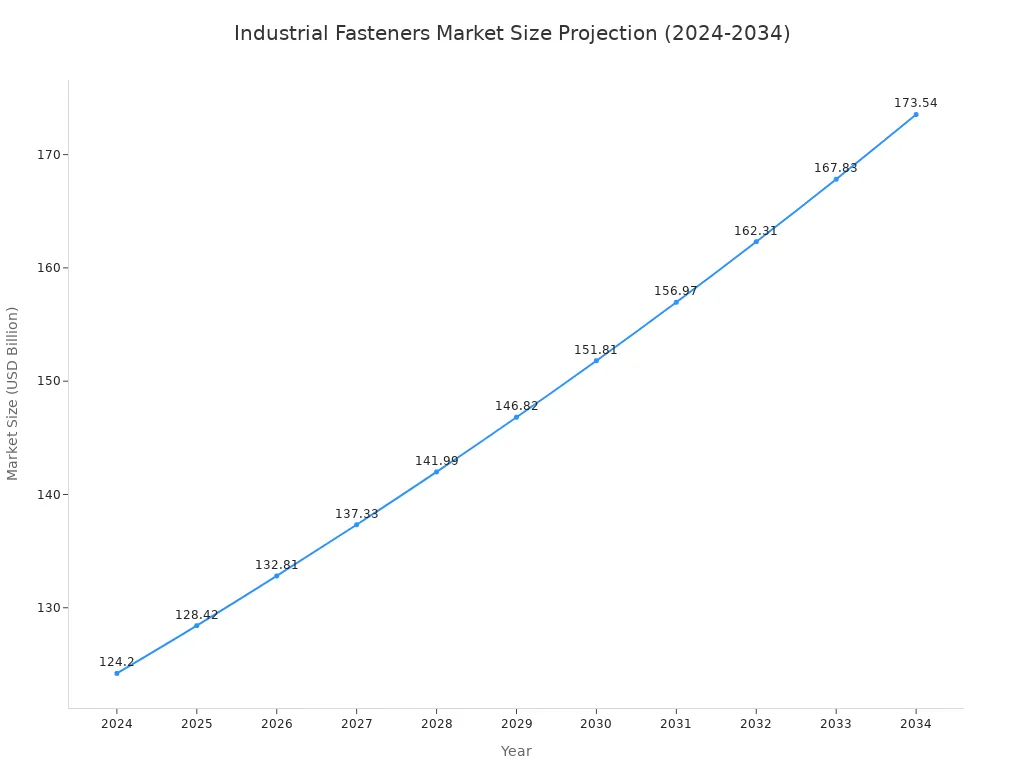

Hex bolts are fundamental components in industries from automotive manufacturing to building construction. The global market for these hex bolts is substantial, with a size projected to grow from USD 124.2 billion in 2024 to over USD 173.8 billion by 2034. A custom fasteners manufacturer uses processes like bolt casting to produce standard hexagon bolts and custom fasteners for these demanding applications. Accurate selection requires understanding the specific hex head bolt dimensions.

