Hex bolts are fundamental components in a vast global market, with the industrial fasteners sector showing significant growth.

| Metric | Value |

|---|---|

| Industrial Fasteners Market Size (2024) | USD 99.63 Billion |

| Projected Industrial Fasteners Market Size (2030) | USD 131.45 Billion |

A single hex bolt is defined by three primary dimensions: diameter, length, and thread pitch. These hex bolt dimensions are governed by a global standard to ensure interchangeability. Selecting the correct size is critical for safety and performance.

❗ Critical Insight: Nearly 95% of fastener failures are attributed to poor fastener selection or improper installation.

Whether using standard hex bolts or sourcing from a custom fasteners manufacturer for unique bolt casting, understanding the proper size of these hex bolts is the first step. These hex bolts and custom fasteners ensure a secure application.

The Fundamentals of Hex Bolt Dimensions

Engineers manufacture hex bolts according to universal specifications. This ensures their dimensional measurements are consistent globally. A hex bolt dimensions chart provides all necessary physical property information. The material may differ, but the core dimensions remain the same. Key properties define the size and shape of all hex bolts.

| Property | Description |

|---|---|

| Nominal Size | The fundamental size designation of the bolt. |

| Body Diameter (E) | The diameter of the unthreaded shank of the bolt. |

| Width Across Flats (F) | The distance between two opposite flat sides of the hex head. |

| Head Height (H) | The vertical dimension of the bolt head. |

| Thread Length (LT) | The length of the threaded portion of the bolt. |

How to Measure Bolt Diameter (Thread Size)

Understanding Major Diameter

The most critical dimension is the nominal or major diameter. This refers to the largest diameter of the bolt’s threads. It determines the bolt’s fundamental size. For example, an M8 bolt has a major diameter of approximately 8 millimeters.

Metric (M) vs. Imperial (Inch) Designations

The global standard uses two primary systems. The metric system designates bolt size with an “M” prefix (e.g., M10 for a 10mm diameter). The imperial system uses inches (e.g., 3/8″). Correctly identifying the system is the first step in selecting the right size.

Essential Tools for Accurate Measurement

Digital or dial calipers provide the most precise measurement of a bolt’s diameter. For accurate results, follow a standard procedure:

- Clean: Ensure the bolt threads and caliper jaws are free of debris.

- Zero: Close the jaws and zero the caliper.

- Placement: Place the caliper’s main jaws perpendicular to the bolt’s centerline, across the threads.

- Reading: Gently close the jaws and read the measurement. Avoid excessive force to prevent inaccurate readings.

How to Measure Bolt Length Correctly

The Standard Measurement Point: Under the Head

Technicians measure the length of most hex bolts from the flat surface underneath the head to the tip of the bolt. This measurement includes the unthreaded shank and the threaded portion. The head height is not part of the bolt’s specified length.

How Head Style Influences Length Measurement

While the “under the head” rule applies to standard hex bolts, some fasteners are different. For example, the length measurement for a flat-head or countersunk bolt includes the head, as it sits flush with the material surface.

Common Length Increments and Tolerances

Manufacturers produce hex bolts in common length increments, such as 5mm or 10mm for metric sizes. A bolt’s actual length will have a small manufacturing tolerance, so it may vary slightly from its nominal length.

Decoding Thread Pitch and TPI

Defining Pitch (Metric) vs. TPI (Imperial)

Thread pitch defines the distance between threads.

- Pitch (Metric): The distance in millimeters between two adjacent thread crests (e.g., 1.25mm). A smaller number means a finer thread.

- TPI (Imperial): Threads Per Inch. This is the number of threads counted along one inch of the bolt’s length. A higher number means a finer thread.

The Difference Between Coarse and Fine Threads

Most hex bolts come in coarse or fine thread options. Coarse threads are more common and install faster. Fine threads, however, offer distinct mechanical advantages.

Expert Insight: Advantages of Fine Threads

- They provide a greater tensile stress area, increasing strength.

- They resist loosening from vibration more effectively.

- They allow for more precise adjustments and higher clamping loads.

Using a Thread Pitch Gauge for Identification

A thread pitch gauge is the most reliable tool for identifying an unknown thread. This tool has a series of blades, each marked with a specific pitch or TPI. Users match a blade to the bolt’s threads until they find a perfect fit, confirming the exact thread size.

