The global market for Anchor Bolts in concrete reached approximately USD 1.17 billion in 2023, reflecting the widespread use of these essential bolts. A successful installation requires a precise process. Professionals install expansion bolts by drilling a correctly sized hole into the concrete. However, improper technique is a significant issue, with some studies showing a 50% failure rate in anchor certification exams. After drilling, operators must thoroughly clean the hole. They then install the anchor and tighten the bolts to secure the anchor. A custom fasteners manufacturer can supply custom anchor bolts for specific concrete applications, ensuring a reliable anchor.

Understanding Concrete Anchor Bolts and How They Work

Before installing expansion anchors, professionals must understand the hardware’s design and function. These fasteners provide robust connection points in solid base materials. Their reliability depends entirely on correct selection and installation.

What Are Expansion Bolts?

Expansion bolts are a category of mechanical fasteners designed to create a secure connection in concrete, brick, or block. They function by expanding inside a pre-drilled hole. This expansion generates immense pressure against the hole’s interior walls, creating a strong, load-bearing anchor point through friction. These concrete anchor bolts are essential for projects requiring high pull-out resistance.

Common Types of Expansion Bolts

Different projects require specific types of anchors. Each design offers unique benefits and load capacities.

Wedge Anchors

Wedge anchors are heavy-duty bolts intended for solid concrete applications. Professionals use these powerful anchors for securing structural steel, heavy machinery, and safety railings. When an installer tightens the nut, a clip at the base of the anchor expands, wedging it firmly into the concrete.

Sleeve Anchors

Sleeve anchors are highly versatile fasteners suitable for concrete, brick, and block. Their applications range from securing shelving units and window frames to mounting grab bars. Unlike a wedge anchor, the entire sleeve of this anchor expands along its length, providing a secure grip in various base materials.

Drop-In Anchors

A drop-in anchor is a female-threaded anchor that sits flush with the concrete surface. Installers use a special setting tool to drive an internal plug downward, which expands the anchor body. These anchors are ideal for overhead applications like suspending cable trays, pipes, and ductwork, as bolts can be inserted and removed as needed.

Strike Anchors

Strike anchors, also known as hammer-drive anchors, are permanent, tamper-resistant fasteners. Installation is straightforward: an installer inserts the anchor into the hole and drives the internal pin with a hammer. This action expands the anchor body, locking it into the concrete.

The Expansion Mechanism: How They Grip Concrete

The holding power of all concrete anchor bolts comes from a simple mechanical principle: controlled expansion. This process creates a powerful frictional grip against the base material. The mechanism engages when the bolts are tightened.

The Science of Grip: A Step-by-Step Look

- An installer tightens the nut on the bolt.

- This action pulls a cone-shaped expander plug up into the anchor sleeve.

- The cone forces the sleeve to expand outward against the inner wall of the drilled hole.

- This expansion generates intense friction between the anchor and the concrete, locking the bolts securely in place.

Gathering Your Essential Tools and Materials

An installer’s success depends on having the right equipment. Preparing the correct tools and materials beforehand ensures a smooth, safe, and secure installation of expansion bolts. This preparation prevents delays and guarantees the anchor performs as designed.

Power Tools for the Job

Power tools provide the necessary force and efficiency for working with concrete. They are indispensable for drilling and cleaning the anchor holes.

Hammer Drill

A hammer drill is a critical tool for this task. It combines rotation with a rapid hammering action, allowing it to efficiently bore into hard materials like concrete. This tool is essential for creating the precise holes required for the anchors.

Shop Vacuum or Blower

A powerful shop vacuum or a dedicated blower is necessary for hole cleaning. These tools effectively remove the fine silica dust and debris generated during drilling. Proper cleaning is a non-negotiable step for achieving the anchor’s maximum holding capacity.

Essential Hand Tools

Alongside power tools, several hand tools are required to install and secure the expansion bolts correctly.

Hammer

A standard hammer is used to gently tap the anchor assembly into the pre-drilled hole. This ensures the anchor is seated at the correct depth without damaging the threads of the bolts.

