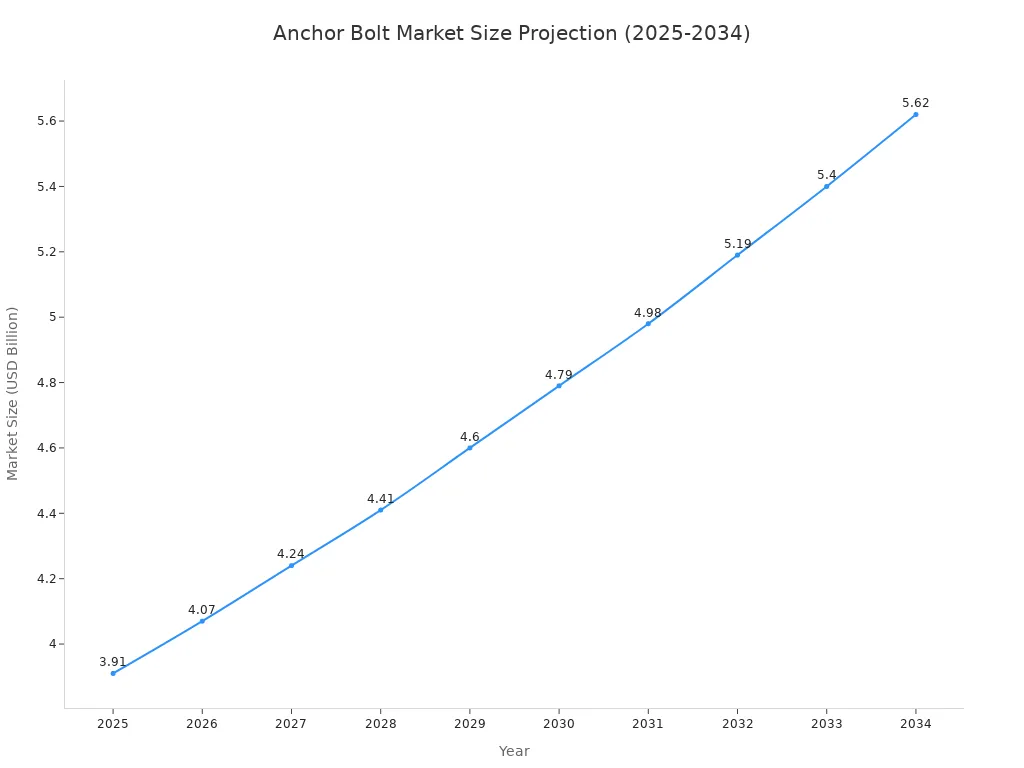

An anchor bolt specification, such as ASTM F1554, establishes a system of grades that define a bolt’s strength, material, and suitability for various applications. These grades, including Grade 36, Grade 55, and Grade 105, offer distinct mechanical properties. Selecting the correct grade is a methodical process. Engineers match these grades to specific project load requirements, environmental conditions, and structural designs. This ensures the anchor bolts perform safely and reliably. The global market for these essential components, including custom anchor bolts, is projected to grow significantly.

Note: A custom fasteners manufacturer can produce custom fasteners to meet unique project requirements when standard parts are unsuitable. The ASTM standard provides the baseline for these specialized anchor bolt specifications.

What Are Anchor Bolts and Why Do Standards Matter?

Anchor bolts are fundamental components in modern construction, creating the critical link between a structure and its foundation. Understanding their function and the standards that govern them is essential for ensuring safety, reliability, and compliance.

The Core Function of Anchor Bolts in Construction

Anchor bolts serve as the primary connection point for transferring immense forces, ensuring a structure remains stable and secure throughout its service life.

Securing Structural Steel to Concrete Foundations

Engineers use anchor bolts to fasten steel columns, beams, and frames securely to concrete footings or slabs. This connection forms the base of the entire building frame, providing a rigid and stable starting point for vertical construction.

Anchoring Heavy Equipment and Machinery

In industrial settings, large machines, generators, and manufacturing equipment generate significant vibration and operational forces. Anchor bolts lock this equipment to the concrete floor, preventing movement that could damage the machine, compromise safety, or disrupt operations.

Resisting Tensile and Shear Loads

The primary engineering purpose of anchor bolts is to manage specific forces. They are crucial for linking a structure to its foundation and resisting powerful forces to ensure proper load distribution.

- They connect structural and non-structural elements to concrete.

- They transfer tension forces, which are the uplift or pulling-apart forces caused by wind or seismic activity.

- They transfer shear forces, which are the lateral or sideways forces that try to slide the structure off its foundation.