A Comprehensive Guide to Hex Bolt Standards

Standardization bodies create the technical rulebook for fasteners. These organizations develop specifications for dimensions, materials, and coatings. Their work ensures the reliability and compatibility of hex bolts across the globe, supporting precision engineering and international trade.

The Role of Standardization Bodies

The primary mission of these groups is to guarantee quality and consistency. They provide a framework that helps manufacturers produce strong, safe, and uniform fasteners.

- Quality: Standards guide manufacturers in assessing hex bolts during production to create durable and safe components.

- Consistency: A global standard offers a foundation for regulation, which reduces barriers to international trade by ensuring fasteners meet the same specifications worldwide.

ISO (International Organization for Standardization)

ISO is a global federation of national standards bodies. It develops and publishes international standards for countless industries. For fasteners, ISO standards are the benchmark for ensuring hex bolts from different countries are interchangeable.

DIN (German Institute for Standardization)

DIN is the German national organization for standardization. For decades, DIN standards for fasteners were widely adopted across Europe and the world. Many DIN specifications served as the foundation for the ISO standards that followed.

ANSI/ASME (American National Standards Institute)

ANSI and ASME are the leading standards developers in the United States. They primarily govern the specifications for imperial (inch-based) fasteners. Their work is critical for industries operating within the U.S. and those using imperial measurements.

The Global Shift from DIN to ISO Standards

The fastener industry has been transitioning from older DIN standards to the more current ISO standards. This global harmonization simplifies engineering, purchasing, and assembly.

Key Takeaway: While many DIN and ISO hex bolts are functionally similar, they are not always identical. Always verify the specific standard required for an application, as dimensional differences can affect tool fitment and joint integrity.

Decoding Common Metric Hex Bolt Standards

Specific standard numbers identify the precise characteristics of a bolt, such as its thread length and pitch. Understanding these designations is essential for selecting the correct component.

ISO 4017 & DIN 933: The Standard for Fully Threaded Hex Bolts

ISO 4017 is the current international standard for fully threaded hex head bolts, replacing the older DIN 933. These hex bolts are threaded along their entire length. While largely interchangeable, some key dimensional differences exist, particularly in the width across the flats (wrench size).

| Feature | DIN 933 (Withdrawn) | ISO 4017 (Current) |

|---|---|---|

| M10 Width Across Flats | 17 mm | 16 mm |

| M12 Width Across Flats | 19 mm | 18 mm |

| M14 Width Across Flats | 22 mm | 21 mm |

| M22 Width Across Flats | 32 mm | 34 mm |

This change in size requires different tooling for installation and maintenance.

ISO 4014 & DIN 931: The Standard for Partially Threaded Hex Bolts

ISO 4014 is the modern standard for partially threaded hex bolts, superseding DIN 931. These bolts feature an unthreaded shank under the head, which provides superior shear strength for structural connections. They share similar dimensional updates to their fully threaded counterparts.

ISO 8676: Fine Pitch Fully Threaded Hex Bolts

ISO 8676 defines the specifications for fully threaded hex bolts with a fine metric thread. Engineers choose these bolts for applications requiring higher tensile strength, better resistance to loosening from vibration, and more precise adjustments.

ISO 8765: Fine Pitch Partially Threaded Hex Bolts

ISO 8765 is the standard for partially threaded hex bolts with a fine metric thread. This specification combines the high shear strength of a partial thread with the enhanced fastening characteristics of a fine thread, making it ideal for high-performance structural and automotive applications.

The Ultimate Hex Bolt Size Chart for Metric Standards

A hex bolt size chart is an indispensable tool for engineers, mechanics, and designers. It provides the critical dimensional data needed to select the correct fastener for a specific task. This section details the dimensions for the most common metric hex bolts according to ISO standards.

