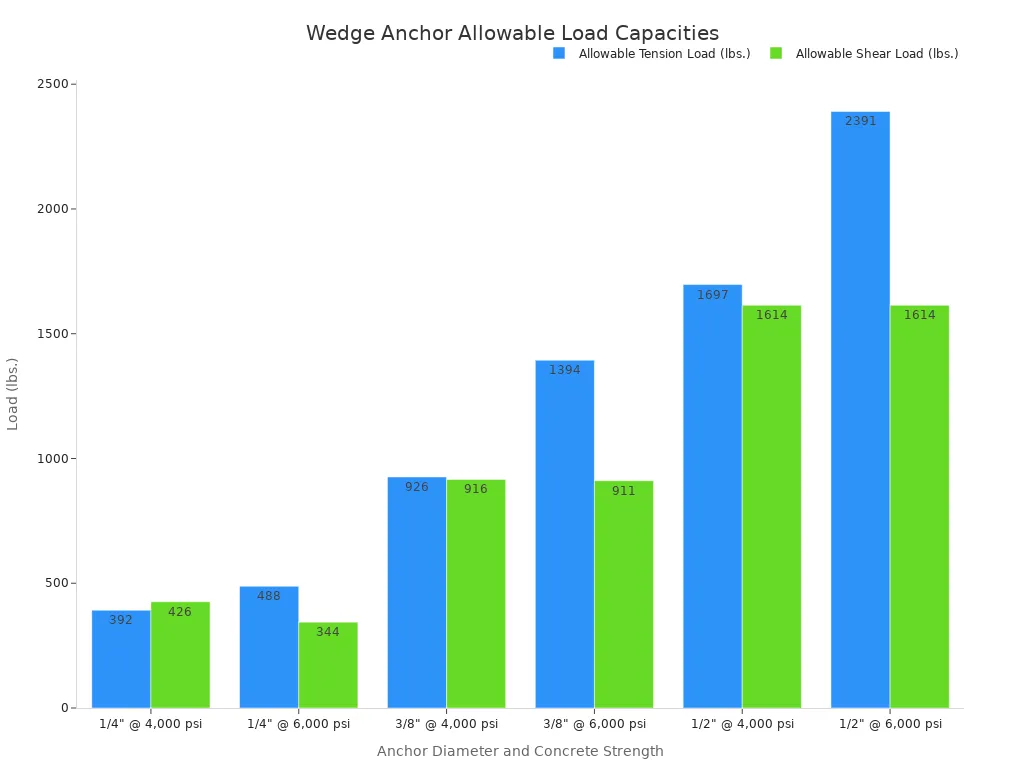

The anchor’s diameter determines its holding power. Larger diameters generally provide higher load capacities. The length must be sufficient to pass through the fixture and achieve the required minimum embedment depth in the concrete. The table below shows how load values change with diameter and embedment.

| Anchor Diameter | Minimum Embedment Depth (in.) | Concrete Compressive Strength | Allowable Tension Load (lbs.) |

|---|---|---|---|

| 1/4″ | 1-1/8″ | 4,000 psi | 342 |

| 3/8″ | 1-5/8″ | 4,000 psi | 686 |

| 1/2″ | 2-1/4″ | 4,000 psi | 1,103 |

| 1/2″ | 3-3/4″ | 6,000 psi | 2,391 |

Material Types (Zinc, Hot-Dipped Galvanized, Stainless Steel)

The anchor’s material dictates its corrosion resistance.

- Zinc-Plated: Best for dry, indoor applications with low corrosion risk.

- Hot-Dipped Galvanized: Offers good protection for outdoor use in non-coastal areas.

- Stainless Steel: Provides the highest level of corrosion resistance. It is the ideal choice for marine environments, coastal regions, and applications involving chemicals, often lasting 15-20 years.

Matching the Anchor to Your Fixture

The final step in selection is matching the anchor to the object being fastened. The hole in the fixture determines the anchor’s diameter. The fixture’s thickness, plus the required embedment depth, determines the necessary length for installing a wedge anchor.

