Professionals often discuss wedge anchors and expansion bolts as separate items. A wedge anchor is actually a specific, high-performance type of expansion fastener. The key difference between these anchors lies in their mechanical design. This design dictates how they generate holding power in concrete. A custom fasteners manufacturer often produces a wide range of Anchor Bolts, including custom anchor bolts for specialized jobs. Choosing the correct fastener is paramount for structural safety.

The International Fastener Institute reports that improper selection or installation is responsible for nearly 95% of all fastener failures. This highlights the critical need for correct project assessment.

What is an Expansion Bolt? A Family of Fasteners

An expansion bolt is a general term for a fastener that secures itself inside a base material through mechanical expansion. These anchors are inserted into a pre-drilled hole. A specific action, like tightening a nut or driving a pin, then forces parts of the anchor to move and expand. This outward force presses firmly against the interior walls of the hole, creating a secure connection.

The Core Principle: Mechanical Expansion

The holding power of an expansion bolt comes from a simple yet powerful physical concept. The fastener consists of multiple parts that move independently. This internal movement is the key to its function.

How Outward Force Creates a Secure Hold

The process begins by drilling a precise hole in the concrete. An anchor is then inserted. The final step involves activating the expansion mechanism. For a torque-controlled wedge-type expansion anchor, this means tightening the nut. As the nut is torqued, it pulls a tapered cone-shaped plug up through an expansion clip or sleeve. This action forces the clip to expand outward, pressing hard against the surrounding concrete. This immense outward pressure is what locks the anchor in place, preventing it from pulling out.

The Role of Friction and Keying

The security of the connection relies on two primary forces: friction and keying.

- Friction: The outward pressure from the expansion generates a massive amount of friction between the anchor and the wall of the hole. This is the main source of the anchor’s resistance to pull-out (tensile) forces.

- Keying: As the anchor expands, it also bites into the small imperfections and pores of the concrete surface inside the hole. This mechanical interlock, known as keying, provides additional resistance, especially against shear (side-to-side) forces.

Common Types of Expansion Bolts

The “expansion bolt” family includes several distinct designs, each engineered for specific loads and base materials. Understanding the most common types helps professionals select the correct fastener for the job.

Wedge Anchors

Considered the workhorse for heavy-duty structural connections in solid concrete, wedge anchors provide exceptional tensile and shear strength. Their design creates a powerful wedging action, making them reliable for securing items like steel columns, heavy machinery, and support beams.

Sleeve Anchors

These versatile anchors are suitable for medium-duty applications in a variety of base materials, including solid concrete, brick, and concrete block. Sleeve anchors use a full-length expanding sleeve, which provides a large contact area, making them a good choice for materials that might be more brittle than solid concrete.

Drop-In Anchors

A drop-in anchor is a female-threaded anchor designed to sit flush with the concrete surface. After being placed in the hole, a special setting tool is used to drive an internal plug downward, which flares the anchor body. They are ideal for overhead applications, such as suspending threaded rods for pipes and cable trays.

Strike Anchors

Also called hammer-set anchors, these are designed for fast, simple installation in light-duty static applications. The anchor is placed in the hole, and a sharp strike with a hammer on the internal pin forces the body to expand. They are often used for attaching wood furring strips or electrical boxes.

A Deep Dive into Wedge Anchors

The wedge-type anchor stands out in the expansion fastener family for its specialized design and immense strength. It is the go-to choice for professionals tackling heavy-duty structural fastening into solid concrete. Understanding its mechanics reveals why it delivers such reliable performance.

Anatomy and Mechanism

The design of a wedge-type expansion anchor is simple yet highly effective. Its body is typically made from carbon steel or stainless steel for durability. Key components work in concert to create a powerful hold.

The Threaded Stud and Tapered Cone

The main body consists of a long threaded stud with a tapered cone, or mandrel, at the bottom. The threaded section extends out of the hole, allowing a nut and washer to be attached for securing a fixture. The tapered cone is the critical element that initiates the expansion process.

