Concrete anchor bolts are heavy-duty fasteners engineered to securely attach steel to concrete. These anchor bolts transfer a fixture’s load into the base material. The anchor manages two primary forces: tensile load and shear load. Each anchor resists tensile (pull-out) forces, while the bolt itself resists shear (sideways) forces. This anchor bolt must handle a specific tensile load. The anchor’s design ensures it withstands the required tensile strength. Every bolt resists shear. This anchor has high shear capacity. The anchor bolt’s performance against tensile and shear forces is critical. A custom fasteners manufacturer can produce custom anchor bolts and other custom fasteners. The concrete anchor market is projected to reach USD 22.8 billion by 2033, showing the growing importance of this anchor.

Fundamental Types of Concrete Anchor Bolts

Engineers and builders select from three fundamental types of concrete anchor bolts. Each category operates on a different principle to create a secure connection. The choice depends on the application’s load requirements, environmental conditions, and base material. The main types are mechanical, adhesive, and screw-type anchors.

Mechanical Anchors

Mechanical anchors are the most common choice in the construction industry. Projections show this anchor type will continue to dominate the market due to its reliability and simple installation. These anchor bolts provide dependable connections, ensuring structural safety and stability. Their versatility allows for a wide range of uses. Common applications include:

- Residential: Securing fixtures like cabinets, shelves, and railings.

- Commercial: Anchoring partitions, signage, and HVAC systems in office buildings and retail spaces.

- Industrial: Fastening heavy machinery, pallet racking, and safety equipment in plants and warehouses.

- Infrastructure: Anchoring structural elements and safety barriers in bridges, tunnels, and highways.

Wedge Anchors

A wedge anchor is a heavy-duty, torque-controlled expansion anchor. Installers insert the bolt into a pre-drilled hole. Tightening the nut pulls the bolt upward, forcing a clip at the bottom to expand and wedge tightly against the concrete. This mechanism gives the wedge anchor the highest holding power among mechanical expansion anchor bolts. They are ideal for heavy-duty structural applications.

| Anchor Type | Typical Load Capacity (lbs) |

|---|---|

| Sleeve Anchor | 200-1000 |

| Wedge Anchor | 6000 or more |

Sleeve Anchors

A sleeve anchor is a versatile expansion anchor suitable for light to medium-duty applications in concrete, brick, and block. This bolt consists of a threaded bolt, a flared cone-shaped nut, and an expansion sleeve. As the installer tightens the bolt, the cone pulls into the sleeve. This action forces the sleeve to expand outward, pressing against the walls of the hole. This anchor has less holding power than a wedge anchor.

Drop-In Anchors

A drop-in anchor is a female (internally threaded) anchor designed for flush-mount applications. After an installer places the anchor in a pre-drilled hole, they use a special setting tool to drive an internal plug downward. This action expands the anchor body, locking it into the concrete. A separate machine bolt or threaded rod is then screwed into the anchor to attach the fixture. This design is excellent for overhead work like suspending pipe, conduit, and cable trays.

Strike Anchors

A strike anchor, also known as a hammer-drive anchor, is a simple, impact-expansion anchor. It consists of a steel body, an expansion pin, and a nut and washer. An installer places the anchor into the hole and drives the internal pin with a hammer. The pin forces the anchor body to expand, creating a secure hold. This bolt is a permanent, tamper-proof fastener best suited for static, light to medium-duty applications.

Adhesive (Chemical) Anchors

Adhesive anchors, or chemical anchors, use a high-strength resin to bond a threaded rod or rebar to the concrete. These systems create a stress-free fastening, making them ideal for applications near concrete edges or where anchor spacing is tight. Their high bond strength and excellent load distribution contribute to their steady market growth. However, their performance is highly dependent on environmental conditions.

