Anchor bolts are specialized fasteners. They connect structural elements, such as steel columns, to a concrete foundation. The primary function of an anchor bolt is to transfer load from the structure into the concrete. These anchors securely fasten the structure to its base. This engineering process creates a secure connection. A custom fasteners manufacturer can produce custom anchor bolts and other custom fasteners for unique structural engineering needs. These anchor bolts are essential for structural stability. An anchor bolt provides a secure connection against forces like wind and seismic activity. This anchor bolt connection ensures a secure connection for any structural project.

The Fundamental Functions of Anchor Bolts

Anchor bolts perform several critical roles in structural engineering. They are not merely fasteners; they are engineered components that manage immense forces. Their primary functions involve resisting tension, counteracting shear, and ensuring the precise alignment and stability of the entire structure. A failure in any of these areas can compromise the safety and longevity of a project.

Resisting Tension and Uplift Forces

Tension is a pulling force that tries to lift a structural element away from its foundation. Anchor bolts directly oppose this force, holding the structure down. This function is essential for maintaining a secure connection under various environmental and operational loads.

Counteracting Wind and Seismic Loads

Tall buildings and lightweight structures are highly susceptible to wind. Wind creates pressure on one side of a building and a suction, or uplift, effect on the other. Similarly, seismic activity causes ground shaking that can generate significant vertical forces, trying to lift the structure off its foundation. An anchor bolt provides the necessary anchor bolt tension capacity to resist these uplift forces. These anchors ensure the building remains firmly attached to the ground.

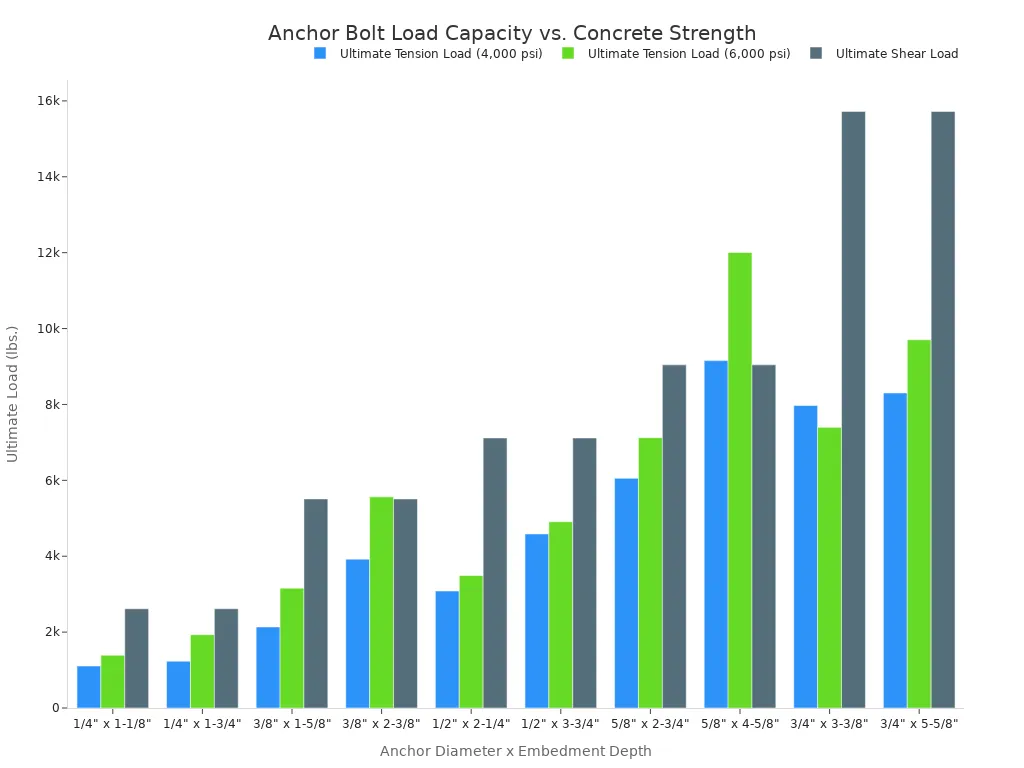

The Role of Embedment Depth

The embedment depth of an anchor bolt is the length of the bolt embedded within the concrete. This depth is a critical factor in determining its load-bearing capacity. A deeper embedment provides a larger surface area for the anchor bolt to grip the concrete, which significantly increases its resistance to being pulled out. The strength of the concrete itself also plays a vital role.