The Role of the Expansion Clip

A movable expansion clip wraps around the tapered cone. This clip is engineered with features like dual undercutting embossments. These features allow it to bite into the walls of the concrete hole, creating the primary grip. The clip is the part that does the heavy lifting, transferring the load from the anchor to the base material.

How Torque Creates the Wedging Action

Installation activates the powerful wedging action. An installer tightens the nut on the threaded stud. This action pulls the stud and its tapered cone upward into the stationary expansion clip. The cone’s tapered shape forces the clip to expand outward, pressing it firmly against the interior walls of the hole. This immense pressure generates the friction and keying needed to secure the anchor.

Primary Use Cases and Strengths

These anchors excel in applications where failure is not an option. Their design provides the highest holding power among common expansion anchors.

Heavy-Duty Structural Connections

Professionals use wedge anchors for the most demanding jobs. Common applications include:

- Securing structural steel columns and beams

- Mounting heavy industrial machinery and equipment

- Installing pallet racking, shelving, and safety guardrails

- Fastening concrete stairs and walkways

Unmatched Tensile and Shear Strength

The anchor’s wedging mechanism provides exceptional resistance to both pull-out (tensile) and side-to-side (shear) forces. This robust performance makes it a trusted component in critical structural assemblies.

Reliability in Cracked and Uncracked Concrete

Modern wedge anchors are engineered and tested for use in both uncracked and cracked concrete. This makes them suitable for areas subject to tension and flexing, ensuring a secure connection even if the base material develops hairline fractures over time.

Limitations and Considerations

Despite their strength, these anchors have specific limitations that require careful planning.

Permanent and Not Removable

Once installed correctly, a wedge anchor is permanent. The powerful expansion makes it nearly impossible to remove without damaging the surrounding concrete. This makes them unsuitable for temporary fixtures.

Strict Spacing and Edge Distance Rules

Critical Safety Note: Inadequate edge distance is a primary cause of anchor failure. Placing anchors too close to an edge or to each other can cause the concrete to crack or break out, severely compromising holding capacity.

Unsuitable for Brick or Hollow Block

The intense, focused pressure from the expansion clip can easily crack or destroy softer or hollow base materials like brick or concrete masonry units (CMU). These materials lack the solid mass required to withstand the anchor’s wedging force.

Exploring Other Expansion Bolts: The Sleeve Anchor

While wedge anchors dominate heavy-duty applications, sleeve anchors offer remarkable versatility for a different class of projects. These fasteners provide reliable holding power for medium-duty tasks across a wider range of base materials. Their unique design distributes pressure differently, making them a valuable tool in a professional’s toolkit.

Anatomy and Mechanism

The sleeve anchor’s effectiveness comes from its multi-part assembly. Each component plays a distinct role in creating a secure connection. The full-sleeve expansion mechanism is what sets these anchors apart.

The Bolt, Nut, and Expanding Sleeve

A sleeve anchor consists of four primary parts that work together during installation. The head style is chosen for aesthetics and does not alter the anchor’s strength.

| Part | Function |

|---|---|

| Threaded Stud | A bolt that, when tightened, pulls up a cone to initiate expansion. |

| Metal Sleeve | A cylindrical sleeve that runs the length of the anchor and expands outward. |

| Washer | Distributes the load from the nut across the fixture’s surface. |

| Nut | Tightens onto the stud to activate the expansion and secure the fixture. |

How the Sleeve Expands Along the Hole

Installation involves a straightforward process. An installer places the anchor into a pre-drilled hole. Tightening the nut pulls the threaded stud’s flared end up into the metal sleeve. This action forces the entire sleeve to expand outward along its full length. The sleeve presses against the interior of the hole, creating friction that secures the anchor. This full-length contact is key to its performance in various materials.

Common Head Styles: Flat, Round, and Hex

Sleeve anchors are available with several head styles to suit different needs. A hex head is standard for easy tightening with a wrench. A flat head allows for a flush finish on the masonry or concrete surface. A round head provides a finished, low-profile appearance.

Primary Use Cases and Strengths

The design of sleeve anchors makes them ideal for situations where extreme load capacity is not the primary requirement. Their strengths lie in their adaptability and ease of use.

