Selecting the right flange face bolt is a critical engineering task for industrial applications. A project’s specific bolt choice factors determine the correct bolt. Professionals must choose flange bolt materials and grades that match the flange pressure and temperature requirements. A leak-proof flange seal depends entirely on the correct Flange Bolt.

The flange requires flange face bolts that meet its exact specifications. The flange design, flange material, and flange gasket all influence the bolt for various applications. A custom fasteners manufacturer can supply custom fasteners or a unique bolt casting to meet these needs. The right flange face bolts ensure the flange remains secure, making this bolt selection vital for safe applications. These flange face bolts are essential.

Step 1: How to Choose Bolts Based on Material Properties

The first step to choose flange bolt integrity is selecting the right material. The operational environment dictates the best material choices for flange face bolts. Engineers must evaluate temperature, pressure, and chemical exposure to determine how to choose bolts that guarantee a safe, long-lasting connection. Different types of flange face bolts offer unique properties for specific applications.

Match Material to Temperature and Pressure

Temperature and pressure directly impact a bolt’s mechanical strength. Extreme heat can cause a bolt to soften and lose strength through a process called creep, while extreme cold can make it brittle. The right material choices for flange face bolts are essential for any flange.

Carbon Steel for General-Purpose Applications

Carbon steel flange face bolts are a cost-effective solution for general-purpose applications. They perform well in moderate temperature and pressure conditions where corrosion is not a primary concern. These types of flange face bolts are common in water, oil, and gas applications within controlled environments. A flange using these flange face bolts must operate within the material’s limits.

Alloy Steel for High-Temperature and High-Pressure Service

For high-temperature and high-pressure applications, alloy steel flange face bolts are the standard. Alloying elements like chromium, molybdenum, and vanadium enhance strength and creep resistance at elevated temperatures. This makes them ideal for power generation, petrochemical processing, and other demanding industrial applications. A flange in these settings requires robust flange face bolts.

| Material | Key Alloying Element | Max. Operating Temperature | Notes |

|---|---|---|---|

| ASTM A193 B7 | Chromium-Molybdenum | 450°C (850°F) | Above this, the material softens, losing strength. |

| ASTM A193 B16 | Chromium-Molybdenum-Vanadium | 540°C (1000°F) | Vanadium enhances creep resistance for higher temperature use. |

Stainless Steel for Corrosion Resistance

Stainless steel flange face bolts provide excellent corrosion resistance, making them suitable for applications involving moisture or corrosive chemicals. Different grades offer varying levels of performance. These types of flange face bolts are critical for a flange in corrosive applications.

- Austenitic stainless steel (e.g., 304, 316): Can operate up to about 870°C (1600°F).

- High-temperature stainless steel (e.g., 310): Can work at temperatures up to 1150°C (2102°F).

These types of flange face bolts are essential for food processing and marine applications.

Exotic Alloys for Extreme Environments

For the most extreme applications, engineers turn to exotic alloys. Materials like Inconel, Monel, and Hastelloy offer superior resistance to extreme temperatures, high-pressure applications, and aggressive chemicals. These specialized types of flange face bolts ensure reliability where other materials would fail. A flange in a severe service environment needs these advanced flange face bolts.

Ensure Chemical Compatibility

Chemicals can attack a bolt, leading to corrosion and failure. Proper material choices for flange face bolts prevent this.

⚠️ Avoid Stress Corrosion Cracking (SCC) Certain chemicals cause specific alloys to crack under tensile stress. For example, chlorides can cause SCC in austenitic stainless steel, while ammonia can damage copper-based alloys. A flange connection’s safety depends on avoiding these material-chemical combinations in your applications.

Reviewing Material Test Reports (MTRs)

A Material Test Report (MTR) is a quality assurance document that certifies a material’s chemical and physical properties. Professionals must review the MTR for each bolt lot. This confirms the bolt meets the required specifications for your applications. The MTR is proof of quality for any bolt.

Consulting Chemical Resistance Charts

Engineers use chemical resistance charts to verify a material’s compatibility with specific substances. These resources rate how different types of flange face bolts react to various chemicals. Consulting these charts helps prevent degradation and ensures the long-term integrity of the flange face bolts in chemical processing applications. This is a key step for any bolt selection in such applications.