💡 Pro-Tip: Engineers carefully calculate the required embedment depth based on the expected load, the anchor bolt diameter, and the concrete’s compressive strength. A deeper anchor is not always better; the design must be optimized for performance and cost.

The following table illustrates how an anchor bolt’s allowable tension load changes based on its diameter, embedment depth, and the concrete’s strength.

| Nominal Anchor Diameter (in.) | Minimum Embedment Depth (in.) | Concrete Compressive Strength (psi) | Allowable Tension Load Capacity (lbs.) |

|---|---|---|---|

| 1/4″ | 1-1/8″ | 4,000 | 342 |

| 1/4″ | 1-3/4″ | 4,000 | 392 |

| 3/8″ | 1-5/8″ | 4,000 | 686 |

| 3/8″ | 2-3/8″ | 4,000 | 926 |

| 1/2″ | 2-1/4″ | 4,000 | 1,103 |

| 1/2″ | 3-3/4″ | 4,000 | 1,697 |

| 5/8″ | 2-3/4″ | 4,000 | 1,985 |

| 5/8″ | 4-5/8″ | 4,000 | 2,524 |

| 3/4″ | 3-3/8″ | 4,000 | 2,571 |

| 3/4″ | 5-5/8″ | 4,000 | 2,667 |

| 1″ | 4-1/2″ | 4,000 | 4,153 |

| 1″ | 8″ | 4,000 | 5,619 |

As shown, increasing either the embedment depth or the concrete strength generally increases the anchor bolt tension capacity.

Resisting Shear and Lateral Forces

Shear forces are lateral, or sideways, pressures that try to push a structure horizontally across its foundation. These forces are common during earthquakes, high winds, or from the operational forces of heavy equipment. Anchor bolts act as rigid dowels to resist this sliding motion.

Preventing Sliding and Overturning

Imagine a strong wind pushing against the side of a large warehouse. This force tries to slide the entire building off its concrete slab. The anchor bolts embedded in the foundation absorb this lateral load and transfer it safely into the concrete mass. This action prevents both sliding and the potential for the structure to overturn, which is critical for structural integrity. The collective strength of all the anchors provides a robust defense against these powerful forces.

Bolt Diameter and Material Impact

The capacity of an anchor bolt to resist shear is directly related to its physical properties.

- Diameter: A larger diameter bolt has a greater cross-sectional area, making it stronger and more resistant to being sheared off.

- Material Strength: The type of steel used for the anchor bolt determines its inherent strength. High-strength steel anchors can handle a much higher shear load than standard carbon steel anchors of the same size.

An engineering professional selects the appropriate diameter and material to ensure the anchor bolts have the necessary tension and shear capabilities for the specific application. This decision directly impacts the overall load-bearing capacity of the connection.

Ensuring Structural Stability and Alignment

Beyond pure strength, anchor bolts serve a foundational purpose in construction: they guarantee positional accuracy and stability from the very beginning of the erection process. They are the fixed points upon which the entire structure is built.

Maintaining Positional Accuracy

In modern structural engineering, many components are prefabricated off-site. These components must fit together perfectly on the job site. Anchor bolts are set in the foundation using precise templates before the concrete is poured. This precision is non-negotiable. For example, a conveyor tower manufacturer might specify a positional tolerance as tight as 1/16 of an inch for each anchor bolt supporting a 65-foot tower. This accuracy ensures that steel columns, beams, and other structural elements align correctly, saving time and preventing costly rework.

