Sleeve anchors are versatile medium-duty anchors for securing fixtures in solid masonry like concrete and brick. The anchor works through mechanical expansion. Tightening a nut on the anchor pulls a cone through a metal sleeve. This action expands the sleeve anchors, creating a secure grip inside the drilled hole. A custom fasteners manufacturer produces many sleeve anchor types. Key types of sleeve anchors include hex nut and flat head anchors. Material choice is critical for performance. A corrosion-resistant anchor is necessary for outdoor use. Standard sleeve anchors and other Anchor Bolts, including custom anchor bolts, provide reliable fastening for projects that do not require heavy-duty anchors. These sleeve anchors are excellent anchors.

What Are Sleeve Anchors and How Do They Work?

Sleeve anchors are essential fasteners for medium-duty applications. Their effectiveness comes from a simple yet powerful mechanical design. Understanding the components and the principles behind their operation helps ensure a secure and reliable installation. These anchors provide excellent holding power in solid masonry materials.

The Anatomy of a Sleeve Anchor

Every sleeve anchor consists of four primary components working together. Each part plays a critical role in creating a secure connection. The design of standard sleeve anchors is both simple and robust.

The Threaded Stud and Expander Cone

The core of the anchor is a threaded metal stud. One end of the stud features threads for a nut or a pre-formed head. The other end tapers into a cone-shaped expander. This cone is the catalyst for the entire expansion process.

The Expansion Sleeve

A cylindrical metal sleeve surrounds the stud and the cone. This sleeve is often scored or split. These features allow it to expand outward when force is applied. The sleeve is the component that directly contacts the wall of the drilled hole.

The Washer and Head/Nut Assembly

The top of the anchor includes a washer and a nut or a pre-formed head (like a flat or round head). An installer tightens this assembly. The washer distributes the load from the nut or head evenly across the surface of the fixture being fastened.

The Mechanical Principle: Expansion and Friction

Sleeve anchors secure themselves using the fundamental principles of expansion and friction. The process transforms rotational force into a powerful outward grip inside the base material. This makes these anchors incredibly reliable.

The Role of Torque

Torque is the rotational force applied when tightening the nut or head of the anchor. This action pulls the threaded stud upward. As the stud moves, it draws the expander cone up into the expansion sleeve, initiating the anchoring process.

How Expansion Creates a Secure Hold

The anchor achieves a secure connection by exerting an outward force against the concrete. As the cone moves, it forces the sleeve to expand outward. This expansion creates 360-degree contact pressure against the interior walls of the hole. The forceful pressing of the expanding sleeve against the rough concrete surface generates high friction. This process is like a ‘mechanical handshake’ with the concrete, where the outward force creates a powerful frictional grip that resists pull-out forces.

Frictional Force in Different Base Materials

The holding power of sleeve anchors relies on friction. The amount of friction generated depends on the base material.

Note: Porous, rough materials like concrete and brick provide excellent surfaces for the sleeve to grip. The sleeve bites into the irregularities, maximizing frictional resistance. Smoother or softer materials may offer less friction, slightly reducing the anchor’s ultimate load capacity.

A Deep Dive into Sleeve Anchor Types by Head Style

Selecting the correct head style is crucial for both the function and final appearance of an installation. The various sleeve anchor types are designed to meet specific project needs, from heavy-duty fastening to a clean, decorative finish. Understanding these different types of sleeve anchors ensures a professional and secure result.

Hex Nut Head Sleeve Anchors

Features and Identification

The hex nut head is the most common and recognizable of all sleeve anchor types. This anchor consists of a threaded stud, an expansion sleeve, a washer, and a separate hexagonal nut. Installers identify it by the external nut that they tighten to set the anchor. This design allows for easy adjustment and high clamping force.

Common Applications

Hex nut sleeve anchors are workhorses for general-purpose fastening. They are commonly used for holding heavy items such as machinery or various support structures. Their strength makes them ideal for a wide range of medium-duty applications.

- Securing light machinery and equipment

- Anchoring HVAC units to concrete pads

- Fastening cable trays and conduits

- Installing handrails and safety barriers

- Supporting bracketed shelving and storage racks

Pros and Cons

Pros: High clamping force, widely available, and versatile for many uses. The nut and washer assembly distributes the load effectively. Cons: The head protrudes from the surface, which can be a snag hazard and is not aesthetically pleasing for finished areas.