Medium-Duty Fastening Applications

These anchors excel at securing moderately heavy items. Installers frequently use them for a variety of common tasks.

- Attaching handrails and guardrails

- Mounting window frames and door frames

- Securing shelving units and brackets

- Fastening electrical junction boxes and signage

Versatility in Concrete, Brick, and Block

A primary advantage of the sleeve anchor is its compatibility with multiple base materials. The long expansion sleeve distributes pressure over a larger area. This reduces the risk of cracking softer materials like brick or hollow concrete block, where a wedge anchor would fail.

Removability and Adjustability

Unlike permanent wedge anchors, sleeve anchors can be removed. An installer can loosen the nut and tap the bolt to release the expansion pressure, allowing the anchor to be extracted. This feature makes them perfect for temporary installations or situations where adjustments may be needed.

Limitations and Considerations

Professionals must also recognize the performance limits of these fasteners to ensure project safety.

Lower Load Capacity vs. Wedge Anchors

Sleeve anchors possess significantly lower tensile and shear strength compared to wedge anchors. Their holding power is suitable for medium-duty loads only. They do not provide the robust security needed for heavy equipment or structural elements.

Not for Critical Structural Loads

⚠️ Professional Advisory: Never use sleeve anchors for life-safety or critical structural applications. This includes securing support columns, heavy machinery, or overhead beams. Such tasks demand the superior strength of a wedge anchor or an adhesive anchor system.

Less Reliable in Cracked Concrete

The holding mechanism of a standard sleeve anchor is less effective in concrete that has developed cracks. The expansion force may not be sufficient to achieve a reliable grip, making them a poor choice for dynamic load environments or areas prone to cracking.

Head-to-Head Comparison: Wedge Anchor vs. Sleeve Anchor

An installer’s choice between a wedge anchor and a sleeve anchor directly impacts a project’s safety and longevity. This head-to-head performance comparison clarifies which fastener excels in specific scenarios. The decision hinges on three factors: load capacity, base material, and project logistics.

Load Capacity and Performance

The fundamental difference between these anchors lies in their holding power. A wedge-type expansion anchor is engineered for maximum strength, while a sleeve anchor provides moderate strength with greater versatility.

Tensile Strength (Pull-Out)

Tensile strength measures an anchor’s resistance to being pulled straight out of the hole.

- Wedge Anchors: These offer the highest tensile strength among mechanical expansion anchors. The focused wedging action creates immense friction and keying, providing a powerful grip in solid concrete. This makes them the only suitable choice for resisting heavy pull-out forces, such as those from tall racking or structural columns.

- Sleeve Anchors: These provide good, but significantly lower, tensile strength. The expansion force is distributed along the entire sleeve, resulting in less concentrated pressure. This is sufficient for medium-duty applications like handrails but inadequate for critical structural loads.

Shear Strength (Side Force)

Shear strength refers to an anchor’s ability to resist side-to-side forces.

- Wedge Anchors: The solid steel stud of a wedge anchor provides exceptional shear strength. The tight, secure fit within the concrete prevents movement, making it ideal for applications subject to lateral forces, like machinery vibration or seismic activity.

- Sleeve Anchors: These also have respectable shear strength, suitable for many medium-duty tasks. However, the multi-part nature of the anchor and the thinner sleeve material result in lower overall shear capacity compared to the solid-body wedge anchor.

Performance in Cracked vs. Uncracked Concrete

Concrete can develop hairline cracks due to tension, shrinkage, or flexing. This condition significantly affects anchor performance.

- Wedge Anchors: Modern wedge anchors are specifically designed and code-listed for reliable performance in both cracked and uncracked concrete. However, the presence of cracks can reduce the ultimate load capacity. Building codes like ACI 318 often assume cracked concrete as the standard for design to ensure safety.

- Sleeve Anchors: Standard sleeve anchors are generally not recommended for cracked concrete. The expansion mechanism is less effective in a cracked base material, which can lead to a loss of holding power and potential failure. They perform best in solid, uncracked concrete or other masonry.