Securing Heavy Machinery and Equipment

Industrial facilities often house heavy machinery that generates constant vibration and dynamic loads. Anchor bolts provide the secure connection needed to hold this equipment in place, preventing movement that could damage the machine, the foundation, or surrounding structures. Proper installation is vital here. Correct tightening techniques create pretension in the anchor bolt. This pretensioning ensures a rigid and stable connection, which is essential for managing operational forces and maintaining the alignment of pre-fabricated structural components. This secure connection is a cornerstone of industrial safety and operational efficiency.

Types of Anchor Bolts and Their Applications

Engineers select an anchor bolt based on load requirements, environmental conditions, and construction sequencing. The choice between setting an anchor bolt before or after the concrete cures is a fundamental decision that divides anchors into two main categories: cast-in-place and post-installed. Each category offers distinct types of anchor bolts suited for specific applications.

Cast-in-Place Anchors

Cast-in-place anchors are positioned in the formwork before concrete is poured. They become an integral part of the foundation as the concrete hardens around them. This method is standard for new construction projects. It offers the highest reliability and load capacity because the anchor bolt engages a large volume of concrete and surrounding steel reinforcement.

For new construction, engineers prefer cast-in-place anchors for several reasons:

- They provide superior reliability and a more predictable load path.

- The installation process avoids common errors associated with post-installed anchors, such as improper hole cleaning or incorrect epoxy mixing.

- These anchors effectively transfer loads into the foundation, engaging the concrete and rebar for maximum strength.

A structural engineer shared a cautionary tale: “We specified cast-in anchor bolts, but the contractor ‘forgot’ to install them. They epoxied them in but didn’t clean the holes well, and the anchors pulled out under load. After that, we started detailing cast-in u-bolts to ensure they do it right. Epoxy anchors are fine for shear, but the quality control better be darn good if you’re going to rely on them in tension.”

Headed Bolts (ASTM F1554)

A headed anchor bolt has a forged hex, heavy hex, or square head on the embedded end. This head provides a large bearing surface that mechanically locks the anchor bolt into the concrete, offering excellent resistance to pullout forces. ASTM F1554 is the primary specification covering these anchor bolts, defining different grades (36, 55, and 105) that correspond to their tensile strength. These are the most common type of anchor bolt for securing structural steel columns and heavy equipment. Their straightforward design makes them one of the most dependable anchors for a wide range of applications.

J-Bolts and L-Bolts

As their names suggest, these anchor bolts are shaped like the letters ‘J’ and ‘L’. The bent portion at the embedded end creates a mechanical hook that resists pullout. While once very common, their use in heavy structural applications has declined in favor of headed bolts. The bend can create stress concentrations in the concrete. However, J-bolts and L-bolts remain useful for lighter-duty applications, such as securing light poles, signs, and residential foundation sill plates.

Threaded Rod with Anchor Plate

This assembly consists of a piece of all-thread rod with a steel plate and nut attached to the embedded end. The plate functions like the head on a headed bolt, creating a large bearing area to resist tension. This type of anchor bolt is highly customizable. Engineers can specify the rod length, diameter, and plate size to meet precise load demands. These custom anchor bolts are often used in deep foundations or for applications requiring extremely high uplift capacity.

Post-Installed Anchors

Post-installed anchors are installed into hardened concrete. A worker drills a hole into the existing concrete, cleans it, and then inserts the anchor. This method is essential for retrofitting, renovation, and projects where anchor locations were not finalized during the initial concrete pour. Their applications are critical for modernizing and strengthening existing structures.

Common retrofitting applications for post-installed anchors include:

- Seismic Retrofitting: Strengthening older buildings to meet current earthquake safety standards.

- Connecting New Structural Elements: Attaching new steel beams, columns, or support brackets to existing concrete walls or foundations.

