A drop-in anchor is a female, internally threaded anchor designed for solid concrete applications. The global construction anchors market, valued at USD 3.01 billion in 2023, is projected to grow at a 3.9% CAGR through 2030, reflecting the industry’s reliance on dependable fastening. Proper installation dictates drilling precise holes, thorough cleaning, inserting the anchor, and expanding it with a setting tool. The final holding strength of the anchor depends entirely on correct hole specifications and proper expansion. A 2023 survey highlighted that installation errors cause 34% of Anchor Bolts failures, making it crucial to install drop in anchors correctly. A leading custom fasteners manufacturer often provides custom anchor bolts for specialized projects, but the fundamental principles for installing drop in anchors remain the same.

What is a Drop-In Anchor and When to Use It?

A drop-in anchor is a female-threaded expansion anchor designed exclusively for use in solid concrete. Its unique mechanism and flush-mount design make it a preferred choice for specific construction and industrial applications. Understanding its function helps professionals select the right fastener for the job.

Understanding the Drop-In Anchor Mechanism

The holding power of this anchor comes from a simple yet effective internal expansion process. This process requires a specific setting tool to guarantee a secure connection.

Key Components of the Anchor

A drop-in anchor consists of two primary parts:

- The Anchor Body: A cylindrical, internally threaded steel shell with four slits at its base.

- The Internal Plug: A solid, cone-shaped metal plug pre-set inside the base of the anchor body.

How the Internal Plug Expands

Installation involves a setting tool that fits inside the anchor. When an installer strikes the tool with a hammer, it drives the internal plug upward. This action forces the slotted base of the anchor to expand, creating a strong friction hold against the walls of the pre-drilled hole in the concrete.

Ideal Applications for Drop-In Anchors

These anchors excel in applications requiring a strong, permanent, and flush fastening point in concrete.

Overhead Fastening (Pipes, Struts)

Installers frequently use these anchors for suspending threaded rods from concrete ceilings. This is ideal for hanging pipes, fire sprinkler systems, HVAC ductwork, and cable trays. The anchor provides a reliable connection point with significant load-bearing capabilities.