ISO 4017 / DIN 933 Hex Bolt Size Chart (Fully Threaded)

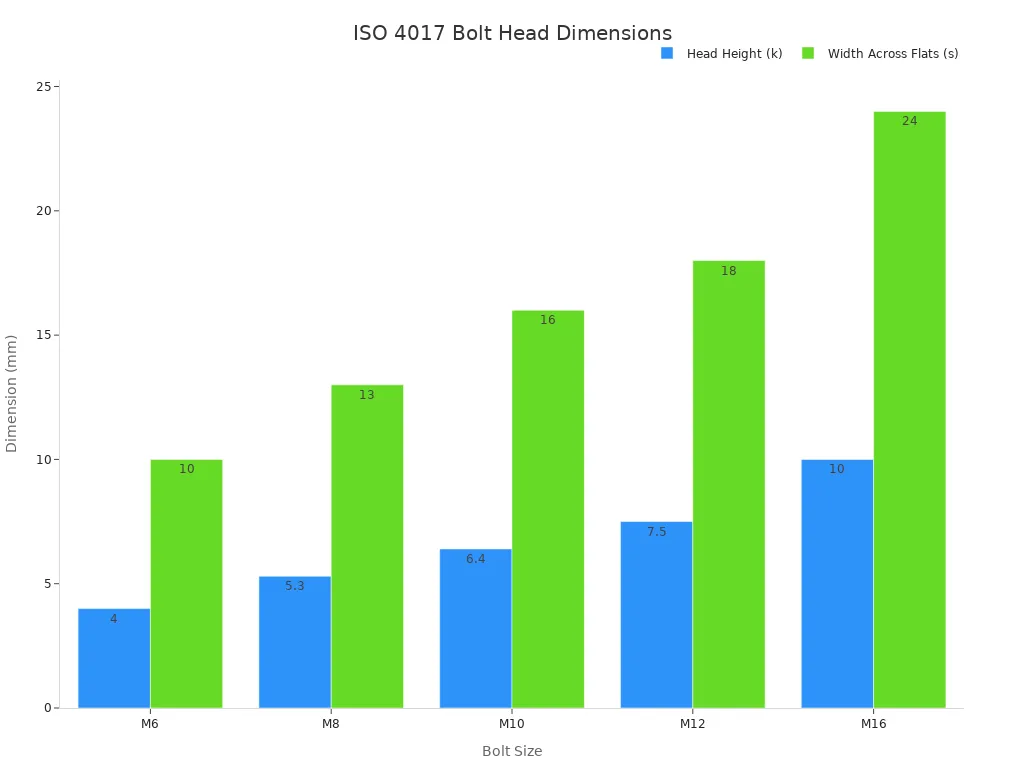

ISO 4017 specifies the characteristics of fully threaded hex bolts. These fasteners have threads running their entire length, making them ideal for applications where maximum grip and clamping force in a tapped hole are required. The head dimensions and thread pitch are fundamental properties for any bolt size.

The following table outlines the key head dimensions for common ISO 4017 hex bolts. The width across flats (s) determines the required wrench size, while the head height (k) is important for clearance calculations.