Step 2: Determining the Correct Bolt Size and Dimensions

After selecting the material, the next step is to determine the correct bolt size and dimensions. An incorrect bolt size compromises joint integrity, leading to potential leaks and safety hazards. Professionals must match the bolt diameter, length, and thread type to the flange specifications to ensure a secure and reliable connection. This is a key part of how to choose flange bolt specifications correctly.

How to Find the Right Diameter and Length

The diameter and length of flange face bolts are critical for achieving the proper clamping force. A bolt that is too short will not engage the nut fully, while a bolt that is too long can interfere with other components.

Using Flange Specification Charts (ASME B16.5)

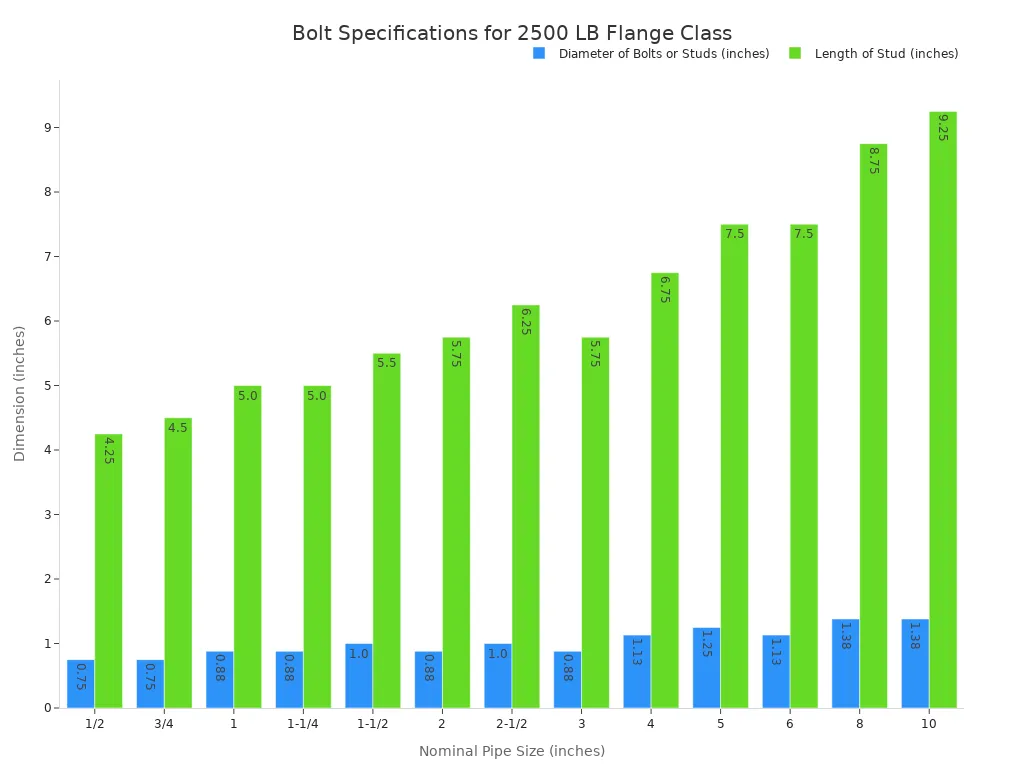

Industry standards provide charts that simplify bolt selection. ASME B16.5 is the primary standard for pipe flanges and flanged fittings. To use these charts, an engineer first identifies the flange class and nominal pipe size. The chart then specifies the required diameter, length, and number of flange face bolts for that specific flange.

For example, the chart below shows bolt requirements for a Class 2500 flange:

| Flange Class | Nominal Pipe Size | # Bolts or Studs | Dia of Bolts or Studs | Length of Stud (1/4 RF) |

|---|---|---|---|---|

| 2500 LB | 1″ | 4 | 0.88″ | 5″ |

| 2500 LB | 2″ | 8 | 0.88″ | 5-3/4″ |

| 2500 LB | 4″ | 8 | 1.13″ | 6-3/4″ |

| 2500 LB | 6″ | 12 | 1.13″ | 7-1/2″ |

Calculating Required Bolt Length

In situations where standard charts are not applicable, engineers can calculate the required bolt length. The basic formula is:

Bolt Length = (2 x Flange Thickness) + Gasket Thickness + (2 x Nut Height) + Protrusion Allowance

This calculation ensures the bolt is long enough to pass through both flanges and the gasket, with sufficient length for full nut engagement and a few extra threads protruding. This ensures the flange face bolts are the correct length for the flange.