Mechanical Expansion Anchors

Mechanical expansion anchors create a connection through friction. After insertion into a pre-drilled hole, the anchor bolt expands as it is tightened. This expansion presses the anchor firmly against the walls of the hole. Wedge anchors and sleeve anchors are common types. Mechanical anchors are popular for their relatively low cost and simple installation. However, their performance can be affected by vibrations, which may cause them to loosen over time. Under static loads, they are a reliable choice if they provide the necessary capacity.

Adhesive (Epoxy) Anchors

Adhesive anchors, also known as epoxy anchors, use a high-strength epoxy or resin to bond a threaded rod or rebar to the concrete. The installer drills a hole, cleans it meticulously, injects the adhesive, and then inserts the anchor element. The adhesive fills the gaps and cures, creating an incredibly strong bond.

🗣️ Expert Insight: As a vibration control specialist, I never recommend expansion anchors for dynamic loads. They tend to loosen from vibrations. Properly installed epoxy anchors are the best choice for these applications.

Adhesive anchors are ideal for applications with high loads, close spacing, or vibratory forces from machinery. While their capacity can exceed that of mechanical anchors, their performance is highly dependent on proper installation. Inadequate hole cleaning or improper epoxy mixing can lead to a dramatic reduction in strength.

Concrete Screw Anchors

Concrete screw anchors are a unique type of post-installed anchor bolt. They feature specialized threads that cut into the concrete, creating a mechanical interlock. Installation is fast: drill a hole and drive the screw. This simplicity reduces the chance of installation error compared to other anchors. Concrete screws are excellent for temporary and permanent applications, such as attaching racking, formwork, or fixtures. They offer good performance in both cracked and uncracked concrete and are often removable, adding to their versatility in various applications.

Anatomy of an Anchor Bolt Assembly

An anchor bolt is more than just a steel rod. It is part of a complete assembly where each component plays a specific role in creating a secure connection. Understanding the anatomy of these anchor bolts reveals how they effectively transfer forces from a structure to its foundation. The assembly includes the bolt body, nuts, washers, and often sleeves and grout.

The Bolt Body and Embedment

The body of the anchor bolt is the primary component that resists applied forces. Its material properties and its depth within the concrete are fundamental to its performance. These factors determine the overall capacity of the anchor bolt connection.

Material Grade and Specification

The steel used to manufacture an anchor bolt dictates its strength. The ASTM F1554 specification is the industry standard for anchor bolts, defining three common grades.

- Grade 36 has a minimum yield strength of 36 KSI. It offers good ductility and is suitable for many general structural applications.

- Grade 105 is a high-strength option with a minimum yield strength of 105 KSI. Engineers specify these anchors for critical connections that must withstand significant forces.

The difference in tensile strength is substantial. Grade 105 anchor bolts are designed for high-stress applications where superior strength is non-negotiable.

| Grade | Tensile Strength (ksi) |

|---|---|

| 36 | 58-80 |

| 105 | 125-150 |

Function of Embedment Depth

Embedment depth is the length of the anchor bolt encased in concrete. A deeper embedment allows the anchor bolt to engage more concrete, creating greater resistance against pullout forces. This depth is a critical design parameter that an engineer calculates to ensure the anchor bolt can handle the expected tension load. Proper embedment ensures the anchors will not pull out of the foundation.

Nuts and Washers

Nuts and washers work together to secure the structural element to the anchor bolts. They are not just simple hardware; they are essential for distributing forces and maintaining the connection’s integrity.

Distributing Clamping Force

A washer is a flat disc placed between the nut and the structural base plate. Its primary job is to distribute the clamping force from the tightened nut over a larger surface area. This prevents the nut from damaging the base plate and ensures a uniform transfer of force from the anchor bolt.

Achieving Proper Preload

Tightening the nut on an anchor bolt stretches it slightly, creating a tension force known as preload. This preload clamps the steel base plate firmly to the foundation. A properly preloaded anchor bolt creates a rigid connection that is better equipped to handle vibrations and fluctuating forces without loosening.

