An Eye Bolt is a fastener featuring a threaded shank and a looped head. Its primary function is to create a secure anchor point. The industrial fastener market, which includes these components, is significant, with projections showing growth from USD 113.2 billion in 2024 to USD 186.2 billion by 2034. The proper use of eye bolts in construction is a matter of critical safety.

A staggering 83% of crane-related incidents stem directly from preventable rigging errors, which underscores the need for dependable hardware like eye bolts.

A custom fasteners manufacturer can use bolt casting to produce custom fasteners, ensuring these eye bolts meet the unique demands of any construction project.

Understanding the Main Types of Eye Bolts

Selecting the correct type of eye bolt is not a matter of preference; it is a fundamental requirement for operational safety and efficiency. Different designs serve distinct purposes, and understanding their capabilities is the first step in proper rigging. Each type possesses unique characteristics tailored for specific load conditions and applications.

Shouldered Eye Bolts

Design for Angular Loads

Shouldered eye bolts feature an integrated collar or “shoulder” between the eye and the threads. Designers create this shoulder to brace the bolt against the load-bearing surface. This design element provides critical support against bending forces, making these eye bolts suitable for angular or off-axis loading. The shoulder effectively transfers the shear stress from the shank to the surface it is mounted on.

Pro Tip: For a shouldered eye bolt to safely handle an angular load, its shoulder MUST be fully flush and seated against the contact surface. Any gap between the shoulder and the surface will negate its ability to resist bending forces and can lead to catastrophic failure.

Applications in Rigging and Lifting

These eye bolts are the workhorses of professional rigging applications. Their ability to handle angular pulls makes them indispensable for complex lifts where a perfectly vertical pull is not possible. Riggers use them to connect slings, shackles, and other lifting hardware for hoisting structural components, precast concrete panels, and heavy materials.

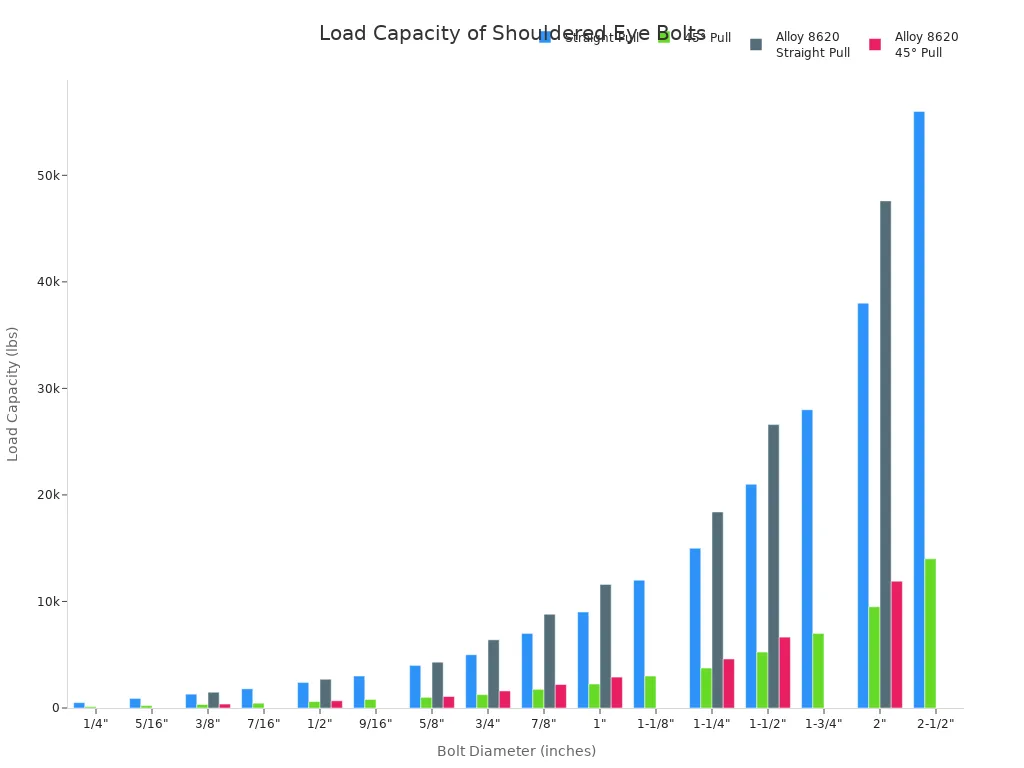

The load capacity of shouldered eye bolts decreases significantly as the pull angle increases from vertical. The table below illustrates the rated capacities for standard and alloy steel shouldered eye bolts at both vertical (0°) and 45° angles.