Design Note: Manufacturer data sheets provide load values for anchors. These ultimate loads must be reduced by a safety factor of at least 4.0 to determine the allowable working load for a safe installation.

Base Material Suitability

The type of masonry is a critical factor in anchor selection. The intense force of a wedge anchor is not suitable for all materials.

Solid Poured Concrete

- Wedge Anchors: This is the ideal base material for wedge anchors. Their design is optimized for the density and compressive strength of solid concrete, allowing them to achieve their maximum load capacity.

- Sleeve Anchors: These also work very well in solid concrete for medium-duty jobs.

Concrete Masonry Units (CMU/Block)

- Wedge Anchors: These are unsuitable for hollow or even grout-filled CMU. The high expansion pressure can easily crack the face shell or cause a blowout failure.

- Sleeve Anchors: This is where sleeve anchors shine. Their long sleeve can expand against the back of a hollow block’s face shell, providing a secure hold. They are a go-to fastener for anchoring into CMU walls.

Brick and Other Masonry

- Wedge Anchors: Do not use wedge anchors in brick. The material is too brittle and will crack under the anchor’s focused pressure.

- Sleeve Anchors: These are an excellent choice for brick and other solid masonry materials. The distributed pressure of the sleeve is less likely to damage the base material, providing a reliable medium-duty connection.

Cost, Versatility, and Availability

Practical considerations like budget and accessibility also influence the final choice.

Per-Unit Cost Comparison

Generally, sleeve anchors are more cost-effective than wedge anchors, especially when comparing standard zinc-plated versions. However, costs can overlap depending on the material and coating.

| Anchor Type (1/2″ Diameter Example) | Typical Per-Unit Cost |

|---|---|

| Zinc Plated Sleeve Anchor | ~$1.00 – $1.50 |

| Zinc Plated Wedge Anchor | ~$1.00 – $2.00 |

| Stainless Steel Sleeve Anchor | ~$2.00 – $3.00 |

| Stainless Steel Wedge Anchor | ~$1.65 – $9.00+ |

Prices for stainless steel anchors vary widely based on the grade (e.g., 304 vs. 316), with the higher grade offering superior corrosion resistance at a premium cost.

Range of Applications

- Wedge Anchors: The application range is narrow but deep. They are specialists, used almost exclusively for heavy-duty fastening in solid concrete.

- Sleeve Anchors: These are generalists. Their versatility across concrete, block, and brick gives them a much broader range of medium-duty applications, from residential to commercial projects.

General Availability

Both anchor types are widely available at hardware stores, home improvement centers, and industrial supply distributors. Wedge anchors are a staple for any professional concrete contractor, while sleeve anchors are a common stock item for general construction and maintenance work.

Critical Installation Factors for All Expansion Anchors

Even the highest-quality anchor will fail if installed improperly. The performance of all expansion anchors depends on meticulous installation. Following manufacturer specifications for hole preparation, torque, and placement is not just a recommendation; it is a requirement for safety and structural integrity.

Hole Preparation

A properly prepared hole is the foundation of a secure anchor point. The diameter, depth, and cleanliness of the hole directly influence the anchor’s ability to function as designed.