Sleeves and Grout Pads

Sleeves and grout are components that facilitate correct installation and ensure effective load transfer. They help bridge the gap between the anchor bolt and the structure it supports.

The Role of Anchor Bolt Sleeves

An anchor bolt sleeve is a plastic or metal tube placed around the upper portion of a cast-in-place anchor bolt before the concrete pour. This sleeve creates a small void around the anchor bolt. This void provides a minor amount of play, allowing for small adjustments to the anchor bolt position to align with the steel column’s base plate.

How Grout Facilitates Load Transfer

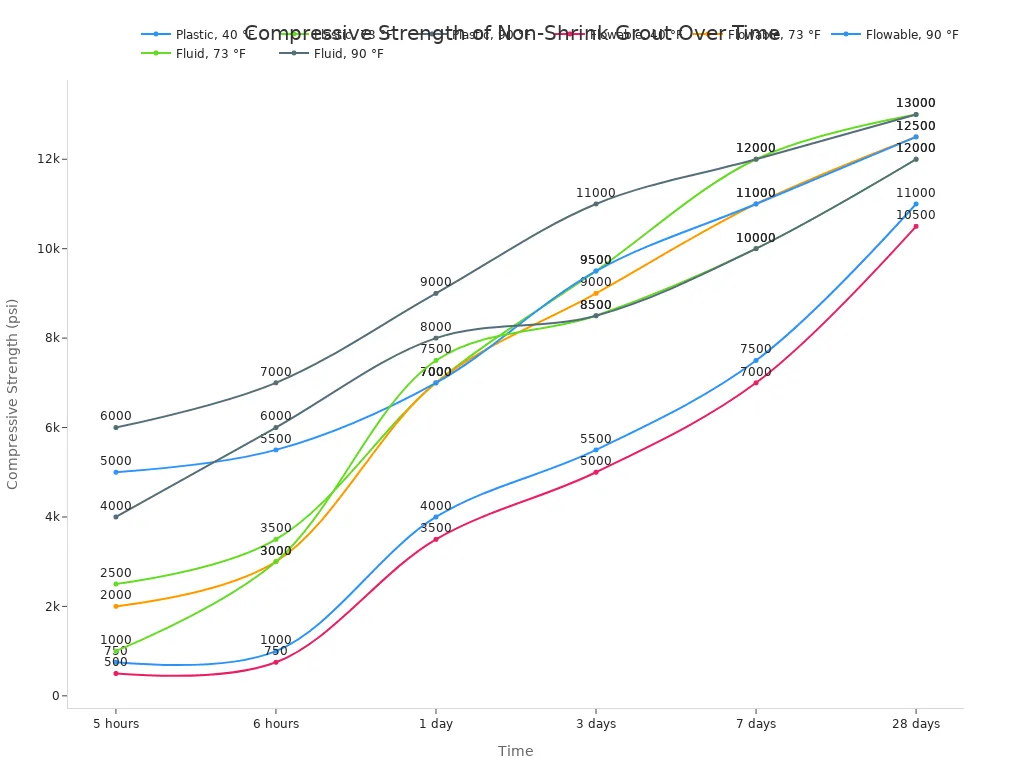

After a column is set and aligned, a contractor fills the gap between the bottom of the base plate and the top of the concrete foundation with non-shrink grout. This grout creates a solid, continuous bearing surface. It ensures the entire base plate uniformly transfers its compressive load to the foundation. The grout’s compressive strength develops over time and is influenced by temperature and consistency.

💡 Note: High-performance non-shrink grout can achieve compressive strengths far exceeding that of typical concrete, ensuring the connection point is not a weak link.

This chart shows how different grout mixtures gain strength, a critical factor for scheduling when the anchors can be fully loaded.

Materials, Coatings, and Anchor Bolt Strength

The selection of materials and protective coatings directly determines the anchor bolt strength and service life. An engineer chooses specific anchor bolt materials to meet the load demands of a structural project. Coatings provide an essential defense against environmental corrosion. The right combination ensures the anchor bolt maintains its integrity for decades. These choices are fundamental to the safety and durability of the connection.