Flat Head (Countersunk) Sleeve Anchors

Features and Identification

A flat head sleeve anchor features a tapered head with a Phillips drive. It is designed to sit flush with the surface of the fixture. This creates a smooth, non-protruding finish. Proper installation requires drilling a countersunk recess in the fixture material so the anchor head can sit level.

Common Applications

These anchors are the go-to choice when a flush surface is non-negotiable. They prevent trip hazards and allow other objects to sit flat against the fixture. Common uses include:

- Fastening metal door frames to block or concrete walls

- Attaching stair treads to concrete steps

- Securing metal thresholds to a concrete floor

Pros and Cons

Pros: Provides a clean, flush finish. It eliminates snagging and tripping hazards, making it ideal for high-traffic areas. Cons: Requires a countersunk hole in the fixture. It may offer slightly less clamping force than a hex nut anchor.

Acorn Nut Head Sleeve Anchors

Features and Identification

Acorn nut head sleeve anchors are preferred when the application requires a decorative finish. The anchor features a domed nut that covers the end of the threaded stud, providing a safe and polished appearance. Even though the stud may protrude slightly into the open-end nut, the design provides an enhanced aesthetic compared to standard types of anchors.

Common Applications

These sleeve anchors are used in visible locations where appearance is a primary concern. They combine secure fastening with a clean, finished look. These anchor types are perfect for architectural and decorative projects.

Pros and Cons

Pros: Offers a safe, decorative, and finished appearance. The domed nut protects against sharp thread edges. Cons: Primarily for aesthetic purposes. These anchors are not typically used for heavy structural loads.

Round Head (Mushroom) Sleeve Anchors

Features and Identification

Round head sleeve anchors, also known as mushroom head anchors, have a low-profile, wide, domed head. This design provides a large bearing surface against the fixture. Installers can identify this anchor by its smooth, rounded top, which often includes a Phillips or slotted drive for installation. These sleeve anchors offer a clean look while distributing clamping force effectively.

Common Applications

The broad head of this anchor makes it suitable for fastening softer materials to masonry. The design prevents the anchor head from pulling through the fixture. Common applications include attaching wood furring strips, plywood, or signage to concrete or block walls. These anchors are a solid choice for projects where a finished appearance is beneficial but a flush mount is not required.

Pros and Cons

Pros: The wide head provides excellent bearing on the fixture material, making it ideal for softer materials. It offers a finished, low-profile appearance compared to a hex nut. Cons: The head protrudes from the surface. It is not suitable for applications requiring a completely flat, countersunk finish.

Tie-Wire Sleeve Anchors

Features and Identification

Tie-wire sleeve anchors are a specialized type of anchor designed for overhead applications. They feature a small hole through the head of the anchor stud. This unique feature allows installers to easily pass and secure ceiling hanger wire. These sleeve anchors are compact and specifically engineered for suspending lightweight systems from concrete ceilings.

Common Applications

These types of sleeve anchors are essential in commercial construction for overhead installations. They provide a secure point for suspending various components. Their use is particularly valuable in situations where powder-actuated tools are impractical, such as in very hard concrete or sensitive environments like hospitals. Key applications include:

- Suspended ceiling installations, anchoring tie wire to concrete slabs

- Securing lightweight fixtures and signage

- Hanging HVAC ductwork hangers

- Supporting other overhead components in commercial and institutional settings

Pros and Cons

Pros: This anchor is purpose-built for speed and efficiency in overhead wire applications. It provides a secure and reliable connection point for suspended systems. These sleeve anchor types are a great alternative in sensitive environments. Cons: The design is highly specialized. These anchors are not intended for general-purpose fastening or for supporting significant structural loads.

Exploring the Different Types of Sleeve Anchors by Material

Choosing the right material for sleeve anchors is just as important as selecting the correct head style. The material determines the anchor’s lifespan, its ability to resist corrosion, and its suitability for different environments. The main types of sleeve anchors are differentiated by their protective coatings or base metal composition.

Zinc-Plated Carbon Steel

Properties and Protection Level

Zinc-plated carbon steel sleeve anchors are the most common and economical option. These anchors receive a thin layer of zinc through an electroplating process, which is governed by standards like ASTM F1941. This zinc coating provides a basic level of protection against rust. It acts as a sacrificial barrier, corroding before the steel anchor underneath. However, this layer is very thin and offers minimal defense in harsh conditions.

