Incorrect hardware selection contributes significantly to lifting failures, with configuration errors accounting for 28% of all incidents. A project’s required load capacity is the primary factor when choosing a brass swivel eye bolt. Users must then assess the environment to determine the correct brass alloy. The market for brass fasteners is growing due to their reliability, and a quality custom fasteners manufacturer ensures their bolt casting produces dependable custom fasteners. To select the right eye bolt, one must also verify the thread and shank dimensions to ensure a secure fit for the eye bolt.

Fundamentals of the Brass Swivel Eye Bolt

Understanding the fundamental design of a brass swivel eye bolt is the first step toward proper selection. This hardware consists of several key parts working together to provide a secure and flexible anchor point. A project’s success depends on a user’s knowledge of these components and the material’s inherent advantages.

Core Components and Function

Each part of an eye bolt serves a distinct and critical purpose. The design ensures both strength and maneuverability for various applications, from lifting to anchoring.

The Eye, Shank, and Shoulder

The Eye is the closed loop at the top, providing an attachment point for ropes, cables, or shackles. The Shank is the threaded body of the bolt that secures it into a tapped hole or through-hole with a nut. Many load-rated bolts feature a Shoulder, which is a flange at the base of the eye. This shoulder sits flush against the mounting surface, providing crucial support against angular (or side) loads.

The Swivel Mechanism

The swivel is the component that sets this hardware apart. It allows the eye to rotate 360 degrees independently of the shank. This function is vital for preventing the twisting and binding of lifting slings or lines under load. The rotation ensures that the pulling force remains aligned with the eye, reducing dangerous side-loading stresses on the bolt.

Why Choose Brass for Swivel Eye Bolts?

Brass offers a unique combination of functional and material benefits. Professionals choose it for its durability, appearance, and critical safety features in specific environments.

Superior Corrosion Resistance

Brass, an alloy of copper and zinc, demonstrates excellent resistance to corrosion. This property makes it a superior choice for marine applications, outdoor fixtures, and humid environments where steel would quickly rust and fail. Its durability ensures a longer service life with less maintenance.

Aesthetic and Decorative Value

The material’s warm, golden luster provides significant aesthetic appeal. This makes brass hardware a popular choice for architectural details, marine brightwork on yachts, and high-end decorative projects. It delivers functionality without compromising on visual quality.

Non-Sparking Safety Properties

A critical safety feature of brass is its non-sparking nature. The material will not create sparks when struck against other metallic surfaces. This property is essential in explosive or flammable atmospheres found in oil and gas facilities, chemical plants, and mining operations. To ensure safety, professionals must use hardware certified to specific standards.

- FM 7910: A U.S. standard for creating spark-resistant tools.

- IS 4595-1969(2006): An Indian Standard for testing non-sparking properties.

- IEC 60079-0:2017: An international standard for equipment in explosive atmospheres.

- ATEX Directive: European Union directives for equipment used in hazardous locations.

Important Safety Note: While brass is inherently non-sparking, it should not be used in hazardous environments without proper certification. Always verify that the hardware meets the required safety standards for your specific application.

Step 1: Determining the Right Load Capacity

Selecting a brass swivel eye bolt begins with a critical safety calculation. The primary function of this hardware is to provide secure attachment points for lifting or anchoring. Therefore, a user must accurately determine the total load the bolt will support. This step ensures the chosen hardware has the strength to perform its job safely and prevent catastrophic failure.

Calculating Your Working Load Limit (WLL)

The Working Load Limit (WLL) is the most important specification for any load-bearing hardware. It represents the maximum mass or force that a piece of equipment can safely handle. Calculating the required WLL for your project involves understanding the difference between strength and safe use, accounting for all forces, and applying a crucial margin of safety.

WLL vs. Breaking Strength

Users must not confuse WLL with Breaking Strength. The Breaking Strength, or Maximum Breaking Load (MBL), is the absolute force at which the hardware will fail. The WLL is a much lower, safer value derived from that number.

The standard formula for calculating the Working Load Limit is:

WLL = MBL / Safety FactorFor instance, if an eye bolt has a Breaking Strength of 2,000 lbs and the manufacturer applies a safety factor of 5, its WLL is 400 lbs. A user must never load the hardware beyond this 400 lb limit.

Calculating Static Loads

A static load is a weight that does not move. Calculating it is straightforward. A user simply determines the total weight of the object they intend to lift or secure. For example, if a user needs to suspend a 150 lb architectural feature, the static load is 150 lbs. This number becomes the baseline for determining the required load capacity.