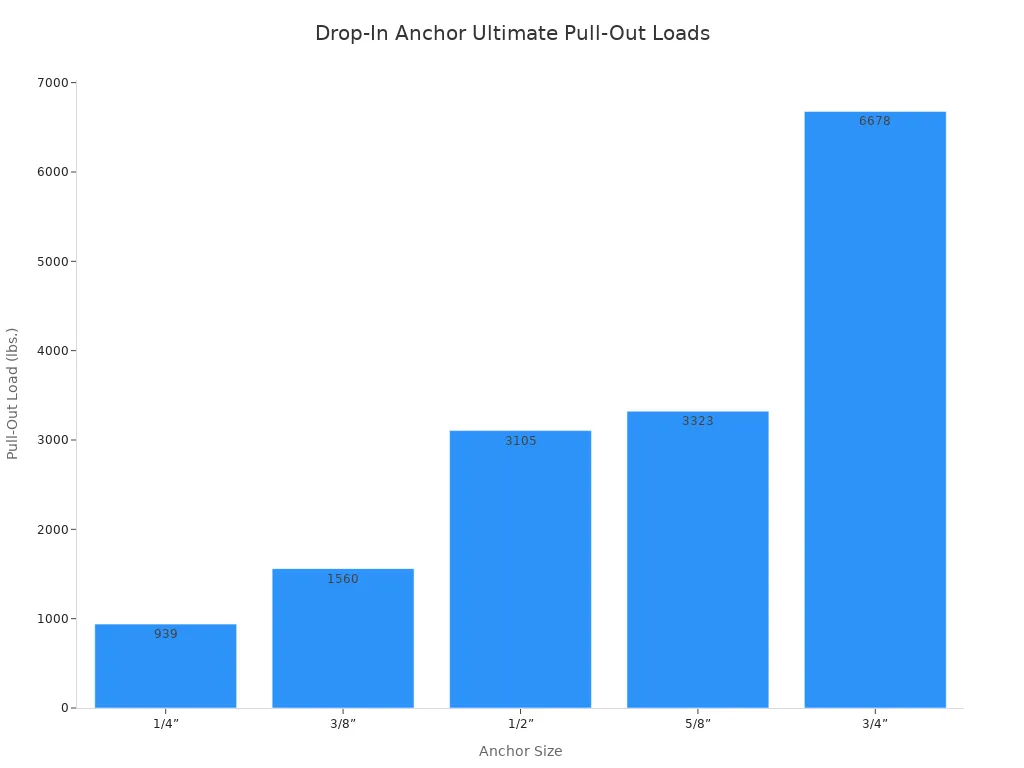

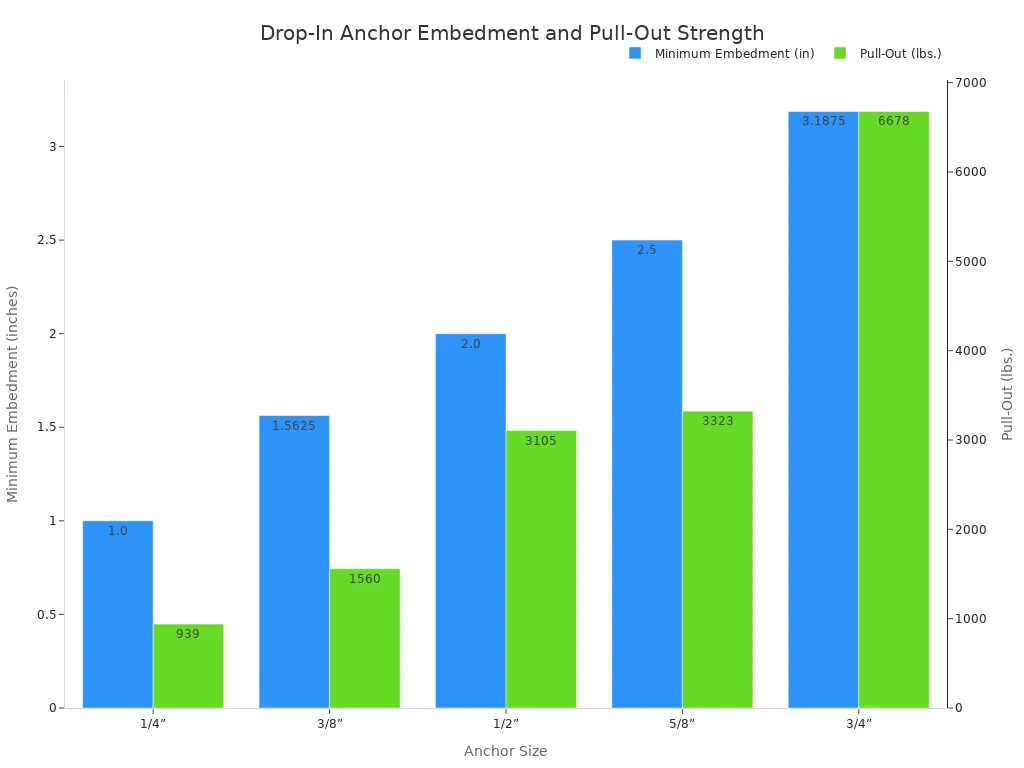

Note: The ultimate pull-out loads shown below are for 2000 PSI concrete. Professionals must apply a safety factor (typically 4:1) to determine safe working loads.

Anchor Size Pull-Out (lbs.) 1/4” 939 3/8” 1560 1/2” 3105 5/8” 3323 3/4” 6678

Mounting Machinery and Racking

The high strength of these anchors makes them suitable for securing heavy machinery, industrial racking, and shelving units to concrete floors.

Flush-Mount Requirements

Once set, the top of the anchor sits flush with or just below the concrete surface. This feature is critical when a smooth surface is needed or when a fixture might be moved later, leaving no protruding studs.