Pre-Installation: Planning Your Anchor Placement

A successful installation begins long before the drilling starts. Careful planning ensures each anchor performs to its maximum capacity and guarantees the structural integrity of the fixture. This involves consulting manufacturer specifications and mapping out anchor locations based on critical spacing requirements.

Understanding Manufacturer Specifications

Every wedge anchor is designed with specific performance parameters. An installer must locate and adhere to these specifications, particularly the minimum embedment depth and required torque.

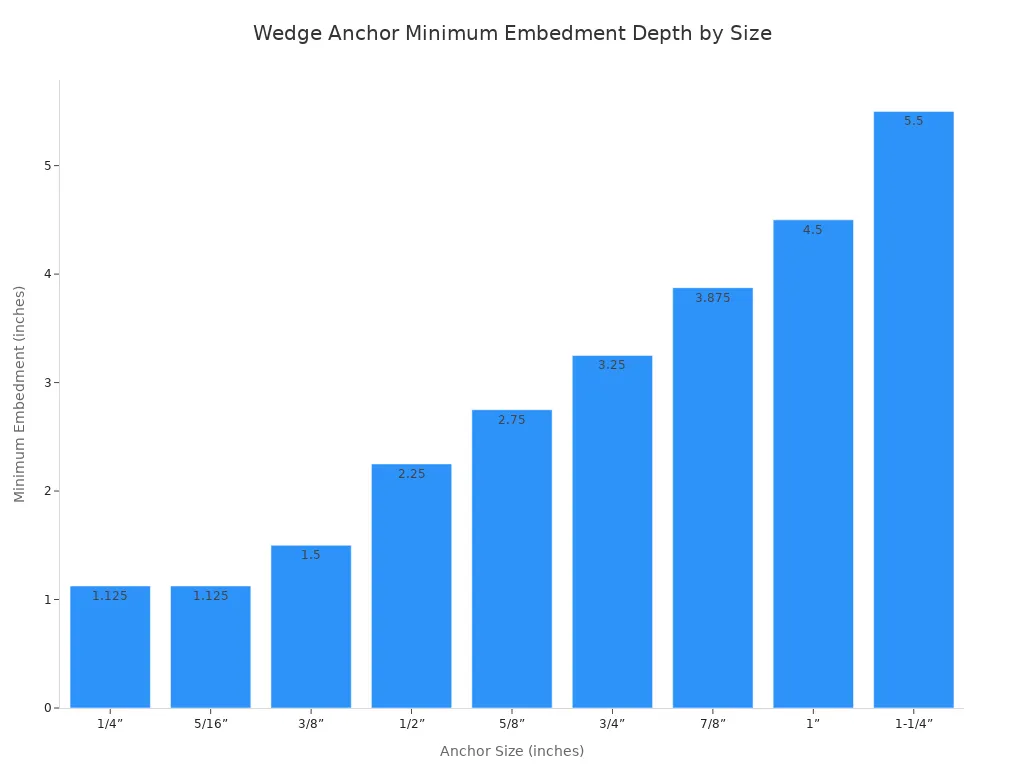

Locating Minimum Embedment Depth

The minimum embedment depth is the shortest distance the anchor must be installed into the concrete to achieve its stated holding value. Failing to meet this depth compromises the anchor’s performance. The required minimum embedment depth is directly related to the anchor’s diameter. The following table outlines standard values.

| Size | Minimum Embedment |

|---|---|

| 1/4” | 1-1/8” |

| 5/16” | 1-1/8” |

| 3/8” | 1-1/2” |

| 1/2” | 2-1/4” |

| 5/8” | 2-3/4” |

| 3/4” | 3-1/4” |

| 7/8” | 3-7/8” |

| 1” | 4-1/2” |

| 1-1/4” | 5-1/2” |

As the chart illustrates, a larger anchor diameter necessitates a greater minimum embedment depth to function correctly. An installer must always verify the correct minimum embedment depth for the specific anchor being used.

Finding Required Torque Values

While precision is key, manufacturers often do not provide a universal torque chart. The standard recommendation for most applications is to tighten the nut to a “snug tight” condition.

Engineer’s Note: If a specific torque value is required for a critical application, the project’s engineer of record must provide that specification. An installer should not guess or apply torque values from a different product.