Verifying the Number of Bolt Holes

The number of flange face bolts is just as important as the bolt size. Using the correct number of flange face bolts ensures that clamping pressure is distributed evenly around the flange. ASME B16.5 charts specify the exact number of bolt holes for each flange size and class, eliminating guesswork. A flange requires this precise number for a safe seal.

Understanding Thread Specifications

The threads on a bolt and nut create the mechanical lock that holds the joint together. Understanding thread specifications is essential for selecting compatible components.

Coarse vs. Fine Threads (UNC vs. UNF)

Threads are categorized as either coarse (UNC) or fine (UNF). Each type offers distinct advantages for different applications. UNC threads are more common in heavy-duty industrial settings, while UNF threads are preferred for precision applications. The choice impacts the performance of the flange face bolts.

| Feature | Coarse Threads (UNC) | Fine Threads (UNF) |

|---|---|---|

| Vibration Resistance | Lower resistance to loosening | Superior resistance to loosening |

| Strength & Durability | Stronger and less likely to strip | More susceptible to stripping under high stress |

| Common Applications | Construction, industrial machinery | Aerospace, precision equipment |

Ensuring Bolt and Nut Thread Compatibility

A fundamental rule of bolting is that the bolt and nut must have identical thread specifications. Mismatched threads will prevent proper assembly and can damage the flange face bolts during installation. Always verify that the thread type (UNC or UNF), diameter, and pitch are the same for both the bolt and the nut.

Understanding Thread Pitch and Diameter

Thread pitch is the distance between adjacent threads, while diameter is the overall width of the bolt. These two measurements define the bolt size. Theoretically, a finer pitch (more threads per inch) provides a greater mechanical advantage, creating more clamping force for a given torque. However, practical factors like friction often reduce this advantage. The “nut factor” (K) in torque calculations accounts for these variables, and the real-world difference in clamping force between coarse and fine flange face bolts is often minimal. The flange connection depends on the correct bolt.

Step 3: Selecting the Right Flange Face Bolt Grade for Strength

Once an engineer determines the material and dimensions, the next crucial step is selecting the right flange face bolt grade. The grade of a bolt defines its mechanical properties, primarily its strength. This characteristic is fundamental to ensuring a bolted flange connection can withstand the operational pressures without failure. A higher-grade bolt provides greater bolt strength, which is essential for high-pressure applications. The process of selecting the right flange face bolt must account for the required clamping force to seal the flange properly.

How Bolt Grade Affects Pressure Rating

The pressure rating of a flange system is directly tied to the bolt strength. A higher internal pressure requires a stronger clamping force to keep the flange sealed. Using flange face bolts with an inadequate grade can lead to insufficient clamping, resulting in leaks or catastrophic joint failure. Therefore, engineers must match the bolt grade to the pressure demands of the application.