Accounting for Dynamic Forces

When selecting an eye bolt, it is crucial to account for dynamic forces if the load is expected to move or shift. Dynamic forces are generated by movement, such as swinging, sudden stops, or rapid acceleration. These forces can dramatically increase the stress on the hardware.

- Sudden acceleration or rapid changes in load direction significantly increase the tension on rigging equipment.

- This increased tension due to shock loading can lead to eye bolt failure.

- For this reason, shock loading any lifting hardware is strongly discouraged.

If dynamic forces are unavoidable, a user must select a bolt with a much higher WLL to handle these unpredictable peak loads.

Applying a Safety Factor (5:1 Rule)

The Safety Factor is a multiplier that manufacturers apply to create a buffer between the WLL and the Breaking Strength. This buffer accounts for variables like environmental conditions, minor shock loads, and potential human error. For general rigging and lifting applications, a safety factor of 5:1 is a common industry standard, though it can be higher for equipment used to lift people.

Matching Capacity to Bolt Specifications

After calculating the required WLL, the next step is to find a brass swivel eye bolt that meets or exceeds that specification. This information is available directly on the hardware and in official manufacturer documentation.

Finding WLL Ratings on Hardware

Reputable manufacturers stamp or forge the WLL directly onto the body of the hardware. For a swivel eye bolt, this marking is often found on the shoulder or the eye itself. Each bolt is typically marked with its WLL and may come with a certified proof load test report. This marking is the quickest way to verify that a piece of hardware is rated for lifting and meets your project’s needs.

Reading Manufacturer Datasheets

For the most precise information, users should consult the manufacturer’s engineering datasheets. These documents provide comprehensive details that may not fit on the hardware itself. An engineering team can provide precise WLL charts for specific applications.

A typical datasheet might present information in a table similar to this:

| Thread Size | Shank Length | WLL (lbs) – 0° | WLL (lbs) – 45° | Alloy Type |

|---|---|---|---|---|

| 1/2″-13 UNC | 2.0″ | 1,200 | 650 | C464 Naval |

| 1/2″-13 UNC | 3.0″ | 1,200 | 650 | C464 Naval |

| 5/8″-11 UNC | 2.5″ | 2,000 | 1,100 | C464 Naval |

This data confirms the bolt’s capacity and shows how it changes with angular loading.

Dangers of Exceeding Rated Capacity

Knowingly or unknowingly exceeding the WLL is the most common cause of hardware failure. The consequences can range from property damage to serious injury. Even if a load is under the WLL, improper use, such as sharp-angled lifting, can cause the forces on the bolt to surpass its breaking strength.

⚠️ Critical Failure Point In one documented incident, an eye bolt shank sheared off during a lifting operation, despite the load being within the rated WLL. Investigators found the failure occurred because of an angular lift. A lift angle of just 15 degrees can reduce an eye bolt’s effective capacity to 55% of its vertical rating, creating a dangerously overloaded condition.

Step 2: Selecting the Correct Brass Alloy

The term “brass” covers a wide family of copper-zinc alloys. Each alloy possesses distinct properties. Choosing the correct one is essential for the longevity and safety of the swivel eye bolts in a specific environment. The alloy’s composition directly impacts its strength, corrosion resistance, and machinability.

Common Brass Alloys for Swivel Eye Bolts

Manufacturers produce hardware from several standard brass alloys. Three of the most prevalent are C360, C464, and C280. Understanding their differences helps a user match the material to the project’s demands.