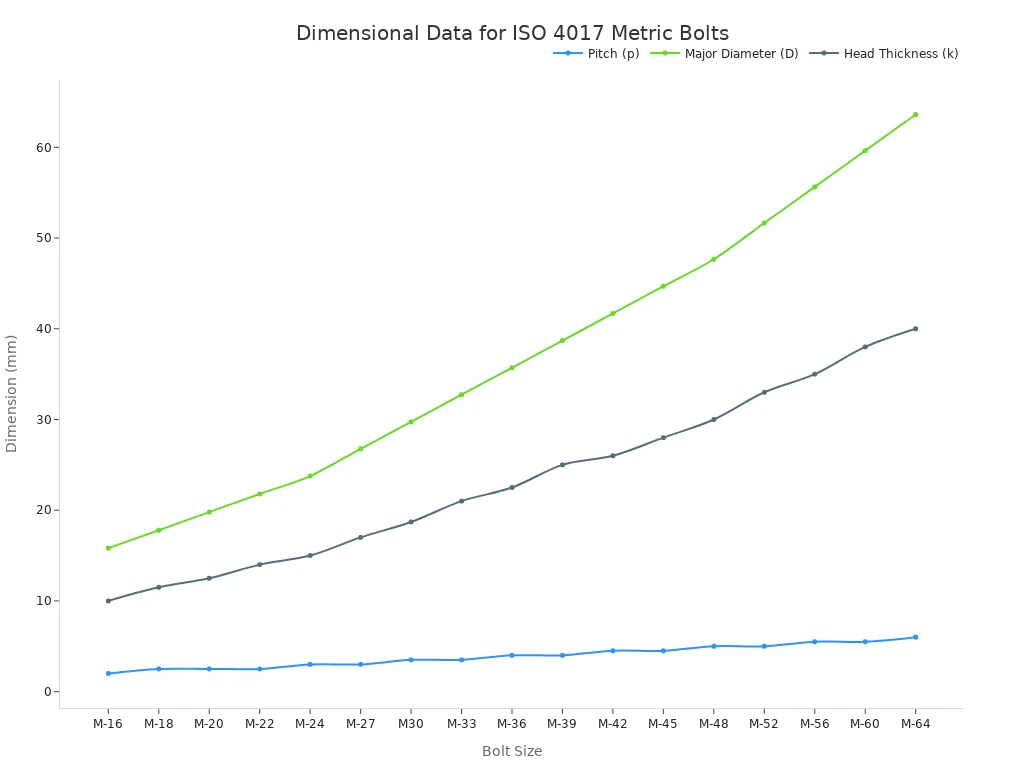

The diagram below illustrates the critical dimensions of a standard hex head hex bolt, defining each part from its length and diameter to its thread size.

[Image of a labeled hex head bolt diagram]

- Shank Length (L): Total length from under the head.

- Thread Length (LT): The length of the threaded portion.

- Shank Diameter (d): The nominal diameter of the bolt’s body.

- Width Across Flats (F): The distance between two parallel sides of the head.

- Head Height (H): The height of the hexagon head.

- Thread Pitch: The distance between threads.

Imperial (Inch) Hex Bolt Size Chart

Imperial hex bolts, measured in inches, are the standard in the United States for construction, machinery, and automotive applications. Understanding their dimensions requires familiarity with the ANSI/ASME standards that govern their design. This hex bolt size chart and guide will help you navigate the specifications for these essential fasteners.

How to Read an Imperial (ANSI/ASME) Chart

The American Society of Mechanical Engineers (ASME) publishes the standards for fasteners. ASME B18.2.1 is the official standard that outlines the dimensional requirements for inch-series hex bolts. This document ensures that all hex bolts meet precise tolerances for a reliable fit. While many standards exist for different fasteners, ASME B18.2.1 specifically covers the dimensions, materials, and grades for the hex bolts discussed here.

Nominal Size (Fractional Inches)

The nominal size is the primary identifier for a bolt’s diameter. It is expressed as a fraction of an inch.

- For a bolt designated as 1/4″-20 x 2″, the nominal size is 1/4 inch. This number gives a general idea of the bolt’s diameter.

Threads Per Inch (TPI)

Threads Per Inch (TPI) indicates the thread density on the bolt’s shank. It is the second number in the bolt’s designation.

- In a 1/4″-20 x 2″ bolt, the “20” means there are 20 threads for every one inch of threaded length.

Shank Diameter Specifications

The nominal size is a reference, not the exact measurement. The actual shank diameter has a specific tolerance range with a maximum and minimum value. These precise specifications ensure a proper fit in pre-drilled holes. For example, a 1/2″ nominal bolt has a maximum shank diameter of 0.515 inches and a minimum of 0.482 inches.

Head Dimension Specifications

Head dimensions are critical for tool selection and clearance.

- Width Across Flats (F): This measurement determines the correct wrench size.

- Head Height (H): This value indicates the vertical space the bolt head will occupy.

Standard Coarse Thread (UNC) Size Chart

Standard Coarse Thread (UNC) is the most common thread type for general-purpose hex bolts. UNC threads are ideal for quick assembly and are more tolerant of adverse conditions. Their deeper profile makes them suitable for softer materials like wood and plastic, reducing the risk of thread stripping. They are widely used in general construction and assembly projects.

Chart for 1/4″ to 1/2″ Bolts

| Nominal Size (in.) | Threads Per Inch (TPI) | Body Dia. Max (in.) | Width Across Flats (in.) | Head Height Max (in.) |

|---|---|---|---|---|

| 1/4″ | 20 | 0.260 | 7/16 | 0.190 |

| 5/16″ | 18 | 0.324 | 1/2 | 0.237 |

| 3/8″ | 16 | 0.388 | 9/16 | 0.253 |

| 7/16″ | 14 | 0.452 | 5/8 | 0.301 |

| 1/2″ | 13 | 0.515 | 3/4 | 0.364 |

Chart for 9/16″ to 1″ Bolts

| Nominal Size (in.) | Threads Per Inch (TPI) | Body Dia. Max (in.) | Width Across Flats (in.) | Head Height Max (in.) |

|---|---|---|---|---|

| 9/16″ | 12 | 0.579 | 13/16 | 0.396 |

| 5/8″ | 11 | 0.642 | 15/16 | 0.444 |

| 3/4″ | 10 | 0.768 | 1-1/8 | 0.524 |

| 7/8″ | 9 | 0.895 | 1-5/16 | 0.604 |

| 1″ | 8 | 1.022 | 1-1/2 | 0.700 |

Chart for 1-1/8″ to 2″ Bolts

Larger hex bolt sizes are used in heavy construction and industrial machinery where significant clamping force is required. The dimensions scale up accordingly to handle greater loads. This chart details the larger sizes available.