Common Anchor Bolt Materials

The type of steel used is a primary factor in the performance of an anchor bolt. Different anchor bolt materials offer varying levels of strength and corrosion resistance, making the selection critical for the application.

Carbon Steel

Carbon steel is one of the most common anchor bolt materials. It provides a good balance of strength and cost-effectiveness for many general structural applications. An anchor bolt made from carbon steel, such as ASTM F1554 Grade 36, offers sufficient strength for standard columns and equipment bases in controlled, dry environments. These anchors are reliable when not exposed to corrosive elements.

High-Strength Alloy Steel

For connections that must withstand extreme forces, engineers specify high-strength alloy steel anchor bolts. These anchor bolt materials, like ASTM F1554 Grade 105, contain additional elements that significantly increase their yield and tensile strength. This added strength allows a smaller anchor bolt to handle loads that would cause a carbon steel anchor bolt to fail. These anchors are essential for critical lifts and high-stress applications.

The following table and chart illustrate the significant differences in strength between common anchor bolt materials.

| Anchor Material Type | Yield Strength (Fy) ksi (MPa) | Ultimate Tensile Strength (fut) ksi (MPa) |

|---|---|---|

| ASTM A307 (Carbon Steel) | Not clearly defined | 60 (410) |

| ASTM A36 or F1554 Grade 36 (Carbon Steel) | 36 (250) | 58 (400) |

| F1554 Grade 105 (Alloy Steel) | 105 (720) | 125 (860) |

| ASTM A193 Grade B7 (Alloy Steel) for bolt diameter (db) ≤ 64 | 105 (720) | 125 (860) |

| ASTM A193 Grade B7 (Alloy Steel) for 64 < db ≤ 102 | 95 (660) | 115 (790) |

| ASTM A193 Grade B7 (Alloy Steel) for db > 102 | 75 (515) | 100 (690) |

Stainless Steel

Stainless steel is the premier choice among anchor bolt materials for corrosion resistance. While carbon steel anchors can rust in humid conditions, stainless steel contains chromium, which creates a passive, corrosion-resistant layer. This makes it the ideal anchor bolt for harsh environments.

Stainless steel anchor bolts are recommended for:

- Marine environments with high humidity or salt water exposure

- Outdoor applications where the anchor bolt is exposed to weather

- Industrial facilities with chemical exposure

- Any application where long-term durability and resistance to oxidation are critical

Protective Coatings for Corrosion Resistance

For carbon and alloy steel anchor bolts, protective coatings are necessary to prevent corrosion. These coatings act as a barrier between the steel anchor bolt and moisture.

Hot-Dip Galvanization

Hot-dip galvanizing provides superior corrosion protection. In this process, a fabricator dips the anchor bolt into a bath of molten zinc. This creates a thick, durable coating that is metallurgically bonded to the steel. A hot-dip galvanized anchor bolt offers a much longer service life than other coatings, making it the standard for outdoor and demanding applications. These anchors are well-suited for infrastructure projects.

Zinc Plating

Zinc plating is a less expensive coating process that applies a very thin layer of zinc to the anchor bolt. It offers limited corrosion protection and is primarily for aesthetic purposes or for use in dry, indoor environments. Zinc-plated anchors are not suitable for outdoor or underwater applications, as the thin coating wears away quickly.

Epoxy Coatings

Epoxy coatings provide a robust barrier against moisture and chemicals. These specialized paints are applied to the anchor bolt to create a protective film. Epoxy-coated anchors are often used in wastewater treatment plants or chemical facilities where specific corrosive agents are present. The effectiveness of these anchors depends on the coating remaining intact without scratches or damage.

Key Principles of Anchor Bolt Design

Proper anchor bolt design is a critical engineering discipline that balances load requirements, material properties, and site conditions. A successful design ensures a safe and durable connection between a structure and its foundation. This process involves careful calculation, an understanding of concrete behavior, and a commitment to precise installation.