Torque Wrench

A torque wrench is the only tool that can guarantee the bolts are tightened to the manufacturer’s exact specification. Applying the correct torque is crucial for activating the expansion mechanism properly and securing the anchors without causing damage.

Socket Set or Adjustable Wrench

A socket set or an adjustable wrench is needed to turn the nut on the anchor. While an adjustable wrench works, a socket set paired with a torque wrench provides a more accurate and reliable method for tightening the bolts.

Wire Brush

A narrow, stiff-bristled wire brush is essential for cleaning the inside of the drilled hole. The brush scours the interior walls, dislodging any dust or debris that a blower or vacuum might miss, ensuring a clean surface for the anchors to grip.

Required Materials and Safety Gear

Selecting the right materials and wearing appropriate safety gear are fundamental to a successful and safe installation.

The Right Expansion Bolts

An installer must choose the correct expansion bolts for the specific application. The selection depends on load requirements, environmental conditions, and the type of fixture being mounted.

Carbide-Tipped Masonry Drill Bits

Installers must use carbide-tipped masonry drill bits that match the diameter specified for the chosen anchor. These durable bits are designed to withstand the abrasive nature of drilling into concrete.

Safety Glasses and Gloves

Drilling concrete creates flying debris and exposes workers to hazards. Safety is paramount.

Safety First! 👷 Drilling into concrete can be hazardous. It produces lung-damaging silica dust and can expose workers to excessive noise and vibration. Proper personal protective equipment (PPE) is not optional; it is a requirement for safety.

Installers must wear safety goggles to protect their eyes. They should also wear waterproof, alkali-resistant gloves to protect their skin from abrasion and wet cement.

Dust Mask or Respirator

Respiratory protection is critical. A high-quality dust mask or respirator prevents the inhalation of harmful silica dust. Ensuring good ventilation in the work area further minimizes exposure risks.

How to Install Expansion Bolts: The 5-Step Process

A successful installation hinges on a methodical and precise approach. This five-step process breaks down how professionals install expansion bolts, ensuring each anchor achieves its maximum holding power. Following these steps meticulously is the key to a secure and reliable outcome.

Step 1: Prepare and Mark the Installation Point

Proper preparation is the foundation of a secure anchor. Before any drilling begins, an installer must accurately identify and prepare the installation points on the concrete surface. This initial phase prevents costly errors and ensures structural integrity.

Measure and Mark the Anchor Location

Accuracy starts with the layout. An installer must carefully measure and mark where each of the bolts will be placed. Using project plans or templates, they can ensure proper alignment and spacing for all anchors.

Best Practices for Marking Locations 🎯

- Plan the Layout: An operator first makes a plan based on project instructions, considering load distribution.

- Use Clear Markers: They use a chalk line or a durable marker to create highly visible lines and points.

- Verify Spacing: The installer ensures the spacing between each anchor meets the required specifications.

- Double-Check Measurements: Before drilling, they double-check all measurements to prevent misplacement of the anchor.

Check for Rebar and Obstructions

Concrete often contains hidden elements like steel reinforcing bars (rebar), pipes, or electrical conduits. Drilling into these obstructions can compromise the structure and damage tools. Professionals use specialized equipment to scan the concrete and locate these hidden objects.

Common detection methods include:

- Ground Penetrating Radar (GPR): This advanced method transmits radio waves into the concrete. It can map the location and size of rebar up to two feet deep.

- Cover Meters: These devices locate steel by sensing changes in the concrete’s electrical or magnetic properties.

- Metal Detectors: A simpler tool, a metal detector can find rebar, wires, and pipes, often distinguishing between different metal types.

Identifying and avoiding these obstacles is a critical part of the preparation process.

Step 2: Drill the Hole in the Concrete

With the locations marked, the next step is to create a precise hole for the anchor. The quality of the drilled hole directly impacts the performance of the bolts. This part of the process demands the correct tools and technique.