| Diameter | Straight Pull (lbs) | 45° Pull (Shoulder Only) (lbs) | Alloy 8620 Straight Pull (lbs) | Alloy 8620 45° Pull (Shoulder Only) (lbs) |

|---|---|---|---|---|

| 1/4″ | 500 | 125 | – | – |

| 3/8″ | 1,300 | 325 | 1,480 | 370 |

| 1/2″ | 2,400 | 600 | 2,700 | 675 |

| 5/8″ | 4,000 | 1,000 | 4,300 | 1,075 |

| 3/4″ | 5,000 | 1,250 | 6,400 | 1,600 |

| 1″ | 9,000 | 2,250 | 11,600 | 2,900 |

| 1-1/4″ | 15,000 | 3,750 | 18,400 | 4,600 |

| 1-1/2″ | 21,000 | 5,250 | 26,600 | 6,650 |

| 2″ | 38,000 | 9,500 | 47,600 | 11,900 |

This data shows a clear relationship between bolt diameter, material, and safe working load, especially when dealing with angular forces.

Plain (Non-Shouldered) Eye Bolts

Design for In-Line Vertical Loads

Plain eye bolts, also known as non-shouldered or “plain pattern” eye bolts, lack the supportive collar found on shouldered models. Their construction is simple: a threaded shank directly connected to the eye. This design offers no resistance to bending or shear forces. Therefore, their use is strictly limited to in-line, vertical lifts where the pulling force is perfectly aligned with the shank. Any side loading will bend the bolt and compromise its integrity.

Use Cases for Straight-Line Pulls

Plain eye bolts are not intended for heavy-duty overhead lifting in professional construction. Instead, they serve lighter-duty functions where only a straight pull is required. Common use cases include:

- Creating tie-down points for securing tarps or light materials.

- Serving as guide wire anchors for small, temporary structures.

- Acting as suspension points for lightweight signage or tools.

- Securing items for transport where the load is static and vertical.

Their simplicity makes them a cost-effective solution for these specific, non-critical tasks.

Machinery Eye Bolts

Forged Steel for High Strength

Machinery eye bolts represent the highest standard in strength and durability. Manufacturers produce them from forged carbon or alloy steel, a process that aligns the steel’s grain structure to enhance its tensile strength and resistance to fatigue. This superior manufacturing method makes them the designated choice for lifting extremely heavy loads. They are engineered to withstand the immense stresses involved in hoisting heavy equipment and components safely.

Lifting Heavy Equipment and Components

The original application for this type of fastener was in early power generators, or dynamos, giving them the alternate name “dynamo eye bolts.” Today, they are integral to moving heavy industrial machinery. Constructors install these eye bolts directly into tapped holes on large motors, gearboxes, industrial pumps, and machine tool components. They provide a certified and reliable lifting point, ensuring that valuable and heavy equipment can be positioned precisely and without damage. Their robust design makes them essential lifting hardware on any site dealing with heavy machinery.

Screw Eye Bolts

Lag Screw Thread Design

Screw eye bolts are distinct due to their thread design. They feature a coarse, sharp-pointed thread known as a lag screw thread. This design is engineered to displace and grip wood fibers effectively. Unlike machine threads that require a pre-tapped hole, a lag screw thread forms its own mating threads as a user drives it into the material. This action creates exceptional holding power within wooden structures. The deep, wide-spaced threads provide a large surface area for engagement, resisting pull-out forces.

Anchoring in Wood Structures

The lag screw design makes these fasteners the ideal choice for creating anchor points directly in wood. Constructors commonly use screw eye bolts in timber framing and other wood-based construction applications. Their primary function is for light to medium-duty anchoring where the load is relatively static.

Common applications include:

- Securing guy wires for temporary bracing on wooden posts.

- Creating tie-down points on wooden decks or platforms.

- Suspending lightweight signage, conduit, or fixtures from wood joists or beams.

- Anchoring ropes for cordoning off areas on a job site.

Important Note: Screw eye bolts are not intended for heavy overhead lifting. Their capacity is limited by the strength of the wood and the thread engagement. Always consult engineering specifications for load-bearing applications in wood.