Critical Spacing Requirements

Placing anchors too close to an edge or to each other can cause the concrete to crack and fail. An installer must calculate these distances correctly.

Calculating Minimum Edge Distance

Edge distance is the measurement from the center of the anchor to the nearest unsupported edge of the concrete. This minimum distance is determined by the anchor’s diameter, not the concrete’s compressive strength (PSI). While stronger concrete can handle higher loads at that distance, the required placement does not change.

Determining Minimum Spacing Between Anchors

To prevent the forces from multiple anchors from overlapping and weakening the concrete, a minimum spacing must be maintained. The industry standard is a simple rule.

- The 10-Diameter Rule: The minimum center-to-center spacing between two anchors should be ten times the anchor’s diameter. For a 1/2″ anchor, the minimum spacing would be 5 inches (10 x 0.5″).

Marking Your Installation Points

Accurate marking translates planning into action. Precise marks ensure the fixture aligns correctly and all spacing requirements are met.

- Use a tape measure to verify all edge and spacing distances.

- Employ a spirit level or laser level to ensure all points are properly aligned.

- Mark the final drilling points clearly on the concrete surface with a carpentry pencil.

Step 1: How to Drill the Hole Correctly

The precision of the drilled hole directly impacts the anchor’s holding power. An installer must use the correct bit, set the proper depth, and employ a steady technique to create the ideal foundation for a secure wedge anchor installation.

Selecting the Right Drill Bit

The drill bit is not just a tool for making a hole; it is a precision instrument that creates the exact cavity required for the anchor to function.

Why Bit Diameter Must Match Anchor Diameter

The fundamental rule for selecting a drill bit is simple: the bit’s diameter must be identical to the anchor’s diameter. A 1/2″ wedge anchor requires a 1/2″ drill bit. This one-to-one relationship ensures a snug fit, which is essential for the anchor’s expansion mechanism to engage the base material correctly.

The Importance of an ANSI-Standard Carbide-Tipped Bit

An installer must use a carbide-tipped masonry bit that meets American National Standards Institute (ANSI) specifications. The performance of a wedge anchor is critically dependent on hole tolerance. Using a non-ANSI bit can lead to significant problems.

- The wedge anchor may not fit into the drilled hole.

- The hole may fail to meet the correct tolerances, preventing the anchor from achieving its intended holding values.

The carbide tip itself is brazed onto the drill bit’s head to harden it, a feature crucial for breaking up aggregate. This design offers superior performance.

- It provides a high level of robustness for a longer product lifespan.

- The hardened tip allows for greater drilling speed.

- It can withstand temperatures up to 1000°C, enabling faster and longer cutting.

Setting the Correct Drilling Depth

A hole that is too shallow will prevent the anchor from being installed correctly and will compromise its load capacity.

Calculating Hole Depth (Embedment + 1/2 Inch)

The hole must be drilled deeper than the anchor’s minimum embedment. The hole depth should be at least 1/2 inch deeper than the anchor’s embedment length. This extra space accommodates any fine dust or cuttings that remain after cleaning, ensuring the anchor can be fully seated without obstruction. The total hole depth is the anchor embedment plus the thickness of the fixture, plus the extra 1/2 inch.

Marking the Depth on Your Drill Bit

An installer can ensure accurate depth by marking the drill bit. A common method is to wrap a piece of electrical or painter’s tape around the bit at the required depth. Alternatively, many hammer drills come with an adjustable depth rod for consistent results.

Proper Drilling Technique

The final element is the physical act of drilling. A steady hand and the right power tool are essential for a clean, straight hole.

Using a Hammer Drill for Concrete

A standard drill is insufficient for this task. An installer must use a hammer drill, which combines rotational movement with a rapid hammering action. This dual-action mechanism pulverizes the concrete, allowing the bit’s flutes to clear the debris efficiently.

How to Drill a Perpendicular Hole

The anchor must be installed in a hole that is perpendicular to the surface. An angled hole can cause uneven stress and reduce the anchor’s effectiveness.

Pro Tip: To maintain a straight angle, an installer can use several techniques.

- Place two speed squares on the surface at a 90-degree angle to each other, creating a visual guide for the bit.

- Create a guide by drilling a straight hole through a thick block of wood.