Comparing Anchor Types

Choosing the correct fastener is vital. Drop-in anchors have distinct advantages over other common concrete anchors in certain situations.

Drop-In vs. Wedge Anchors

Wedge anchors are male fasteners with an integrated stud and nut. They are excellent for through-bolting applications. In contrast, the female-threaded drop-in anchor allows for fixture removal without leaving a protruding bolt, offering a cleaner finish.

Drop-In vs. Sleeve Anchors

Sleeve anchors are more versatile, but drop-ins provide superior strength in solid concrete. The primary difference lies in their approved base materials.

| Anchor Type | Material Suitability |

|---|---|

| Sleeve Anchors | Best for hollow materials and a range of base materials (concrete, brick, block) |

| Drop-in Anchors | Designed for solid concrete applications only. |

Sleeve anchors work well in various masonry, including brick and block. Drop-in anchors are specialized fasteners engineered specifically for the demands of solid concrete.

Gathering Your Tools and Materials

An installer’s success depends on having the right equipment. Preparing all necessary tools and materials before starting ensures a smooth, safe, and secure installation process. This preparation prevents delays and helps guarantee the anchor performs as expected.

Essential Tools to Install Concrete Anchors

Using the correct professional-grade tools is non-negotiable for a proper installation. Each tool serves a specific function in creating a reliable fastening point.

Hammer Drill or Rotary Hammer

A standard drill is insufficient for concrete. An installer must use a hammer drill or a more powerful rotary hammer. These tools combine rotation with a hammering action, pulverizing the concrete to create clean, precise holes. A rotary hammer is the preferred choice for larger diameter anchors or harder concrete.

ANSI-Standard Carbide-Tipped Masonry Bit

The drill bit must match the anchor’s required diameter. Installers should use a carbide-tipped masonry bit that meets American National Standards Institute (ANSI) specifications. Adherence to ANSI standards is crucial for ensuring the drill bit’s diameter meets the precise requirements for proper anchor installation. While some bits are engineered with even tighter tolerances to enhance performance, using an ANSI-compliant bit guarantees the hole is not oversized, which would compromise the anchor’s holding power.

Drop-In Anchor Setting Tool

This is a specialized, non-negotiable tool. Each size of drop-in anchor requires a corresponding setting tool. The tool features a pin that fits inside the anchor and a shoulder that stops on the anchor’s lip. This design ensures the internal plug is driven to the correct depth for full expansion without damaging the internal threads.

Hammer or Mallet (2-3 lb)

A heavy-duty hammer or mallet, typically weighing 2 to 3 pounds, provides the necessary force to set the anchor. The installer strikes the setting tool with the hammer until the tool’s shoulder makes solid contact with the top of the anchor body.

Hole Cleaning Supplies

Concrete dust and debris left in the drilled hole can prevent the anchor from setting correctly and drastically reduce its load capacity. Meticulous cleaning is a critical step.

Wire Brush (Sized to Hole Diameter)

A stiff wire brush, sized specifically for the hole’s diameter, is essential. The installer uses it to scrub the inside walls of the hole, dislodging any dust or small particles left behind after drilling.

Compressed Air or High-Velocity Blower

After brushing, the installer must remove all loose debris. A blast of compressed air or a high-velocity blower effectively clears the hole. This step should be repeated until no more dust emerges.

Shop Vacuum

A shop vacuum offers an alternative or supplementary method for dust removal. It is particularly useful in indoor environments or occupied spaces to control airborne dust and maintain a cleaner work area.

Required Materials and Safety Gear

Selecting the correct materials and wearing appropriate personal protective equipment (PPE) is fundamental to safety and project success.

Drop-In Anchors (Correct Size and Material)

The installer must choose the correct size and material for the drop-in anchors based on the load requirements and environmental conditions. Options typically include zinc-plated carbon steel for dry, indoor use and stainless steel for corrosive or outdoor environments.