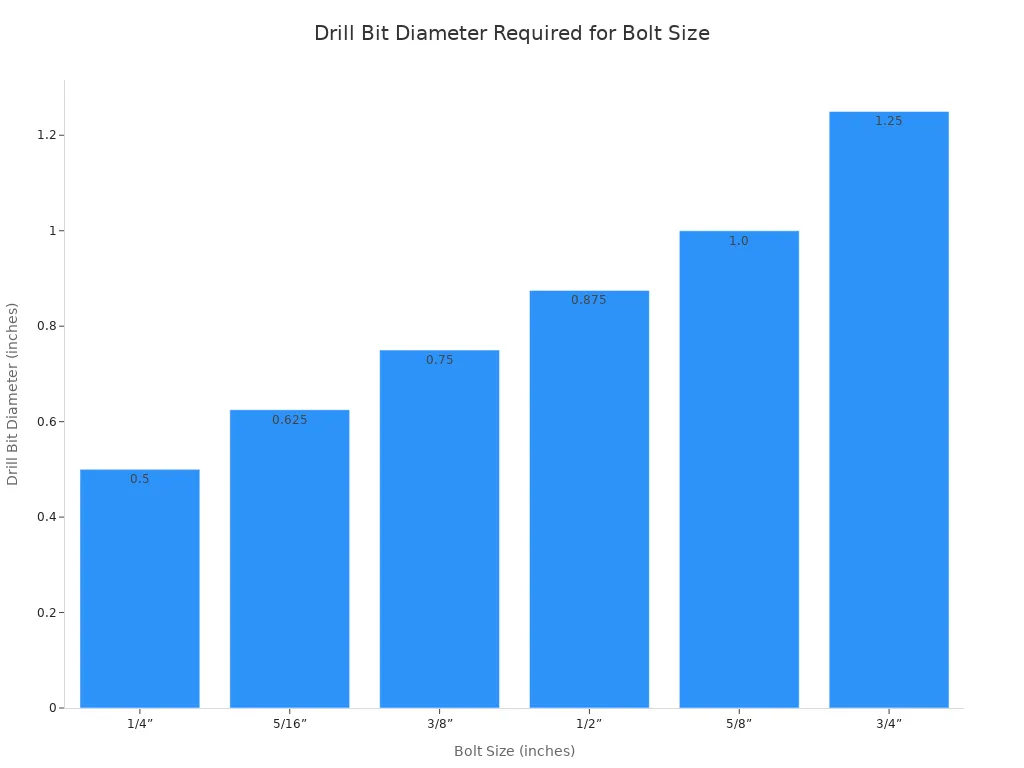

Select the Correct Drill Bit Size

An installer must select a carbide-tipped masonry drill bit that matches the diameter specified by the anchor manufacturer. The hole diameter is non-negotiable; a hole that is too small will prevent the anchor from being inserted, while a hole that is too large will prevent the expansion mechanism from gripping the concrete. The anchor size determines the required drill bit size.

Set the Proper Drill Depth

The hole must be drilled to the correct depth to ensure the anchor has sufficient embedment. Most manufacturers require the hole to be deeper than the anchor’s length to provide space for dust and debris to settle. An installer can set the depth using the depth gauge on the hammer drill or by wrapping a piece of tape around the drill bit to serve as a visual guide.

Drill Perpendicular to the Concrete Surface

The installer must hold the hammer drill firmly and align the bit with the marked point. It is crucial to keep the drill perfectly perpendicular (at a 90-degree angle) to the surface throughout the drilling process. Drilling at an angle can compromise the holding strength of the anchors and create issues when mounting fixtures over the bolts.

Step 3: Thoroughly Clean the Drilled Hole

A clean hole is essential for a strong anchor. Concrete dust and debris left inside the hole act as a lubricant, severely reducing the friction the anchor needs to grip the surrounding material. This cleaning process must be thorough.

Use a Blower or Compressed Air

The first cleaning action involves forcefully blowing out all loose dust and debris. An installer uses a shop vacuum in reverse, a hand-held blower, or oil-free compressed air to evacuate the fine particles created during drilling.