Note: Temperature and moisture significantly impact the curing process and final strength of an adhesive anchor. Installers must follow manufacturer guidelines closely for a reliable bond.

| Condition | Effect on Anchor Performance | Best Practices |

|---|---|---|

| High Temperatures (above 30°C/86°F) | Accelerates resin curing, potentially causing improper bonding. | Use temperature-resistant epoxies; install during cooler times of the day. |

| Wet Conditions (Rain, High Humidity) | Interferes with the chemical bond, leading to poor performance. | Thoroughly clean and dry the hole; use a moisture-resistant adhesive. |

| Condensation | Can weaken the bond if it forms on the substrate during installation. | Use fast-curing resin to minimize exposure time. |

Epoxy-Based Systems

Epoxy anchors are two-component systems (a resin and a hardener) that offer the highest bond strength and chemical resistance. They have a longer cure time, which allows for deeper embedment and precise anchor alignment. Tensile tests show that high temperatures progressively decrease the adhesive’s strength and stiffness.

Hybrid and Vinylester Systems

Hybrid and vinylester systems also use a two-part resin but offer a much faster curing time than epoxies. This speed makes them popular for projects requiring a quick turnaround. While strong, they are generally more sensitive to installation conditions and may offer slightly lower load capacities than a pure epoxy anchor.

Screw-Type Anchors

Screw-type anchors are a unique category of concrete fasteners. They are valued for their ease of installation and removability. These types of anchor bolts are a popular choice for both temporary and permanent fixtures.

Self-Tapping Thread Design

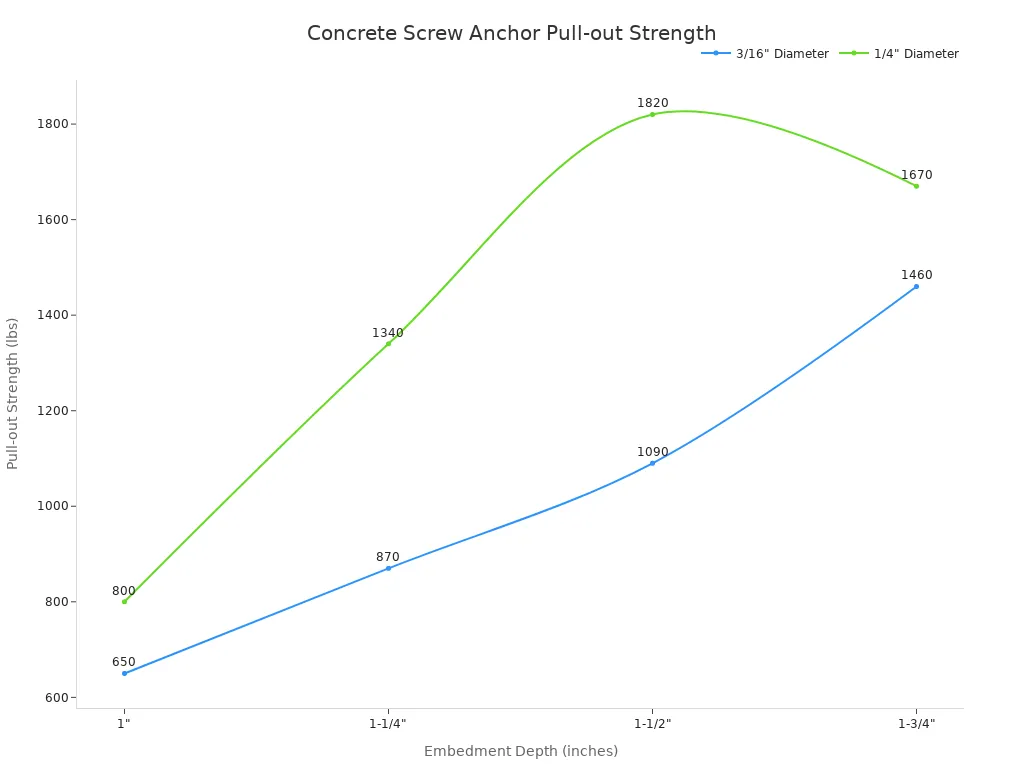

A concrete screw features a specialized, hardened thread designed to cut its own mating threads into concrete, brick, or block. An installer simply drills a pilot hole and drives the screw directly into the base material. This action creates a strong mechanical interlock. The anchor’s pull-out strength is directly related to its diameter and embedment depth, as shown in the data for 4000 PSI concrete.

| Diameter | Embedment (inches) | Pull-out Strength (lbs) |

|---|---|---|

| 3/16″ | 1″ | 650 |

| 3/16″ | 1-3/4″ | 1460 |

| 1/4″ | 1″ | 800 |

| 1/4″ | 1-3/4″ | 1670 |

Removability and Reusability

While a key feature of a screw-type anchor is its removability, reusing the bolt is strongly discouraged from a professional engineering and safety perspective.