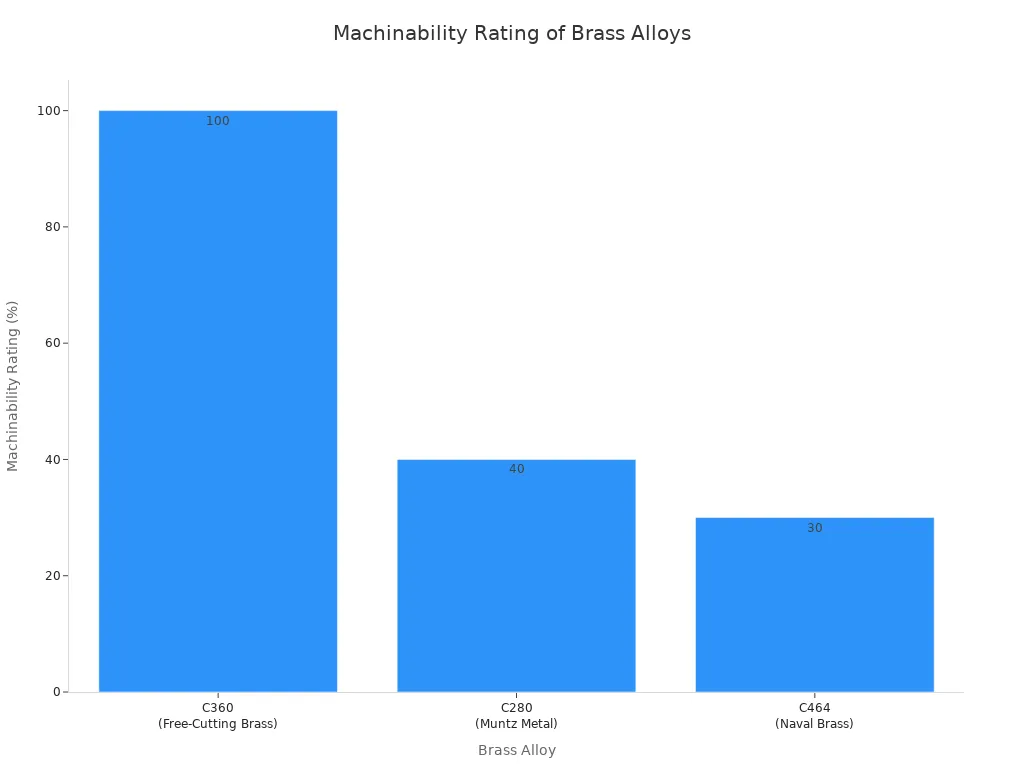

C360 Free-Cutting Brass

C360 is renowned for its outstanding machinability. It is the standard against which other alloys are measured. The inclusion of lead in its composition makes it easy to cut, drill, and shape, reducing manufacturing costs. This property makes it ideal for complex or decorative parts. However, its resistance to corrosion, particularly dezincification in saltwater, is poor.

C464 Naval Brass for Marine Use

C464 Naval Brass is specifically engineered for marine environments. The small amount of tin added to its copper-zinc base dramatically improves its resistance to saltwater corrosion. This alloy provides good strength and fatigue resistance, making it a reliable choice for demanding marine jobs. Its composition makes it a durable and long-lasting option for saltwater exposure.

| Alloy (UNS No.) | Common Name | Composition (Approx. %) |

|---|---|---|

| C36000 | Free-Cutting Brass | 61.5% Cu, 35.5% Zn, 3% Pb |

| C46400 | Naval Brass | 60% Cu, 39.2% Zn, 0.8% Sn |

C280 Muntz Metal for Architectural Use

C280 Muntz Metal offers a balance of strength and corrosion resistance. It is stronger and harder than C360, providing better performance in structural and architectural roles. While it does not match the saltwater resistance of Naval Brass, it performs well in general atmospheric and outdoor conditions. Its lower machinability compared to C360 is a trade-off for its increased durability.

Comparing Alloys for Your Environment

The project’s environment is the deciding factor for alloy selection. A user must align the material’s properties with the expected exposure to moisture, salt, and other corrosive elements. The chart below shows how machinability, a key manufacturing factor, differs greatly between these alloys.

Best for Saltwater and Marine Apps

C464 Naval Brass is the undisputed choice for saltwater applications. Its tin content prevents dezincification, a process where zinc leaches from the alloy, causing it to weaken. Three-year coastal exposure tests confirm that C464 components far outlast other brasses in marine settings.

Best for Outdoor and Humid Areas

For general outdoor use, such as architectural fixtures or non-marine rigging, C280 Muntz Metal is an excellent option. It provides good resistance to atmospheric corrosion and has greater strength than C360, making it suitable for load-bearing common applications exposed to rain and humidity.

Best for Indoor and Decorative Use

C360 Free-Cutting Brass is best suited for indoor and decorative projects. Its superior machinability allows for intricate designs and a fine finish. In a controlled indoor environment, its lower corrosion resistance is not a concern.

Step 3: Choosing Protective Finishes

Beyond the base alloy, a protective finish can significantly enhance a brass swivel eye bolt’s durability and appearance. The right coating provides an extra layer of defense against environmental factors while achieving a specific aesthetic. A user should select a finish that aligns with both the project’s visual goals and its performance requirements.

Finishes for Aesthetics and Durability

Finishes range from simple polishes that showcase the natural material to robust plating that alters its properties. Each option offers a unique balance of look, maintenance, and protection.