Threaded Rods or Bolts

These are the male fasteners that thread into the set drop-in anchor. The installer must ensure the bolt or rod has the correct thread size (e.g., a 3/8″ anchor requires a 3/8″ bolt) and sufficient length for the fixture being attached.

Safety Glasses and Gloves

Drilling concrete creates flying debris and fine dust. Safety glasses are mandatory to protect the eyes. Heavy-duty gloves protect the hands from abrasion and impact during the installation process.

Dust Mask or Respirator

Inhaling crystalline silica dust from concrete is a serious health hazard. A dust mask or, preferably, a respirator is crucial to protect the installer’s respiratory system, especially during extensive drilling operations.

Pre-Installation Checks and Measurements

Careful planning before drilling is the foundation of a secure installation. An installer must verify the anchor selection, hole specifications, and layout to prevent component failure and ensure long-term reliability. These preliminary steps are just as critical as the physical installation process.

Selecting the Right Drop-In Anchor

The first decision involves choosing an anchor that matches both the load it will support and the environment where it will be installed.

Matching Anchor to Load Requirements

An installer must select an anchor with a load capacity that far exceeds the intended working load. Manufacturers provide ultimate load ratings for their anchors. Professionals apply a safety factor, typically 4:1, to these ratings. This means the safe working load should not be more than 25% of the anchor’s stated ultimate pull-out strength.

Choosing the Material (Zinc-Plated vs. Stainless Steel)

The anchor’s material composition is critical for its longevity, especially in demanding conditions. Installers should consider environmental factors like moisture and chemical exposure.

- Zinc-Plated Steel: This is the standard choice for dry, indoor applications where corrosion is not a concern.

- Stainless Steel: This material offers excellent corrosion resistance. It is the recommended choice for high-humidity areas, outdoor installations, or facilities with chemical exposure.

- Specialty Brass: For highly specific conditions, other materials are available. Marine-grade brass anchors are used for saltwater environments, while chemical-resistant brass anchors are suitable for processing plants.

Determining Hole Specifications

The performance of all drop-in anchors depends on precisely drilled holes. The diameter and depth must match the manufacturer’s specifications for the chosen anchor size.

Finding the Required Hole Diameter

The required hole diameter is always the same as the nominal outer diameter of the anchor. For example, a 1/2″ drop-in anchor requires a 1/2″ diameter hole. Using an ANSI-standard carbide-tipped bit ensures the hole is not oversized, which would prevent the anchor from expanding correctly.

Calculating the Minimum Embedment Depth

Minimum embedment is the shallowest depth at which an anchor can be installed to achieve its published load values. Deeper embedment generally yields higher holding strength. The anchor must be installed deep enough for the entire body to be flush with or below the concrete surface.

| Anchor Size | Minimum Embedment |

|---|---|

| 1/4” | 1” |

| 3/8” | 1-9/16” |

| 1/2” | 2” |

| 5/8” | 2-1/2” |

| 3/4” | 3-3/16” |

Pro Tip: A general rule for satisfactory performance is a minimum embedment of 4-1/2 bolt diameters. Always consult the manufacturer’s data for specific requirements.

Planning Your Anchor Layout

Properly spacing multiple anchors from each other and from concrete edges prevents the concrete from cracking under stress.

Minimum Spacing Between Anchors

When installing multiple anchors, they must be spaced far enough apart to avoid overlapping stress zones in the concrete. ACI (American Concrete Institute) guidelines generally recommend a minimum spacing of 4 to 6 times the anchor diameter. Placing anchors too close together can compromise the holding power of the entire group.

Required Distance from Concrete Edges

An installer must also maintain a minimum distance from any unsupported concrete edge. The expansion force of the anchor can cause the concrete to spall or break if the hole is too close to an edge. For a common 1/2-inch drop-in anchor, the required minimum distance from an edge is 3-1/8 inches.