The act of removing and reinstalling a concrete screw fundamentally compromises its holding power. It introduces risks of metal fatigue and voids all warranties and safety certifications. Even if a bolt appears visually undamaged, micro-fractures and dulled threads make a secure second installation impossible.

Reusing a screw-type bolt creates several critical issues:

- Compromised Holding Power: The removal process damages the threads cut into the concrete and wears down the screw’s own threads. This leads to a drastic and unpredictable reduction in holding power.

- Metal Fatigue: The intense forces from the initial installation can create micro-fractures in the bolt. Re-torquing the bolt can cause these fractures to grow, leading to sudden failure.

- Voided Compliance: Reusing a concrete screw immediately voids any manufacturer warranty or European Technical Approval (ETA). This action can lead to significant legal liability and failed inspections.

For any structural or safety-critical application, professionals must use a brand-new, correctly specified screw for every anchor point.

Critical Anchor Bolt Specification: Load Capacity

An anchor bolt’s primary purpose is to safely manage applied forces. The load capacity is the most critical anchor bolt specification. Engineers must match the anchor’s strength to the application’s load requirements. This ensures the connection remains secure under stress. The overall performance of the bolt depends on understanding these forces and the factors that influence its strength.

Understanding Load Forces

An anchor experiences forces from different directions. The two primary forces are tensile and shear. Testing agencies use standardized methods to determine the strength of anchor bolts against each type of load.

Tensile Load (Pull-Out Strength)

Tensile load, or pull-out strength, measures the force required to pull an anchor straight out of its base material. This is a critical performance metric for any anchor. Technicians determine the ultimate tensile strength of an anchor using a “Pull Out Test.”

- A hydraulic pump applies a tensile load parallel to the anchor bolt.

- A displacement transducer measures the bolt’s movement in real time.

- This test method complies with the ASTM E488-10 standard for measuring tensile strength.

This type of test can be destructive, where the bolt is pulled to its ultimate load, or non-destructive, where a proof load is applied to verify installation without damaging the material. The tensile strength of the anchor must exceed the expected tensile loads of the application.

Shear Load (Lateral Strength)

Shear load measures the sideways force an anchor can withstand. This force acts perpendicular to the length of the bolt. A “Shearing Test” determines the shear strength of an anchor. A hydraulic pump applies a load perpendicular to the bolt until failure. The shear strength is vital for applications involving wind, seismic activity, or fixtures that hang off a wall. The bolt itself resists the shear load.

Combined Tension and Shear Loads

Most real-world applications subject an anchor to both tensile and shear forces simultaneously. Engineers calculate this “Tension Shear Interaction” to ensure the anchor can handle the combined load. A complex formula, (Nxua / φNxn)^(5/3) + (Vxua / φVxn)^(5/3), is used to verify the anchor’s performance under these combined stresses. This calculation confirms the bolt meets the necessary load requirements for a safe design.

Factors Influencing Load Performance

Several factors directly impact the load-bearing performance and strength of concrete anchor bolts. A correct specification considers the anchor itself and the concrete it is installed into.

Anchor Diameter and Embedment Depth

The diameter of the bolt and its embedment depth are fundamental to its strength. A larger diameter bolt generally provides greater tensile and shear strength. Deeper embedment gives the anchor more concrete to grip, significantly increasing its tensile strength. Proper embedment is a key specification for achieving the required performance.

Concrete Compressive Strength (PSI)

The strength of the concrete base material is a major factor. Concrete with a higher compressive strength (measured in PSI) provides a stronger foundation. This allows the anchor to transfer a greater load and achieve higher tensile and shear strength values.