- Practice on a scrap piece of material to develop a steady hand and better control.

Step 2: Why and How to Clean the Drilled Hole

After drilling, an installer’s focus must shift to preparing the hole for the anchor. A clean hole is not a suggestion; it is a requirement for a safe and reliable installation. This step ensures the wedge anchor can perform exactly as the manufacturer designed it to.

The Critical Role of a Clean Hole for a Secure Hold

The holding power of a wedge anchor depends on direct contact between its expansion clip and the concrete base material. Any concrete dust or debris left in the drilled hole creates a barrier. This fine particulate matter interferes with the anchor’s expansion mechanism, preventing it from achieving full purchase within the substrate. When the anchor cannot expand correctly, its rated load capacity is significantly compromised.

An installer must remove all dust and debris from the drilled hole to maximize friction and grip. This action ensures the anchor makes solid contact with the concrete, allowing it to develop the necessary holding values for a secure connection. A clean hole is the difference between a temporary fixture and a permanent, reliable installation.

The Three-Step Cleaning Method

Professionals follow a simple yet highly effective three-step process to guarantee a perfectly clean hole. This “blow-scrub-blow” sequence removes both loose and compacted debris, preparing the hole for optimal anchor performance.

Step 1: Blow Out Debris

The first action is to remove the loose dust and cuttings created during drilling. An installer uses a blow-out bulb, hand pump, or oil-free compressed air to forcefully eject the debris from the hole.

Installer’s Note: The tool used for this step matters. Lungs cannot generate the high pressure of a dedicated pump.

- Dedicated blow-out pumps are highly effective and can generate significant pressure.

- A Hilti-style bulb puffer works well for smaller, shallower holes.

- For deeper holes (over 100mm), a more powerful hand pump is the preferred tool to ensure all debris is cleared.

Step 2: Scrub with a Wire Brush

Blowing out the hole only removes loose particles. The drilling process often compacts a fine layer of dust onto the interior walls of the hole. An installer uses a stiff wire brush to scrub the inside of the hole thoroughly. The brush must match the diameter of the hole to make firm contact with the walls, dislodging any remaining caked-on dust. Several passes up and down the length of the hole are necessary.

Step 3: Final Blow Out

The final step is to repeat the blowing process. This action removes all the fine dust that the wire brush dislodged in the previous step. The installer continues this final blow-out until no more dust emerges from the hole. Only a completely clean and dust-free hole is ready to receive the wedge anchor. This meticulous cleaning ensures the anchor will set correctly and achieve its maximum holding capacity.

Step 3: The Process to Install Wedge Anchor

With a clean, properly drilled hole, an installer can proceed to the physical installation. This step involves correctly positioning the anchor and fixture, then carefully seating the anchor into the concrete base material. Proper technique at this stage is essential to prepare the anchor for final tightening and to prevent damage to its components.

Positioning the Fixture and Anchor

The first phase of the installation process involves preparing the anchor and aligning it with the fixture and the drilled hole. This ensures all components are correctly oriented before the anchor is driven into the concrete.

Assembling the Nut and Washer on the Anchor

An installer begins by preparing the wedge anchor for insertion. The washer is placed onto the threaded end of the anchor first. Following the washer, the nut is threaded on for just a few turns. This assembly keeps all parts together and readies the anchor for the next action. Leaving the nut at the top of the threads is a critical part of the process to install wedge anchor correctly.

Inserting the Anchor Through the Fixture

The installer aligns the hole in the fixture with the drilled hole in the concrete. They then guide the pointed end of the anchor assembly through the fixture’s hole and into the concrete. The anchor should slide in easily until it meets the bottom of the hole. This action positions the entire assembly, making it ready to be hammered into its final depth.

Tapping the Anchor into the Hole

Gentle but firm force is required to drive the anchor to the correct embedment depth. An installer uses a hammer for this task, but the technique is crucial to avoid damaging the anchor’s threads, which would prevent proper tightening.

Using a Hammer to Seat the Anchor

Protecting the threads is the primary concern when hammering. A damaged thread makes it impossible to tighten the nut and set the anchor. Professionals use a specific technique to prevent this.