| Bolt Size | Head Height (k) (mm) | Width Across Flats (s) (mm) |

|---|---|---|

| M6 | 4 | 10 |

| M8 | 5.3 | 13 |

| M10 | 6.4 | 16 |

| M12 | 7.5 | 18 |

| M16 | 10 | 24 |

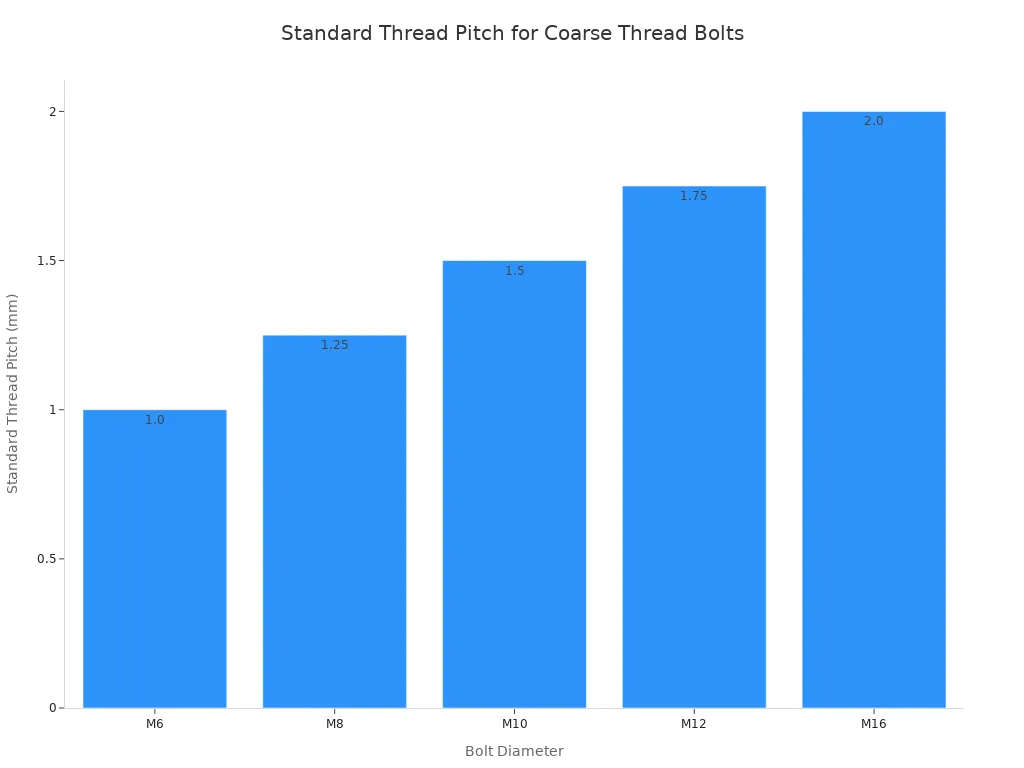

Equally important is the thread pitch. For standard coarse-threaded hex bolts, the pitch increases with the bolt’s diameter.

| Bolt Diameter (mm) | Standard Thread Pitch (mm) |

|---|---|

| M6 | 1.0 |

| M8 | 1.25 |

| M10 | 1.5 |

| M12 | 1.75 |

| M16 | 2.0 |

M6 Dimensions

An M6 bolt has a nominal diameter of 6 mm. It uses a 1.0 mm coarse thread pitch and requires a 10 mm wrench. Technicians commonly use this size in machinery, electronics, and automotive assemblies where space is limited and high strength is not the primary requirement.

M8 Dimensions

The M8 bolt is a versatile fastener with a nominal diameter of 8 mm. Its standard coarse thread pitch is 1.25 mm, and it pairs with a 13 mm wrench. This popular size appears frequently in furniture, light-duty structural frames, and general mechanical repairs.

M10 Dimensions

With a 10 mm nominal diameter, the M10 bolt offers a significant increase in strength. It features a 1.5 mm coarse thread pitch and is driven by a 16 mm wrench. Engineers specify this bolt size for automotive suspensions, engine mounts, and medium-duty structural applications.

M12 Dimensions

The M12 bolt is a robust fastener used in demanding applications. It has a 12 mm nominal diameter, a 1.75 mm coarse thread pitch, and requires an 18 mm wrench. Its strength makes it suitable for construction, heavy machinery, and structural steel connections.

M16 Dimensions

An M16 bolt provides substantial clamping force and strength. This large fastener has a 16 mm nominal diameter, a 2.0 mm coarse thread pitch, and fits a 24 mm wrench. It is a common choice for major structural projects, large equipment assembly, and infrastructure.

ISO 4014 / DIN 931 Hex Bolt Size Chart (Partially Threaded)

ISO 4014 is the standard for partially threaded hex bolts. These fasteners have an unthreaded shank under the head, which provides superior resistance to shear forces. The thread length is not fixed; it varies depending on the overall bolt length. This hex bolt size chart section focuses on the thread lengths for common sizes.

Pro Tip: Calculating Thread Length (b) For ISO 4014 bolts, the thread length (

b) is calculated based on the nominal length (l).