Cracked vs. Uncracked Concrete Conditions

Concrete can develop fine cracks over time due to tension, shrinkage, or stress. An anchor installed in cracked concrete will have a significantly reduced tensile strength compared to one in solid, uncracked concrete.

Important: For applications in cracked concrete, engineers must select an anchor specifically tested and approved for this condition. Using a standard anchor in a cracked zone poses a serious safety risk and fails to meet proper load requirements.

Material and Coating Specification Guide

An anchor bolt‘s material and coating are a critical specification that dictates its durability and suitability for a given environment. Selecting the correct material prevents premature failure from corrosion, ensuring the long-term safety and integrity of the connection. The choice between carbon steel and stainless steel anchor bolts depends entirely on the application’s exposure to moisture and corrosive elements.

Carbon Steel Anchor Bolts

Carbon steel is a common material for anchor bolts due to its high strength and cost-effectiveness. The ASTM F1554 specification governs the material properties for these anchor bolts, defining grades based on their strength. The chemical composition and mechanical strength vary by type and size, allowing engineers to select the appropriate bolt for specific load requirements.

| Element | Carbon Steel | Carbon Boron Steel | Alloy Steel | Alloy Boron Steel |

|---|---|---|---|---|

| Carbon | 0.30 – 0.52% | 0.30 – 0.52% | 0.30 – 0.52% | 0.30 – 0.52% |

| Manganese, min | 0.60% | 0.60% | 0.60% | 0.60% |

| Phosphorus, max | 0.040% | 0.040% | 0.035% | 0.035% |

| Sulfur, max | 0.050% | 0.050% | 0.040% | 0.040% |

The tensile strength of a carbon steel bolt is a key performance indicator. This strength varies with the bolt’s diameter.

| Size | Tensile Strength (ksi) | Yield Strength (ksi) |

|---|---|---|

| 1/4 – 1 | 120 min | 92 min |

| 1 1/8 – 1 1/2 | 105 min | 81 min |

| 1 5/8 – 3 | 90 min | 58 min |

Because carbon steel is susceptible to rust, it requires a protective coating. The type of coating determines where the anchor can be safely used.

Zinc-Plated Finish for Dry Conditions

A zinc-plated finish is a thin, electroplated coating applied to a carbon steel anchor. This coating provides a basic level of corrosion resistance suitable only for dry, interior applications. The zinc layer acts as a sacrificial barrier, but it wears away over time when exposed to any moisture. While suitable for indoor uses, the service life of a zinc-plated anchor is limited. For example, the typical service life of a carbon steel chemical anchor is around 10 years in a controlled environment. The zinc coating’s primary function is to prevent rust during shipping and in non-corrosive settings.

Hot-Dipped Galvanized (HDG) for Moist Environments

Hot-dip galvanizing involves immersing a carbon steel bolt in a bath of molten zinc. This process creates a much thicker and more durable protective layer than standard zinc plating. An HDG anchor offers good corrosion resistance, making it suitable for outdoor applications in moist or humid environments. This robust coating significantly extends the life of the bolt in settings where it might be exposed to rain or condensation.

Stainless Steel Anchor Bolts

Stainless steel anchor bolts provide superior corrosion resistance because the protective qualities are inherent to the material itself, not just a surface coating. This makes them the ideal choice for harsh, corrosive, or long-term outdoor applications. The two most common types are 304 and 316 stainless steel.

Type 304 for General Corrosion Resistance

Type 304 stainless steel is an excellent material for general-purpose corrosion resistance. It performs well in most outdoor environments and can withstand exposure to freshwater and typical atmospheric conditions. This type of anchor is a reliable choice for many exterior projects where the bolt will not be exposed to saltwater or harsh chemicals. Its inherent strength and durability make it a popular specification for quality construction.

Type 316 for Marine and Chemical Environments

Type 316 stainless steel contains an important element: molybdenum. This addition gives the material superior strength and resistance against chlorides, such as salt and de-icing chemicals.