The Critical Role of Anchor Bolt Specifications

Standardized specifications provide a clear, enforceable framework that dictates the material properties, manufacturing processes, and performance capabilities of anchor bolts.

Ensuring Structural Safety and Preventing Failure

Adherence to a standard is the first line of defense against structural failure. Building codes, such as the International Building Code (IBC), mandate strict requirements for anchor bolts to ensure structures can resist lateral forces from earthquakes and high winds. Lessons from events like the 1994 Northridge earthquake led to code updates, such as requiring heavy plate washers in seismic zones. This change prevents bolts from tearing through wood sill plates, a failure that compromised many buildings during that event.

Guaranteeing Performance and Reliability

When an engineer specifies a bolt grade, they are selecting a component with predictable and verifiable mechanical properties. A recognized standard guarantees that the bolt will meet minimum strength, ductility, and hardness requirements, ensuring it performs as designed under anticipated loads.

Establishing Legal and Building Code Compliance

Using anchor bolts that conform to a recognized specification is a legal and contractual requirement. Project plans and local building codes explicitly reference standards like ASTM F1554. Failure to comply can result in failed inspections, costly rework, and significant legal liability.

Simplifying Design, Specification, and Procurement

A universal system of anchor bolt specifications creates a common language for everyone involved in a project. This system allows engineers to clearly communicate their requirements, helps fabricators to source the correct materials, and enables suppliers to stock the right parts for various applications.

A Deep Dive into the Primary Standard: ASTM F1554

The ASTM F1554 standard is the definitive specification for anchor bolts designed to anchor structural supports to concrete foundations. Engineers, fabricators, and contractors rely on this document to ensure consistency and safety in construction. It covers three distinct grades of steel fasteners: Grade 36, Grade 55, and Grade 105.

Decoding the ASTM F1554 Specification

Understanding the ASTM F1554 specification is the first step toward selecting the correct anchor bolt materials for a project. This standard provides a clear framework for manufacturing and testing.

Scope and Purpose of the Standard

The primary purpose of the ASTM F1554 standard is to govern the mechanical and chemical requirements for straight, bent, headed, and headless anchor bolts. It creates a uniform system for defining strength, dimensions, and material composition. This ensures that a bolt specified as a particular grade will perform predictably under calculated loads, regardless of the manufacturer. The standard specification simplifies the design process for engineers and the procurement process for contractors.

How F1554 Consolidated and Replaced Previous Standards

Before 2007, engineers often specified anchor bolts using a variety of ASTM standards that were not written specifically for anchoring. This created confusion and inconsistency. ASTM International introduced ASTM F1554 to consolidate and replace these older, less-specific standards for anchoring applications. It created a single, comprehensive document that streamlined the entire system of anchor bolt specifications.

F1554 Grade 36: The General-Purpose Choice

F1554 Grade 36 is the most common and economical of the F1554 grades. It is a low-carbon steel anchor bolt suitable for a wide range of general-purpose anchoring tasks where high strength is not the primary requirement.

Material Composition and Mechanical Properties

Grade 36 anchor bolts are manufactured from low-carbon steel. The grade number itself refers to its minimum yield strength in kilopounds per square inch (ksi). This grade offers excellent ductility, which is the ability to deform under tensile stress without fracturing.

| Property | Grade 36 (KSI) | Grade 36 (PSI) |

|---|---|---|

| Minimum Yield Strength | 36 | 36,000 |

| Tensile Strength Range | 58–80 | 58,000–80,000 |

Common Applications for Light-Duty Anchoring

The combination of moderate strength and cost-effectiveness makes this grade ideal for many situations. Common applications for Grade 36 anchor bolts include:

- Light pole and signage installations

- Securing steel building columns in light commercial projects

- Anchoring machinery bases with low vibration

- Fastening non-structural elements to concrete

Identification: Plain Finish or Blue Color Code

Proper identification prevents job site mix-ups. F1554 Grade 36 anchor bolts are typically supplied with a plain, unfinished steel surface. For clear visual confirmation, the end of the bolt that will project from the concrete is often color-coded blue.

F1554 Grade 55: The Medium-Strength Workhorse

When project requirements exceed the capacity of Grade 36, engineers often specify F1554 Grade 55. This medium-strength anchor bolt provides a significant increase in load-bearing capacity.

Material Composition and Enhanced Properties

This grade is made from a modified mild steel that delivers higher minimum yield and tensile strengths compared to Grade 36. The enhanced properties of this grade make it a versatile choice for more demanding structural applications. The ASTM standard requires specific mechanical properties for this grade to ensure reliable performance.