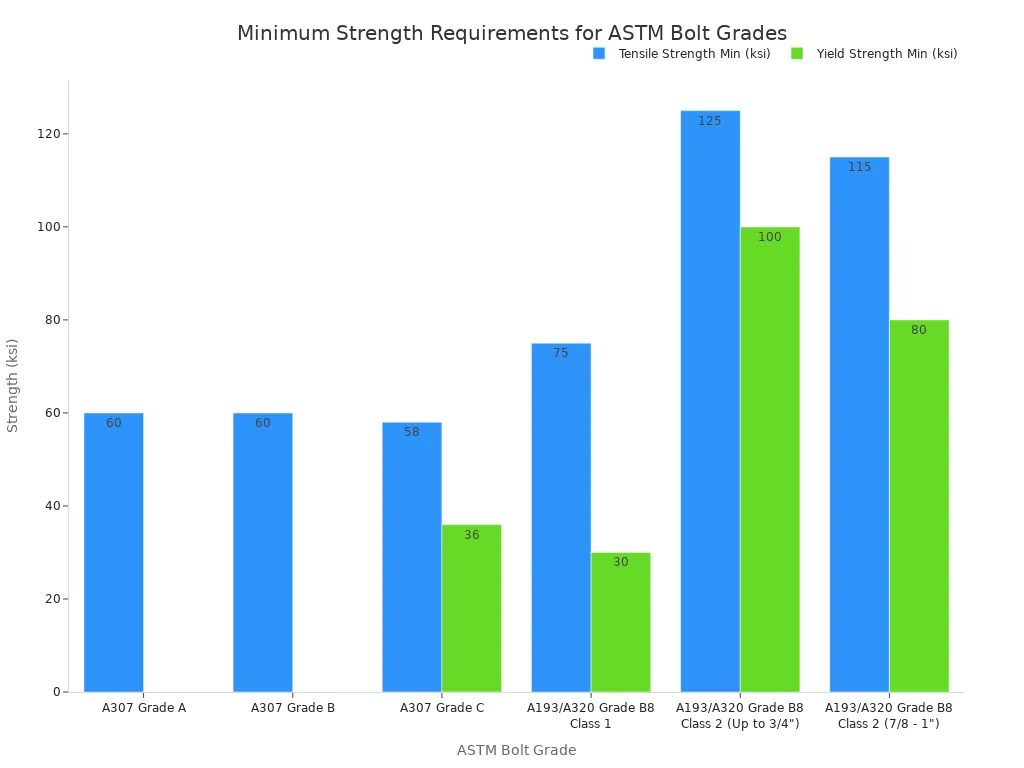

Understanding Common ASTM Grades (A193, A307, A320)

ASTM International sets the standards for bolt grades. Each grade has specific chemical and mechanical properties designed for different service conditions.

- ASTM A307: This standard covers carbon steel flange face bolts for general-purpose use. Grade A is for general applications, while Grade B is intended for flanged joints in piping systems under low-pressure conditions.

- ASTM A193: This specification is for alloy steel and stainless steel flange face bolts used in high-temperature or high-pressure service. Grade B7 is a common choice for industrial applications due to its high strength.

- ASTM A320: This standard covers alloy steel and stainless steel flange face bolts for low-temperature service. Grade L7 flange face bolts, for example, are designed to remain ductile and resist becoming brittle in cold environments.

Selecting Grade for Required Tensile Strength

Tensile strength is the maximum stress a bolt can withstand before breaking. Yield strength is the point at which a bolt begins to deform permanently. When selecting the right flange face bolt, an engineer must choose a grade with tensile and yield strengths that exceed the calculated load requirements for the flange. The table below outlines the minimum strength properties for common grades.

| Grade Marking | Tensile Strength Min (ksi) | Yield Strength Min (ksi) |

|---|---|---|

| A307 Grade A | 60 | – |

| A307 Grade B | 60 min, 100 max | – |

| A193/A320 Grade B8 Class 1 | 75 | 30 |

| A193/A320 Grade B8 Class 2 (Up to 3/4″) | 125 | 100 |

The Role of Head Markings and Stamps

Head markings are the identification codes stamped onto the head of a bolt. These markings are critical because they allow for visual verification of the bolt grade and manufacturer. This ensures the correct flange face bolts are installed on the flange.

How to Identify Bolt Grade by Markings

Engineers and installers can identify a bolt grade by its unique head stamp. These markings are standardized to prevent confusion.

- ASTM A307 Grade A: The head is marked with “A307 A”.

- ASTM A193 Grade B7: The head is simply marked with “B7”.

- ASTM A354 Grade BD: The head displays “BD”.

Checking these markings is a simple but vital quality control step before installing any flange face bolts on a flange. This is a key part of how to choose flange bolt components correctly.

Verifying Authenticity and Compliance

Verifying head markings helps prevent the use of counterfeit or non-compliant flange face bolts. A counterfeit bolt may look correct but lacks the required material properties, posing a significant safety risk to the flange.

⚠️ DANGER: Counterfeit Bolts Compromise Safety The use of counterfeit flange face bolts has led to catastrophic failures. Pentagon audits found over a million bogus components in critical military systems, including helicopters and missile platforms. In one case, two counterfeit bolts on an M109 howitzer failed, leading to a fatality. Officials identified these parts by checking for improper head markings, such as Grade 8.2 boron steel bolts being falsely stamped with the six radial lines of a higher-strength Grade 8 alloy bolt. Always verify markings to ensure the bolt is authentic and compliant with the flange specifications.