Ideal Environments

These sleeve anchors are strictly for indoor, dry applications. They perform well when used to fasten items in climate-controlled environments where exposure to moisture is non-existent. Think of interior walls, storage rooms, or enclosed workshops.

Limitations

The primary limitation of zinc-plated anchors is their low corrosion resistance. Exposure to moisture, humidity, or outdoor elements will quickly compromise the thin zinc layer, leading to rust and potential failure of the anchor. They are unsuitable for any outdoor or damp location.

Hot-Dipped Galvanized (HDG) Carbon Steel

The Galvanization Process Explained

Hot-dip galvanizing creates a much more robust anchor. In this process, a steel anchor is submerged in a bath of molten zinc. This creates a thick, durable coating that is metallurgically bonded to the steel. Standards such as ASTM A153/A153M and ASTM F2329 define the requirements for this process, ensuring a continuous and uniform finish. The resulting coating is significantly thicker than standard zinc plating.

| Class of Material | Minimum Coating Thickness (microns) |

|---|---|

| Class C – Fasteners > 3/8” diameter | 53 µm |

| Class D – Fasteners < 3/8” diameter | 43 µm |

Enhanced Corrosion Resistance

HDG sleeve anchors offer superior corrosion resistance for outdoor use. The thick zinc coating provides both a physical barrier and cathodic protection. If the surface gets scratched, the surrounding zinc will still protect the exposed steel. Furthermore, the zinc forms a protective patina layer of zinc carbonate, which slows corrosion and extends the anchor’s life. This makes these corrosion-resistant sleeve anchors a reliable choice.

Ideal Environments

These anchors are the standard for most outdoor applications. Use them for projects like securing deck posts, attaching satellite dishes, or mounting signage. They can withstand rain, humidity, and general atmospheric conditions far better than zinc-plated anchors.

304 Stainless Steel

Composition and Benefits

304 stainless steel is a steel alloy containing high percentages of chromium and nickel. This composition makes the material inherently corrosion-resistant throughout its entire structure, not just on the surface. Unlike coated anchors, a scratch on a stainless steel anchor will not create a point of failure, as the exposed metal is also resistant to rust. This makes these sleeve anchor types extremely durable.

When to Choose 304 Stainless

Choose 304 stainless steel sleeve anchors when aesthetics and long-term corrosion resistance are important. These anchors maintain their appearance over time without rusting or staining the surrounding masonry. They are a significant upgrade from galvanized anchors for specific applications.

Applications in Wet Environments

304 stainless steel anchors are excellent for wet or damp environments. They are ideal for use in food processing facilities, breweries, and bathrooms. These anchors are also suitable for outdoor projects where the anchor will be frequently exposed to rain or fresh water.

316 Stainless Steel

For the most demanding and corrosive environments, 316 stainless steel sleeve anchors represent the highest standard of performance and longevity. These premium anchors offer unparalleled protection where other materials would quickly fail. Their unique composition makes them the definitive choice for critical projects requiring maximum durability.

Superior Chloride and Corrosion Resistance

The superior performance of 316 stainless steel sleeve anchors comes from a key ingredient: molybdenum. This element, typically added at around 2%, fundamentally enhances the material’s ability to fight corrosion. Molybdenum strengthens the passive film, the invisible protective layer on the steel’s surface. It helps this film resist breakdown when exposed to chlorides, which are found in saltwater, de-icing salts, and certain industrial chemicals.

This addition significantly improves the anchor’s resistance to pitting, a localized form of corrosion that can create deep cavities and compromise the anchor’s structural integrity. The molybdenum helps the passive film to thicken and self-repair more effectively, ensuring the anchor remains protected. This makes the material inherently corrosion-resistant throughout, providing a level of defense that surface coatings cannot match. These sleeve anchors are built for extreme conditions.

The Best Choice for Marine Environments

The exceptional chloride resistance of 316 stainless steel makes these anchors the undisputed best choice for marine environments. Salt spray and direct saltwater immersion create a highly corrosive setting that rapidly degrades lesser materials like zinc-plated or even galvanized steel.

Safety First: In coastal construction, the integrity of an anchor is a matter of safety. Using 316 stainless steel sleeve anchors for securing docks, boat lifts, railings, and fixtures on seaside buildings is a critical investment. These corrosion-resistant sleeve anchors prevent rust staining on the surrounding concrete and ensure a secure, long-lasting hold against the relentless effects of the marine atmosphere. Choosing the right anchor here is non-negotiable.