How to Install Drop In Anchors: A Step-by-Step Guide

Following a precise, methodical process is the only way to guarantee a secure and reliable fastening. This step-by-step installation guide breaks down the critical actions an installer must take, from drilling the holes to inserting the anchors. Each phase is essential for achieving the anchor’s maximum performance.

Step 1: Drill the Hole

The first physical step involves creating a clean, properly sized cavity in the concrete. The quality of the hole directly impacts the anchor’s ability to expand and grip the base material. Proper technique when drilling the holes is fundamental to the entire process.

Setting the Drill Depth Stop

An installer must drill the hole to the correct depth. The hole must be deep enough to allow the entire anchor body to sit flush with or just below the concrete surface.

Pro Tip: The easiest way to ensure correct depth is to use the depth stop rod on the hammer drill. An installer can also measure the length of the anchor and wrap a piece of tape around the drill bit to mark the required depth. This visual guide prevents drilling a hole that is too shallow.

Drilling a Perpendicular Hole

The hole must be drilled straight into the concrete, perpendicular to the surface. An angled hole will prevent the anchor from sitting flush and can compromise its holding power. To maintain a perpendicular drilling angle, an installer should:

- Use a correctly sized masonry bit for the task.

- Maintain a moderate, steady drilling speed.

- Keep the drill body perpendicular to the concrete surface.

- Avoid applying excessive downward pressure; let the tool do the work.

- Regularly clear dust from the drilling area for better visibility.

Step 2: Clean the Hole Thoroughly

This is the most critical and often overlooked step when people install drop in anchors. Concrete dust left in the hole acts as a barrier, preventing the anchor from making full contact with the concrete walls. Inadequate hole cleaning, characterized by loose particles, obstructs proper contact and can lead to bond failure. This failure significantly reduces the ultimate tensile and shear capacity of the fastening by compromising the bond strength essential for effective load transfer.

A professional cleaning process involves a sequence of blowing, brushing, and blowing again.

Blowing Out Debris with Air

Immediately after drilling, an installer uses compressed air or a high-velocity blower to force the bulk of the dust and debris out of the hole. The nozzle should be placed at the bottom of the hole to ensure debris is pushed up and out, not compacted at the base.

Scrubbing with a Wire Brush

Next, the installer uses a stiff wire brush sized to the hole’s diameter. He or she inserts the brush to the bottom of the hole and scrubs the interior walls with an up-and-down and twisting motion. This action dislodges any fine particles and dust that the initial air blast left behind.

Performing a Final Air Blast

After brushing, a final blast of compressed air removes all the newly loosened particles. The installer repeats this step until no more dust emerges from the hole. The holes are now properly prepared for the next stage.

Step 3: Inserting the Anchors

With a clean hole, the installer can proceed with inserting the anchors. This step is straightforward but requires correct orientation and placement.

Positioning the Anchor Correctly

The installer orients the drop-in anchor with the slotted, expandable end facing down. He or she then inserts the anchor into the prepared hole. It should slide in with minimal resistance. If the anchor binds, the hole may be undersized or still contain debris.

Tapping the Anchor Flush with the Surface

Once positioned, the installer uses a hammer to gently tap the top of the anchor. He or she continues tapping until the top lip of the anchor is either flush with the concrete surface or slightly recessed below it. This ensures that the fixture will sit flat against the concrete and that the setting tool can engage the anchor properly in the next step.

Step 4: Set the Anchor

This step activates the anchor, creating the friction hold inside the concrete. Proper expansion is non-negotiable for achieving the anchor’s specified load capacity. The installer uses a specific setting tool and a hammer to drive the internal plug into the anchor’s expansion sleeve.

Placing the Setting Tool in the Anchor

An installer selects the setting tool that corresponds to the anchor size. He or she inserts the narrow end of the setting tool into the body of the anchor. The tool is designed to bottom out on the internal expansion plug. The wider shoulder of the setting tool will rest on the top lip of the anchor body. This design prevents the tool from going too deep and damaging the internal threads.