- The installer threads the nut onto the anchor until the top of the nut is flush with the top of the anchor body. This configuration shields the threads from direct impact.

- They then use a hammer to strike the top of the nut, driving the anchor into the hole.

- For larger diameter anchors that require a heavier hammer, an installer must exercise extra caution to deliver straight, controlled strikes.

Pro Tip 💡: Some anchors feature a “bullnose” or stepped-down end designed for direct hammering. Even with this feature, threading the nut flush remains the recommended best practice for maximum thread protection.

Ensuring the Washer is Snug Against the Fixture

The installer continues to tap the anchor until the washer rests firmly against the surface of the fixture. The nut and washer should be snug, with no gap between the washer and the material being fastened. This visual confirmation indicates that the anchor has reached the proper depth and is ready for the final, critical step of tightening. A properly seated wedge anchor is a prerequisite for a secure installation.

Step 4: Tightening the Nut to Set the Wedge Anchor

The final step in the installation process is tightening the nut. This action is not just about securing the fixture; it is the critical mechanism that activates the wedge anchor and generates its holding power. Proper execution of this step ensures a safe and permanent connection.

How Tightening Activates the Anchor

Tightening the nut initiates a simple but powerful mechanical process. As an installer turns the nut, it pulls the threaded anchor stud upward. This movement draws the tapered cone at the bottom of the anchor into the expansion clip. The clip is forced outward, pressing firmly against the interior walls of the drilled hole. This friction and expansion create the immense holding force required to install wedge anchor securely. The process follows four key actions:

- The installer tightens the anchor nut clockwise until it is snug.

- They apply an additional 1/4 to 1/2 turn with a wrench.

- This action pulls the cone upward, causing the wedge clip to expand.

- The expanded clip then grips the concrete walls, locking the anchor in place.

The Tightening Sequence

A consistent tightening sequence ensures the anchor sets correctly without being over-stressed. The process begins with hand-tightening and finishes with a specified number of turns from a wrench.

Hand-Tightening the Nut

An installer first turns the nut by hand until the washer is snug against the fixture. This initial step removes any slack in the assembly. It ensures the anchor is properly seated before applying mechanical force.

Applying 3-5 Turns with a Wrench

After hand-tightening, the installer uses a standard wrench to turn the nut three to five full rotations. This is the general guideline for most applications. These turns provide the necessary force to pull the cone into the clip and fully expand the wedge anchor.

Using a Torque Wrench for Precision

For critical applications where load values are specified, a torque wrench is essential. This tool allows an installer to apply a precise amount of rotational force, preventing the common errors of over-tightening or under-tightening.

Why Manufacturer Torque Specs Matter

Adhering to manufacturer-specified torque values is non-negotiable for ensuring structural integrity. Using an uncalibrated tool or guessing the torque can lead to catastrophic failure.

- Over-torquing can over-stress and damage the anchor, strip the threads, or even crack the concrete.

- Under-torquing prevents the anchor from expanding sufficiently, which can cause the fixture to loosen over time.

- Improper torque can invalidate product warranties and compromise the entire installation.

Critical Alert: Not using a calibrated torque wrench can lead to improper expansion. Smaller anchors are easily overtightened, while larger anchors may not be tightened enough, causing the attachment point to fail.

How to Set and Use a Torque Wrench

An installer sets the torque wrench to the value specified by the project engineer. They then tighten the nut until the wrench clicks, indicating the correct torque has been reached. To ensure this precision, the tool itself must be reliable. Industry standards recommend calibrating a torque wrench at least once a year or every 5,000 cycles to maintain its accuracy.

Common Mistakes When Installing Wedge Anchors

Even with the right tools, an installer can make critical errors that compromise the safety and integrity of the connection. Understanding these common pitfalls is the first step toward avoiding them. Successful installation depends on avoiding procedural shortcuts and environmental misjudgments.

Top Installation Errors to Avoid

The most frequent mistakes occur during the core installation steps. Each error directly impacts the anchor’s ability to achieve its specified holding value.

Using an Incorrectly Sized Drill Bit

An installer must use a drill bit that matches the anchor’s diameter. A hole that is too large will prevent the expansion clip from making firm contact with the concrete. A hole that is too small will prevent the anchor from being inserted at all. Both scenarios result in a failed connection.