When to Specify Grade 55 Over Grade 36

Engineers specify Grade 55 when the calculated tensile or shear loads are too high for a Grade 36 bolt of the same diameter. It provides a stronger connection without needing to increase the bolt size, which can save space and reduce concrete edge distance requirements. It is a popular choice for building columns, bridge railings, and heavy equipment.

Identification: Yellow Color Code

To distinguish it from other F1554 grades, Grade 55 is identified with a yellow color code painted on the projecting end. This simple visual check helps inspectors and installers verify that the correct grade has been used.

Understanding the S1 Supplementary Requirement for Weldability

A critical aspect of the Grade 55 specification is weldability. Standard Grade 55 anchor bolts are not guaranteed to be weldable.

Important Note: For applications requiring welding, such as attaching a plate or other steel element to the anchor bolt in the field, the S1 supplementary requirement must be included in the project documents. The S1 designation ensures the steel’s chemical composition is controlled to allow for safe and effective welding. Mill test reports must certify this weldability. Without the S1 designation, attempting to weld a Grade 55 bolt is unsafe and not permitted by the ASTM F1554 standard.

F1554 Grade 105: The High-Strength Solution

For the most demanding structural connections, engineers turn to F1554 Grade 105. This high-strength anchor bolt is engineered for applications where extreme tensile and shear forces are expected. Its superior mechanical properties make it the premier choice for critical infrastructure and high-stress environments.

Material Composition and Quenched & Tempered Properties

The exceptional strength of the Grade 105 bolt comes from its material and manufacturing process. This grade is produced from a medium-carbon alloy steel. It undergoes a mandatory heat treatment to achieve its specified properties. F1554 Grade 105 anchor rods require controlled quenching and tempering treatments. Quenching involves rapid cooling to increase toughness and strength. Tempering is a controlled reheating and cooling process that enhances ductility after quenching. This precise control of time and temperature during tempering is crucial for achieving balanced mechanical properties. The result is a fastener with a minimum yield strength of 105 ksi.

Applications in Critical and High-Stress Structures

The high capacity of this grade makes it essential for specific, high-load applications. Engineers specify this grade for projects including:

- Major bridge and highway structures

- Large-scale wind turbine foundations

- Anchoring heavy industrial equipment subject to extreme vibration

- Building columns in high-seismic or high-wind regions

Identification: Red Color Code

To prevent any confusion with lower-strength grades on a job site, the ASTM F1554 standard requires a clear identification mark. The projecting end of a Grade 105 anchor bolt is color-coded red. This visual cue provides immediate verification for installers and inspectors.

Mandatory Heat Treatment Requirements

The heat treatment process is not an optional enhancement for this grade; it is a fundamental requirement of the ASTM specification. Every F1554 Grade 105 bolt must be quenched and tempered to develop its characteristic high strength and toughness. This process ensures that the anchor bolt materials meet the rigorous performance demands expected of this grade. The ASTM standard strictly defines this manufacturing step.

Comparing ASTM F1554 Grades: A Technical Snapshot

A direct comparison of the three F1554 grades highlights the distinct performance capabilities of each grade. The ASTM F1554 specification outlines specific minimum and maximum values for key mechanical properties. These differences guide engineers in selecting the appropriate grade for their design loads.

| Property | Grade 36 | Grade 55 | Grade 105 |

|---|---|---|---|

| Yield Strength Min (ksi) | 36 | 55 | 105 |

| Tensile Strength (ksi) | 58–80 | 75–95 | 125–150 |

| Elongation % Min | 23 | 21 | 15 |

Yield Strength Comparison

Yield strength is the amount of stress a material can endure before it begins to deform permanently. The jump in yield strength between the grades is significant. Grade 55 offers over 50% more yield strength than Grade 36. Grade 105 nearly doubles the yield strength of Grade 55, providing a massive increase in load-bearing capacity before permanent stretching occurs.

Tensile Strength Comparison

Tensile strength, or ultimate tensile strength, is the maximum stress a material can withstand while being pulled or stretched before breaking. The ASTM standard provides a strength range for each grade. This ensures the bolt is strong enough to meet the minimum requirement but not so hard that it becomes brittle. The Grade 105 bolt has a minimum tensile strength of 125 ksi, far exceeding the other two grades.

Elongation and Reduction of Area Comparison

Elongation measures a bolt’s ductility, or its ability to stretch before it fractures.

Key Takeaway: There is an inverse relationship between strength and ductility. As the strength of the steel increases, its ability to elongate decreases.

The table shows that the lower-strength Grade 36 is the most ductile, with a minimum elongation of 23%. The high-strength Grade 105 is the least ductile, with a minimum elongation of 15%. This trade-off is a critical consideration for engineers, especially in designs that must accommodate seismic movement. A related property, reduction of area, also measures ductility by calculating how much the bolt’s cross-section narrows at the point of fracture.