Expert Tip: For any project near the coast or involving exposure to harsh chemicals, specifying Type 316 stainless steel is non-negotiable. Its ability to resist pitting and crevice corrosion is critical for safety and longevity.

Laboratory salt spray tests confirm the superior performance of a Type 316 anchor. In simulated saltwater environments, a Type 316 bolt can last up to 10 years, whereas a Type 304 bolt may show significant corrosion within just one year. This makes Type 316 the only acceptable choice for:

- Marine and coastal environments

- Wastewater treatment plants

- Areas with heavy use of de-icing salts

- Chemical processing facilities

Selecting Materials Based on Application

The final material specification for concrete anchor bolts must align with the environmental conditions of the installation site. The ISO 9223 standard classifies environments into corrosivity categories, from C1 (Very Low) to CX (Extreme), which helps guide material selection.

| ISO Category | General Description | Recommended Anchor Material |

|---|---|---|

| C1-C2 | Dry interiors, rural areas | Zinc-Plated Carbon Steel |

| C3 | Urban areas, some humidity | Hot-Dipped Galvanized, Type 304 Stainless |

| C4 | Industrial areas, coastal areas | Type 316 Stainless Steel |

| C5-CX | Heavy industrial, marine splash zones | Type 316 Stainless Steel or higher grade alloy |

Interior and Dry Applications

For indoor applications with controlled humidity and no exposure to moisture, zinc-plated carbon steel anchor bolts offer sufficient strength and protection. These are cost-effective for securing fixtures in dry, stable environments.

Exterior and Humid Applications

For general outdoor uses or in humid interior spaces like unconditioned warehouses, a hot-dipped galvanized anchor or a Type 304 stainless steel anchor is necessary. These materials provide the required strength and corrosion resistance to withstand moisture and temperature fluctuations.

Corrosive and Coastal Applications

In environments classified as C4 or C5, such as coastal regions, industrial zones, or areas with chemical exposure, only Type 316 stainless steel should be used. This material’s enhanced corrosion resistance is essential for maintaining the anchor’s structural strength and ensuring a safe, long-lasting installation.

Anchor Bolt Dimensions: Diameter, Length, and Threading

Selecting the correct physical dimensions is a fundamental anchor bolt specification. The diameter, length, and threading of an anchor bolt directly influence its installation success and load-bearing strength. Engineers must carefully define each dimension to ensure a safe and effective connection.

Anchor Diameter Specification

The diameter of the anchor is a primary driver of its performance. This specification affects both strength and compatibility.

Impact on Load Capacity

An anchor’s diameter has a direct correlation with its strength. A larger diameter bolt possesses a greater cross-sectional area. This increased area enhances the anchor’s capacity to resist both tensile and shear forces. A bolt with a larger diameter can handle a heavier load, making it a critical factor for achieving the required structural strength.

Matching Diameter to Fixture Hole Size

Installers must match the anchor diameter to the hole size of the fixture being attached. A proper fit ensures the load transfers correctly from the fixture to the anchor. An oversized hole can cause movement and reduce the connection’s overall strength, while an undersized hole makes installation impossible.

Determining Correct Anchor Length

The correct anchor length is essential for achieving the necessary embedment and securing the fixture. The total length of the bolt must be carefully calculated.

Calculating Required Bolt Length

Professionals determine the required bolt length by considering the fixture’s thickness and the anchor’s embedment depth. The goal is to select a bolt with a length that falls within an approved range. The basic formulas are:

In this calculation,

tfixrepresents the thickness of the fixture. The valuesls,minandls,maxrepresent the minimum and maximum anchor length values based on the specific anchor’s approval assessment. This ensures the anchor has the proper length for its application.

Relationship Between Length and Embedment

A longer bolt does not automatically provide greater strength. The anchor’s pull-out strength comes from its embedment depth into the concrete. A bolt’s length must be sufficient to achieve the minimum required embedment while also passing through the fixture and accommodating the nut and washer. The correct length enables the proper embedment, which is key to the anchor’s holding strength.

Thread Specification

The thread specification of anchor bolts dictates how the fixture is secured and how the anchor performs under certain conditions.