Swivel Hoist Rings

Pivoting and Rotating Mechanism

Swivel hoist rings, also known as ring bolts, represent a significant evolution in lifting hardware. Their advanced design features a lifting ring mounted on a base that allows for 360° rotation and 180° pivoting. This mechanism enables the lifting ring to automatically align itself with the direction of the pulling force. The internal bushing ensures smooth movement under load, preventing the bolt from binding or being subjected to dangerous side-loading stresses. This dynamic functionality makes them fundamentally safer than standard eye bolts for many lifting scenarios.

Advantages for Complex and Angular Lifts

The primary advantage of swivel hoist rings is their ability to handle complex and angular lifts without a reduction in capacity. While shouldered eye bolts lose significant strength when pulled at an angle, a swivel hoist ring maintains its full working load limit (WLL) regardless of the sling angle. This eliminates the risk associated with improper de-rating calculations and provides a much larger margin of safety.

This capability makes them indispensable for tasks involving multi-axis movement, such as flipping dies, positioning molds, or lifting components with offset centers of gravity. The comparison below highlights the critical differences between swivel hoist rings and traditional eye bolts.

| Feature | Swivel Hoist Rings | Shouldered Eye Bolts |

|---|---|---|

| Angular Lift Performance | Maintain 100% load capacity at any lift angle. | Capacity decreases dramatically; a 45° lift can reduce strength by over 70%. |

| Movement Capability | Allow full 360° rotation and 180° pivoting for multi-axis movement. | Designed for straight-line pulls; angular lifts are limited and require careful alignment. |

| Safety in Setup | More forgiving; automatically swivels to align with the load direction. | Requires precise alignment; risk of failure increases if the shoulder is not flush. |

| Ideal Applications | Complex rigging, lifting heavy equipment, loads that may shift or rotate. | Vertical lifting, static lifting points where the load direction is predictable. |

| Risk of Failure | Significantly reduced risk during multi-directional or angular lifts. | Increased risk of bending or catastrophic failure from improper side loading. |

Ultimately, the superior flexibility and inherent safety of swivel hoist rings make them the preferred choice for modern, complex rigging operations. They provide riggers with greater control and confidence, especially when lifting valuable or heavy equipment where mistakes are not an option. Their design mitigates many of the risks associated with standard eye bolts.

Primary Uses of Eye Bolts in Construction

Eye bolts are fundamental components on any construction site, serving a diverse range of functions critical to safety and project execution. Their primary applications fall into three main categories: lifting heavy objects, securing materials and equipment, and anchoring essential support systems. The correct use of these fasteners in each scenario is non-negotiable for maintaining a safe and efficient work environment.

Lifting and Hoisting Operations

The most demanding use for eye bolts involves overhead lifting. In these high-stakes situations, forged steel eye bolts provide certified and reliable connection points for cranes and hoists.

Attaching to Steel Beams and Precast Concrete

Constructors create secure lifting points by installing heavy-duty eye bolts directly into structural elements. For steel beams, workers drill and tap a hole to match the bolt’s machine threads. In precast concrete panels, they use embedded anchors or chemical anchoring systems to create a threaded receptacle. In both cases, the eye bolt provides a robust point for hoisting the component into place.

Connecting Slings, Shackles, and Hoists

The loop or “eye” of the bolt is the interface for all lifting hardware. Riggers connect crane hooks, chain slings, wire rope slings, and shackles directly to the eye. A shouldered eye bolt allows for the connection of a multi-leg sling for a balanced lift. The integrity of the entire lift depends on this single connection, making proper eye bolt selection and installation paramount.

Rigging and Securing Loads

Beyond lifting, eye bolts play a crucial role in stabilizing materials and equipment, both in transit and on-site. They create dependable tie-down points that prevent dangerous movement.

Creating Tie-Down Points on Structures

Establishing a secure tie-down point requires careful planning and adherence to best practices. The choice of eye bolt is the first critical decision.

- Load and Material: Select an eye bolt with a Working Load Limit (WLL) that exceeds the anticipated force. Match the bolt material (e.g., galvanized or alloy steel) to the environmental conditions.

- Installation: The shoulder of a collared eye bolt must sit perfectly flush against the mounting surface to handle angular loads. Workers should never undercut the bolt to make it fit; instead, they can use washers to eliminate any gap.

- Inspection: Teams must regularly inspect all eye bolts used for rigging. They should check for bending, corrosion, or damaged threads and remove any compromised hardware from service immediately.