How to Select the Right Anchor Bolt Specification

Selecting the right anchor bolt involves a systematic, multi-step evaluation. Engineers do not choose a grade or type based on a single factor. Instead, they conduct a thorough analysis of structural forces, environmental conditions, and installation constraints. This methodical approach ensures the chosen anchor bolt specifications meet all project safety and performance requirements.

Step 1: Analyze Structural Load Requirements

The first and most critical step is to understand the forces the anchor bolts must resist. The structural design dictates these load requirements, which form the basis for all subsequent decisions, including anchor bolt sizing and grade selection.

Calculating Tensile (Uplift) Loads

Tensile loads are the forces that attempt to pull an anchor bolt straight out of the concrete foundation. These uplift forces often result from wind acting on a building’s roof or overturning moments on tall structures. Engineers use specific formulas provided by design standards to calculate the required tensile capacity of the anchor.

Calculating Shear (Lateral) Loads

Shear loads are lateral forces that try to slide the connected structure horizontally across the foundation. These forces are common in seismic events or from the operational forces of heavy machinery. Like tensile loads, shear capacity is determined using established engineering principles.

For the Engineer: Structural design codes from organizations like the American Institute of Steel Construction (AISC) and the American Concrete Institute (ACI) provide detailed formulas for calculating anchor bolt capacities. The following table offers a snapshot of these complex calculations.

| Standard | Load Type | Formula |

|---|---|---|

| AISC 15th Edition, J3.6 | Tensile Capacity (LRFD) | 0.5625 * Fu * Ab |

| Shear Capacity (LRFD) | 0.3375 * Fu * Ab | |

| ACI 318-19 | Tensile Capacity | 0.75 * Ase * Futa |

| Shear Capacity (Cast-in Stud) | 0.65 * Ase * Futa | |

| Combined Tensile & Shear | (Tensile / Tensile Capacity)^n + (Shear / Shear Capacity)^n <= 1.0 (Interaction check, n=5/3) |

Note: Fu = Ultimate Tensile Stress, Ab = Nominal Bolt Area, Ase = Tensile Stress Area, Futa = Specified Tensile Strength of Anchor Steel.

Factoring in Dynamic, Seismic, and Wind Forces

Structures are rarely subjected to static loads alone. Dynamic forces from wind, earthquakes, and vibrating equipment introduce complex stresses. In regions with high seismic activity, special considerations are mandatory.

- For structures in Seismic Design Category C or higher, engineers must design anchor bolts with an overstrength factor, often as high as 2.0. This effectively doubles the expected tension force, demanding a stronger grade or deeper embedment.

- Chemical (adhesive) anchors often perform better under seismic loads and vibrations compared to some mechanical anchors, making them a preferred choice in these applications.

- The increased risk in these zones also leads to more frequent and rigorous anchor inspections to verify correct installation and integrity.

Step 2: Evaluate Environmental and Service Conditions

The long-term performance of anchor bolts depends heavily on the environment where they are installed. Corrosion, extreme temperatures, and chemical exposure can all degrade an anchor connection over time.

Corrosion Resistance: Plain, Galvanized, and Other Coatings

For anchor bolts exposed to moisture, soil, or outdoor weather, corrosion protection is essential. While a plain finish is suitable for dry, interior conditions, most applications require a protective coating. Hot-dip galvanizing is a common and effective solution. Two primary ASTM standards govern this process.

| Feature | ASTM A153 (Hardware) | ASTM F2329 (Fasteners) |

|---|---|---|

| Primary Application | General hardware, including bolts | Specifically for fasteners like bolts, nuts, and screws |

| Coating Thickness | Specified by hardware class (e.g., Class C) | Specified by fastener diameter |

| Lubrication | Not required | Allows for customer-requested lubrication to aid assembly |

Performance in High and Low-Temperature Extremes

Extreme temperatures affect the entire anchor system, including the steel bolt and the surrounding concrete.

- Low Temperatures: Cold conditions down to -20°C can actually increase concrete strength, which may positively impact anchor performance.

- High Temperatures: Elevated temperatures are a greater concern. While performance may not vary significantly below 400°C, temperatures above this threshold can degrade the concrete-to-steel bond. This degradation reduces the pull-out strength of the anchor.

Exposure to Chemicals or Abrasive Elements

Industrial facilities, chemical plants, and coastal marine environments expose anchor bolts to aggressive substances. In these cases, standard galvanizing may not be sufficient. Engineers may specify stainless steel anchor bolts or specialized coatings to resist specific chemical attacks and prevent premature failure.