- For

l≤ 125 mm:b = 2d + 6 mm(wheredis the nominal diameter)- For 125 mm <

l≤ 200 mm:b = 2d + 12 mm- For

l> 200 mm:b = 2d + 25 mm

M8 Dimensions and Thread Lengths

An M8 partially threaded bolt maintains the same head dimensions and thread pitch as its fully threaded counterpart. The key difference is the specified thread length, which changes based on the bolt’s total length.

| Total Bolt Length (mm) | Thread Length (mm) |

|---|---|

| 40 | 22 |

| 60 | 22 |

| 80 | 22 |

M10 Dimensions and Thread Lengths

M10 partially threaded hex bolts are specified for structural joints requiring a 10 mm fastener. The unthreaded shank provides a smooth bearing surface, preventing thread damage in shear planes.

| Total Bolt Length (mm) | Thread Length (mm) |

|---|---|

| 50 | 26 |

| 80 | 26 |

| 100 | 26 |

M12 Dimensions and Thread Lengths

For M12 hex bolts under ISO 4014, the thread length increases for longer bolts to ensure adequate engagement. This size is a workhorse in structural engineering.

| Total Bolt Length (mm) | Thread Length (mm) |

|---|---|

| 60 | 30 |

| 100 | 30 |

| 140 | 36 |

M16 Dimensions and Thread Lengths

M16 partially threaded bolts are designed for high-stress structural connections. The combination of a large diameter and a strong, unthreaded shank makes them ideal for resisting powerful shear forces in steel-to-steel connections.

| Total Bolt Length (mm) | Thread Length (mm) |

|---|---|

| 80 | 38 |

| 120 | 38 |

| 160 | 44 |

Selecting the Right Hex Bolts for Your Application

Choosing between a fully threaded and a partially threaded bolt is a critical decision that directly impacts the safety and longevity of a joint. The selection depends on whether the application requires superior clamping force or high shear strength. Similarly, the choice between coarse and fine threads affects installation speed, strength, and vibration resistance.

Fully Threaded Bolts for Superior Clamping Force

Fully threaded hex bolts, defined by standards like ISO 4017, are designed for applications where grip strength is the primary concern.

Key Applications in Tapped Holes and Assemblies

Engineers specify fully threaded hex bolts for tasks that demand strong clamping action. These fasteners are ideal for securing components into a tapped (pre-threaded) hole. Common industrial uses include:

- Fastening equipment panels together

- General construction and OEM applications

- Automotive assemblies, such as securing body panels

In these scenarios, the bolt acts like a clamp, pulling two or more parts together tightly.

How Full Threads Maximize Engagement

The continuous threading along the bolt’s entire shank ensures that load is distributed evenly across its full length. This complete engagement maximizes the contact area within a threaded hole, providing uniform pressure and exceptional grip strength. This characteristic makes fully threaded hex bolts the superior choice for generating and maintaining clamping force.

Partially Threaded Bolts for High Shear Strength

Partially threaded hex bolts, governed by standards like ISO 4014, excel in applications subjected to shear, or sideways, forces.

The Function of the Unthreaded Shank

The defining feature of these bolts is the smooth, unthreaded shank located under the head. This solid portion has a larger cross-sectional area than the threaded section. It provides a smooth bearing surface and eliminates the stress concentration points found in threads, making the bolt inherently stronger against shear loads.

Structural Integrity Note: A joint is approximately 20% stronger when the shear plane passes through the unthreaded shank rather than the threads.

Ideal Applications in Structural Joints

The unthreaded shank makes these hex bolts perfect for structural connections where precise alignment and shear resistance are more critical than grip. They are used to join plates or beams in building frames, bridges, and heavy machinery, where forces try to slice the fastener in half.

Preventing Thread Damage in Shear Planes

Using a partially threaded bolt ensures the smooth shank, not the delicate threads, bears the shear load. This design prevents the threads from being stripped or damaged, which would compromise the joint’s integrity. Structural engineers design connections to ensure the shear plane aligns with this stronger, unthreaded portion of the hex bolts.

Coarse Thread (UNC/Metric Coarse) vs. Fine Thread (UNF/Metric Fine)

The final key decision is selecting the thread type. This choice involves a trade-off between installation efficiency and mechanical performance.

When to Choose Coarse Threads for Speed and Durability

Coarse threads are the industry default for most applications. Their key advantages include:

- Faster Installation: The wider spacing allows for quicker assembly.

- Increased Durability: They are less susceptible to cross-threading, galling, or damage.

- Tolerance: They perform better in environments with dirt or debris.

This robustness makes coarse threads ideal for construction and general heavy-duty industrial use.