Safety Alert: Dynamo or plain pattern eye bolts are designed only for loads applied directly in line with the threads. For any angular pull, riggers must use a collared or shouldered eye bolt and de-rate its capacity according to manufacturer specifications.

Stabilizing Materials During Transport

The dynamic forces involved in moving materials across a construction site can be immense. The use of eye bolts in construction helps secure heavy or unwieldy items, preventing them from shifting, sliding, or tipping during transport. These fasteners provide fixed anchor points on vehicles or the materials themselves. Common items stabilized with eye bolts include:

- Heavy machinery and large turbines

- Bundles of steel I-beams

- Large precast concrete panels

- Other bulk construction materials

Anchoring Support Systems

Eye bolts also serve as stationary anchors for various temporary and permanent support structures. In these applications, they primarily resist static tension forces.

Securing Guy Wires and Support Cables

Crews use eye bolts to anchor guy wires and support cables that brace structures like communication towers, utility poles, and temporary event tents. A screw eye bolt can be driven into a wooden pole, while a shouldered eye bolt with a nut and washer can secure a cable to a steel frame. These anchors provide the stability needed to counteract wind and other lateral forces.

Anchoring Scaffolding and Temporary Structures

Worker safety on scaffolding depends on its stability, which is often achieved by anchoring the system to the building’s main structure. Specialized eye bolts are designed for this exact purpose. These safety-critical fasteners must meet stringent manufacturing and material standards to ensure they can withstand the required loads without failure. The technical specifications for a typical scaffolding anchor eye bolt highlight these high requirements.

| Property | Value |

|---|---|

| Material | Carbon Steel |

| Tensile Strength | 65,000 PSI minimum |

| Yield Strength | 30,000 PSI minimum |

| Manufacturing Standards | ASME B18.15, ASTM A489 |

| Compliance | ANSI, CSA, and OSHA |

These robust specifications ensure that the eye bolts provide a completely reliable anchor point for fall protection and structural stability, safeguarding workers at height.

Fall Protection Systems

Beyond lifting and rigging, eye bolts perform their most critical function in safeguarding personnel. The use of eye bolts in construction for personal fall arrest systems (PFAS) is a life-saving application. These systems rely on a series of components working together, with the anchor point serving as the foundation for worker safety. A failure at this single point renders the entire system useless.

Serving as Certified Anchor Points

An anchor point for fall protection is not just any attachment point; it is a certified component engineered to withstand the immense forces generated during a fall. Eye bolts selected for this purpose must meet stringent regulatory standards. The Occupational Safety and Health Administration (OSHA) provides clear directives on the strength requirements for these anchors.

According to OSHA 1910.140(c)(13), anchorages must be:

- Capable of supporting at least 5,000 pounds (22.2 kN) for each employee attached; or

- Designed, installed, and used, under the supervision of a qualified person, as part of a complete personal fall protection system that maintains a safety factor of at least two.

This regulation gives teams two compliance pathways. They can either use a prescriptive approach by installing an anchor rated for 5,000 pounds, or they can use an engineered system. An engineered system, designed by a qualified person, calculates the specific forces and ensures the anchor’s capacity is at least twice the maximum potential load. Even in these engineered systems, the eye bolts and hardware used typically carry a minimum rating of 5,000 pounds to provide a robust margin of safety.

Connecting Lanyards and Lifelines

The certified eye bolt serves as the direct connection point for a worker’s fall protection equipment. A worker wearing a full-body harness connects to the anchor using a lanyard, which often includes a shock-absorbing element to reduce impact forces on the body. The integrity of this connection is paramount.

Making a secure connection involves several key considerations:

- Compatibility: The snap hook on the lanyard must be compatible with the eye bolt. It should be a locking type that cannot be accidentally opened or dislodged from the eye.

- Proper Orientation: The lanyard should be connected in a way that allows it to align with the direction of a potential fall, minimizing side-loading on the anchor.

- Clearance: Workers must ensure there is sufficient fall clearance below them, accounting for lanyard length, deceleration distance, and worker height.

- Inspection: Both the eye bolt and the lanyard must be inspected before each use for any signs of wear, damage, or corrosion.

These specialized eye bolts provide the secure foundation necessary for a complete fall arrest system, allowing workers to perform tasks at height with confidence.

Choosing the Right Eye Bolts for the Job

Selecting the appropriate fastener is a critical engineering decision, not a simple hardware choice. The process of choosing the right eye bolts involves a careful analysis of the load, the direction of the pull, and the operational environment. Getting this decision wrong can compromise safety and lead to catastrophic equipment failure.