Applications in Chemical and Coastal Areas

The robust nature of 316 stainless steel extends its use beyond the coastline. These anchors are essential in any area where chemical exposure is a concern. Their ability to withstand aggressive substances makes them ideal for a range of industrial and infrastructure applications.

Key applications include:

- Wastewater treatment plants

- Pharmaceutical and chemical manufacturing facilities

- Food processing areas with harsh cleaning agents

- Indoor swimming pools with high chlorine exposure

- Infrastructure in regions with heavy road salt use

For these challenging applications, 316 stainless steel sleeve anchors provide the reliability and peace of mind that no other material can offer. They ensure that the fastening point remains strong and secure for the life of the project.

The Ultimate Selection Guide: Choosing the Right Anchors

Selecting the correct sleeve anchor involves more than just grabbing one off the shelf. A successful and safe installation depends on a careful evaluation of several key factors. This complete guide to anchors breaks down the selection process into three critical steps: assessing the base material, evaluating the environment, and determining the right size for the load. Following this process ensures the chosen anchor performs reliably for the life of the project.

Factor 1: Base Material Assessment

The material you are drilling into is the foundation of the entire fastening system. Sleeve anchors are designed specifically for solid masonry, and their performance varies significantly between different types.

Solid Concrete

Solid concrete is the ideal base material for sleeve anchors. Its high density and compressive strength provide a superior surface for the anchor’s expansion sleeve to grip. When installed in solid concrete, these anchors offer predictable and robust holding values, making them a reliable choice for a wide range of medium-duty applications.

Solid Brick

Solid brick is another suitable base material for sleeve anchors. However, installers must exercise caution. While effective, using these anchors in brick bases could potentially cause cracking or spalling on the surface if not done carefully. The quality and hardness of the brick can vary, affecting the anchor’s ultimate holding power. It is important to use a sharp drill bit and avoid over-torquing the anchor.

Concrete Masonry Units (CMU)

Installers can use sleeve anchors in concrete masonry units, but only in the solid sections of the block. The hollow portions of a CMU do not provide the necessary material for the anchor to expand against. The holding capacity of the anchor is directly related to the compressive strength of the CMU. According to ASTM C90, the minimum net area compressive strength for these units is 2,000 psi (13.8 MPa).

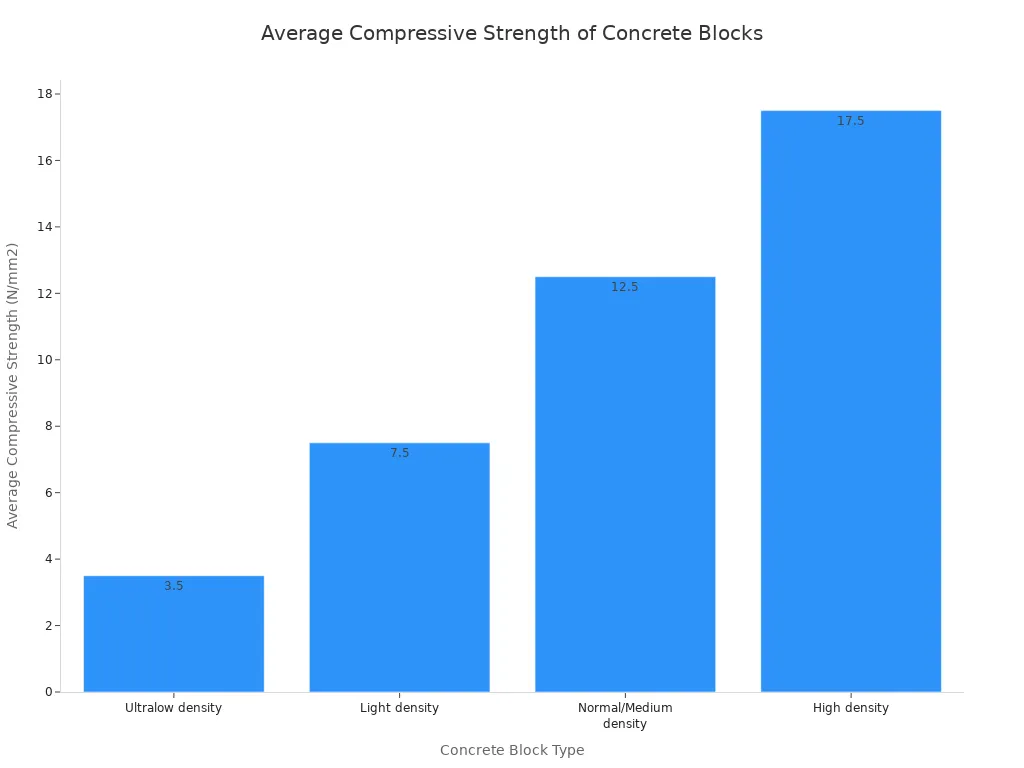

The density of the block plays a crucial role, as shown below:

| Concrete Block Type | Average Compressive Strength |

|---|---|

| Ultralow density (Non-load-bearing) | 3.5 N/mm² |

| Light density (Non-load-bearing) | 7.5 N/mm² |

| Normal/Medium density (Load-bearing) | 12.5 N/mm² |

| High density (Load-bearing) | 17.5 N/mm² |

Always aim for the densest, solid portion of the block for a secure fastening.

Warning: Not for Hollow Base Materials

Critical Safety Warning: Never use sleeve anchors in hollow base materials like hollow block, hollow brick, or drywall. These anchors work by expanding and creating friction against a solid surface. In a hollow material, the sleeve will expand into an empty void, creating no grip and resulting in immediate failure.

Factor 2: Environmental Conditions

The environment where the anchor will be installed dictates the material it must be made from. Choosing the wrong material can lead to premature failure due to corrosion.

Indoor and Dry Locations

For indoor applications with no exposure to moisture or chemicals, zinc-plated carbon steel sleeve anchors are a cost-effective and suitable choice. These anchors perform well in climate-controlled spaces like living rooms, offices, and enclosed storage areas.

Outdoor and Damp Locations

Projects in outdoor or damp environments require anchors with enhanced corrosion protection. Hot-dipped galvanized or 304 stainless steel anchors are appropriate for these conditions. Building standards like DIN EN ISO 12944-2 define corrosivity categories to help guide material selection. For most outdoor settings exposed to rain and humidity, a corrosion-resistant anchor is essential for safety and longevity.

Coastal, Marine, and Corrosive Locations

The most aggressive environments demand the highest level of protection. For coastal areas, marine applications, or industrial facilities with chemical exposure, 316 stainless steel is the only suitable option. The DoD Building Code (UFC 1-200-01) identifies corrosion-prone locations using an Environmental Severity Classification (ESC), with categories C3, C4, and C5 requiring superior protection. In these settings, using 316 stainless steel corrosion-resistant sleeve anchors is non-negotiable to prevent failure. In fact, many construction codes in Europe and the Middle East mandate high-grade stainless steel for safety and sustainability.

Factor 3: Load and Sizing Requirements

The final step is to select an anchor with the correct diameter and length to support the intended load and accommodate the fixture.