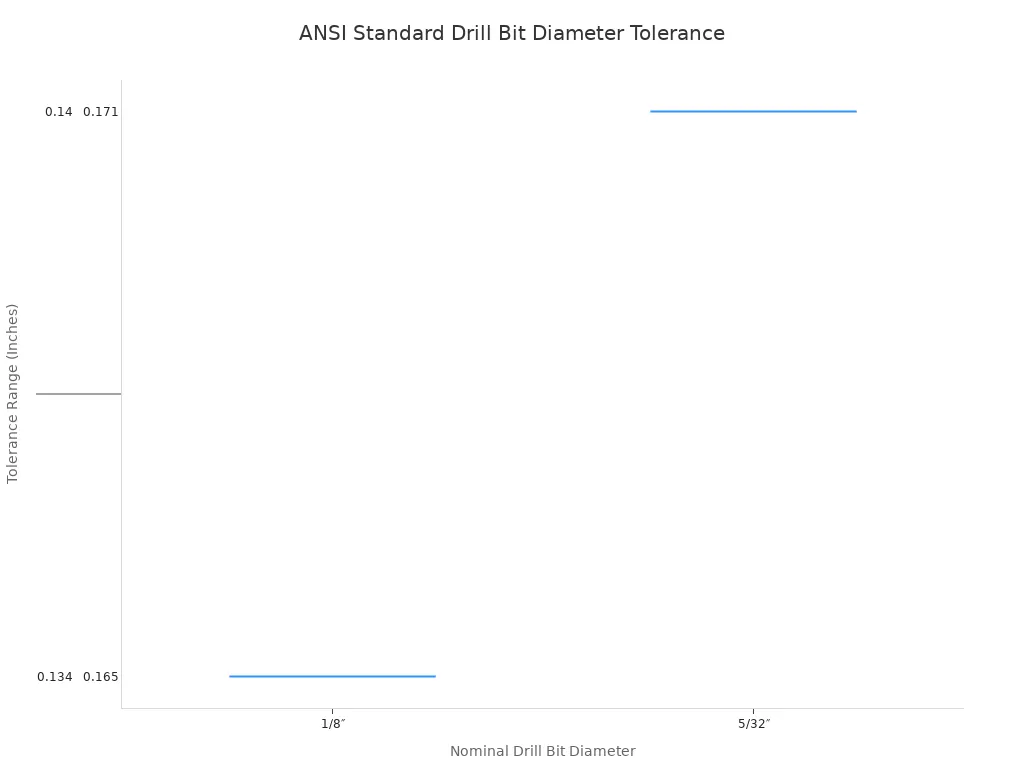

Choosing the Correct Drill Bit Diameter

An installer must use a carbide-tipped drill bit that matches the anchor’s specified diameter. A hole that is too small will prevent the anchor from being inserted, while a hole that is too large will prevent the expansion mechanism from engaging the concrete properly. ANSI standards define strict tolerance ranges for drill bits to ensure a correct fit.

Achieving the Proper Embedment Depth

Embedment depth is the distance the anchor is installed into the base material. Deeper embedment generally provides greater holding power. Installers must drill the hole to the minimum depth specified by the manufacturer to ensure the anchor’s expansion mechanism engages a sufficient mass of concrete.

The Importance of Cleaning Debris

Drilling creates a significant amount of dust and debris. The BS:8539 Code of Practice mandates the removal of this debris. Residual dust prevents the anchor from reaching its full embedment depth. It can also cause smaller anchors to bind and snap before they are fully seated. Installers must clean the hole thoroughly with compressed air, a wire brush, or a vacuum to ensure the anchor makes solid contact with the concrete.

Torque Control

Applying the correct amount of rotational force, or torque, is essential for activating the anchor’s holding power. This step creates the clamping force that secures the fixture.

Why Torque Specifications Matter

Manufacturers provide specific torque values for each anchor size. These values are determined through extensive testing to ensure the anchor achieves its designed load capacity without being damaged. Adhering to these specifications is the only way to replicate the tested performance and guarantee a safe connection.

Risks of Under-Torquing and Over-Torquing

Both under-torquing and over-torquing create significant risks.

- Under-torquing: Fails to fully engage the expansion mechanism, resulting in inadequate holding power and a loose fixture.

- Over-torquing: Can damage the anchor by stripping threads or snapping the bolt. It can also over-stress the concrete, leading to failure.

Using a Calibrated Torque Wrench

A calibrated torque wrench is the only tool that can reliably apply the specified torque. Manual tightening is inaccurate and risky. Using a calibrated wrench is a critical step for compliance with building codes and ensures the product warranty remains valid. It provides tangible proof of a correct and safe installation.

Spacing and Edge Distance

The location of an anchor relative to edges and other anchors is as important as the installation itself. Improper placement can cause the concrete to fail, not the anchor.

Defining Edge Distance and Spacing

- Edge Distance: The distance from the center of the anchor to the nearest unsupported edge of the concrete.