Usable Thread for Fixture Attachment

An anchor has a specific length of usable thread. The overall bolt length specification must ensure enough thread protrudes past the fixture. This allows for the full engagement of the nut and washer, which is necessary to apply the correct torque and secure the load.

Coarse vs. Fine Thread Considerations

The choice between Coarse Thread (UNC) and Fine Thread (UNF) affects the anchor’s performance. UNC threads are the standard for most concrete anchor bolts.

- Strength: UNC threads have a larger cross-section, giving them higher shear strength and better performance when bearing a large tensile load or impact forces.

- Installation: Coarse threads are faster to install and more tolerant of debris, which is common on construction sites.

- Vibration: UNF threads offer better tightness and resistance to loosening from vibration due to a smaller helix angle. However, UNC threads are generally preferred for their overall robust strength in static structural connections.

Essential Installation Specifications for Anchor Bolts

An anchor bolt’s performance is only as good as its installation. Following precise installation specifications is not just a recommendation; it is a fundamental requirement for safety and structural integrity. A successful anchor bolt installation depends on three core areas: correct hole preparation, adherence to placement geometry, and proper tightening. Each step is a critical anchor bolt specification that ensures the fastener achieves its designed load capacity and provides a reliable, long-term connection.

Hole Preparation Requirements

The installation process begins with creating a precise hole in the concrete. The quality of this hole directly impacts the anchor’s ability to function correctly. Every detail, from the drill bit used to the final cleaning, contributes to the overall strength of the connection.

Correct Drill Bit and Hole Diameter

Selecting the correct drill bit and creating a hole of the proper diameter is the first critical step. The anchor manufacturer specifies the required hole diameter, which must be strictly followed. Using the wrong size has significant consequences for the anchor’s performance.

- A hole that is too small can damage the anchor during installation or lead to anchor failure under load.

- A hole that is excessively large will compromise the holding strength of the anchor.

- A properly sized hole allows the anchor to fit snugly, which is essential for achieving its full holding capacity.

- This secure fit enhances the anchor’s holding power and ensures its long-term stability.

The type of drill bit is also important. For most anchor bolt installation procedures, a carbide-tipped bit that meets ANSI standards is the professional requirement.

Proper Hole Depth

The depth of the drilled hole is another crucial specification. The hole must be deep enough to accommodate the full embedment of the anchor plus a small amount of extra space for any dust that might settle at the bottom. Drilling a hole that is too shallow will prevent the anchor from reaching its required embedment depth, severely reducing its pull-out strength. Conversely, drilling an excessively deep hole is inefficient and can be problematic for certain anchor types. The manufacturer’s instructions provide the exact hole depth requirement for each anchor size.

Critical Hole Cleaning Procedures

A clean hole is absolutely essential for achieving maximum anchor strength, especially for adhesive anchors. Concrete dust and debris left in the hole act as a bond-breaker, preventing the anchor from making full contact with the base material. This drastically reduces its holding power. Professionals use a systematic cleaning process to ensure a perfect installation.

Pro Tip: Immediate hole cleaning after drilling is crucial. Debris like dust or loose rock must be removed to promote strong adhesion and optimize the bond between the anchor and the surrounding material.

A reliable cleaning method involves a sequence of blowing and brushing. The “2x2x2” procedure is a common industry best practice:

- Blow: Use a hand pump or oil-free compressed air (minimum 90 psi) to blow dust out of the hole. Always blow from the back of the hole forward.

- Brush: Use a stiff wire brush with a diameter matching the hole size. Insert the brush to the bottom and twist it as you pull it out.

- Blow Again: Repeat the blowing step to remove all loosened particles.

- Repeat: Perform this entire blow-brush-blow cycle a second time to guarantee a completely clean hole for the anchor installation.

For an even more efficient installation, systems like the Hilti Safe Set use a hollow drill bit connected to a vacuum, cleaning the hole as it is being drilled. Regardless of the method, the goal is to create a pristine surface for the anchor to bond with, maximizing its strength.