Polished Brass

Polished brass is the most traditional finish. It presents the material in its natural, brilliant golden state. This finish provides a classic, high-end look popular in architectural and decorative applications. However, unprotected polished brass is susceptible to oxidation and will tarnish over time, especially when exposed to air and moisture. It requires regular cleaning and polishing to maintain its luster.

Lacquered Brass

Lacquered brass offers the beauty of polished brass without the demanding upkeep. A clear protective coating is applied over the polished surface to seal it from the environment. This finish is an excellent choice for preserving the bright, golden appearance.

How Lacquer Protects Brass:

- Manufacturers apply a clear lacquer to create a robust shield against oxidation and tarnish.

- This coating contains anti-tarnish additives specifically designed to maintain the brass surface’s brilliance.

- A properly applied lacquer finish can last for many years, even in environments that are unfriendly to unprotected metal.

For the lacquer to be effective, the brass surface must be thoroughly cleaned before application to ensure proper adhesion.

Chrome-Plated Brass

Chrome plating gives brass hardware a sleek, modern, silver-like finish. This process involves electroplating a thin layer of chromium onto the brass surface. The result is a finish known for its exceptional hardness and reflectivity. Decorative chrome plating, typically between 0.13 and 1.3 micrometers thick, significantly enhances the natural durability of brass. It provides increased resistance to impact and corrosion and has a reduced risk of delamination, ensuring long-term performance and a lasting, polished look.

Nickel-Plated Brass

Nickel plating is another popular choice for a durable, silver-toned finish. Compared to chrome, nickel has a slightly warmer, yellowish hue. It provides excellent resistance to corrosion and wear, making it a functional alternative to chrome for both industrial and decorative hardware. Nickel-plated brass is often used in plumbing fixtures, hardware, and electronics for its combination of durability and aesthetic appeal.

Step 4: Verifying Dimensions and Threading

After determining load capacity and material, a user must verify the physical dimensions of the hardware. An incorrect thread size or shank length can compromise the integrity of the entire assembly. Proper measurement ensures the brass swivel eye bolt fits the mounting surface securely and functions as intended.

Measuring Thread Size and Type

Threads are the helical ridges on the shank that allow the bolt to screw into a tapped hole or nut. They are defined by a specific standard, diameter, and pitch. Selecting the correct thread type is non-negotiable for a safe and secure installation.

Unified Thread Standard (UNC vs. UNF)

The Unified Thread Standard (UTS) is common in the United States. It includes two primary thread series:

- UNC (Unified National Coarse): UNC threads have deeper, more widely spaced threads. They are easier to assemble without cross-threading and are more tolerant of minor damage. This makes them a common choice for general-purpose applications.

- UNF (Unified National Fine): UNF threads are shallower and more closely spaced. They offer greater tensile strength and finer adjustment capabilities. Their design makes them more resistant to loosening from vibration.

Application Tip: A user should choose UNC for most standard installations. They should select UNF for applications requiring high precision or where the assembly will experience significant vibration.

Metric Thread Standards

The metric system uses a simpler standard defined by the International Organization for Standardization (ISO). Metric threads are identified by their diameter and pitch, both measured in millimeters. For example, an M12 x 1.75 bolt has a 12 mm nominal diameter and a thread pitch of 1.75 mm.

How to Measure Thread Diameter

The thread diameter is the outside dimension of the threads. A user can measure this with a simple tool.

- Obtain a caliper or a precise ruler.

- Place the jaws of the caliper on the outermost edges of the threads.

- Read the measurement. This value is the nominal diameter. For a 1/2″-13 UNC bolt, the measurement will be very close to 0.5 inches.

Using a Thread Pitch Gauge

A thread pitch gauge is a tool used to identify the thread pitch or threads per inch (TPI). It consists of a series of metal leaves, each stamped with a specific thread profile.

- Select a leaf from the gauge that appears to match the bolt’s threads.

- Press the leaf firmly against the threads.

- Hold it up to a light source. If no light passes between the gauge and the threads, the user has found a perfect match. The number stamped on the leaf indicates the TPI (for UTS) or pitch in millimeters (for metric).

Selecting Shank and Eye Dimensions

The shank and eye dimensions are just as critical as the threads. The shank length determines how the bolt engages with the mounting surface, while the eye must be compatible with the connecting hardware.

Choosing Shank Length

The shank length must be sufficient to achieve full thread engagement in the receiving hole. The threaded portion of the eye bolt must pass completely through the load-bearing material.