Scrub with a Wire Brush

After the initial blow-out, the installer uses a narrow wire brush sized for the hole. They insert the brush and scrub the interior walls vigorously. This action dislodges any compacted dust that the air blast missed, ensuring the surface is completely raw.

Repeat the Blow-Brush-Blow Process

A single cleaning cycle is not enough. To achieve a truly clean hole, professionals repeat the cleaning sequence.

The Blow-Brush-Blow Method A professional will blow the hole out, brush the interior walls, and then blow the hole out a final time. This sequence ensures all loose and compacted debris is removed, preparing the hole to install the anchor for maximum performance.

Step 4: Install Anchor Bolts into the Hole

After preparing a perfectly clean hole, the installer begins the physical installation process. This step involves carefully placing the anchor assembly into the concrete. Precision here prevents damage to the anchor and ensures it is positioned correctly for the final tightening.

Insert the Bolt Assembly

An operator first prepares the anchor for insertion. The nut and washer should be threaded onto the top of the anchor. This simple action protects the threads from damage during the next part of the process.

Professional Insertion Technique

- Assemble the Anchor: An installer confirms the nut and washer are on the end of the bolts. The nut should be flush with the top of the anchor to shield the threads.

- Attach Fixtures: If the project involves a hanger or bracket, they attach it to the anchor before insertion.

- Position the Anchor: The operator aligns the tip of the anchor with the opening of the drilled hole.

This careful preparation ensures the anchor is ready to install without issue.

Tap the Anchor into Place with a Hammer

With the anchor assembly in position, the installer uses a hammer to drive it into the hole. They must use firm but controlled taps on the head of the nut, not directly on the threads of the bolts. The goal is to seat the anchor until the washer rests snugly against the concrete surface or the fixture. If the anchor becomes difficult to drive, the installer should stop. Forcing a tight anchor can damage the bolts or the concrete. This resistance often indicates the hole is too small or still contains debris. The operator must remove the anchor and re-verify the hole’s diameter and cleanliness.

Step 5: Tighten and Secure the Anchor

This final step is where the anchor develops its holding power. The tightening process activates the expansion mechanism, locking the anchor firmly into the concrete. Following the correct procedure is critical to install anchor bolts that meet their specified load capacity.

Hand-Tighten the Nut Initially

Before applying mechanical force, an installer hand-tightens the nut. They turn the nut clockwise until it is snug. This initial tightening engages the expansion clip at the bottom of the anchor against the concrete. It prevents the entire anchor assembly from spinning when the operator applies final torque. This small action is a key part of a successful installation process. These anchors depend on this initial grip.

Apply Final Torque with a Wrench

The operator now uses a calibrated torque wrench to secure the anchor. This is the only tool that guarantees the correct amount of rotational force is applied. Each anchor has a specific torque value provided by the manufacturer, which is often found on the packaging or a technical data sheet.

- Select the Right Socket: The installer chooses the correct socket size for the nut. For example, a 10mm anchor often requires a 17mm socket.

- Set the Torque Wrench: They set the torque wrench to the manufacturer’s specified value.

- Tighten Smoothly: The operator tightens the nut in a smooth, continuous motion until the wrench clicks, indicating the target torque has been reached.

This final action pulls the cone into the expansion sleeve, forcing the anchors to expand and grip the concrete with immense pressure. This completes the procedure to install expansion bolts, creating a strong and reliable fastening point for the bolts.

Critical Factors for a Secure Installation

Following the five-step process is essential, but several critical factors determine whether an installation is successful or destined for failure. An operator’s attention to detail regarding hole dimensions, cleanliness, and torque application directly impacts the safety and reliability of the final anchor point. A proper installation ensures the anchor performs to its engineered capacity.

Hole Diameter and Depth Accuracy

The dimensions of the drilled hole are the most critical element of the entire process. Even a minor deviation can severely compromise the performance of the anchor.

Why the Correct Diameter is Non-Negotiable

The anchor’s diameter specification is absolute. Using an incorrect drill bit size, often due to a worn bit or a simple mistake, makes a secure installation impossible. This error compromises the effectiveness of the anchor and can lead to structural issues.