Step 3: Assess Material and Installation Constraints

The final step in selecting the right anchor bolt involves practical considerations related to material properties and on-site installation practices. A theoretically perfect design can fail if it is not practical to build.

Weldability Needs for Field Connections

Field welding is sometimes necessary to attach plates or other elements to an anchor. This requirement heavily influences the selection of the right anchor bolt grade.

- F1554 Grade 55: This grade is only weldable if the S1 supplementary requirement is specified. The S1 supplement controls the steel’s chemistry to ensure a safe, strong weld.

- F1554 Grade 105: This high-strength grade is a heat-treated product. Welding is generally not recommended because the intense heat of the welding process can alter the bolt’s carefully engineered mechanical properties and compromise its strength.

Compatibility with Specified Concrete Strength

An anchor connection is a system. The strength of the anchor bolt must be compatible with the strength of the concrete foundation. Installing a high-strength Grade 105 anchor into low-strength concrete is an inefficient design. The connection will fail by concrete breakout long before the bolt’s full capacity is reached. The design must balance the capacity of both materials.

Required Embedment Depth and Edge Distance

Proper installation is defined by two key geometric constraints:

- Embedment Depth: This is how deep the anchor is installed into the concrete. Deeper embedment provides greater resistance to pull-out forces. The required depth is a direct function of the load requirements.

- Edge Distance: This is the distance from the anchor to the nearest edge of the concrete slab or footing. If an anchor is too close to an edge, it can cause the concrete to break out under load.

Step 4: Consult Engineering and Project Documents

Theoretical calculations and environmental assessments are vital, but the project’s official documents provide the definitive requirements. Engineering drawings and specifications are the authoritative source for all construction details. Contractors and fabricators must treat these documents as the primary guide for selecting and installing anchor bolts. This final verification step ensures every component aligns with the overall structural design.

Reading Anchor Bolt Callouts on Structural Drawings

Structural drawings communicate the engineer’s design intent through a system of notes and symbols called “callouts.” An anchor bolt callout is a specific instruction that provides all the necessary information for a particular connection. Misinterpreting a callout can lead to incorrect material procurement and installation errors. A typical callout on a foundation plan contains precise details.

Blueprint Breakdown: A callout acts as a complete recipe for the anchor bolt assembly. It leaves no room for guesswork and ensures the correct parts are ordered and installed in the right place.

Key information found in an anchor bolt callout includes:

- Bolt Diameters: The callout specifies the required diameter of the bolt, such as 3/4″ or 1″.

- Bolt Configurations: It details the anchor setup for different structural members, like an I-beam column versus a C-channel column.

- Number of Bolts: The plans indicate the exact quantity of bolts needed for each connection or section of the building.

- Placement Details: Drawings show the precise location for each anchor group, distinguishing between endwalls, interior frames, and framed openings.

- Column Types: The plans often use identifiers (e.g., Column Type A, B, C) to link specific column designs to their corresponding anchor bolt requirements.

The Role of the Engineer of Record (EOR)

The Engineer of Record (EOR) is the licensed professional engineer who holds ultimate responsibility for the structural design’s integrity and safety. The EOR creates and stamps the structural drawings, making their specifications legally binding. The anchor bolt grade, diameter, embedment, and coating specified by the EOR are not suggestions; they are mandates based on detailed load calculations and code requirements.

If a contractor or fabricator finds a discrepancy in the plans or has a question about a specification, they must not make an assumption. The correct procedure is to submit a formal Request for Information (RFI). The EOR will review the RFI and provide a formal, written clarification. This process creates a documented record and protects all parties by ensuring any change is approved by the responsible design professional.

Verifying Compliance with Local Building Codes

Engineering documents are developed to meet the requirements of local and national building codes, such as the International Building Code (IBC) and ACI 318. These codes provide the minimum standards for design and construction to protect public safety. They contain specific chapters dedicated to structural loads, steel construction, and concrete anchoring.

For example, building codes dictate special requirements for structures in areas with high seismic activity or hurricane-force winds. These provisions often demand stronger anchor materials (like F1554 Grade 105), deeper embedment depths, or specific anchor types proven to perform well under dynamic loads. Verifying that the specified anchor bolts meet these local code requirements is a final, critical checkpoint. It confirms that the project is not only structurally sound but also legally compliant.

Other Relevant Anchor Bolt Specifications and Types

While ASTM F1554 is the primary standard for anchor bolts, engineers sometimes encounter other ASTM specifications. Understanding the differences is key to appreciating why ASTM F1554 is the preferred choice for anchoring. This section also explores the different types of anchor bolts available.