Step 4: Understanding Flange and Gasket Compatibility

A bolted flange connection is a system of three components: the flange, the gasket, and the bolt. The success of the entire joint depends on these parts working together. The right flange face bolts create the necessary clamping force to compress the gasket, forming a tight seal between two flange faces. Selecting a bolt without considering the gasket type can lead to leaks or damage to the flange itself.

Matching Gasket Type to Bolt Strength

The gasket material determines how much force is needed to create a seal. The bolt strength of the selected flange face bolts must be appropriate for the gasket type. A mismatch can result in either a leaking connection or a crushed gasket.

Compressing Soft Gaskets (Non-Metallic)

Soft gaskets, such as those made from rubber or cork, require relatively low seating stress. They compress easily to fill imperfections on the flange surface. Using a high-strength bolt for this type of flange is often unnecessary and risky. Excessive force from a powerful bolt can crush the soft gasket material, causing it to extrude out of the joint and fail. Lower-strength flange face bolts are typically sufficient and safer for these applications.

Seating Semi-Metallic and Metallic Gaskets

Semi-metallic gaskets (like spiral-wound types) and metallic gaskets (like ring-type joints) are much harder. They require a significant amount of clamping force to “seat” or deform into the flange grooves. This seating action creates a highly reliable, metal-to-metal seal. An engineer must select flange face bolts with adequate bolt strength to achieve this high load. An under-specified bolt will not be strong enough to properly compress the gasket, resulting in a leak path on the flange.

How Bolt Selection Prevents Flange Damage

The right bolt selection does more than just seal the gasket; it also protects the flange from damage. The goal is to apply enough force to seal the joint without exceeding the mechanical limits of the flange.

Avoiding Over-Tensioning and Flange Warping

Over-tensioning a bolt can apply too much stress, causing the flange to warp or bow. A warped flange will not seal correctly and may need to be replaced. Proper bolt selection helps prevent this by matching the bolt’s capabilities to the flange and gasket requirements. Several factors contribute to joint failure and flange damage.

Key Causes of Flange Joint Failure

- Improper flange preparation, including uncleaned surfaces or misalignment.

- Incorrect gasket selection for the application.

- Poor installation procedures or using uncalibrated torque tools.

- Using low-cost, non-compliant flange face bolts or untrained personnel.

Ensuring Even Load Distribution

A secure seal depends on distributing the clamping force evenly across the entire flange. The number and pattern of flange face bolts are designed specifically for this purpose. Using the correct flange face bolts ensures each bolt can handle its designated load. Following proper tightening procedures is critical for achieving this balance. Best practices include lubricating the bolt threads, using a calibrated torque wrench, and tightening the flange face bolts in a crosswise or star pattern. This methodical approach prevents uneven stress on any single point of the flange, ensuring joint integrity.

Step 5: Deciding on a Protective Coating or Finish

Selecting a protective coating is a final, critical step in how to choose flange bolt components. A coating acts as a barrier, shielding the bolt from corrosion and other environmental threats. It can also improve installation efficiency and extend the service life of the entire flange assembly. The right finish ensures the flange face bolts perform reliably in their intended service environment.

When to Use Coated Flange Face Bolts

Engineers specify coated flange face bolts when the operational environment poses a threat to the base metal or when installation challenges like friction need to be managed.

Assessing Environmental Factors (Humidity, Saltwater, Chemicals)

Environmental conditions are a primary driver for coating selection. Coated flange face bolts are mandatory in marine environments due to constant exposure to saltwater, humidity, and temperature fluctuations. These harsh conditions can quickly cause rust and corrosion on an unprotected flange, leading to equipment failure. A protective coating is essential for long-term performance and safety. Chemical processing plants also require specific coatings to protect the flange from corrosive substances.

Preventing Galling During Installation

Galling, or cold welding, is a common problem when tightening fasteners, especially those made of stainless steel. The pressure during tightening can break down the material’s natural protective oxide layer. This breakdown allows direct metal-to-metal contact, which increases friction and can fuse the nut and bolt threads together.

💡 Tip: How Coatings Prevent Galling Protective coatings like PTFE or specialized lubricants act as a barrier between the thread surfaces. This barrier prevents the breakdown of the oxide film and reduces friction, ensuring a smooth installation and allowing for accurate torque application on the flange.