- Hole Too Large: A hole that is oversized prevents the expansion mechanism from making firm contact with the concrete, drastically reducing the anchor’s holding strength.

- Hole Too Small: Forcing an anchor into an undersized hole can damage the anchor’s threads, preventing the nut from tightening. It can also deform the expansion sleeve, leading to anchor failure.

The Importance of Proper Embedment Depth

Embedment depth is the distance the anchor is installed into the concrete. A deeper embedment generally provides a higher load-bearing capacity for the anchors. Adhering to the manufacturer’s minimum embedment depth is crucial for proper anchor performance.

The shearing capacity of an anchor increases with anchorage depth. For an optimum embedment depth, the anchor shear capacity reaches its maximum. It then remains constant, unaffected by further increases in depth.

The Importance of a Debris-Free Hole

A clean hole is a strong hole. Concrete dust left inside the drilled hole can reduce an anchor’s holding power by over 50%. This is a common but avoidable mistake when installing expansion anchors.

How Debris Reduces Holding Power

Dust and debris act as a lubricant. They create a barrier between the anchor and the raw concrete, preventing the expansion sleeve from generating the necessary friction to grip the hole walls. Failure to clean the hole properly can lead to insufficient expansion or premature failure of the anchors under load. This principle applies to all types of anchors, from mechanical to chemical.

Best Practices for Hole Cleaning

The only reliable method is the “blow-brush-blow” technique. An operator uses compressed air to blow out loose dust, scrubs the interior with a wire brush to dislodge compacted particles, and then blows the hole out a final time. This ensures the anchor makes direct contact with solid concrete.

Applying the Correct Torque

Torque is the final step that activates the anchor. Applying the right amount of force is a delicate balance that ensures a secure connection without damaging the components.

What is Torque and Why It Matters

Torque is the measurement of rotational force. When an operator tightens a nut, they are applying torque to stretch the bolt. This tension creates a clamping force that holds the fixture securely. Applying the correct torque ensures the anchor holds its intended load.

Finding the Manufacturer’s Torque Specifications

Every anchor has a specific torque value determined by the manufacturer. An installer can find this critical information on the product’s packaging or in its technical data sheet. Always refer to these specifications for a successful installation.

Risks of Over-Tightening vs. Under-Tightening

Improper torque application poses significant risks.

- Under-Tightening: An under-tightened anchor will not expand sufficiently, resulting in poor holding values and a loose connection.

- Over-Tightening: Excessive torque can strip the threads or even snap the bolt. It is not difficult to torque an anchor to its yield point, especially with less expensive hardware, creating a hidden failure point.

Common Mistakes When You Install Expansion Bolts (And How to Avoid Them)

Even seasoned professionals can make errors that compromise the integrity of an anchor installation. Understanding these common mistakes is the first step toward avoiding them. A few key areas require special attention to ensure a safe and secure result every time an operator needs to install expansion bolts.

Drilling an Incorrectly Sized Hole

One of the most frequent and damaging mistakes is using the wrong drill bit. The anchor manufacturer provides precise diameter specifications for a reason. A hole that is even slightly too large prevents the expansion sleeve from making firm contact with the concrete, which severely reduces the holding power of the anchors. Conversely, a hole that is too small makes it impossible to install the anchor without force. This can damage the anchor’s threads or deform the expansion clip, leading to a failed installation.

Rule of Thumb 📏 Always double-check that the carbide-tipped masonry bit diameter matches the anchor’s required hole diameter. Worn bits can also create undersized holes, so operators should inspect their tools regularly.

Inadequate Hole Cleaning

A clean hole is a strong hole. Many installers underestimate the negative impact of concrete dust. When left in the hole, this fine debris acts as a lubricant, creating a barrier between the anchor and the base material. This prevents the expansion mechanism from generating the friction needed to grip the hole walls. The result is a significant loss of holding capacity, sometimes by more than 50%. This oversight turns reliable anchors into a potential failure point. The only way to guarantee a clean hole is to follow the blow-brush-blow method meticulously.