| Nominal Size (in.) | Threads Per Inch (TPI) | Body Dia. Max (in.) | Width Across Flats (in.) | Head Height Max (in.) |

|---|---|---|---|---|

| 1-1/8″ | 7 | 1.149 | 1-11/16 | 0.780 |

| 1-1/4″ | 7 | 1.277 | 1-7/8 | 0.876 |

| 1-1/2″ | 6 | 1.531 | 2-1/4 | 1.036 |

| 1-3/4″ | 5 | 1.785 | 2-5/8 | 1.196 |

| 2″ | 4.5 | 2.039 | 3 | 1.388 |

Fine Thread (UNF) Size Chart

Fine Thread (UNF) bolts have more threads per inch compared to their UNC counterparts. This design provides higher tensile strength and superior resistance to loosening from vibration.

Pro Tip: UNF threads are preferred in precision applications. You will find them in the aerospace, automotive, and military sectors where reliability and strength are critical. Their larger minor diameter contributes to greater strength, making them a top choice for high-performance machinery.

Chart for 1/4″ to 1/2″ Bolts

| Nominal Size (in.) | Threads Per Inch (TPI) | Body Dia. Max (in.) | Width Across Flats (in.) | Head Height Max (in.) |

|---|---|---|---|---|

| 1/4″ | 28 | 0.260 | 7/16 | 0.190 |

| 5/16″ | 24 | 0.324 | 1/2 | 0.237 |

| 3/8″ | 24 | 0.388 | 9/16 | 0.253 |

| 7/16″ | 20 | 0.452 | 5/8 | 0.301 |

| 1/2″ | 20 | 0.515 | 3/4 | 0.364 |

Chart for 9/16″ to 1-1/2″ Bolts

As the bolt diameter increases, the difference in TPI between UNC and UNF remains significant. These larger UNF sizes are used in specialized equipment where fine adjustment and high clamping force are necessary.

| Nominal Size (in.) | Threads Per Inch (TPI) | Body Dia. Max (in.) | Width Across Flats (in.) | Head Height Max (in.) |

|---|---|---|---|---|

| 9/16″ | 18 | 0.579 | 13/16 | 0.396 |

| 5/8″ | 18 | 0.642 | 15/16 | 0.444 |

| 3/4″ | 16 | 0.768 | 1-1/8 | 0.524 |

| 7/8″ | 14 | 0.895 | 1-5/16 | 0.604 |

| 1″ | 12 | 1.022 | 1-1/2 | 0.700 |

| 1-1/8″ | 12 | 1.149 | 1-11/16 | 0.780 |

| 1-1/4″ | 12 | 1.277 | 1-7/8 | 0.876 |

| 1-1/2″ | 12 | 1.531 | 2-1/4 | 1.036 |

Metric Hex Bolt Size Chart

Metric hex bolts are the international standard, specified in millimeters and governed by the International Organization for Standardization (ISO). These fasteners are ubiquitous in automotive, machinery, and electronics industries worldwide. Understanding the metric system is essential for anyone working in a global or modern engineering context. This metric hex bolt size chart provides the necessary data for accurate selection.

How to Read a Metric (ISO/DIN) Chart

Metric fastener specifications were historically defined by the German Institute for Standardization (DIN). Today, ISO standards have largely superseded them. While many DIN and ISO standards are interchangeable, key differences exist. Modern engineering and manufacturing practices prioritize ISO standards for global compatibility.

Note: The transition from DIN to ISO standards aimed to harmonize international fastener specifications. For example, ISO 4017 is the modern equivalent of DIN 933.

The table below shows the relationship between older DIN standards and their current ISO equivalents for various hex bolts.

| Description | DIN Standard | ISO Equivalent |

|---|---|---|

| Hex Head Bolts (Fully Threaded), Metric Coarse | DIN 933 | ISO 4017 |

| Hex Head Bolts (Partially Threaded), Metric Coarse | DIN 931 | ISO 4014 |

| Hex Head Bolts (Fully Threaded), Metric Fine | DIN 961 | ISO 8676 |

| Hex Head Bolts (Partially Threaded), Metric Fine | DIN 960 | ISO 8765 |

While dimensions often align, ISO standards can specify tighter tolerances. For instance, the wrench size for some hex bolts differs. An M10 bolt under DIN 933 requires a 17 mm wrench, but an M10 bolt under ISO 4017 uses a 16 mm wrench. Similar differences exist for M12, M14, and M22 sizes.