Drilling a Hole That Is Too Shallow

The anchor must reach its specified minimum embedment depth. A shallow hole prevents the wedge anchor from being driven in far enough. This mistake leaves the expansion mechanism in a weaker section of the concrete or prevents it from engaging properly, severely reducing its load capacity.

Failing to Clean the Hole Thoroughly

A dirty hole is a primary cause of anchor failure. An installer who skips the “blow-scrub-blow” cleaning method leaves a layer of dust and debris. This material prevents the clip from gripping the concrete, which means the anchor will never reach its rated holding power.

Over-Torquing or Under-Torquing the Nut

Applying the correct torque is critical when installing wedge anchors. Both too much and too little force can lead to failure.

- Under-torquing causes the anchor to under-expand, resulting in a lower clamping force and increased movement when a load is applied.

- Over-torquing is equally dangerous. It can cause the concrete to break apart, the steel anchor itself to fail, or the entire assembly to pull out of the hole. A common sign of this error is the anchor spinning freely in the hole.

Environmental and Placement Mistakes

The location of the anchor and the condition of the base material are just as important as the installation technique.

Installing Too Close to an Edge or Another Anchor

An installer must respect minimum edge and spacing distances. Placing anchors too close to an edge or to each other creates overlapping stress cones within the concrete. This can cause the concrete to crack and spall, leading to a catastrophic failure of the fastening point.

Attempting to Install in Cracked or Weak Concrete

Standard wedge anchors are designed for use in solid, uncracked concrete. An installer should never attempt to set these anchors in visibly cracked, soft, or questionable base material. The expansion force can widen existing cracks and will not provide a secure hold in weak material.

Warning ⚠️: A previously used wedge anchor should never be reinstalled. The expansion clip is a single-use component designed to deform permanently. Reusing it provides no reliable holding power.

Reusing a Previously Set Wedge Anchor

The expansion clip on a wedge anchor is designed for a single use. Once it has been expanded, it is permanently deformed. An installer must never remove and attempt to reuse an anchor. A reused anchor will not set correctly and offers no guarantee of holding strength.

An installer completes the job with a final verification. They must confirm the fixture is completely immobile and the nut is tightened to the correct specification. This last inspection validates the entire process.

The five core steps—planning, drilling, cleaning, inserting, and tightening—are the foundation of a proper installation. Adhering to this sequence ensures a secure, professional-grade result for any wedge anchor application.

FAQ

Can an installer use a wedge anchor in brick or block?

No. An installer must only use wedge anchors in solid concrete. The expansion forces can crack or break weaker base materials like brick or cinder block. Specific anchors exist for these other applications.

What should an installer do if the anchor spins in the hole?

An anchor spinning in its hole indicates a problem. This often results from an oversized hole or over-torquing. The installer must abandon that anchor point, drill a new hole, and use a new wedge anchor.

How does an installer remove a wedge anchor?

Removing a wedge anchor is a destructive process. An installer can cut the anchor flush with the concrete surface using a grinder. Alternatively, they can drive the anchor deeper into the hole if space permits.

Is a regular drill sufficient for installing a wedge anchor?

A regular drill lacks the necessary force for concrete. An installer must use a hammer drill. This tool combines rotation with a hammering action, which is essential for pulverizing the concrete and drilling an effective hole.

What is the difference between embedment and anchor length?

Anchor length is the total measurement from end to end. Embedment depth is the specific length of the anchor that must be installed into the concrete to achieve its holding power.

Why is a torque wrench so important?

A torque wrench ensures the installer applies the precise rotational force specified by the engineer. This prevents over-tightening, which can crack concrete, and under-tightening, which results in a loose and unsafe connection.

Expert Reminder 💡: A calibrated torque wrench is not optional for critical applications. It is a requirement for a safe, professional-grade installation that meets engineering specifications.

How long do wedge anchors last?

The lifespan of a wedge anchor depends on its material and environment.

- Zinc-Plated: Suitable for dry, indoor use.

- Hot-Dipped Galvanized: Good for outdoor use.

- Stainless Steel: Offers maximum corrosion resistance, lasting 15-20 years in harsh environments.