Installing Too Close to a Concrete Edge

Placing anchors too near an edge or corner is a critical structural error. When an anchor is tightened, it exerts immense outward pressure, creating a “cone” of stress in the material around it. If an operator places an anchor too close to an edge, this stress cone cannot fully form within the concrete. This makes the edge vulnerable to cracking or “spalling,” where a chunk of the surface breaks away.

A general rule is to maintain a minimum distance of at least 12 times the anchor’s diameter from any edge. However, professionals must always consult the manufacturer’s technical data.

- For example: A 5/8″ carbon steel Kwik Bolt TZ requires a minimum edge distance of 3.25 inches.

- Consequence: An attempt to install these anchors closer than the specified distance can easily cause the concrete to fracture during installation, ruining the anchor point.

Over-Torquing the Nut and Bolt

Applying excessive force when tightening the nut is a common and critical error. Some installers mistakenly believe that a tighter bolt equals a stronger hold. This assumption is incorrect and dangerous. Over-torquing stresses the anchor, the fixture, and the concrete beyond their design limits. This can lead to immediate or eventual failure. A calibrated torque wrench is the only tool that ensures the correct rotational force is applied.

An operator can identify an over-torqued bolt by looking for several warning signs. These indicators show that the material has been compromised.

- Deformed or stretched threads on the bolt

- Cracks appearing on the fixture’s flanges or the concrete surface

- The bolt head snapping off completely during tightening

- Damage to gaskets, leading to potential leaks

Exceeding the manufacturer’s torque specification introduces severe risks. The immense pressure can cause different types of failure, including concrete failure, where the base material itself breaks. It can also cause steel failure of the anchor, where the bolt yields or fractures. In other cases, it leads to anchor pullout failure, where the entire assembly loses its grip.

Hitting Rebar During Drilling

Reinforcing steel, or rebar, is a common component of structural concrete. Hitting rebar during drilling is a frequent problem that requires an immediate and correct response. An operator will feel the drill bit stop making progress and may hear a change in the sound of the drill. Continuing to drill can damage the bit, the drill, and, most importantly, the structural rebar.

Protocol: When You Hit Rebar 🛑 The correct procedure is to stop drilling immediately. The operator should not try to force the drill through the obstruction. The safest and most recommended solution is to relocate the anchor point.

The primary and preferred solution is to abandon the hole and move the fastening point. An installer should move the new hole several inches away to avoid the rebar completely. If project constraints make it impossible to move the anchor, the decision to cut the rebar rests solely with the Engineer of Record (EOR). An EOR must approve any modification to the reinforcing steel. If the EOR approves drilling through the rebar, they will likely require onsite testing after the anchor is installed to verify its performance and ensure it meets load requirements.

Choosing the Right Concrete Anchor Bolts for Your Project

Selecting the correct concrete anchor bolts is a critical decision that directly impacts project safety and longevity. An installer must evaluate load requirements, environmental factors, and the condition of the concrete itself. This ensures the chosen anchor performs reliably under its intended service conditions.

Evaluating Load Requirements

An operator must first understand the forces the anchor will need to resist. These forces are categorized into two primary types: tensile and shear loads.

Shear vs. Tensile Loads

The type of load an anchor must handle dictates its selection. Engineers use complex formulas to determine an anchor’s capacity, considering factors like anchor yielding and concrete breakout.

- Tensile Load: This is a pulling force that tries to pull the anchor straight out of the concrete.

- Shear Load: This is a side-to-side force that runs parallel to the concrete surface.

When both forces are present, an interaction check is performed to ensure the combined loads do not exceed the anchor’s capacity.

Light, Medium, and Heavy-Duty Applications

Anchors are rated for different load capacities. Choosing the right duty rating prevents anchor failure. Lighter bolts are suitable for simple tasks, while heavy-duty anchors are necessary for structural connections.

| Duty Rating | Load Rating (lbs) | Example Anchor Types |

|---|---|---|

| Light-Duty | 5-25 | Plastic Expansion Anchors |

| Medium-Duty | 25-75 | Self-Drilling Anchors |

| Heavy-Duty | 75+ | Wedge & Sleeve Anchors |

Considering Environmental Conditions

The environment where the anchor is installed plays a major role in material selection. Moisture and chemicals are primary concerns that can compromise the integrity of the bolts.