Nominal Size (M-Designation)

The M-designation is the primary identifier for a metric bolt’s size. This designation provides a clear and standardized way to communicate fastener specifications.

- The label begins with the letter ‘M’ for metric.

- It is followed by the nominal diameter in millimeters (e.g., M8 for an 8 mm diameter bolt).

- The thread pitch can be specified next, separated by an ‘x’ (e.g.,

M8x1.0). - If the pitch is not specified, it automatically denotes a standard coarse thread (e.g., M8 implies a coarse pitch of 1.25 mm).

- The bolt’s length in millimeters follows, also separated by an ‘x’ (e.g.,

M8x1.25x30).

Thread Pitch (mm)

Metric thread pitch is the distance in millimeters between two adjacent thread crests. A smaller number indicates a finer thread, while a larger number indicates a coarser thread. This is a direct measurement, unlike the Imperial TPI system.

Shank Diameter Specifications

The M-designation represents the nominal diameter. The actual shank diameter of a bolt is manufactured within a specific tolerance range (maximum and minimum) to ensure a proper fit. For example, an M10 bolt has a maximum shank diameter of 10.00 mm and a minimum of 9.78 mm.

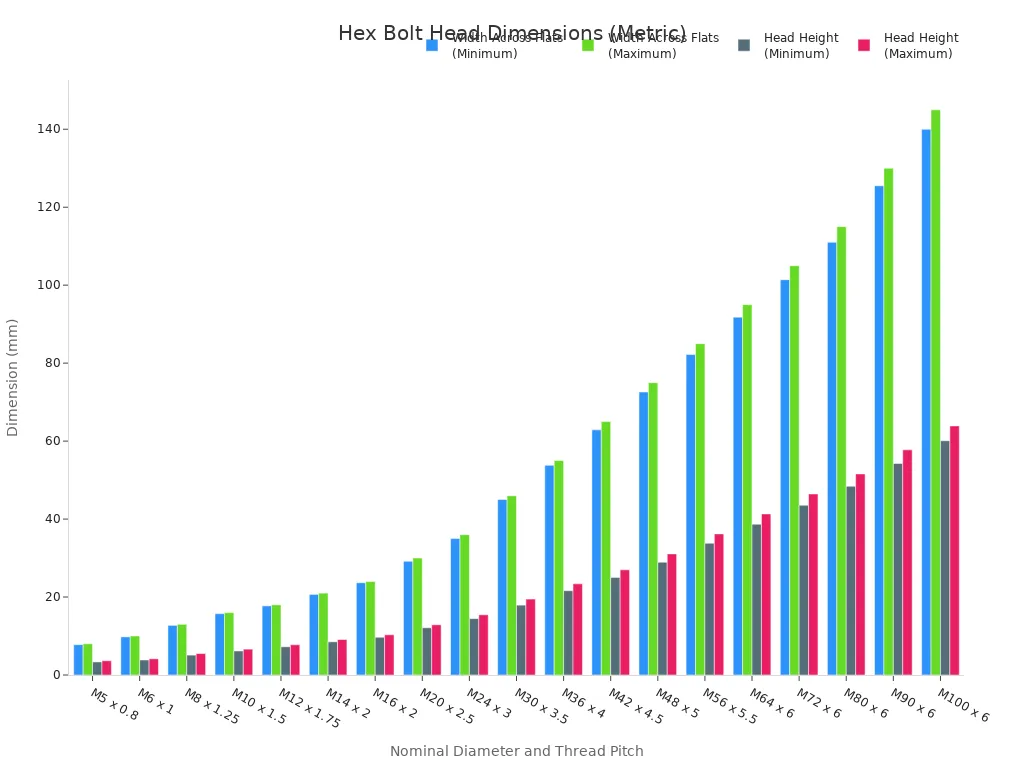

Head Dimension Specifications

Head dimensions determine the required tooling and clearance for an application.

- Width Across Flats (s): This measurement, in millimeters, dictates the correct wrench size.

- Head Height (k): This value specifies the vertical space the bolt head occupies.

Standard Coarse Pitch (ISO 4017) Chart

Standard coarse pitch hex bolts are the default choice for most applications. They are used extensively in construction, machinery, automotive assembly, and general industrial projects. Their deeper threads offer fast assembly and good resistance to stripping, especially in materials like steel and aluminum. ISO 4017 defines the specifications for fully threaded coarse pitch hex bolts.