ASTM F1554 vs. ASTM A307

Before the adoption of ASTM F1554, engineers often specified ASTM A307 for general-purpose anchoring. The ASTM A307 specification covers low-carbon steel bolts and studs.

Comparing A307 Grade A and Grade B

The ASTM A307 standard includes two main grades. Grade A is intended for general applications, while Grade B is designed for flanged joints in piping systems. For anchoring, the now-obsolete A307 Grade C was mechanically similar to F1554 Grade 36.

Why F1554 is the Preferred Specification for Anchor Bolts

The ASTM F1554 standard was created specifically for anchoring. It provides a clearer and more complete set of requirements. A key difference in the ASTM F1554 compared to other standards is the mandatory ductility test.

| Grade | Tensile, ksi | Yield, ksi min | Elongation % min | Reduction of Area % min |

|---|---|---|---|---|

| A307 Grade C (Obsolete) | 58–80 | 36 | 23 | No Requirement |

| F1554 Grade 36 | 58–80 | 36 | 23 | 40 |

Key Insight: The F1554 Grade 36 specification requires a minimum 40% Reduction of Area. This test ensures a level of ductility that the older ASTM A307 standard did not, making it a safer and more reliable choice.

High-Strength Structural Bolt Comparisons

For high-stress applications, engineers may consider other high-strength bolt specifications besides F1554 Grade 105.

ASTM A449 for General Engineering Headed Bolts

ASTM A449 covers medium-strength, heat-treated steel headed bolts. Its mechanical properties are similar to F1554 Grade 105, but it is primarily intended for general engineering applications, not specifically for anchoring.

ASTM A193 Grade B7 for High-Temperature/Pressure Service

Engineers specify ASTM A193 Grade B7 bolts for high-temperature and high-pressure service. This grade is made from heat-treated chromium-molybdenum alloy steel. Its chemical composition makes it ideal for equipment in petrochemical plants and power generation facilities.

When to Use These Over F1554 Grade 105

An engineer chooses a specific grade based on the project’s unique demands. While F1554 Grade 105 is the default for high-strength anchoring, ASTM A193 Grade B7 is the correct choice for connections exposed to extreme heat and pressure.

Understanding Different Types of Anchors

Beyond material specifications, there are different types of anchor bolts based on installation method.

Cast-in-Place vs. Post-Installed Anchors

The two main installation types are cast-in-place and post-installed. Each has distinct advantages.

| Anchor Type | Advantages | Disadvantages |

|---|---|---|

| Cast-in-Place | Highest reliability and strength. | Requires precise placement before concrete pour. |

| Post-Installed | Flexible placement in existing concrete. | Lower strength; installation quality is critical. |

Mechanical Expansion Anchor Types

These post-installed anchors create a connection by expanding against the concrete. Common types include wedge anchors and sleeve anchors. They are popular for their quick installation.

Adhesive (Chemical) Anchor Types

Adhesive anchors use a two-part epoxy or resin to bond a threaded rod to the concrete. These types offer excellent strength, especially in resisting vibration and seismic loads.

Best Practices for Anchor Bolt Installation

Proper anchor bolt installation is as critical as selecting the correct specification. A flawless design can be compromised by procedural errors during the installation process. Following established best practices ensures the connection performs as engineered.

Critical Pre-Installation Checks and Verification

Before any concrete is poured or drills are started, a series of checks must be completed. This verification stage prevents costly rework and ensures the right components are used.

Verifying Material Test Reports (MTRs)

Installers must first verify the Material Test Reports (MTRs) for the supplied anchor bolts. These documents certify that the chemical and mechanical properties of the steel meet the specified ASTM grade requirements. This check confirms the material’s strength and ductility.

Checking Bolt Dimensions, Threads, and Grade Markings

A physical inspection of the fasteners is necessary. This involves measuring the key components of anchor bolts to confirm they match the project drawings, including diameter, length, and thread specifications. Correct anchor bolt sizing is crucial. Installers also check for the correct grade identification, such as the blue, yellow, or red color code on the bolt end.

Anchor Bolt Template and Layout Verification

Using a template is essential for accurately placing cast-in-place anchors. The layout verification follows a precise installation process:

- Anchor Bolt Positioning: The crew verifies the correct location, spacing, and orientation against the construction drawings. Tolerances are strict, often within ±3 mm for spacing and projection.

- Fixing and Alignment: They ensure a proper template or jig holds the bolts securely. The team checks for any movement before and after the concrete is poured.

- Post-Pour Inspection: After the pour, a final check confirms the alignment, projection height, and exposed length of the bolts, ensuring no displacement occurred.