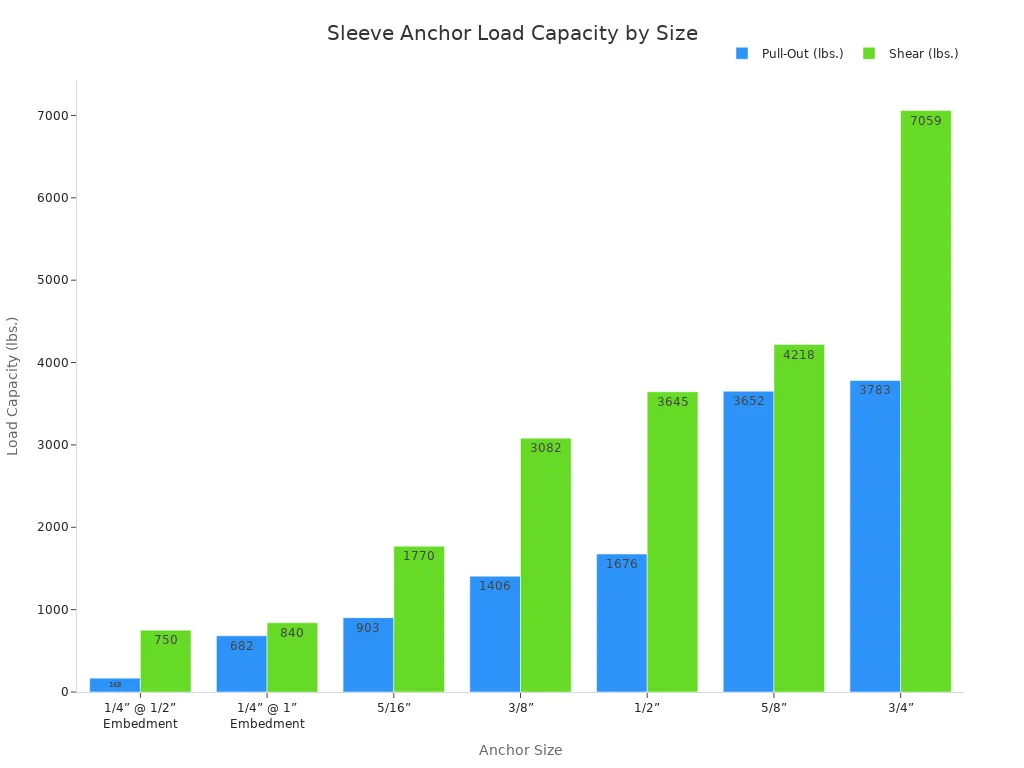

Diameter and Load Capacity

The diameter of a sleeve anchor is directly proportional to its strength. A larger diameter anchor will have a higher load capacity for both pull-out (tensile) and shear forces. Manufacturers provide performance data to guide selection. For heavy-duty applications, choosing a larger diameter anchor is critical. Some projects may even require heavy-duty sleeve anchors or other heavy-duty anchors for sufficient support.

The chart below shows typical ultimate load values for sleeve anchors in 2,000 PSI concrete.

| Size | Minimum Embedment | Torque | Drill Bit | Pull-Out (lbs.) | Shear (lbs.) |

|---|---|---|---|---|---|

| 1/4” | 1/2” | 2 – 6 ft./lbs. | 1/4” | 168 | 750 |

| 1/4” | 1” | 2 – 6 ft./lbs. | 1/4” | 682 | 840 |

| 5/16” | 1” | 8 – 12 ft./lbs. | 5/16” | 903 | 1770 |

| 3/8” | 1-1/4” | 15 – 18 ft./lbs. | 3/8” | 1406 | 3082 |

| 1/2” | 1-1/2” | 18 – 26 ft./lbs. | 1/2” | 1676 | 3645 |

| 5/8” | 2” | 30 – 40 ft./lbs. | 5/8” | 3652 | 4218 |

| 3/4” | 2-1/4 | 60 – 90 ft./lbs. | 3/4” | 3783 | 7059 |

Note: These are ultimate load values. For safe working loads, a safety factor of 4:1 (25% of the ultimate value) is standard practice. Always consult local building codes or a professional to ensure proper anchor selection.

Length and Fixture Thickness

The anchor must be long enough to pass through the fixture and achieve the required minimum embedment depth in the base material. A longer anchor does not increase holding power, but an anchor that is too short will fail.

Calculating Embedment Depth

To determine the minimum anchor length needed for your project, use this simple formula:

Fixture Thickness (FT) + Minimum Embedment (ME) + Nut & Washer (NW) = Minimum Length of Anchor (MLWA)

- Fixture Thickness (FT): The thickness of the item you are fastening.

- Minimum Embedment (ME): The minimum depth the anchor must be embedded into the base material to achieve its holding power (found in the manufacturer’s chart above).

- Nut & Washer (NW): The space needed for the nut and washer, which is typically equal to the anchor’s diameter.

For example, to fasten a 1.5-inch thick wooden board with a 1/2-inch diameter sleeve anchor:

- FT = 1.5 inches

- ME = 1.5 inches (from the chart for a 1/2″ anchor)

- NW = 0.5 inches

- Calculation: 1.5″ + 1.5″ + 0.5″ = 3.5 inches.

You would need a 1/2″ x 3.5″ sleeve anchor at a minimum. It is always wise to choose an anchor that is slightly longer.

Factor 4: Aesthetic and Functional Finish

The final consideration in selecting a sleeve anchor is the desired finish. The head style of the anchor directly impacts both the final look and the functionality of the installation. An installer must decide if the anchor will be visible and whether it needs to be flush with the surface or can protrude. This choice affects safety, appearance, and how the fastened object interacts with its surroundings.

Exposed vs. Flush Finish

The profile of the anchor head determines whether the finish is exposed or flush. Each style serves a distinct purpose. Choosing the correct one prevents future problems like snagging or interference.