Striking the Tool Firmly with a Hammer

The installer holds the setting tool straight and perpendicular to the concrete surface. He or she then strikes the top of the setting tool with several firm, square blows from a 2-3 lb hammer. The installer continues striking the tool until its shoulder sits flush against the top of the anchor.

Professional Confirmation: A properly set anchor produces a distinct change in sound. The initial dull thuds will change to a solid, ringing sound. This “ring” indicates the expansion plug is fully set and the tool’s shoulder has made solid contact with the anchor body.

This positive stop confirms the anchor is expanded correctly within the hole. The anchor is now ready to accept a threaded bolt or rod.

Step 5: Attach Your Fixture

With the anchors properly set, the final step is to mount the desired object. This phase completes the process to install drop in anchors and secures the fixture to the concrete.

Aligning the Fixture Over the Anchor

The installer carefully places the fixture (such as a machine base, support bracket, or racking post) over the set anchors. He or she ensures the mounting holes in the fixture align perfectly with the threaded openings of the anchors in the concrete. A clean, flush surface is essential for even load distribution.

Threading in the Bolt or Rod

The installer inserts the correctly sized bolt or threaded rod through the fixture’s mounting hole and into the anchor. He or she should start threading the bolt by hand for the first few turns. This practice prevents cross-threading, which can damage the threads on both the bolt and the anchor. Once the bolt is hand-tight, the installer uses a wrench to tighten it to the manufacturer’s recommended torque specification.

Caution: Avoid over-torquing the bolt. Excessive force does not increase holding power and can damage the anchor’s internal threads or even crack the surrounding concrete.

Verifying a Secure Installation

A successful installation depends on more than just following the steps. An installer must perform final checks to confirm the anchor is secure and will perform as expected. This verification process prevents potential failures and ensures the integrity of the fastening.

Confirming the Anchor is Properly Set

Two simple, tactile checks provide immediate feedback on the quality of the set. An installer should perform both for every anchor.

Checking the Setting Tool Shoulder

The design of the setting tool provides a built-in visual confirmation. When an installer sets the anchor correctly, the shoulder of the setting tool will make full, flush contact with the top lip of the anchor body. If a gap remains between the tool’s shoulder and the anchor, the internal plug is not driven far enough.

The “Ring” Test for Solid Contact

An experienced installer also listens for auditory confirmation. As he or she strikes the setting tool, the sound provides crucial feedback. Initially, the strikes produce a dull thud. When the anchor is properly set, the sound it makes when struck with a hammer changes, producing a different noise. This solid, metallic “ring” signifies that the plug is fully engaged and the anchor is locked tightly against the concrete.

Inspecting for Common Installation Errors

Visual inspection can reveal common mistakes that compromise holding strength. An installer should look for signs of an improperly set anchor.

Signs of an Under-Set Anchor

An under-set anchor is not fully expanded and will not achieve its rated load capacity. Key indicators include:

- The setting tool’s shoulder did not make contact with the anchor’s lip.

- The anchor feels loose or can be spun by hand after the setting attempt.

- The bolt or rod does not thread in smoothly, suggesting the plug is obstructing the threads.

Signs of an Over-Set Anchor

It is also possible to over-set an anchor, though less common. This usually happens when an installer uses excessive force or an improper tool. Signs include damaged internal threads or visible cracks (spalling) in the concrete around the anchor.

What to Do if the Anchor is Loose

A loose anchor is unusable and unsafe. An installer must understand the cause to apply the correct solution.

Causes of a Spinning Anchor

A spinning anchor is a clear sign of failure. The most common causes are an oversized hole drilled with a worn-out bit or inadequate hole cleaning that left too much dust and debris. Both issues prevent the anchor from gripping the concrete walls during expansion.

Solutions for an Improperly Set Anchor

Unfortunately, a poorly set drop-in anchor cannot be “fixed” in place. The only reliable solution is abandonment and replacement. The installer must drill a new hole, adhering to minimum spacing requirements for anchors. He or she then repeats the installation process, paying close attention to hole diameter, cleaning, and proper setting technique.