Proper Anchor Bolt Installation Procedures

The physical installation process demands precision. Each step, from hole preparation to bolt setting, contributes to the final strength of the connection.

Hole Drilling and Cleaning for Post-Installed Anchors

For post-installed anchors, the hole must be drilled to the correct diameter and depth.

Critical Step: The hole must be thoroughly cleaned of all dust and debris using compressed air and a wire brush. Improper cleaning is a leading cause of adhesive and mechanical anchor failure.

Bolt Setting, Grouting, and Curing

Cast-in-place bolts are set within the template before the concrete pour. After the concrete cures, non-shrink grout is often used to fill the void between the base plate and the foundation, ensuring uniform load transfer.

Correct Nut and Washer Installation

Installers must use the specified nuts and washers. Using an incorrect or lower-grade washer can lead to pull-through failure under load.

Torqueing, Tensioning, and Final Inspection

The final steps involve applying the correct tension and performing a final inspection.

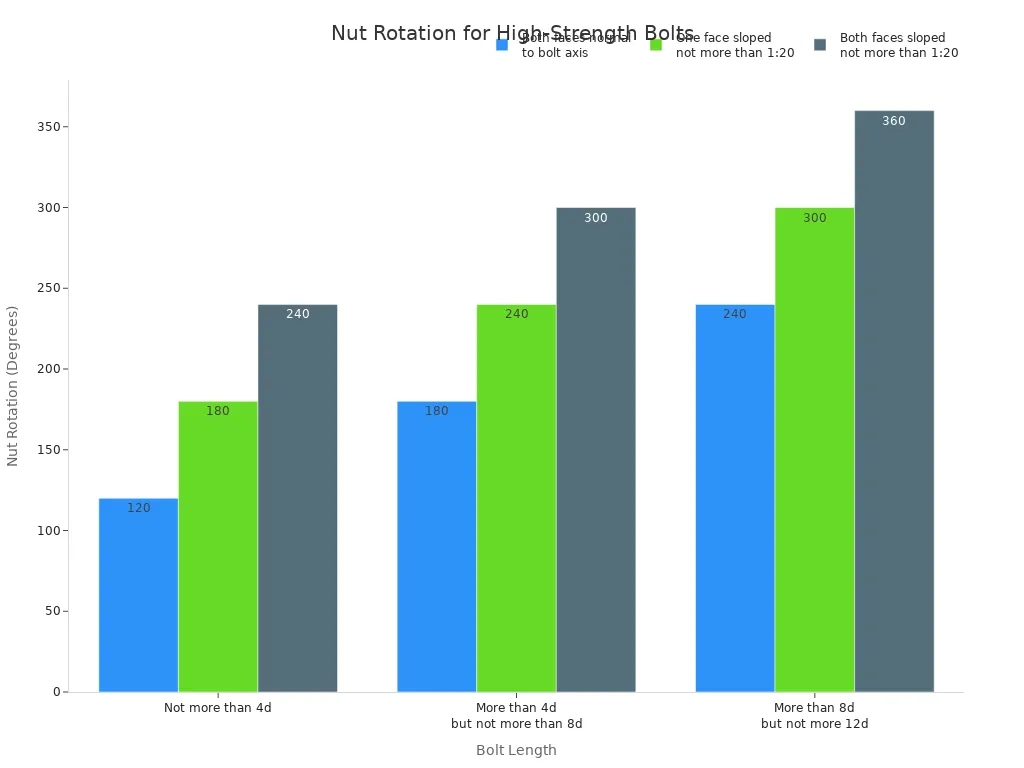

Understanding the Turn-of-Nut Method

The turn-of-nut method is a procedure for tensioning high-strength structural bolts. It involves rotating the nut a specific amount after it reaches a snug-tight condition. However, this method typically does not apply to anchor bolts, as most applications only require the nuts to be snug-tightened.

In special cases, such as double nut moment connections, a modified turn-of-nut method may be used. AASHTO provides specific guidelines for this scenario.

| Diameter | F1554g36 | F1554g55, g105, A449, A615 and A706g60 |

|---|---|---|

| 1-1/2” and below | 1/6 turn (60deg) | 1/3 turn (120deg) |

| Above 1-1/2” | 1/12 turn (30deg) | 1/6 turn |

Note: Applicable only to the top nut in double nut moment connections.

Using a Calibrated Wrench for Torqueing

When project specifications require a specific torque value instead of the turn-of-nut method, workers must use a calibrated torque wrench. This ensures the correct amount of tension is applied to the bolt without over-tightening.

Post-Installation Inspection Requirements

A final inspection verifies that the complete anchor bolt sizing and installation process followed the engineering drawings and specifications. This includes checking nut tightness, bolt projection, and overall connection integrity.