- Spacing: The distance between the centers of two or more anchors.

Why These Distances are Critical for Strength

When an anchor is loaded, it creates a cone-shaped zone of stress in the concrete. If these stress cones overlap (due to improper spacing) or are cut off by an edge (due to inadequate edge distance), the anchor’s holding capacity is severely reduced. Manufacturers provide minimum distances to prevent this stress interference.

Consequences of Improper Placement

Placing anchors too close to an edge or to each other can cause a “blowout” failure, where a chunk of concrete breaks away. For a typical 3/8-inch wedge anchor, installers should maintain a minimum edge distance of 1-7/8 inches and a minimum spacing of 3-3/4 inches. Ignoring these rules weakens the concrete and dramatically increases the risk of failure, especially under dynamic loads or vibration.

How to Select the Right Anchor for Your Project

Selecting the correct concrete anchors involves a systematic evaluation of the project’s specific demands. A professional installer analyzes load requirements, the base material, and the surrounding environment. This three-step process ensures the chosen fastener provides safe, long-term performance.

Step 1: Assess the Load Requirements

The first step is to quantify the forces the anchor must resist. This assessment distinguishes between the weight of the object and the types of forces it will exert.

Heavy-Duty vs. Medium-Duty Loads

Load requirements are often defined by building codes. An installer must determine if the application is heavy-duty or medium-duty. For example, the New York City Building Code provides clear definitions for scaffold loads, which offer a useful reference point.

| Load Requirement | Definition (New York City Building Code 2022) |

|---|---|

| Heavy-Duty Scaffold | Uniformly distributed load not to exceed 75 pounds per square foot (psf) |

| Medium-Duty Scaffold | Uniformly distributed load not to exceed 50 psf |

Understanding Static vs. Dynamic Forces

Installers must also identify the type of force. Mechanical expansion anchors are primarily designed for static loads. A static load is a constant, non-moving force, like a mounted cabinet. Dynamic loads involve movement and variations in force, such as from vibrating machinery. These changing stresses require complex calculations and are generally not suitable for standard mechanical anchors.

Consulting Manufacturer Technical Data

After assessing the load, an installer must consult the anchor manufacturer’s technical data sheets. These documents provide the ultimate load capacities for specific anchor sizes and embedment depths. Professionals apply a safety factor to these values to determine the final allowable working load.

Step 2: Identify the Base Material

The composition and condition of the masonry material dictate which anchors are appropriate. The intense forces from some fasteners can damage brittle or hollow materials.

Solid Concrete vs. Hollow or Grout-Filled Block

Solid poured concrete provides the ideal substrate for high-strength wedge anchors. Hollow or grout-filled block, however, lacks the mass to resist the focused pressure of a wedge anchor. For these materials, a sleeve anchor is a better choice because it distributes pressure over a larger surface area.

Assessing Concrete Age and Condition

The strength of concrete is a critical variable. It gains compressive strength as it cures over time. This change affects the tensile splitting strength, which is crucial for anchor holding power. Machine learning models confirm that concrete strength and embedment depth are the most sensitive factors affecting the breakout strength of anchors under tension.

Step 3: Evaluate Environmental Conditions

The anchor’s location determines its exposure to moisture and corrosive elements. Choosing the right material and coating is essential for durability.

Interior vs. Exterior Use

Anchors used in dry, interior environments can often be standard zinc-plated carbon steel. Exterior applications or damp interior locations demand superior corrosion resistance to prevent premature failure.

Choosing the Right Coating for Corrosion Resistance

For exterior use, installers select anchors with specialized protective coatings.

- Hot-Dip Galvanizing (ASTM F2329): This process creates a thick, durable zinc coating that is metallurgically bonded to the steel. It offers excellent, long-term protection in harsh environments.

- Mechanical Galvanizing: This method applies a uniform zinc coating without high heat, making it ideal for high-strength fasteners where hydrogen embrittlement is a concern.

Quick Decision Guide: Which Anchor to Choose

Making the right choice between anchor types is straightforward when an installer matches the fastener’s strengths to the project’s demands. This guide simplifies the decision-making process for common applications.