Load Calculation and Analysis

Engineers begin the design process by analyzing the forces the anchor bolts must resist. This analysis is fundamental to selecting the correct type, size, and number of anchors for any structural application.

Tension and Shear Interaction

An anchor bolt rarely experiences a simple, single force. More often, it must handle a combination of tension (pulling) and shear (sideways) forces. Structural engineering uses interaction equations to evaluate the combined effect of these forces. Designers calculate load ratios for both tension and shear to ensure the combined load on the anchor bolt does not exceed its total capacity. This rigorous analysis prevents failure when the anchor is subjected to complex forces from wind or seismic events.

Factored vs. Unfactored Loads

In structural design, engineers work with “factored” loads. They take the expected service loads (unfactored) and multiply them by safety factors defined in building codes. This approach creates a conservative design, ensuring the anchor bolts have more than enough strength to handle any foreseeable load, providing a crucial margin of safety for the entire structure.

Concrete Condition and Strength

The concrete itself is half of the connection system. Its condition and strength directly influence the performance and load-bearing capacity of every anchor bolt.

Cured vs. Green Concrete

Concrete does not gain its full strength overnight. It cures over time, a process that can take 28 days or more. An anchor bolt cannot be subjected to its full design load until the concrete has reached its specified compressive strength. Loading anchors in “green,” or uncured, concrete can lead to connection failure.

Cracked vs. Uncracked Concrete

Design codes like ACI 318 often require engineers to assume a “cracked concrete” condition. This is because concrete can develop fine cracks under structural load. These cracks can reduce the ultimate anchor bolt tension and shear capacity. As shown in the data below, higher concrete strength generally increases the tension capacity of an anchor bolt, but its shear strength is more dependent on the steel itself. This conservative design approach ensures the anchors perform safely even if cracks appear near the installation point.

Installation Best Practices

A perfect design is meaningless without proper anchor bolt installation. The installation process is where the engineering plan becomes a physical reality, and precision is non-negotiable.

Hole Preparation and Cleaning

For post-installed anchors, the condition of the drilled hole is critical. A successful anchor bolt installation depends on a clean surface for the anchor to bond with or grip.

Pro-Tip: Proper hole cleaning is essential for achieving the specified load-bearing capacity, especially for adhesive anchors. Best practices include:

- Removing all loose debris, dirt, and oil from the hole.

- Using compressed air, a vacuum, and a wire brush to thoroughly clean dust from the hole’s interior walls.

- Ensuring the hole is dry before injecting any adhesive.

Torque and Tensioning Procedures

Applying the correct torque is the final step in a proper installation. Torqueing the nut stretches the anchor bolt, creating a clamping force called preload.

- Insufficient torque results in low preload, allowing the connection to loosen under vibration.

- Excessive torque can stretch the anchor bolt beyond its yield strength, causing it to fracture or damage the threads.

Correct tensioning ensures a rigid and secure connection, which is vital for the long-term performance of all anchor bolts.

Understanding Failure Modes in Structural Engineering

A core responsibility in structural engineering is to prevent failure. Engineers must understand how an anchor bolt connection can fail to design a safe and resilient structural system. Failures are broadly categorized by which component gives way first: the steel anchor bolt or the surrounding concrete. A proper engineering design considers all potential failure modes for the selected anchors.

Steel Failure Modes

Steel failures occur when the applied load exceeds the capacity of the anchor bolt itself. These failures are directly related to the material properties and dimensions of the anchor bolt.

Tensile Failure of the Bolt

Tensile failure happens when a pulling force stretches an anchor bolt beyond its ultimate strength. The anchor bolt elongates and then fractures. This is a ductile failure mode, meaning the anchor bolt shows signs of stretching before it breaks. The tensile capacity is a function of the steel grade and the cross-sectional area of the anchor bolt. Stronger steel makes for a stronger anchor bolt.