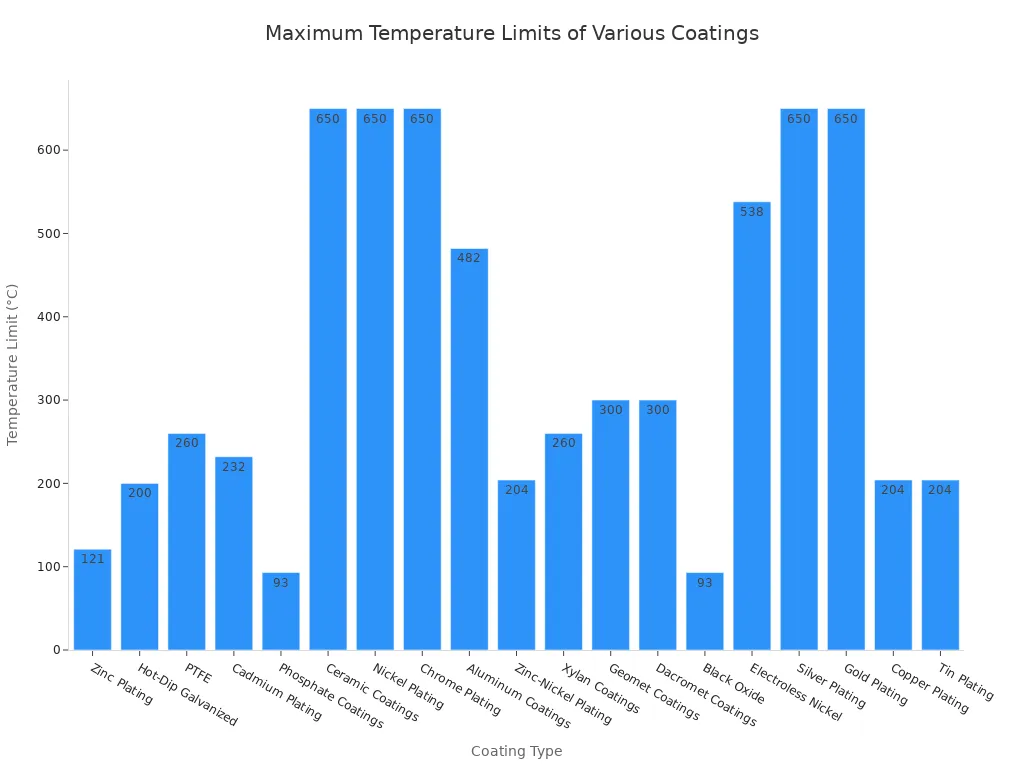

Comparing Common Coating Types

A wide variety of coatings are available, each offering a unique balance of corrosion resistance, temperature limits, and cost. The table below provides a comparison of common options for flange face bolts.

| Coating Type | Corrosion Resistance | Temperature Limits | Cost |

|---|---|---|---|

| Zinc Plating | Good for mild environments | Up to 250°F (121°C) | Low |

| Hot-Dip Galvanized | Excellent for outdoor use | Up to 392°F (200°C) | Moderate |

| PTFE (Fluoropolymer) | Excellent in chemical environments | Up to 500°F (260°C) | High |

| Cadmium Plating | Good, especially in marine settings | Up to 450°F (232°C) | Moderate to High |

| Phosphate Coatings | Mild; provides a base for oil/paint | Up to 200°F (93°C) | Low |

Zinc Plating

Zinc plating is a cost-effective choice for mild, indoor environments. It provides a sacrificial layer of protection but can be compromised if scratched.

Hot-Dip Galvanizing

This process involves dipping bolts in molten zinc, creating a thick, durable, and highly corrosion-resistant coating. It is an excellent choice for outdoor and industrial applications.

Fluoropolymer (PTFE) Coatings

Often known by brand names like Teflon or Xylan, PTFE coatings offer superior chemical resistance and low friction. This makes them ideal for corrosive environments and helps prevent galling.

Cadmium Coatings

Cadmium provides good corrosion resistance and lubricity, which reduces the friction between the nut and bolt. However, its use is highly restricted.