Choose a Wedge Anchor If…

Securing heavy structural loads like beams or columns.

Professionals should select wedge anchors for critical structural connections. These fasteners are essential in structural engineering for creating secure connections and reinforcing concrete structures with exceptional strength. In large commercial building projects, for example, engineers use high-strength anchors to secure steel columns that support multiple floors, ensuring the stability of the entire building.

You require the maximum possible holding strength.

The design of these anchors delivers the highest possible tensile and shear strength among mechanical expansion fasteners. Their powerful wedging action creates an unparalleled grip inside solid concrete, making them the default choice for applications where failure is not an option.

You are anchoring into solid, uncracked or cracked concrete.

These fasteners are engineered specifically for use in solid concrete. They provide reliable performance in both uncracked and cracked conditions, a critical feature for ensuring safety in structures that may experience tension and flexing over time.

The fastener will be permanent.

Installation Note: Once a wedge anchor is properly set, its powerful expansion makes it a permanent part of the structure. It cannot be removed without significantly damaging the surrounding base material.

Choose a Sleeve Anchor If…

Fastening medium-duty items like handrails or brackets.

Sleeve anchors are the ideal solution for a wide range of medium-duty jobs in both residential and commercial settings. Common applications include:

- Securing handrails and stair guards to landings.

- Attaching shelving and storage racks to garage block walls.

- Mounting utility items like electrical conduit straps and junction boxes.

- Fastening light machinery or HVAC units.

You are anchoring into concrete block or brick.

A key advantage of these anchors is their effectiveness in various masonry materials. Their design expands over a larger surface area, providing consistent holding values in both hollow and solid brick. This makes them a reliable choice for materials where a focused expansion force would cause damage.

The ability to remove the fastener is important.

Installers can easily remove these fasteners if needed. Loosening the nut releases the expansion pressure, allowing the anchor to be extracted from the hole. This feature makes them perfect for temporary fixtures or applications that may require future adjustments.

Cost-effectiveness for a non-structural job is key.

For many non-structural projects, sleeve anchors offer a reliable and budget-friendly fastening solution. They provide sufficient holding power for numerous applications without the higher cost associated with heavy-duty structural anchors.

Professionals select wedge anchors as the specialized, top-tier choice for heavy-duty structural fastening in solid concrete. In contrast, sleeve anchors and other expansion fasteners offer versatility for medium-duty tasks across a wider range of masonry materials. The final decision between these expansion anchors must always be based on a careful evaluation of load and base material. As improper selection of sleeve anchors can lead to failure, consulting an engineer or manufacturer data is critical to prevent concrete breakout or anchor slippage.

FAQ

Can an installer reuse a wedge anchor?

No. A correctly installed wedge anchor is permanent. The expansion process makes removal impossible without damaging the anchor and the surrounding concrete. An installer must always use a new anchor for a new connection.

What happens if an installer uses the wrong size drill bit?

Using the wrong drill bit leads to failure.

- Too large: The anchor’s clip cannot engage the concrete, resulting in no holding power.

- Too small: The anchor cannot be inserted into the hole. Installers must always use the ANSI-standard bit size specified by the manufacturer.

Why is cleaning the hole so important?

Drilling debris prevents the anchor from reaching its full embedment depth. This reduces the anchor’s contact with the base material, which severely compromises its load capacity and creates a significant safety hazard.

Can an installer use an impact wrench to tighten anchors?

⚠️ Warning: Never use an impact wrench for installation. It delivers uncontrolled torque, which can easily snap the anchor or strip its threads. A calibrated torque wrench is the only professional tool for applying the correct, specified torque.

Are wedge anchors suitable for fastening into asphalt?

No. Asphalt is a soft, flexible material that lacks the compressive strength of concrete. The expansion force from a wedge anchor will cause the asphalt to crumble, leading to immediate connection failure.

What is the best anchor for overhead applications?

For overhead tasks like suspending threaded rod, a drop-in anchor is often the best choice. These female-threaded concrete anchors sit flush with the surface, providing a secure and clean finish for ceiling installations.