Embedment, Spacing, and Edge Distance

The placement of an anchor within the concrete slab is governed by three geometric specifications: embedment depth, spacing between anchors, and distance from a concrete edge. Ignoring these parameters can lead to premature concrete failure and compromise the entire connection’s strength.

Minimum Embedment Depth

Minimum embedment depth is the shortest distance an anchor must be installed into the concrete to achieve its specified holding strength. This is a critical specification determined by several factors:

- Anchor Type and Diameter: Different anchor types (mechanical vs. adhesive) and larger diameter bolts require greater embedment to develop their full strength.

- Concrete Strength: Weaker concrete may require a deeper embedment to achieve the same load capacity as an anchor in stronger concrete.

- Load Type: Heavy tension loads demand a deeper embedment to resist pull-out forces.

- Environmental Factors: Applications subject to vibration may need a deeper embedment for added stability.

Engineers consult standards like ACI 318 and manufacturer data to determine the correct embedment requirement for a specific application. A deeper embedment gives the anchor more concrete to engage, which is fundamental to its pull-out strength.

Minimum Anchor Spacing Distance

When multiple anchors are installed in a group, they must be spaced far enough apart to prevent their load zones from overlapping. If anchors are too close, the concrete between them can fail before the bolts reach their full capacity. This interaction significantly reduces the strength of the entire anchor group. The ACI 318 building code provides formulas and tables for calculating the minimum spacing requirement. As a general rule, placing anchors too close together has a significant negative impact on their collective strength.

Minimum Concrete Edge Distance

The distance from an anchor to the nearest edge of the concrete is another critical installation parameter. An anchor installed too close to an edge can cause the concrete to break out sideways, a failure mode known as “concrete edge breakout.” This type of failure can occur at a much lower load than the anchor’s rated strength. ACI 318 specifies minimum edge distance requirements, noting that small edge distances have an even greater negative impact on anchor capacity than close spacing. For any structural installation, maintaining the specified edge distance is a non-negotiable safety requirement.

Torque and Tightening Specification

The final step in a mechanical anchor installation is applying the correct amount of torque. Torque is the rotational force that activates the anchor’s expansion mechanism and preloads the bolt, creating a secure clamp force on the fixture.

Following Manufacturer Torque Values

For proprietary, post-installed anchor bolts, manufacturers provide a specific installation torque value. This value is engineered to properly set the anchor without damaging the bolt or the concrete. Installers must use a calibrated torque wrench to apply this exact force. For general-purpose anchor bolts, such as cast-in-place rods, the AISC Steel Construction Manual often recommends tightening to a “snug-tight” condition. This is achieved by an ironworker using a standard spud wrench with their full effort. Any requirement for special pretensioning must be explicitly defined by the design engineer.

Risks of Improper Torquing

Applying the wrong torque value creates significant risks and can lead to connection failure.

- Under-Torquing: An under-tightened bolt will not be properly preloaded. This can lead to loosening under vibration and ultimately cause fatigue failure, which is the most common failure mode for bolts. The anchor will not achieve its intended clamping force or holding strength.

- Over-Torquing: Applying too much torque can cause the bolt to yield or fracture, a failure known as steel rupture. It can also damage the anchor’s expansion mechanism or even crack the surrounding concrete, completely compromising the installation and its strength.

Following the correct torque specification is the final quality check that ensures the anchor performs as designed.

Understanding Approvals and Certifications

Approvals and certifications are a critical specification for concrete anchor bolts. They provide independent verification that an anchor meets established safety and performance standards. Engineers and inspectors rely on these credentials to ensure the selected anchor is suitable for its intended purpose, especially in structural applications. A certified anchor guarantees that its published strength and performance data are reliable.

Key Industry Standards

Two primary sources define the requirements for anchor design and performance in the United States. These standards form the basis for nearly all anchor bolt specification and approval processes.

International Code Council (ICC-ES) Reports

An International Code Council Evaluation Service (ICC-ES) report is a document that confirms a specific anchor product’s compliance with building code requirements. Manufacturers submit their products for rigorous testing to obtain an ICC-ES report. This report provides engineers with essential data on the anchor’s performance, including its load strength in various conditions. It serves as trusted, third-party proof that an anchor performs as advertised, ensuring safety and reliability.