Installation Rule: For a blind tapped hole, the ideal thread engagement is 1.5 times the bolt’s nominal diameter. For a 1/2″ diameter bolt, this means the shank should engage at least 0.75″ of threads within the material. Insufficient engagement dramatically reduces the bolt’s load-bearing capacity.

Shoulder vs. Plain Pattern Bolts

Swivel eye bolts come in two main patterns, and the choice has significant safety implications.

| Bolt Pattern | Description | Best Use Case |

|---|---|---|

| Shouldered | Features a flange or “shoulder” where the eye meets the shank. This shoulder must sit flush against the mounting surface. | Essential for any lift involving an angle (angular loading). The shoulder provides support and prevents the bolt from bending. |

| Plain (Non-Shouldered) | Lacks a shoulder and has a simple transition from the eye to the threaded shank. | Strictly for vertical, in-line lifts only. This plain pattern eye bolt offers no resistance to bending forces from side loads. |

⚠️ Warning: A user must never apply an angular load to a plain pattern bolt. Doing so can cause the shank to bend or shear, leading to catastrophic failure.

Matching Eye Diameter to Hardware

The internal diameter of the eye must be compatible with the hardware connecting to it, such as a shackle, hook, or rope. The shackle pin or hook must fit freely inside the eye without binding. A tight fit can introduce dangerous side-loading forces and prevent the swivel from functioning correctly. Always check manufacturer specifications to ensure the eye can accommodate the connecting hardware.

Step 5: Understanding Swivel Mechanism Types

The “swivel” feature is not a one-size-fits-all solution. Different mechanisms are engineered for distinct purposes. A user must understand the difference between a swivel designed for positioning and one built to rotate under load. This distinction is fundamental to safe and effective rigging and lifting operations.

Differentiating Swivel Functions

The primary differentiator in swivel mechanisms is their ability to rotate while bearing weight. Choosing the wrong type can lead to equipment damage or failure.

Swivels Designed to Turn Under Load

These advanced swivels are engineered for dynamic lifting. They incorporate internal mechanisms like ball bearings or bushings that allow the eye to rotate smoothly even when under full tension. This function is critical in applications where the load may twist or spin during movement. The swivel absorbs the rotational force, preventing it from transferring to the lifting sling and causing it to bind or weaken.

Positioning-Only Swivels

Many standard swivel eye bolts feature a positioning-only swivel. This type allows a user to rotate the eye to align it with the pull direction before applying the load. Once tension is applied, the friction within the mechanism prevents it from turning.

⚠️ Important: A user should never expect a positioning-only swivel to rotate under load. Attempting to force its rotation can damage the swivel mechanism and compromise the integrity of the eye bolt.

Common Swivel Designs

The hardware’s physical design often indicates its intended function and capacity. Users will encounter several common designs in the field.

Standard Swivel Eye Bolts

This hardware is a significant upgrade from a fixed eye bolt. It allows for initial alignment with the load, reducing stress on the lifting components. These are suitable for many common applications where the primary need is to orient the eye correctly before a straight-line lift.

Swivel Hoist Rings for Heavy-Duty Lifting

Swivel hoist rings represent a more robust and versatile design. They are engineered for mobility and complex angular lifting. The design allows for a 360° swivel, enabling the hardware to move with the load’s pull without losing strength. This makes them superior for angular lifts, as they maintain their working load limits at various angles.

| Application Type | Swivel Hoist Rings Ideal For | Eye Bolts Ideal For |

|---|---|---|

| Lifting Angle | Multiple angles (e.g., machining, fabrication) | Vertical lifting (e.g., removing covers, plates) |

| Load Movement | Loads that shift during the lift (e.g., heavy equipment) | Static lifting points; permanent fixtures |

| Industry Specific | Offshore, aerospace, energy sectors (precision & safety critical) | Maintenance shops, assembly operations (light-duty) |

Ball Bearing vs. Bushing Mechanisms

The internal components determine how smoothly a swivel performs under load.

- Ball Bearing: Mechanisms with ball bearings offer the smoothest rotation with the least amount of friction. They are the premium choice for heavy loads and frequent rotation.

- Bushing: A bushing is a plain sleeve bearing. Swivels with bushings are more economical and provide good performance for moderate loads or less frequent rotational needs.

Step 6: Proper Installation Techniques

Correct installation is as critical as selecting the right hardware. A high-quality brass swivel eye bolt can fail if it is not installed correctly. Understanding how to properly install an eye bolt ensures the creation of strong and secure attachment points, maximizing safety and performance. The process involves careful preparation of the mounting surface and precise installation of the hardware itself.