⚠️ WARNING: Cadmium is Highly Toxic Cadmium is a toxic heavy metal, and its use is banned or heavily regulated in many regions due to environmental and health concerns. When used with a stainless steel flange, it can also cause preferential corrosion.

Phosphate Coatings

Phosphate coatings offer minimal corrosion resistance on their own. Their primary function is to serve as a surface preparation for a secondary coating, like oil or paint, which provides the main protective layer.

Step 6: Key Industry Standards to Choose Flange Bolt Compliance

Adhering to industry standards is not optional; it is a fundamental requirement for ensuring the safety and reliability of any bolted flange connection. These standards provide a universal language for manufacturers, engineers, and installers. They govern everything from material chemistry to dimensional tolerances, guaranteeing that every component of the flange assembly works as a predictable system. Following these established guidelines is the only way to ensure a bolt is fit for service on a critical flange.

Navigating Critical Bolting Standards

Engineers rely on a core set of standards to specify and verify bolts. These documents from organizations like ASME and ASTM provide the technical foundation for every decision. A compliant flange depends on understanding these key specifications.

Understanding ASME B16.5 for Flanges

ASME B16.5 is the master standard for pipe flanges and flanged fittings. It defines the dimensions, pressure-temperature ratings, and materials for the flange itself. Crucially, it also specifies the number, size, and type of bolts required for each flange class. For most applications, especially in high-temperature service, the standard recommends using stud bolts with a nut at each end to ensure reliable clamping of the flange.

Following ASTM Material Specifications

While ASME defines the flange system, ASTM International standards define the bolt material. ASTM specifications dictate the required chemical composition, mechanical properties (like tensile strength), and heat treatment for each bolt grade. This ensures the material can handle the service conditions of the flange. Common pairings include:

| Material Type | Bolt Specification | Nut Specification |

|---|---|---|

| Carbon Steel High-Temp | A193 Gr B7 | A194 Gr 2H |

| Carbon Steel Low-Temp | A320 Gr L7 | A194 Gr 7 |

| Austenitic Stainless Steel | A193 Gr B8 | A194 Gr 8 |

Adhering to ASME B18.2.1 for Bolt Dimensions

This standard governs the physical dimensions of bolts and studs. ASME B18.2.1 (for bolts) and ASME B18.2.2 (for nuts) specify details like head type, thread length, and overall tolerances. Compliance ensures that the flange face bolts will fit the flange holes correctly and engage with nuts properly.

The Importance of Traceability and Documentation

Specifying a standard is only half the battle; an engineer must also verify that the supplied bolts actually meet it. Traceability provides this proof. It creates a documented chain of custody from the raw metal to the finished bolt on the flange.

Why You Must Request Mill Test Reports (MTRs)

A Mill Test Report (MTR) is a quality assurance document that acts as a “birth certificate” for the metal used to make the bolts. It provides a certified record of the material’s properties.

An MTR is non-negotiable for critical applications. It certifies the material’s chemical composition and mechanical properties (yield, tensile strength), confirming it meets the specified ASTM standard. This document is the ultimate proof that the material is suitable for a high-pressure flange.

Verifying Lot Numbers and Heat Codes

Traceability is achieved through a system of unique identifiers.

- Heat Number: This code traces the bolt back to the original molten batch of steel, verifying its chemical makeup from the source.

- Lot Number: This code tracks a specific production run of finished flange face bolts through manufacturing processes like forging and heat treatment.

Together, these codes allow an inspector to link a single bolt back to its MTR, providing a complete and verifiable history. This ensures every bolt installed on a flange is fully compliant and safe.

Step 7: Installation Tips for Flange Face Bolts

Proper installation is as important as selecting the right components. Even a perfectly specified bolt can fail if the installation is incorrect. These installation tips for flange face bolts focus on achieving the correct torque and following a precise tightening sequence. A successful installation ensures the integrity and safety of the entire flange connection.

Why Proper Torque is Critical for a Secure Seal

Torque is the rotational force applied to a nut, but its real purpose is to create a specific tension in the bolt. This tension, known as preload, is the clamping force that holds the flange joint together. A successful installation depends on achieving the correct preload.

Achieving the Correct Bolt Load and Preload

An engineer must understand that most of the applied torque does not create preload. In a typical dry installation, friction consumes about 90% of the energy. Approximately 50% is lost to friction under the nut face, and 40% is lost in the threads. This leaves only 10% of the torque to stretch the bolt and generate the required clamping force. This relationship is defined by the “nut factor” (K), which accounts for friction. A proper installation manages this factor carefully.