Matching the Bolt to the Load

Calculating the Working Load Limit (WLL)

The first step is to determine the total weight of the object being lifted or secured. With this information, a professional must select an eye bolt with a manufacturer-rated working load limit (WLL) that safely exceeds this weight. The working load limit is the maximum mass or force that a piece of lifting equipment is certified to handle. Never assume an unmarked bolt’s capacity; always refer to manufacturer specifications.

Considering Dynamic vs. Static Loads

Crews must distinguish between static loads (stationary weight) and dynamic loads (forces from motion). Dynamic loads are far more hazardous because they introduce sudden and amplified forces. For instance, a 600-pound static load that is stopped abruptly during a lift can generate a momentary force of 900–1,200 pounds. This shock loading can stretch or deform eye bolts and compromise the entire system. The selected working load limit must account for these potential dynamic forces, as a working load limit designed for static conditions is insufficient for repeated shock loads.

Assessing the Load Direction

When to Use Shouldered vs. Plain Eye Bolts

The anticipated direction of the pull dictates the type of eye bolt required.

- Plain (Non-Shouldered) Eye Bolts: Use these only for perfectly vertical, in-line pulls.

- Shouldered Eye Bolts: These are necessary for any lift where the pull will be at an angle (off-axis). The shoulder braces the bolt against bending forces.

De-rating Capacity for Angular Lifts

Even a shouldered eye bolt loses significant strength when pulled at an angle. This reduction in capacity is known as de-rating. The working load limit decreases dramatically as the angle of the pull moves away from vertical. Riggers must consult manufacturer charts to determine the adjusted working load limit for any angular lift.

Important: An eye bolt’s working load limit is rated for a straight, vertical pull (0°). Any deviation requires a reduction in its rated capacity.

| Direction of Pull (from vertical) | Adjusted Working Load Limit |

|---|---|

| 45 degrees | 30% of vertical Working Load Limit |

| 90 degrees (horizontal) | 25% of vertical Working Load Limit |

Material Compatibility

Selecting Bolts for Steel, Concrete, or Wood

The base material determines the correct type of eye bolts and installation method. Machine thread eye bolts are used for tapped holes in steel, while lag screw eye bolts are designed to grip wood fibers. For concrete, teams use specialized anchoring systems to create a secure threaded point.

Factoring in Environmental Conditions

Environmental exposure plays a major role in the longevity and safety of eye bolts. Corrosion from moisture or salt can weaken a bolt over time.

- Marine Environments: 316 stainless steel offers the best rust-proof protection for saltwater and coastal applications.

- General Outdoor Use: 304 stainless steel is suitable for humid or wet climates but not direct saltwater exposure.

- Specialized Coatings: Advanced coatings like Stalgard provide excellent corrosion resistance, making them ideal for construction fasteners in moderate marine environments.

Critical Safety and Inspection Procedures

A robust safety and maintenance protocol is not optional; it is the foundation of safe lifting and rigging operations. Rigorous inspection and a clear understanding of load limits prevent equipment failure and protect personnel.

Understanding Working Load Limit (WLL)

What WLL Means

The working load limit (WLL) is the most critical safety specification for any piece of rigging hardware. It represents the maximum safe force or mass that an eye bolt can handle during regular use. The manufacturer determines this value by dividing the hardware’s ultimate breaking strength by a safety factor. This built-in safety margin accounts for variables like wear and unforeseen stresses. The working load limit is the practical, operational capacity, not the failure point.

| Aspect | Working Load Limit (WLL) | Breaking Strength |

|---|---|---|

| Definition | The maximum safe force for regular use. | The maximum force a device can withstand before breaking. |

| Purpose | Ensures safety by providing an operational limit. | Determines the ultimate capacity of the material. |

| Safety Factor | Includes a significant safety margin. | No safety margin; this is the absolute failure point. |

| Usage | Guides daily operations and ensures compliance. | Used for engineering, testing, and certification. |

Why You Must Never Exceed Rated Capacity

Exceeding the working load limit is extremely dangerous because it consumes the essential safety factor. While a bolt may not fail immediately, overloading it can cause microscopic damage, stretch the material, and lead to sudden, catastrophic failure under a future load. Adhering strictly to the working load limit ensures the hardware operates within its designed parameters, preserving its integrity and guaranteeing site safety. Every lift that exceeds the working load limit is a gamble against material fatigue.