Advanced Tips for Installing Drop-In Anchors

Mastering the basics is essential, but professional installers encounter variables that require advanced knowledge. Understanding how to adapt to different concrete conditions and environments ensures a successful outcome for every project. These tips help professionals move beyond a standard installation to achieve superior results.

Working with Different Concrete Conditions

Concrete is not a uniform material. Its age, hardness, and composition can affect the drilling and setting process.

Considerations for Cured vs. Green Concrete

Installers must only install drop in anchors in fully cured concrete, which typically takes at least 28 days. Green, or uncured, concrete has not reached its specified compressive strength. Attempting an installation in green concrete will result in a weak hold and likely failure.

Adjusting for Hard Aggregate Concrete

Some concrete mixes contain extremely hard aggregate. When drilling, an installer may feel the bit struggling. In these situations, a rotary hammer is superior to a standard hammer drill. The installer should maintain steady pressure, let the tool do the work, and use a sharp, high-quality bit to power through the aggregate without deflecting.

Avoiding Common Installation Mistakes

Many installation failures stem from a few common, preventable errors. Paying close attention to these details is critical.

Drilling an Oversized or Undersized Hole

The hole diameter must be exact. Using an oversized drill bit makes it difficult to properly set the anchor and will reduce its load capacity. An installer must also avoid wobbling the drill, as this can ream the opening and create improperly shaped holes that diminish holding power. An undersized hole will prevent the anchor from being inserted at all.

Consequences of Inadequate Hole Cleaning

A clean hole is non-negotiable. Debris left in the hole creates a barrier between the anchor body and the concrete. This prevents the expansion mechanism from achieving the necessary friction, severely compromising the fastener’s strength.

Preventing Damaged Threads

The internal threads are vital for attaching the fixture. An installer prevents damage by always using the correct setting tool for the anchor size. The tool’s shoulder is designed to stop on the lip of the anchor, ensuring the internal plug is set without the tool striking and damaging the threads.

Environmental Factors

The anchor’s environment dictates the material an installer must choose for long-term performance and safety.

Interior vs. Exterior Applications

For dry, indoor environments, standard zinc-plated steel anchors are sufficient. However, any exposure to moisture, humidity, or outdoor conditions requires a material with enhanced corrosion resistance.

Choosing Stainless Steel for Corrosive Areas

When installing drop-in anchors in exterior or corrosive areas, stainless steel is the preferred choice. However, not all stainless steel is the same.

Note: 316 stainless steel generally offers better corrosion protection than 304 in most environments. Its added molybdenum content provides superior resistance to pitting and crevice corrosion.

| Feature/Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Molybdenum Content | Absent | Present |

| SCC Resistance | Significant problems | Significant problems |

| UIAA Recommendation | Not for SCC areas | Not for SCC areas |

Despite being an upgrade, even 316 stainless steel is not a complete solution for areas with a high risk of Stress Corrosion Cracking (SCC).

Troubleshooting Common Installation Problems

Even with careful preparation, installers can encounter issues during an installation. Recognizing the problem’s cause is the first step toward implementing the correct solution and ensuring a secure fastening. This section addresses the most common challenges and provides professional remedies.

Problem: The Anchor Spins in the Hole

A spinning anchor is a critical failure. It indicates the anchor body has not achieved the necessary friction against the concrete walls and cannot support any load.

Cause: Oversized Hole or Debris

This issue almost always stems from one of two errors. The installer may have used a worn-out or incorrect size drill bit, creating an oversized hole. Alternatively, inadequate hole cleaning left a layer of dust and debris, preventing the anchor from gripping the concrete during expansion.

Solution: Re-Drill or Use a Larger Anchor

An installer cannot salvage a spinning anchor. The only safe and reliable solution is to abandon the faulty hole. He or she must drill a new hole, ensuring it is far enough away to meet minimum spacing requirements. The installer then repeats the installation process, using a new anchor and paying strict attention to correct bit size and meticulous hole cleaning.