Chart for M3 to M10 Bolts

These smaller sizes are common in electronics, furniture, and light machinery where high clamping force is not the primary requirement.

| Nominal Size | Pitch (mm) | Body Dia. Max (mm) | Width Across Flats (mm) | Head Height Max (mm) |

|---|---|---|---|---|

| M3 | 0.5 | 3.00 | 5.5 | 2.12 |

| M4 | 0.7 | 4.00 | 7.0 | 2.92 |

| M5 | 0.8 | 5.00 | 8.0 | 3.65 |

| M6 | 1.0 | 6.00 | 10.0 | 4.15 |

| M8 | 1.25 | 8.00 | 13.0 | 5.45 |

| M10 | 1.5 | 10.00 | 16.0 | 6.58 |

Chart for M12 to M20 Bolts

This mid-range of bolt sizes is a workhorse in the automotive and industrial machinery sectors. They provide a balance of significant clamping force and manageable size.

| Nominal Size | Pitch (mm) | Body Dia. Max (mm) | Width Across Flats (mm) | Head Height Max (mm) |

|---|---|---|---|---|

| M12 | 1.75 | 12.00 | 18.0 | 7.68 |

| M14 | 2.0 | 14.00 | 21.0 | 8.98 |

| M16 | 2.0 | 16.00 | 24.0 | 10.29 |

| M18 | 2.5 | 18.00 | 27.0 | 11.85 |

| M20 | 2.5 | 20.00 | 30.0 | 12.85 |

Chart for M22 to M36 Bolts

Large-diameter hex bolts are essential for heavy construction, infrastructure projects, and large-scale industrial equipment. Their dimensions are scaled to handle extreme loads and provide maximum clamping security. The following chart details these larger sizes.

| Nominal Size | Pitch (mm) | Body Dia. Max (mm) | Width Across Flats (mm) | Head Height Max (mm) |

|---|---|---|---|---|

| M22 | 2.5 | 22.00 | 34.0 | 14.35 |

| M24 | 3.0 | 24.00 | 36.0 | 15.35 |

| M27 | 3.0 | 27.00 | 41.0 | 17.35 |

| M30 | 3.5 | 30.00 | 46.0 | 19.12 |

| M36 | 4.0 | 36.00 | 55.0 | 22.92 |

Fine Pitch (ISO 8676) Chart

Fine pitch hex bolts, governed by ISO 8676, offer greater tensile strength and resistance to loosening from vibration. Their shallower threads and larger stress area make them ideal for precision applications in aerospace, high-performance engines, and sensitive equipment. A fine pitch bolt of a given size is stronger than its coarse pitch equivalent.

Chart for M8 to M16 Bolts

| Nominal Size | Pitch (mm) | Body Dia. Max (mm) | Width Across Flats (mm) | Head Height Max (mm) |

|---|---|---|---|---|

| M8 | 1.0 | 8.00 | 13.0 | 5.45 |

| M10 | 1.25 | 10.00 | 16.0 | 6.58 |

| M12 | 1.25 | 12.00 | 18.0 | 7.68 |

| M14 | 1.5 | 14.00 | 21.0 | 8.98 |

| M16 | 1.5 | 16.00 | 24.0 | 10.29 |

Chart for M18 to M30 Bolts

| Nominal Size | Pitch (mm) | Body Dia. Max (mm) | Width Across Flats (mm) | Head Height Max (mm) |

|---|---|---|---|---|

| M18 | 1.5 | 18.00 | 27.0 | 11.85 |

| M20 | 1.5 | 20.00 | 30.0 | 12.85 |

| M22 | 1.5 | 22.00 | 34.0 | 14.35 |

| M24 | 2.0 | 24.00 | 36.0 | 15.35 |

| M30 | 2.0 | 30.00 | 46.0 | 19.12 |

Understanding Hex Head Bolt Dimensions in Detail

The size charts provide essential data, but a deeper understanding of each dimension ensures correct fastener selection. Key hex head bolt dimensions like diameter, length, and head size follow strict manufacturing standards. These standards guarantee that hex bolts from any certified manufacturer will be interchangeable and perform reliably.

Shank Diameter (d) and Nominal Size

The diameter is arguably the most critical dimension of a bolt. It dictates the fastener’s strength and the hole size required for installation.

What “Nominal Size” Means

The nominal size is a reference name used for identification. For example, a bolt may be called a “1/2 inch” or “M12” bolt. This size provides a convenient label but does not represent the exact physical measurement of the shank. It simplifies communication and organization when dealing with various fastener sizes.

Understanding Diameter Tolerances

Manufacturing processes cannot produce parts with perfect precision. For this reason, standards define an acceptable tolerance range for the shank diameter. The actual diameter of a bolt will be slightly less than its nominal size to ensure it fits easily into a corresponding hole. These precise hex bolt dimensions are specified with maximum and minimum values in official standards.