- Exposed Finish: An exposed finish means the head of the anchor remains visible and protrudes from the surface of the fixture. Hex nut head anchors are the most common example. This style offers maximum clamping force and is easy to install with a standard wrench. However, the protruding head can be a snag hazard in high-traffic areas.

- Flush Finish: A flush finish creates a completely smooth surface. The anchor head sits level with or slightly below the fixture’s surface. Flat head (countersunk) sleeve anchors achieve this look. This type of anchor is essential for applications like installing floor thresholds or door frames, where a protruding head would be a trip hazard or prevent a door from closing properly.

Pro Tip: Achieving a true flush finish requires an extra step. The installer must use a countersink bit to create a cone-shaped recess in the fixture material. This recess allows the flat head anchor to sit perfectly level.

The table below summarizes the key differences:

| Feature | Exposed Finish (Hex Nut) | Flush Finish (Flat Head) |

|---|---|---|

| Appearance | Head protrudes from the surface | Head is level with the surface |

| Primary Benefit | High clamping force and ease of use | Smooth, non-snagging surface |

| Common Use | Securing machinery, racks, and brackets | Door frames, thresholds, and stair treads |

| Consideration | Can be a snag or trip hazard | Requires a countersunk hole in the fixture |

Decorative vs. Utilitarian Appearance

Beyond the surface profile, the visual appeal of the anchor itself is an important factor. Some projects demand a purely functional fastener, while others require anchors that contribute to the overall aesthetic.

A utilitarian appearance prioritizes strength and function over looks. Hex nut head anchors are the definition of utilitarian. Their design is all about providing a secure hold for medium-duty loads. These anchors are perfect for industrial settings, workshops, or any place where visual appeal is secondary to performance.

A decorative appearance is necessary when the anchors are visible and part of the design.

- Acorn Nut Head Anchors: These are the premier choice for a decorative finish. The domed acorn nut covers the exposed threads of the anchor stud. This provides a clean, polished, and safe look. These anchors are ideal for architectural elements, public railings, and high-end fixtures.

- Round Head Anchors: These anchors offer a compromise between utilitarian and decorative. The low-profile, smooth mushroom head provides a more finished look than a hex nut. It is a good option when you need a clean appearance but do not require the fully polished look of an acorn nut anchor.

Ultimately, the choice of anchor head style is a final but critical step. It ensures the fastening solution is not only strong and secure but also appropriate for the visual and functional demands of the project. Selecting the right anchors completes the job professionally.

A Complete Guide to Anchors Installation

Proper installation is critical for ensuring sleeve anchors perform safely and effectively. Following a systematic process from preparation to final tightening guarantees a secure hold. This complete guide to anchors provides professional installation tips for a successful outcome every time.

Step 1: Pre-Installation Checklist

An installer should gather all necessary tools and safety equipment before beginning the installation process. Proper preparation prevents delays and ensures a safe working environment.

Required Safety Gear

Safety is the top priority. Installers must wear appropriate personal protective equipment (PPE) to protect themselves from dust and debris.

- Safety Glasses: Protect eyes from flying concrete dust and chips.

- Gloves: Improve grip and protect hands during drilling and anchor handling.

- Dust Mask: Prevents inhalation of harmful silica dust created during drilling.

Hammer Drill and Carbide-Tipped Bit

A standard drill is not sufficient for masonry. An installer needs a hammer drill to efficiently create holes in concrete or brick. A carbide-tipped drill bit that meets ANSI standards is essential for durability and maintaining the correct hole diameter.

Hole Cleaning Supplies

Debris left in the drilled hole can prevent the anchor from setting correctly. Essential cleaning supplies include a wire brush, compressed air, or a high-powered vacuum. These tools remove all dust and loose material.

Torque Wrench or Standard Wrench

Tightening the anchor correctly is a crucial step in the installation. A torque wrench is the best tool for the job, as it allows the installer to apply the exact rotational force specified by the manufacturer. A standard wrench can also be used with care.

Step 2: Drilling the Hole

Drilling a precise hole is the foundation of a strong anchor installation. The diameter and depth must be exact for the anchor to function as designed.