Shear Failure of the Bolt

Shear failure occurs when a lateral force acts perpendicular to the anchor bolt, effectively cutting it in half. Imagine a giant pair of scissors slicing through the steel. This type of failure is common in seismic events or from high wind loads. The shear capacity of an anchor bolt depends on its diameter and material strength. A larger diameter anchor bolt provides greater resistance to this structural failure.

Concrete Failure Modes

Concrete failures happen when the anchor bolt remains intact, but the concrete around it breaks. These failures are often brittle and can occur without warning, making them a critical focus in structural engineering. The design of anchor bolts must prevent these outcomes.

🗣️ Expert Insight: The most unpredictable failures involve the concrete. That is why modern engineering codes are so conservative. We design the anchor bolt connection so that if a failure were to occur, it would be a ductile steel failure, not a sudden concrete breakout.

Concrete Cone Breakout

This is the most common failure mode for anchors under tension. The anchor bolt pulls a cone-shaped piece of concrete out of the foundation. The size of this cone depends on several factors:

- The embedment depth of the anchor bolt.

- The spacing between adjacent anchor bolts.

- The distance of the anchor bolt from a concrete edge.

Deeper anchors engage more concrete, increasing resistance to this failure.

Pullout and Pryout Failure

Pullout failure is specific to headed anchors or mechanical anchors. The anchor bolt pulls through the concrete without creating a large cone breakout. This can happen if the head of the anchor bolt is too small. Pryout failure is a secondary failure related to shear. A short, stiff anchor bolt under a shear load can rotate and pry out a shallow piece of concrete from the surface. Many anchor bolts are susceptible to this.

Side-Face Blowout

Side-face blowout occurs when a large-diameter anchor bolt with a deep embedment is installed too close to a concrete edge. The high tensile force in the anchor bolt creates immense pressure, causing the side of the concrete to burst outwards. This failure is a major concern for anchors near the edge of a foundation or wall. Proper spacing for all anchor bolts is essential.

Anchor bolts are fundamental components in structural engineering. These anchor bolts create the critical connection between a structural element and its foundation. The core functions of each anchor bolt are non-negotiable for structural integrity. Proper anchor bolt design and meticulous installation are paramount for all anchor bolts. This engineering design prevents failure. The installation of these anchors ensures long-term performance. In structural engineering, the anchor bolt is key.

Good engineering ensures the anchor bolt works. The design of these anchors is a core structural engineering task. These anchor bolts and each anchor bolt secure our world. The structural performance of these anchors and anchor bolts depends on the anchor bolt. The final anchor bolt is the result of this structural process. The design of the anchor bolt connection is a key engineering task. These anchors are vital for structural integrity and structural engineering.

FAQ

What is the main difference between cast-in-place and post-installed anchors?

Cast-in-place anchors are set in wet concrete during new construction. Post-installed anchors are installed into hardened, existing concrete. The first method generally offers higher reliability, while the second provides flexibility for retrofitting and renovations.

Why is torque important for an anchor bolt?

Proper torque creates preload, which is a clamping force. This force secures the connection, prevents loosening from vibrations, and ensures the anchor bolt functions as designed. Incorrect torque can lead to connection failure or damage to the steel.

Can someone reuse an anchor bolt?

Engineers generally do not recommend reusing a structural anchor bolt. The initial installation process stretches the steel. Re-torquing a used anchor can compromise its strength and lead to an unsafe connection. It is always safer to use a new anchor.

What happens if an anchor is installed too close to a concrete edge?

Placing an anchor too close to an edge can cause a side-face blowout failure. The force from the anchor bolt can burst the side of the concrete. Designers follow strict spacing guidelines to prevent this dangerous failure mode.

Which anchor bolt is best for outdoor use?

Stainless steel or hot-dip galvanized steel anchors are best for outdoor applications. These materials and coatings provide excellent corrosion resistance. They protect the anchor bolt from moisture and environmental elements, ensuring long-term durability and safety.