Shank Length (L): How to Measure It Correctly

Measuring the length of hex bolts is straightforward, but the correct method is crucial for ensuring proper engagement and fit.

Measuring from Under the Head

Industry standards like ASME B18.2.1 provide a clear definition for measuring bolt length. The length (L) is the distance from the flat bearing surface under the head to the extreme end of the bolt.

- For hex bolts, the measurement starts directly underneath the head.

- It extends parallel to the bolt’s axis down to the very tip of the threads.

Important: The head itself is never included in the length measurement for hex bolts. This ensures the calculated grip length is accurate for the materials being joined.

Fully Threaded vs. Partially Threaded Hex Bolts

Hex bolts come in two main styles:

- Fully Threaded (Tap Bolts): Threads run the entire length of the shank. These are ideal when the full length needs to engage with a tapped hole.

- Partially Threaded: These have an unthreaded portion (grip length) under the head. The unthreaded shank provides superior shear strength, making these hex bolts suitable for applications where forces act perpendicular to the bolt.

Head Dimensions: Finding the Right Wrench Size

The head dimensions determine the tooling required and the space needed for installation. These dimensions are just as standardized as the shank and thread sizes.

Width Across Flats (F) for Wrench Fit

The “width across flats” is the distance between two parallel sides of the bolt head. This measurement directly corresponds to the required wrench or socket size. Using the correct size wrench prevents rounding the bolt head and ensures proper torque can be applied.

Head Height (H) for Clearance

Head height specifies the vertical space the bolt head will occupy. This is a critical consideration in designs with limited overhead clearance. As bolt diameters increase, the head dimensions also increase proportionally to handle higher torque and load requirements.

Thread Specifications Explained

The threads on a bolt are more than just a spiral groove; they are a complex feature engineered for performance. Thread specifications dictate how a bolt engages with a nut or tapped hole, influencing its strength, installation speed, and resistance to loosening. Understanding these details is essential for selecting the correct hex bolts for any job.

Thread Pitch: Coarse vs. Fine

Thread pitch defines the density of the threads on a bolt’s shank. In the imperial system, it is measured as Threads Per Inch (TPI). In the metric system, it is the distance in millimeters between adjacent threads. Every nominal size has a standard coarse pitch and one or more fine pitch options.

Coarse Threads: These have a larger pitch and deeper grooves. Coarse threads allow for faster installation of hex bolts and are less likely to cross-thread. Their robust nature makes them more tolerant of minor damage and debris. Fine Threads: These have a smaller pitch and more threads per unit of length. The increased thread engagement provides greater tensile strength and better resistance to loosening from vibration.

Imperial Threads: UNC vs. UNF

The Unified Thread Standard (UTS) governs imperial fasteners used in the United States. It defines several thread series, each suited for different mechanical requirements. The most common imperial thread types for hex bolts are:

- Unified National Coarse (UNC): This is the default, general-purpose thread. It is used in the vast majority of applications, from construction to general machinery repair.

- Unified National Fine (UNF): This thread is used in precision applications where higher strength and vibration resistance are necessary, such as in the automotive and aerospace industries.

- Unified National Extra Fine (UNEF): This series is reserved for specialized cases requiring very fine adjustments or use in thin-walled materials.

UNC threads are the standard choice unless a specific engineering requirement calls for the superior performance characteristics of UNF threads.

Metric Threads: Coarse vs. Fine Pitch

Metric hex bolts also come in coarse and fine pitch varieties, governed by ISO standards. A key difference is how they are designated. If a pitch is not specified in a metric bolt’s name (e.g., “M12”), it is automatically a coarse thread. A fine pitch must always be explicitly stated (e.g., “M12x1.25”).

Coarse pitch metric threads are the workhorse for general assembly, offering speed and durability. Fine pitch threads provide a higher clamping force and are less likely to vibrate loose. This makes fine pitch metric hex bolts excellent for high-performance engines, precision instruments, and applications subject to constant movement.

How to Choose the Right Hex Bolts for Your Project

Selecting the correct fastener is critical for the safety and longevity of any project. This systematic guide simplifies the process of choosing the right hex bolts by breaking it down into manageable steps. Following these guidelines ensures your connections are secure and reliable.

Step 1: Determine Required Diameter and Length

The physical dimensions of hex bolts are the first consideration. An incorrect size can compromise the entire assembly.

Measuring the Hole Diameter

The bolt’s nominal diameter should correspond to the diameter of the pre-drilled hole. This ensures a snug fit without damaging the materials being joined. A precise measurement of the hole is the starting point for selecting the right fastener.

Calculating Required Grip Length

The required length of a bolt is more than just the thickness of the materials. A proper calculation sums the grip length (total material thickness), the height of any washers, and the height of the nut. This ensures the bolt is long enough to function correctly.