Problem: The Bolt Won’t Thread In

A bolt that refuses to thread into a set anchor is a frustrating setback. This problem typically points to an issue with the anchor’s internal threads.

Cause: Damaged Threads from Setting Tool

The most common cause is damage inflicted during the setting process. An installer may have used an incorrect setting tool or excessive, uncontrolled force. These actions can cause the setting tool to strike and deform the delicate internal threads, blocking the bolt’s path.

Solution: Using a Tap to Clean Threads

In some cases, an installer can repair the damaged threads using a thread repair kit. These kits contain the necessary tools to restore the threading.

Professional Repair Process: Thread repair kits, often containing high-strength stainless steel wire inserts, provide a durable solution. The process involves:

- Placing the special tap from the kit into a tap wrench.

- Applying tapping fluid and carefully tapping the bore to the required depth.

- Sliding the thread insert onto the installation tool.

- Rotating the insert into the newly tapped hole until it sits just below the surface.

- Removing the installation tool and using it to sharply break off the insert’s tang.

This procedure creates new, strong threads, making the anchor usable.

Problem: Concrete Cracks or Spalls

Visible cracks or chipping (spalling) on the concrete surface around the anchor indicate that the base material has failed. This compromises the integrity of the fastening.

Cause: Anchor Too Close to Edge

This type of failure occurs when the expansion force of the anchor is too great for the surrounding concrete to withstand. It is a direct result of drilling the hole too close to an unsupported edge or corner.

Solution: Adhering to Edge Distance Specs

Prevention is the only solution for this problem. An installer must always consult and strictly adhere to the manufacturer’s specifications for minimum edge distance for the specific size of anchors being used. This ensures there is enough concrete mass to absorb the expansion forces without fracturing.

A successful drop-in anchor installation hinges on three critical phases. An installer must follow precise specifications when drilling the holes. Meticulous cleaning after drilling the holes is essential for achieving the anchor’s maximum holding capacity. He confirms the anchor is fully set when the setting tool’s shoulder makes solid contact with the anchor body. Following these steps creates a secure and reliable fastening point in solid concrete for any application.

FAQ

Can an installer reuse a drop-in anchor?

No. An installer cannot reuse a drop-in anchor. The expansion process permanently deforms the anchor body. Removing it destroys its integrity, making re-installation unsafe. A professional always uses a new anchor for each new hole to guarantee a secure connection.

What happens if the hole is too deep?

A hole that is too deep is generally not a problem. The installer simply taps the anchor into the hole until its top is flush with the concrete surface. The anchor will set correctly as long as it achieves its minimum required embedment depth.

Why is a specific setting tool required?

The setting tool is essential for a professional installation. Its design ensures the internal plug is driven to the correct depth for full expansion. It also protects the anchor’s internal threads from damage, a common issue when using improper tools.

Can an installer use drop-in anchors in brick or block?

No. Installers must use drop-in anchors only in solid concrete. The anchor’s expansion mechanism requires the high compressive strength of solid concrete to create a secure hold. Using them in hollow or softer materials like brick or block will result in failure.

Warning: ⚠️ Using drop-in anchors in base materials other than solid concrete is unsafe and can lead to catastrophic failure of the fastening.

How tight should the bolt be?

An installer should tighten the bolt to the manufacturer’s recommended torque specification using a torque wrench. Over-tightening does not increase holding power. It can damage the anchor’s internal threads or crack the concrete, compromising the entire fastening.

What is the main difference between a drop-in and a wedge anchor?

The primary difference is the threading type and final profile.

| Feature | Drop-In Anchor | Wedge Anchor |

|---|---|---|

| Threading | Female (Internal) | Male (External Stud) |

| Profile | Sits flush in concrete | Protrudes from concrete |

| Use Case | Removable fixtures | Permanent fixtures |

An installer chooses a drop-in when a flush surface is required.