Common Installation Mistakes and How to Avoid Them

Even with the correct specifications, the anchor bolt installation is prone to human error. A flawed installation process can undermine the strength of the entire connection, leading to potential structural failures. Awareness of common mistakes is the first step toward preventing them.

Incorrect Embedment Depth or Edge Distance

Installers must strictly follow the embedment depth and edge distance values on the engineering drawings. Inadequate edge distances weaken an anchor bolt’s capacity. When an anchor is too close to an edge, the concrete’s stress cone cannot fully develop. This makes the edge vulnerable to cracking or spalling, which can cause premature anchor failure because the surrounding concrete cannot resist the concentrated forces.

Similarly, insufficient embedment depth reduces load-carrying capacity. As the depth decreases, the cone of influence shrinks and engages less concrete. This significantly reduces both the tensile and shear capacities of the anchor.

How to Avoid It: Always measure and mark the required embedment depth on the drill bit. Use a template to ensure the anchor group is placed at the correct distance from all concrete edges, as specified in the project plans.

Improper Hole Cleaning Leading to Bond Failure

This mistake is a primary cause of failure for post-installed anchors. After drilling, the hole contains fine concrete dust and debris. If left in the hole, this dust acts as a barrier, preventing adhesive anchors from bonding properly to the concrete. For mechanical anchors, the debris can obstruct the expansion mechanism, preventing it from gripping the hole securely.

To avoid this critical error, follow a strict cleaning procedure:

- Use compressed air to blow out the initial loose dust.

- Scrub the inside of the hole with a properly sized wire brush.

- Perform a final blowout with compressed air to remove all remaining particles.

Over-Torqueing or Under-Torqueing the Nut

Applying the correct torque is essential for achieving the specified tension in the bolt. Both over-tightening and under-tightening create significant problems.

- Over-torqueing can stretch the bolt beyond its yield strength, permanently damaging it. It can also crack the concrete or crush the grout pad beneath the base plate.

- Under-torqueing results in a loose connection that cannot effectively transfer loads. The base plate may shift under shear forces, and the connection will not resist uplift forces as designed.

How to Avoid It: Use a calibrated torque wrench to tighten the nut to the value specified by the Engineer of Record. Never use an impact wrench for final torqueing unless specifically permitted and controlled by a documented procedure.

Selecting the right anchor bolt is a critical decision. Engineers must methodically evaluate load requirements and environmental conditions for various applications to choose the correct anchor bolt specifications, especially within the ASTM F1554 framework. Proper installation of anchor bolts is just as vital as selection. Procedural errors can compromise entire structures, leading to costly failures.

- Improper anchor spacing in a power plant caused refractory cracking and operational shutdowns.

- Incorrect anchor positioning in a steel facility led to misalignments and significant production losses.

Always refer to project drawings and consult a qualified engineer to ensure all ASTM F1554 requirements are met.

FAQ

What is the main difference between F1554 grades?

The primary difference is strength. Grade 36 is a low-carbon steel for general use. Grade 55 offers medium strength for heavier loads. Grade 105 is a heat-treated, high-strength steel for critical structural applications where maximum load capacity is necessary.

Can I weld any F1554 anchor bolt?

No. Weldability is not guaranteed. Engineers must specify F1554 Grade 55 with the S1 supplementary requirement for welding. The astm standard prohibits welding Grade 105 bolts, as the heat can ruin their mechanical properties. Welding standard Grade 55 or Grade 36 is also unsafe.

Why is the color code on anchor bolts important?

The color code provides immediate visual identification of the bolt’s grade on a job site. Blue signifies Grade 36, yellow indicates Grade 55, and red marks Grade 105. This simple system helps prevent installation errors and ensures the correct part is used.

What happens if I use the wrong anchor bolt grade?

Using an incorrect grade can lead to structural failure. A weaker bolt may not handle the design loads, while an overly strong bolt might lack necessary ductility. This mistake also violates building codes and engineering specifications, requiring costly rework and creating liability.

Is a stronger anchor bolt always better?

Not necessarily. A stronger bolt, like Grade 105, is less ductile and cannot stretch as much before fracturing. In seismic zones, engineers may prefer a more ductile bolt that can deform without breaking. The best choice always depends on the specific engineering design requirements.

Who is responsible for choosing the anchor bolt specification?

The Engineer of Record (EOR) holds the ultimate responsibility. The EOR calculates the structural loads and environmental factors to select the appropriate anchor bolt grade, diameter, and embedment depth. These details are mandated on the official project drawings per astm and building code requirements.