Ensuring Proper Thread Engagement

For a connection to achieve its full strength, the bolt must fully engage with the nut. A widely accepted rule is to have at least two to three full threads showing past the outer face of the nut after tightening. This visual confirmation indicates that the load-bearing threads are properly engaged.

Step 2: Select the Correct Thread Type

The choice between coarse and fine threads directly impacts the performance of hex bolts in an application.

Coarse Threads for Speed and Durability

Coarse threads (UNC) are the standard for most general-purpose applications. They assemble more quickly and are less susceptible to cross-threading or damage from debris. Their deeper profile also makes them more tolerant of thicker protective coatings without seizing.

Fine Threads for Vibration Resistance and Precision

Fine threads (UNF) provide a larger tensile stress area, making them stronger than coarse threads of the same size. Their smaller helix angle offers superior resistance to loosening under vibration. These characteristics make fine-threaded hex bolts ideal for precision machinery and automotive or aerospace applications.

Step 3: Choose the Material and Grade

The bolt’s material determines its strength, corrosion resistance, and suitability for a specific environment.

Common Steel Grades: Grade 2, Grade 5, Grade 8

Steel hex head bolts are categorized by grade, which indicates their tensile strength. Lower grades like Grade 2 are for light-duty applications. Grade 5 offers good strength for many automotive and industrial uses. Grade 8 provides the highest strength for critical, high-stress connections.

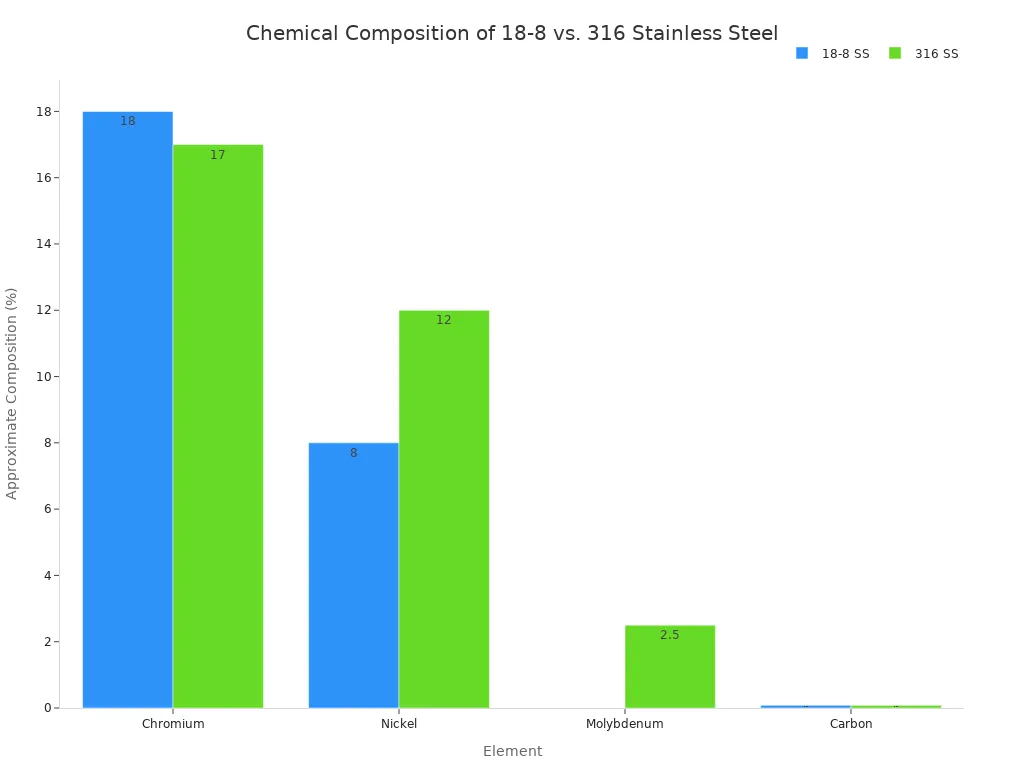

Stainless Steel Types: 18-8 and 316

Stainless steel offers excellent corrosion resistance.

- 18-8 Stainless Steel: Contains approximately 18% chromium and 8% nickel. It provides good corrosion resistance for general applications but can be susceptible to corrosion from chlorides like salt.

- 316 Stainless Steel: Includes molybdenum in its composition. This addition significantly enhances its resistance to harsh chemicals and saltwater, making it the superior choice for marine and chemical environments.

Protective Coatings: Zinc, Hot-Dip Galvanized

For carbon steel hex bolts used outdoors, a protective coating is essential. Zinc plating offers moderate corrosion resistance for dry or indoor environments. A hot-dip galvanized (HDG) coating provides a much thicker layer of zinc, offering superior, long-term protection against rust in demanding outdoor conditions.