Preventing Leaks and Joint Failure

Incorrect torque directly leads to joint failure. Both under-tightening and over-tightening create dangerous conditions for the flange. An improper installation can cause gasket failure, which is often indicated by leaking fluids or gases.

| Tightening Error | Resulting Condition | Consequence |

|---|---|---|

| Under-tightening | Insufficient preload on the gasket | Leakage and potential joint blowout |

| Over-tightening | Excessive stress on the bolt and flange | Bolt fatigue, flange warping, and crushed gaskets |

| Uneven tightening | Uneven load distribution | Localized stress points and leak paths |

Following the Correct Tightening Pattern

Applying the final torque value is not a one-step process. A methodical tightening pattern is essential for distributing the load evenly across the flange. These installation tips for flange face bolts are critical for preventing a lopsided installation.

The Star (Criss-Cross) Pattern Explained

The star, or criss-cross, pattern is the industry-standard method for tightening a flange. This technique involves tightening bolts on opposite sides of the flange in sequence. For an 8-bolt flange, an installer would tighten bolts in the order 1-5-3-7-2-6-4-8. This installation is performed in multiple passes to gradually increase the load.

💡 Professional Tip: A typical installation involves three passes:

- First pass at 30% of the final torque.

- Second pass at 60% of the final torque.

- Final pass at 100% of the final torque. A final rotational pass ensures all flange face bolts are uniformly tight.

Using a Calibrated Torque Wrench

Achieving an accurate torque value is impossible without the right tool. A calibrated torque wrench is non-negotiable for any critical flange installation. Using an uncalibrated tool introduces guesswork and makes the entire installation unreliable.

The Role of Lubrication in Achieving Accurate Torque

Lubrication is one of the most effective installation tips for flange face bolts. It stabilizes the nut factor (K) by reducing friction. This makes the relationship between applied torque and achieved preload far more predictable. A well-lubricated bolt requires less torque to achieve the same clamping force as a dry bolt, reducing the risk of over-stressing the material during installation. Proper lubrication is key to a consistent and safe installation.

A systematic evaluation of project needs guides how professionals choose flange bolt components. Selecting the right flange face bolt is critical for safety in all applications.

An engineer verifies the material, size, and grade of flange face bolts against the flange specifications. This ensures a reliable connection for various applications and promotes overall safety. Adherence to industry standards like ASME and ASTM guarantees flange integrity. Following precise installation procedures is the final step for flange safety in demanding applications. This commitment to detail ensures operational safety.

FAQ

What is the most common flange bolt?

ASTM A193 Grade B7 stud bolts are the industry standard for most plant piping applications. Engineers specify them for their high strength and good performance in moderate to high-temperature service. They are typically paired with ASTM A194 Grade 2H heavy hex nuts for reliable connections.

Can installers reuse flange bolts?

No, professionals should not reuse flange bolts in critical applications. The initial tightening process stretches the bolt permanently. Reusing a bolt compromises its clamping force and increases the risk of fatigue failure, leading to potential leaks and safety hazards on the flange.

Why is lubrication important for flange bolts?

Lubrication reduces friction between the nut and bolt threads during installation. This allows an installer to achieve the correct bolt tension with less torque. It ensures a more accurate and consistent clamping force across the flange, which is critical for a reliable, leak-free seal.

What happens if the bolt grade is too low?

Using a bolt with a grade too low for the application’s pressure results in insufficient clamping force. The bolt may stretch or break under load. This can cause the gasket to fail, leading to dangerous leaks or a catastrophic blowout of the flange joint.

How do engineers verify bolt authenticity?

Engineers verify authenticity through two key methods:

- Visual Inspection: They check the head markings to confirm the grade and manufacturer.

- Documentation Review: They request and review the Mill Test Report (MTR) to certify the bolt’s chemical and mechanical properties against ASTM standards.

What is the difference between a stud bolt and a machine bolt?

A stud bolt is a threaded rod with no head, used with two nuts. A machine bolt has a head on one end and requires one nut. Stud bolts are preferred for flanged connections because they provide more accurate and even clamping force.