Preparing the Mounting Surface

A secure installation begins with a properly prepared surface. Each step in this phase is essential for the bolt’s ultimate load-bearing capacity.

Drilling the Correct Pilot Hole

The first step is to drill a pilot hole. The hole’s diameter must match the tap drill size specified for the bolt’s threads, not the bolt’s nominal diameter.

- Consult a tap drill chart to find the correct drill bit size for your bolt’s thread specification (e.g., 1/2″-13 UNC).

- Ensure the drill is held perpendicular to the mounting surface.

- Drill the hole to a depth that allows for full thread engagement.

Tapping Threads for a Secure Fit

After drilling, a user must cut threads into the hole using a tap. This process creates the internal threads that the eye bolt will screw into. The user should apply a suitable cutting fluid to the tap. This lubricates the process and helps produce clean, precise threads. The tap must remain perpendicular to the surface to prevent misaligned threads.

Ensuring a Clean and Flat Surface

The mounting surface must be completely flat and free of debris. Any dirt, burrs, or unevenness will prevent the bolt’s shoulder from seating flush. This gap can introduce dangerous bending forces and significantly reduce the hardware’s capacity. A user should clean the hole and the surrounding surface thoroughly before installation.

Installing the Brass Swivel Eye Bolt

With the surface prepared, the user can now install the hardware. Proper technique is vital for achieving the bolt’s rated strength.

Achieving Full Thread Engagement

The shank must be screwed in far enough to engage the threads fully. A general rule is that the thread engagement length should be at least 1.5 times the bolt’s nominal diameter. Insufficient engagement is a primary cause of thread stripping and pull-out failures under load.

Firmly Seating the Shoulder

For shouldered bolts, the shoulder must be seated firmly and flush against the mounting surface. There should be no gap between the shoulder and the surface.

Installation Alert ⚠️ A gap under the shoulder compromises the bolt’s ability to handle angular loads. The user must tighten the bolt until the shoulder makes full, even contact with the mounting surface.

Correct Torque Application

Applying the correct amount of torque is the final step. Over-tightening can stretch the bolt and cause permanent damage, while under-tightening can allow it to loosen under vibration. Manufacturers often provide recommended torque values for their hardware.

| Bolt Size | Recommended Torque (Dry, Steel) |

|---|---|

| 1/4″-20 | 6-8 ft-lbs |

| 3/8″-16 | 18-22 ft-lbs |

| 1/2″-13 | 45-55 ft-lbs |

A user should always consult the manufacturer’s specific guidelines, as values can vary based on the brass alloy and lubrication.

Step 7: Safety, Inspection, and Maintenance

Ongoing safety practices are crucial after selecting and installing the correct hardware. A user must understand loading rules, perform routine checks, and know when to retire an eye bolt. This diligence preserves the integrity of the lifting assembly and protects both personnel and property.

Angular Loading Rules

Applying a load at an angle introduces complex forces that can compromise an eye bolt’s strength. Understanding these dynamics is critical for safe lifting.