Pre-Use Inspection Checklist

A visual inspection before each use is a non-negotiable safety step. A few moments of inspection can prevent a serious incident.

Checking for Bending, Cracks, or Corrosion

Personnel must visually inspect every bolt before it is put into service. Key signs of damage include:

- Any bending, twisting, or distortion of the eye or shank.

- Visible cracks, nicks, or gouges on any part of the bolt.

- Excessive pitting or corrosion that compromises the material’s surface.

- Indications of heat damage, such as weld spatter or discoloration.

- Missing or illegible manufacturer markings, which are required for identification.

Inspecting Thread Integrity

The threads are critical for a secure connection. A thorough inspection must confirm that the threads are clean and undamaged. Any signs of excessive wear, burrs, or cross-threading are grounds for immediate rejection. The threads must be able to achieve full, proper engagement in the receiving hole to support the intended load.

Guidelines for Removing Damaged Eye Bolts from Service

Criteria for Discarding a Bolt

A damaged eye bolt must be removed from service and destroyed to prevent accidental reuse. According to ASME standards, the criteria for removal include:

- Bent, stretched, or otherwise distorted load-bearing components.

- A reduction in the original dimension by 10% or more at any point.

- Excessive thread damage.

- Any unauthorized welding or modifications.

- Visible cracks or excessive nicks and gouges.

The Risks of Reusing Damaged Hardware

Reusing a compromised bolt is a severe safety violation. A damaged fastener has an unknown and unreliable capacity. It could fail at a fraction of its original working load limit without warning, leading to dropped loads, equipment damage, and serious injury or death. There is no acceptable level of risk when it comes to damaged rigging hardware.

Best Practices for Eye Bolt Installation

Proper installation is as critical as selecting the right hardware. A correctly chosen fastener can fail if it is not installed according to manufacturer and industry standards. Following best practices ensures that the anchor point achieves its full rated capacity.

Installation into Metal

Preparing Tapped Holes

Crews must prepare the receiving hole with precision. A clean, correctly sized hole is the foundation for a secure connection.

- Workers should always countersink the receiving hole. This creates a beveled edge that helps the shoulder of the eye bolt seat properly.

- The hole must be completely free of dirt, debris, or cutting fluid before threading the bolt.

Ensuring Full Thread Engagement

Full thread engagement is non-negotiable for achieving the rated load capacity. The bolt must be screwed down completely until it is properly seated.

- For shouldered eye bolts, the tapped hole must accommodate the full threaded length of the shank.

- Plain pattern eye bolts require the hole to be threaded for the entire length of engagement.

- The bolt must be screwed down until the shoulder is fully flush with the mounting surface.

Installation into Concrete

Using Mechanical Anchors

Mechanical anchors create a connection through friction or expansion. They are often faster to install and suitable for light to medium loads. However, their holding power depends heavily on the quality of the concrete.

Applying Chemical and Epoxy Anchors

Chemical anchors use a resin to bond a threaded rod into the concrete. This method offers superior strength and is ideal for heavy loads or dynamic applications. The table below compares these two common methods for creating anchor points in concrete.

| Feature | Chemical Anchors | Mechanical Anchors |

|---|---|---|

| Holding Power | Superior; resin creates a strong bond ideal for heavy loads. | Relies on friction; holding power is limited by concrete quality. |

| Vibration Resistance | Excellent; resin absorbs and distributes stress effectively. | Can loosen over time under vibration or dynamic loads. |

| Installation | Requires precise mixing and curing time. | Generally faster and simpler with no curing needed. |

| Edge Distance | Less sensitive to anchor spacing and edge distances. | Requires greater distance from edges to prevent material failure. |

Correctly Seating the Eye Bolt

Ensuring the Shoulder is Flush

For any angular lift, the shoulder of the eye bolt must be perfectly flush against the load-bearing surface. Any gap will prevent the shoulder from resisting bending forces, drastically reducing the bolt’s capacity.

Pro Tip: After applying the first load on an angular lift, crews should unload the hardware and re-check the seating. The initial force can sometimes cause the bolt to back away from the surface. If this occurs, workers must reseat it properly before continuing.

Proper Use of Washers

Washers are a critical tool for achieving a flush fit.

- If a gap exists between the shoulder and the surface after the bolt is fully threaded, workers should use steel washers to fill it.