When to Choose Fine Threads for Precision and Strength

Fine threads offer distinct mechanical benefits for specialized applications. Technicians choose them when performance is paramount, such as in the automotive and aerospace industries. Fine threads provide higher tensile strength and are significantly more resistant to loosening from vibration, making them essential for securing components on heavy machinery and engines.

Beyond Dimensions: Material, Grade, and Finish

While dimensions define a bolt’s size and shape, the material, property class (grade), and finish determine its strength and durability. These properties are not immediately obvious but are critical for selecting safe and reliable fasteners. Understanding these characteristics is essential for any engineering or mechanical task involving hex bolts.

How to Read Hex Bolt Head Markings

Identification markings on the head of a bolt reveal its most important properties. These markings typically include the property class, which indicates strength, and a unique manufacturer’s mark for traceability.

Identifying Metric Property Class (e.g., 8.8, 10.9)

Metric hex bolts use a numerical system to denote strength. These numbers are stamped directly onto the head. For example, a bolt marked “8.8” or “10.9” clearly communicates its specific mechanical properties according to ISO standards.

Identifying Imperial Grade Markings (e.g., Grade 5, Grade 8)

Imperial fasteners use a system of radial lines to indicate the grade. The number of lines corresponds to a specific strength level.

| Marking Type | Description | Examples |

|---|---|---|

| Property Class (Metric) | A two-number system indicating tensile and yield strength. | 8.8, 10.9, 12.9 |

| Grade Markings (Imperial) | Radial lines indicating the bolt’s strength grade. | Grade 5: Three lines. Grade 8: Six lines. |

| Manufacturer’s Mark | A unique symbol identifying the maker for quality control. | Letters or symbols like ‘F’ or ‘B’. |

Common Materials for Hex Bolt Sizes

The choice of hex bolt materials directly influences performance, corrosion resistance, and cost. Manufacturers select materials based on the intended application’s demands.

Carbon Steel and Alloy Steel

Carbon steel is the most common material for steel hex bolts. Manufacturers create alloy steel hex bolts by adding elements like chromium and molybdenum to carbon steel, enhancing properties like hardness and strength. For instance, SCM435 is a common alloy steel used for high-strength hex bolts.

Stainless Steel (A2 and A4 Grades)

Stainless steel hex bolts contain a minimum of 10% chromium, which provides excellent corrosion resistance without needing a protective coating. The two most common types are A2 and A4.

A2 vs. A4 Stainless Steel The key difference is the addition of molybdenum to A4 steel. This element gives A4 superior corrosion resistance, especially in saltwater or chemical environments, making it the preferred choice for marine applications.

Brass, Bronze, and Other Non-Ferrous Metals

Engineers also specify hex bolts made from non-ferrous metals like brass and bronze for applications requiring corrosion resistance and electrical conductivity.

Understanding Property Classes and Strength

The property class of a metric bolt defines its mechanical strength. This system makes it easy to identify the capabilities of different fasteners.

Decoding the Numbers:

- The first number (e.g., the 8 in 8.8) multiplied by 100 gives the ultimate tensile strength in megapascals (MPa).

- The second number (e.g., the .8 in 8.8) represents the percentage of tensile strength at which the bolt will begin to yield or permanently stretch.

Class 8.8: The Versatile Industry Workhorse

Class 8.8 steel hex bolts offer a good balance of strength and toughness. This makes them the most widely used grade for general automotive, machinery, and construction applications. Their reliable performance makes them a versatile choice for a huge range of hex bolt sizes.

Class 10.9: For High-Strength Applications

Class 10.9 steel hex bolts provide a significant increase in tensile and yield strength over Class 8.8. Engineers select this grade for more demanding applications, such as securing engines, suspensions, and structural components that experience high loads.

Class 12.9: For Maximum Tensile Strength Fasteners

Class 12.9 represents one of the highest strength classes commercially available for hex bolts. These fasteners are used in critical, high-stress applications where maximum clamping force and fatigue resistance are essential, such as in performance engines and heavy industrial equipment.

The Importance of Protective Coatings and Finishes

A bolt’s material provides its core strength, but its finish or coating delivers crucial protection against environmental threats. Protective coatings act as a barrier against corrosion, extending the service life of hex bolts and ensuring the long-term integrity of a connection. The choice of coating depends entirely on the application’s environment, from indoor machinery to harsh outdoor or marine conditions.