Load Reduction at an Angle

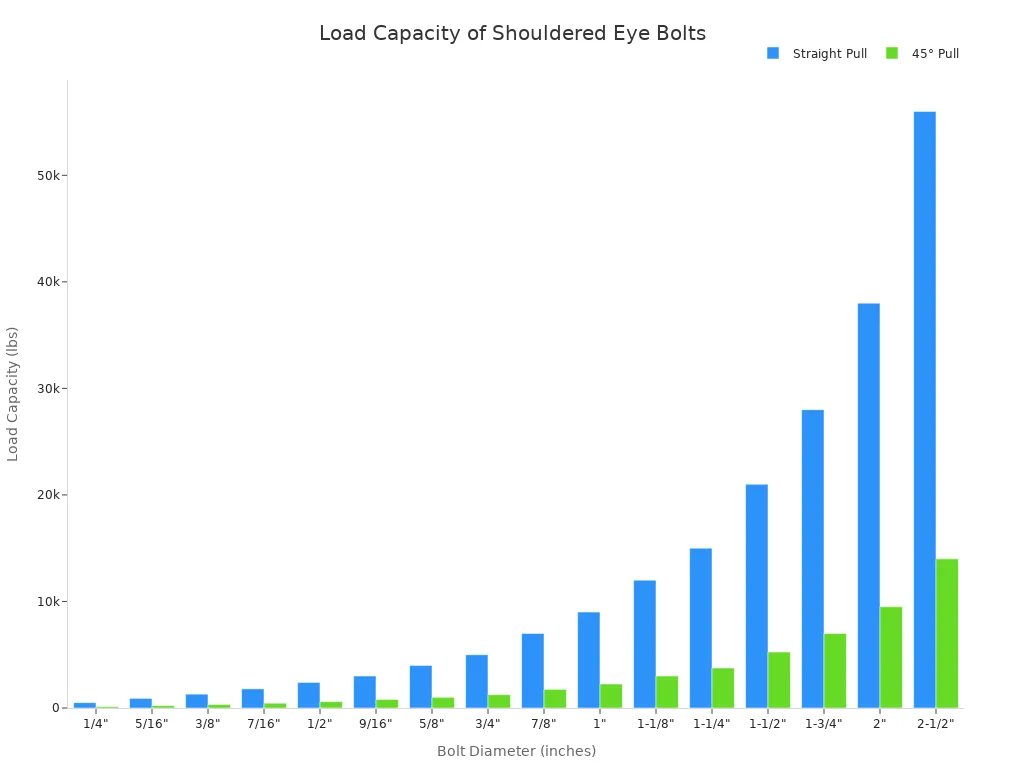

When a load is pulled at an angle, the force on the eye bolt increases significantly. This action creates both tension and bending stress, which dramatically reduces its effective Working Load Limit (WLL). A pull at a 45-degree angle can reduce the bolt’s capacity to just 30% of its vertical rating. A 90-degree pull (a pure side load) reduces it even further to 25%.

Angular Load Capacity Reduction The following chart illustrates how a 45-degree pull drastically lowers the WLL for standard shouldered eye bolts.

Why Shouldered Bolts are Essential

A shouldered eye bolt is mandatory for any angular lift. The shoulder sits flush against the mounting surface, transferring the bending force into the surface material. This design prevents the shank from bending or shearing under side load. A non-shouldered bolt lacks this support and is only safe for perfectly vertical, in-line lifts.

Routine Inspection Checklist

Regular inspection is a key part of any safety program. The ASME B30.26 standard provides clear criteria for removing rigging hardware from service. A user should perform these checks before each use.

Checking for Wear and Deformation

A user must visually inspect the hardware for any signs of physical damage. Key indicators for removal include:

- Bent, twisted, or stretched components.

- Excessive nicks, gouges, or cracks.

- Any reduction in dimension greater than 10% from the original specification.

- Damaged or worn threads that could compromise engagement.

Identifying Signs of Corrosion

While brass is corrosion-resistant, it is not immune. A user should look for excessive pitting or discoloration. The presence of dezincification (a pinkish hue on the brass) in marine environments indicates the alloy is weakening and must be replaced.

Testing the Swivel Action

The swivel mechanism must rotate freely before a load is applied. For load-bearing swivels, a user should check for smooth rotation. Any binding, grinding, or lack of free movement indicates internal damage or contamination. According to ASME B30.26, a swivel that cannot rotate freely is unsafe for use.

Maintenance and Retirement

Proper care extends the life of hardware, but every component has a finite lifespan. Knowing when to perform maintenance and when to retire an eye bolt is crucial for safety.

Cleaning and Lubricating the Swivel

A user should periodically clean the hardware to remove dirt and grime that could interfere with the swivel. For swivels with bushings or bearings, applying a manufacturer-recommended lubricant ensures smooth operation and prevents premature wear.

When to Retire an Eye Bolt

An eye bolt must be immediately removed from service if it fails any part of the inspection checklist. This includes missing or illegible WLL markings, signs of heat damage like weld spatter, or any unauthorized modifications. When in doubt, a user should always err on the side of caution and replace the hardware.

Common Mistakes to Avoid When Choosing Swivel Eye Bolts

Even with the correct hardware, simple errors in application can lead to significant failures. Users can enhance safety and project success by understanding and avoiding a few common mistakes. These errors often involve improper loading, misapplication of hardware, and overlooking environmental conditions.

Sideloading a Plain (Non-Shouldered) Eye Bolt

One of the most critical errors in rigging and lifting is applying a side load to a plain, non-shouldered eye bolt. This type of hardware is designed exclusively for in-line, vertical tension.

How Sideloading Causes Failure

Plain pattern eye bolts lack a reinforced shoulder and are highly susceptible to bending under any angular load. When a user applies force at an angle, it introduces powerful bending stresses that the shank is not designed to withstand. This misuse can cause the shank to distort, strip its threads, or fracture completely. The capacity of a standard eye bolt can drop to just 30% of its vertical rating when pulled at a 45-degree angle. To prevent this catastrophic failure, users must never apply a side load to a non-shouldered bolt.