- The washers ensure the shoulder makes firm contact with the surface, allowing it to handle angular loads correctly.

- The thickness of the washer stack should not exceed one thread pitch to maintain adequate thread engagement.

Key Standards and Regulations for Eye Bolts

Compliance with industry standards is not optional; it is a legal and ethical requirement for ensuring site safety. Two primary organizations, ASME and OSHA, establish the rules for using eye bolts and other rigging hardware in the United States. Adherence to these regulations protects workers and prevents equipment failure.

ASME (American Society of Mechanical Engineers)

ASME develops comprehensive standards that guide the manufacturing and use of mechanical devices. Their publications are the benchmark for quality and performance in the rigging industry.

ASME B30.26: Rigging Hardware Safety Standard

This standard is a critical resource for any rigging operation. ASME B30.26 establishes the requirements for the construction, installation, operation, inspection, and maintenance of detachable rigging hardware. The standard applies to a wide range of components used in load-handling activities.

Key hardware covered by ASME B30.26 includes:

- Shackles

- Turnbuckles

- Eyebolts and hoist rings

- Links and swivels

- Wire rope clips

This document provides the technical criteria that riggers and site supervisors must follow to ensure hardware is used correctly and safely.

ASME B18.15: Forged Eye Bolt Dimensional and Material Standards

While B30.26 covers usage, ASME B18.15 focuses on the fastener itself. This standard specifies the exact dimensions, material properties, and manufacturing tolerances for forged eye bolts. Compliance with B18.15 ensures that a bolt meets the strength and quality expectations for its rated capacity.

OSHA (Occupational Safety and Health Administration)

OSHA is the federal agency responsible for enforcing workplace safety laws. Its regulations are mandatory, and non-compliance can result in significant penalties.

Regulations for Rigging Equipment in Construction

OSHA’s standard 29 CFR Part 1926 outlines the rules for material handling. A qualified rigger must inspect all rigging equipment before each shift. This inspection ensures the hardware is free from defects. The regulations strictly prohibit employers from loading any sling or fastener beyond its recommended safe working load. Furthermore, any rigging gear with missing or illegible identification tags must be removed from service immediately.

Requirements for Fall Protection Anchor Points

OSHA places extreme importance on fall protection. When used as part of a personal fall arrest system, an anchor point must meet stringent strength requirements. The regulation mandates that anchorages must be capable of supporting at least 5,000 pounds per employee attached. This non-negotiable rule ensures the anchor can withstand the immense forces generated during a fall.

The use of eye bolts in construction provides strong, reliable anchor points for many tasks. These fasteners are critical for a wide range of applications, from lifting and rigging to ensuring worker safety. Proper selection, inspection, and installation of the correct eye bolts are non-negotiable procedures. Adherence to these practices ensures a safe and efficient construction site.

FAQ

What is the main difference between shouldered and plain eye bolts?

Shouldered eye bolts have a collar to support angular loads. Plain eye bolts lack this feature. Professionals must use plain eye bolts only for perfectly vertical, in-line pulls to prevent bending and failure.

Can a team reuse an eye bolt after a heavy lift?

Personnel should never reuse an eye bolt that shows signs of overload, such as stretching or bending. A compromised bolt has an unknown capacity and presents a severe safety hazard. It must be removed from service and destroyed.

What does WLL mean for an eye bolt?

WLL stands for Working Load Limit. It is the maximum safe force the manufacturer certifies for the hardware. Exceeding the WLL eliminates the built-in safety factor and risks catastrophic failure.

How do workers identify a damaged eye bolt?

A damaged eye bolt must be discarded immediately. Key signs of damage include:

- Any bending, stretching, or twisting.

- Visible cracks, nicks, or gouges.

- Excessive corrosion or pitting.

- Damaged or worn threads.

Why is the angle of a lift so important?

Angular lifts create bending forces that reduce an eye bolt’s capacity. A shouldered eye bolt pulled at a 45-degree angle may only support 30% of its vertical WLL. Riggers must always de-rate the capacity for angular pulls.

Is it safe to weld or modify an eye bolt?

No. Welding or making unauthorized modifications alters the steel’s heat treatment and compromises its structural integrity. ASME standards require that any modified eye bolt be removed from service immediately to prevent accidents.

When should a team use a swivel hoist ring?

A team should use a swivel hoist ring for complex or angular lifts. This hardware pivots 180° and rotates 360° to align with the load. It maintains 100% of its WLL at any angle, offering a superior safety margin.