Zinc Plating for Corrosion Resistance

Zinc plating, also known as electroplating, is a common and cost-effective finish. This process applies a thin layer of zinc to the surface of the steel.

- It provides a sacrificial barrier against moisture, offering moderate corrosion resistance.

- The coating is typically less than one mil thick, so it does not significantly alter the bolt’s dimensions.

- Mating nuts generally do not require overtapping, making it a straightforward choice for general-purpose applications.

Technicians often choose zinc-plated hex bolts for indoor or dry environments where aesthetics and minimal protection are sufficient.

Hot-Dip Galvanizing for Harsh Environments

Hot-dip galvanizing (HDG) offers superior corrosion protection for hex bolts used in demanding settings. The process involves immersing the fastener in a bath of molten zinc, creating a thick, durable, and metallurgically bonded coating. This coating is substantially thicker than zinc plating, often ranging from 2 to 5 mils. This added thickness directly impacts thread fit, requiring that the internal threads of a mating nut be tapped oversize to ensure proper assembly.

According to the British Standard BS 4190, when a thick protective coating is applied to a high-strength bolt (like grade 8.8 or 10.9) that requires the nut thread to be overtapped, technicians should use the next higher grade of nut to maintain the assembly’s strength.

This robust finish makes HDG the standard for outdoor structural steel, coastal areas, and industrial plants.

Black Oxide and Phosphate Coatings

Black oxide and phosphate are conversion coatings, meaning they chemically alter the surface of the fastener rather than adding a layer of metal. A black oxide finish provides mild corrosion resistance and is often used for aesthetic purposes or when tight dimensional tolerances are critical.

Phosphate coatings, governed by standards like ASTM F1137/F1137M-25, offer good corrosion protection and an excellent surface for paint adhesion. This specification outlines requirements for phosphate/oil coatings that provide both corrosion resistance and lubrication. These finishes are ideal for fasteners in automotive and machinery applications where a decorative finish is not the primary goal.

Selecting the correct hex bolts requires a systematic approach. Technicians first identify the three key dimensions: diameter, length, and thread pitch. They then match the bolt size to the appropriate standard, choosing between fully threaded and partially threaded hex bolts based on application needs. Finally, verifying the material and grade via head markings ensures the fasteners provide a safe and durable connection. Following these steps for all hex bolt dimensions guarantees reliable performance.

FAQ

What is the difference between a hex bolt and a hex cap screw?

A hex bolt is designed for use with a nut. A hex cap screw threads directly into a tapped hole. In practice, people often use the terms interchangeably for the same fastener.

Can technicians reuse high-strength hex bolts?

No. Technicians must not reuse high-strength bolts (e.g., Class 10.9) that have been tightened to their specified torque. The tightening process can permanently stretch the bolt, compromising its strength and clamping ability for future use.

Why did my wrench not fit an M10 bolt?

The required wrench size for some metric bolts changed during the global shift from DIN to ISO standards.

Example: An older DIN 933 M10 bolt uses a 17 mm wrench. The current ISO 4017 M10 bolt requires a 16 mm wrench. Always verify the standard.

What does the “M” in M8 stand for?

The “M” designation simply stands for Metric. The number that follows indicates the nominal diameter of the bolt in millimeters. Therefore, an M8 bolt has a nominal diameter of 8 mm.

How do I choose between a fully threaded and partially threaded bolt?

Your choice depends on the type of force on the joint.

- Fully Threaded (ISO 4017): Best for clamping force in tapped holes.

- Partially Threaded (ISO 4014): Ideal for shear resistance in structural joints.

Is a Class 10.9 bolt stronger than a Grade 8 bolt?

Yes. A metric Class 10.9 bolt has a higher ultimate tensile strength than an imperial Grade 8 bolt. Engineers select Class 10.9 for applications requiring greater strength and load-bearing capacity.

What happens if I use a nut with the wrong thread pitch?

Using a mismatched thread pitch will cause the threads to cross and bind, a problem known as galling. This damages both the bolt and nut, prevents proper tightening, and creates a weak, unreliable connection.