Indoor vs. Outdoor Use

Outdoor installations expose anchors to moisture, which can cause rust and corrosion. High humidity levels accelerate this process, weakening the fasteners. Indoor applications are generally less harsh, but an installer must still consider potential moisture or chemical exposure.

Corrosion Resistance: Zinc-Plated vs. Galvanized vs. Stainless Steel

The material of the bolts determines their lifespan. Each coating or material offers a different level of protection.

| Material | Corrosion Resistance | Best For |

|---|---|---|

| Zinc-Plated | Good | Indoor or dry environments with low corrosion risk. |

| Hot-Dip Galvanized | Very Good | Outdoor and industrial applications with moderate moisture. |

| Stainless Steel | Excellent | Marine, chemical, and high-moisture environments. |

Assessing the Concrete’s Condition

The state of the base material is as important as the anchor itself. The age and strength of the concrete are critical factors.

Cured vs. Green Concrete

Installers must never install expansion anchors in “green” or uncured concrete. Fresh concrete shrinks as it cures. This shrinkage loosens the anchor, rendering it weak and unreliable. An anchor installed in uncured concrete will not gain strength; it will only become weaker. The ultimate strength of all concrete anchor bolts depends on the compressive strength of fully cured concrete.

Factoring in Concrete Strength (PSI)

The compressive strength of concrete, measured in pounds per square inch (PSI), directly affects an anchor’s holding power. A higher PSI value means the concrete is stronger and can support a greater load. For example, an anchor’s rating can nearly double when moving from 2500 PSI concrete to 6000 PSI concrete. Manufacturers often base load capacities on a standard concrete strength, so an operator must verify the project’s specific PSI to select the appropriate anchors.

To successfully install expansion bolts, an installer must follow the core steps of drilling, cleaning, inserting, and tightening. This process ensures each anchor achieves its full potential. Professionals always consult the manufacturer’s specifications for the specific anchor to guide the installation.

A correctly installed anchor provides a strong and reliable fastening point. Operators install the anchor with precision to guarantee safety and performance.

FAQ

What should an operator do if an anchor spins in the hole?

A spinning anchor often indicates a problem with the hole. The operator should remove the anchor and check for two common issues:

- The hole contains excessive dust.

- The hole was drilled too large.

Cleaning the hole or drilling a new one correctly usually solves this problem.

Can an installer reuse expansion bolts?

No, an installer cannot reuse expansion bolts. The expansion mechanism permanently deforms during the initial installation to grip the concrete. Removing the anchor destroys its ability to create a secure connection again.

Safety Tip ⚠️ Always use a new anchor for every installation point.

How long must an installer wait to apply a load?

Mechanical expansion anchors are ready for immediate loading. Once an operator tightens the anchor to the specified torque, it achieves its full holding power. There is no cure time required, unlike chemical anchors. This allows for faster project completion.

Which expansion anchor is best for brick or block?

Sleeve anchors are an excellent choice for brick and block applications. Their expansion mechanism distributes pressure along the length of the sleeve. This design reduces the risk of cracking these more brittle base materials, providing a secure hold without causing damage.

Why is a torque wrench so important?

A torque wrench guarantees the correct clamping force. It prevents the common mistakes of over-tightening or under-tightening the anchor. Proper torque application is essential for the anchor to perform as designed.

| Condition | Risk |

|---|---|

| Under-Tightened | Anchor may pull out under load. |

| Over-Tightened | Bolt may snap or concrete may crack. |

How does an operator fix a hole that was drilled too big?

The safest and most professional solution is to abandon the oversized hole. The operator should move over and drill a new, correctly sized hole. Attempting to use an expansion anchor in a large hole will result in a weak and unreliable connection.