ACI 318 Building Code Requirements

The American Concrete Institute’s ACI 318, “Building Code Requirements for Structural Concrete,” is the governing code for concrete design. This code contains detailed provisions for anchor design to ensure structural safety.

A key principle of the ACI 318 code is the assumption that concrete in tension zones is cracked. This conservative approach ensures a higher level of safety, as cracks can reduce an anchor’s ultimate load strength.

The code outlines several critical mandates:

- Seismic Design: The code defines a specific seismic anchor design requirement for structures in high-risk seismic zones.

- Qualification Testing: Post-installed anchors must undergo qualification testing in cracked concrete to verify their performance under seismic load conditions.

- Strength Reduction: The code requires the application of a strength reduction factor to the anchor’s nominal strength. This accounts for potential concrete damage during a seismic event and distinguishes between ductile and brittle steel failure modes to determine the correct design strength.

The Importance of Certified Anchors

Using a certified anchor is a non-negotiable requirement for ensuring safety and achieving compliance in modern construction. The certification mark on a bolt signifies its tested strength and predictable performance.

Ensuring Performance and Safety

Certification guarantees that an anchor has passed standardized tests for strength and durability. This process validates the manufacturer’s performance claims, giving designers confidence that the bolt will handle the specified loads. This verification is fundamental to the safety of the connection. A certified anchor provides a known level of performance, which is essential for protecting property and lives.

Compliance for Structural Applications

For most structural applications, building codes mandate the use of certified products. Using a non-certified anchor can result in failed inspections, costly rework, and significant legal liability. Specifying a certified anchor ensures compliance with the governing building code. This adherence to a recognized specification is the final step in guaranteeing a safe, reliable, and professionally executed installation.

Concrete anchor bolts are essential fasteners that safely transfer a fixture’s load into a concrete base. A successful anchor bolt installation is critical for performance.

Selecting the correct anchor bolt requires careful consideration of the load, the anchor bolt material, and the installation specification. The installation code for the anchor bolt material ensures the anchor bolt can handle the load. This installation code also dictates the anchor bolt embedment for safety. The installation of each anchor bolt must follow the material code and installation code for compliance and safety. This installation specification ensures the anchor bolt provides safety under its design load. The installation and embedment of every anchor bolt is a critical part of the installation.

FAQ

What is the most important factor for anchor selection?

The primary factor is the application’s load requirements. An engineer must select an anchor with sufficient tensile strength to handle the expected load. This ensures a safe and reliable anchor installation for the anchor anchor.

Why is a clean hole critical for anchor installation?

A clean hole ensures maximum anchor contact. Debris reduces the anchor’s tensile strength and overall performance. A clean installation is essential for achieving the anchor’s designed strength and tensile capacity.

Can I reuse a concrete screw anchor?

Professionals advise against reusing a screw-type anchor. The re-installation process compromises the anchor’s threads. This action reduces the anchor’s tensile strength and holding strength, creating a safety risk for the anchor.

What does the ASTM F1554 specification cover?

The ASTM F1554 specification defines the material properties for a steel anchor. ASTM F1554 outlines the requirement for an anchor, including its tensile strength. ASTM F1554 ensures the anchor material has the correct tensile strength. ASTM F1554 and ASTM F1554 are key anchor standards.

How does embedment depth affect anchor strength?

Deeper embedment gives an anchor more concrete to grip. This increases its load-bearing strength and tensile performance. A proper installation depth is critical for the anchor to meet its specified load capacity and overall tensile strength.

Why is the ASTM F1554 requirement important for an anchor?

The ASTM F1554 requirement ensures an anchor meets specific load requirements. ASTM F1554 governs the anchor material’s tensile strength. Following ASTM F1554 is vital for a safe installation. This bolt standard, ASTM F1554, and ASTM F1554, guarantees anchor quality and strength.

What is the difference between tensile load and shear load?

An anchor’s design provides tensile strength against a pull-out load. The anchor body itself resists shear strength. This dual capability makes the anchor a versatile fastener. The anchor is a critical component.