Using Decorative Hardware for Lifting

Another frequent mistake is using decorative hardware for load-bearing tasks. Hardware sold for aesthetic purposes does not undergo the same rigorous testing as rated lifting components.

Rated vs. Unrated Hardware

Rated hardware is manufactured and tested to meet specific performance standards. It is clearly marked with its Working Load Limit (WLL) and other identifiers. Unrated hardware, often found in general hardware stores, has no guaranteed strength.

Safety First ⚠️ Using an unrated, decorative brass swivel eye bolt for any lifting task is extremely dangerous. It may look identical to a rated component, but it lacks the material strength and engineering to handle a load safely.

The Importance of Traceability

Traceability marks are essential for safety and legal compliance in commercial settings. These permanent marks link the hardware to its certification and inspection history.

- Each piece of verified equipment must be marked with its WLL and a unique identification number.

- If a primary tag is lost, a direct mark on the equipment allows for the recovery of its documentation.

- Any hardware with illegible markings must be removed from service immediately.

Ignoring Environmental Factors

The environment where the hardware will be used plays a crucial role in its long-term performance. Ignoring factors like moisture, chemicals, and temperature can lead to premature failure.

Understanding Galvanic Corrosion

Galvanic corrosion occurs when two different metals are in contact in the presence of an electrolyte, like moisture. The less noble metal corrodes at an accelerated rate. For instance, if a brass eye bolt is installed into an aluminum or steel structure in a wet environment, the aluminum or steel will corrode. Even water runoff from a brass surface can carry enough dissolved copper to accelerate the corrosion of less noble metals like zinc on galvanized steel.

Impact of Chemicals and Temperature

Exposure to harsh chemicals can degrade brass alloys, leading to a loss of strength. Similarly, extreme temperatures can affect the material’s properties. High heat can anneal (soften) the brass, while extreme cold can make it more brittle. Users must always consult manufacturer specifications to ensure their chosen swivel eye bolts are suitable for the specific chemical and thermal conditions of their common applications.

A user ensures project safety by choosing the correct brass swivel eye bolt. This final checklist helps guide the selection process for any application.

- Verify the Working Load Limit (WLL) and apply a suitable safety factor.

- Select a brass alloy and finish appropriate for the specific environment.

- Confirm the thread type, size, and shank length match the mounting surface.

- Choose the correct swivel mechanism (load-bearing vs. positioning).

- Prioritize safety by following manufacturer guidelines for the eye bolt.

FAQ

Can a user lift people with a brass swivel eye bolt?

No. A user must never use standard rigging hardware to lift people. Equipment for lifting personnel requires a higher safety factor, typically 10:1, and must meet specific OSHA or other regional safety standards. Always use hardware explicitly designed and certified for lifting personnel.

What happens if a user sideloads a non-shouldered eye bolt?

Applying a side load to a non-shouldered eye bolt creates intense bending forces. This action can cause the shank to bend or fracture, leading to catastrophic failure. A user must only use shouldered eye bolts for any lift that is not perfectly vertical.

How can a user identify a rated eye bolt?

A user can identify rated hardware by its markings. Reputable manufacturers stamp the Working Load Limit (WLL), their company logo, and the material grade directly onto the bolt. Unmarked hardware is considered unrated and unsafe for any lifting application.

Why does a brass eye bolt turn pink?

A pinkish hue on brass indicates dezincification. This corrosive process occurs when zinc leaches out of the alloy, typically in marine environments. It severely weakens the material. A user must immediately retire any hardware showing signs of dezincification.

Can a user weld or modify a brass swivel eye bolt?

No. A user must never weld, grind, or otherwise modify a rated eye bolt.

Warning ⚠️ Heat from welding can anneal the brass, permanently reducing its strength. Any modification voids the manufacturer’s WLL rating and makes the hardware unsafe for use.

How often should a user inspect their eye bolts?

A user should perform a visual inspection before each use. A qualified person must conduct a thorough, documented inspection periodically. The frequency depends on the application’s severity, with ASME standards recommending at least an annual inspection for normal service.

What is the main difference between UNC and UNF threads?

UNC (Unified National Coarse) threads are deeper and more common for general use. UNF (Unified National Fine) threads are shallower and closer together. UNF threads provide greater strength and better resistance to loosening from vibration, making them suitable for precision applications.