Step 4: Match the Bolt to the Application

The final step involves synthesizing all information to match the fastener to its specific job. This ensures the connection is not only secure but also durable and safe for its intended service life.

Considering Load-Bearing and Shear Strength

An application’s load requirements directly dictate the necessary bolt grade. Engineers select higher grade hex bolts for applications involving greater weight and dynamic forces. For example, demanding industrial and automotive manufacturing jobs often require high-strength alloy steel hex bolts. The material’s treatment and composition determine its ultimate strength.

The table below details the properties of high-performance metric hex bolts used in safety-critical components and heavy machinery.

| Grade | Material | Tensile Strength (psi) | Yield Strength (psi) | Hardness (Rockwell C) | Typical Use |

|---|---|---|---|---|---|

| 10.9 | Alloy steel, heat-treated | 170,000 | 136,000 | 35 to 42 | High-impact loads, heavy machinery |

| 12.9 | High-grade alloy steel, quenched and tempered | 190,000 | 152,000 | 39 to 45 | Aerospace, military, safety-critical parts |

Assessing Environmental Factors

The operational environment is a critical factor in material selection. Exposure to moisture, chemicals, or extreme temperatures can cause fastener failure if the material is not appropriate.

- Stainless Steel Bolts: These hex bolts, made from alloys like 304 or 316, provide excellent corrosion resistance. Grade 316 offers superior performance in marine or saltwater environments.

- Galvanized Bolts: A zinc coating gives these steel hex bolts robust protection against rust, making them ideal for outdoor construction and equipment.

- Titanium and Inconel Bolts: High-performance alloys like these serve extreme conditions. They offer exceptional strength and resistance to very high temperatures, making them essential in aerospace and high-tech industries.

Pairing with Correct Nuts and Washers

A bolted connection is a system, and all components must be compatible to function correctly. Mismatched parts can compromise the strength of the entire assembly.

Pro Tip: For safety-critical applications, the Industrial Fastener Institute (IFI) recommends that the nut’s tensile strength should exceed the bolt’s strength by at least 20%. This ensures the bolt will fail in tension before the threads strip.

The nut’s grade must always meet or exceed the bolt’s grade. The following table provides a guide for matching common nut and bolt grades.

| System | Nut Grade/Property Class | Matching Bolt Grade/Property Class |

|---|---|---|

| Metric | 10 | 10.9 |

| 12 | 12.9 | |

| SAE | Grade B | Grade 5 |

| Grade C | Grade 8 |

Washers also play a role. Hardened washers (F436) are necessary for high-strength hex head bolts (like Grade 8 or 10.9) to distribute the load properly without deforming. Softer, larger-diameter washers (F844) are often used with lower-grade bolts in materials like wood. Always consult project specifications to ensure all components of the fastener system are correctly matched.

Selecting the correct hex bolts is a critical engineering decision that prevents costly failures. Understanding the core hex head bolt dimensions—diameter, length, thread pitch, and head size—forms the foundation for proper selection.

The provided imperial and metric hex bolt size chart serves as an essential reference. This chart helps professionals quickly identify the right fastener size.

Engineers must also factor in material, grade, and thread type to ensure safety and durability. A comprehensive grasp of hex head bolt dimensions and specifications allows for the confident selection of hex bolts, guaranteeing a secure and reliable assembly for any application.

FAQ

What is the difference between a hex bolt and a hex cap screw?

Hex cap screws feature a washer face under the head and are made to tighter tolerances. Hex bolts are typically used for construction and heavy-duty applications where such precision is not required.

How do I find the right wrench size for a hex bolt?

The “width across flats” (F or s) dimension on a chart specifies the correct wrench size. This measurement ensures a proper fit for the bolt head size, preventing damage during tightening.

Can I use a metric nut on an imperial bolt?

No, metric and imperial fasteners are not interchangeable. Their thread standards and diameter size are fundamentally different. Mismatched components will not create a secure connection and will damage the threads.

Why do some hex bolts have an unthreaded shank?

The unthreaded shank, or grip, provides superior shear strength compared to a fully threaded bolt. This design is ideal for applications where forces act perpendicular to the bolt’s axis, preventing shearing.

What do the markings on a bolt head mean?

Markings on a bolt head indicate its material grade and tensile strength. For example, radial lines on an imperial bolt head signify its grade. Numbers on a metric bolt head (e.g., 10.9) denote its property class.

How do I choose between coarse and fine threads?

Choose coarse threads (UNC) for faster assembly and general-purpose use. Select fine threads (UNF) for applications requiring higher tensile strength and resistance to vibration, such as in automotive or aerospace equipment.