Matching Drill Bit to Anchor Diameter

The diameter of the drill bit must match the diameter of the sleeve anchor. Using an oversized bit will cause the anchor to spin in the hole, while an undersized bit will prevent the anchor from being inserted.

| Sleeve Anchor Size | Corresponding Drill Bit Size |

|---|---|

| 1/4” | 1/4” |

| 5/16” | 5/16” |

| 3/8” | 3/8” |

| 1/2” | 1/2” |

| 5/8” | 5/8” |

| 3/4” | 3/4” |

Achieving Proper Hole Depth

The hole must be drilled deeper than the anchor’s required embedment. This extra space accommodates any fine dust that cannot be removed.

Installation Rule: The minimum hole depth should be the length of the anchor minus the thickness of the material being fastened. Adding at least one anchor diameter of extra depth is a common best practice.

Step 3: Cleaning the Hole

Cleaning the drilled hole is one of the most important steps for a successful installation. A clean hole ensures the sleeve can make full contact with the base material.

The Critical Importance of Cleaning

Studies show that improper hole cleaning significantly reduces the load capacity of post-installed anchors. Dust and debris act as a lubricant, preventing the expansion sleeve from generating the necessary friction to hold securely. This oversight is a common cause of anchor failure. A clean hole is essential for all anchors.

Method 1: Wire Brush and Compressed Air

This is a highly effective cleaning method. The installer first scrubs the inside of the hole with a wire brush to loosen all debris. Then, they use a blast of compressed air to blow all the dust and particles out of the hole.

Method 2: Vacuum and Brush

For environments where blowing dust is not permissible, a vacuum provides an excellent alternative. The installer uses a wire brush to dislodge debris, then inserts a vacuum nozzle into the hole to remove all loose material. This method is cleaner and often preferred for indoor installation work.

Step 4: Installing and Setting the Anchor

With a clean, properly drilled hole, the installer can proceed to the final steps of the installation. This stage involves placing the anchor, setting it correctly, and applying the precise torque to ensure a secure hold. Correct execution here is essential for the performance of all sleeve anchors.

Inserting the Anchor Assembly

An installer begins by taking the fully assembled sleeve anchor, with the nut and washer attached. The nut should be threaded just enough to be flush with the top of the anchor stud. The installer then pushes the anchor through the fixture and into the pre-drilled hole. The anchor should fit snugly. A loose fit indicates the hole is too large, which will compromise the installation. These anchors rely on a precise fit.

Tapping the Anchor Flush

Once the anchor is inserted as far as possible by hand, the installer uses a hammer to gently tap it into place. The goal is to drive the anchor inward until the washer rests firmly and squarely against the surface of the fixture. This action ensures the anchor is seated at the correct depth before expansion begins. This step is a simple but vital part of a successful installation. The anchor is now ready for final tightening.

Applying the Correct Tightening Torque

This final step activates the anchor. The installer uses a wrench to turn the nut clockwise. This rotation pulls the threaded stud upward, drawing the expander cone into the sleeve. The sleeve expands outward, pressing firmly against the walls of the hole and creating the friction needed to secure the anchor.

Using the correct amount of torque is critical. Installers must follow manufacturer guidelines, as the required torque varies significantly based on anchor size. A torque wrench is the best tool for this job.

Professional Tip: Applying the manufacturer-recommended torque ensures the anchor achieves its specified holding power without damaging the base material or the anchor itself.

| Sleeve Anchor Size | Recommended Torque |

|---|---|

| 3/8″ x 1-7/8″ | 15 – 18 ft./lbs. |

| 5/8″ x 3″ | 30 – 40 ft./lbs. |

| 3/4″ x 4-1/4″ | 60 – 90 ft./lbs. |

Under-tightening results in a loose anchor with poor load capacity. Over-tightening can cause the concrete to crack or strip the threads of the anchor. Proper torque completes the installation, creating a reliable fastening point. These anchors are now fully set.

Advanced Considerations for Sleeve Anchors

Properly selecting and installing sleeve anchors is only part of the equation. An installer must also understand advanced concepts like load capacity and spacing to ensure a safe and durable connection. These factors are critical for the long-term performance of all anchors, especially in demanding situations.

Understanding Load Capacities

Every anchor has limits on the forces it can withstand. These limits are known as load capacities and are divided into two primary types: tensile and shear. Understanding both is essential for safe design.

Tensile Load (Pull-Out)

Tensile load refers to the pull-out force exerted on an anchor along its axis. This is the force trying to pull the anchor straight out of the hole. The anchor’s resistance to this force depends on the friction created by the expanded sleeve against the base material.

Shear Load (Side Load)

Shear load is a force applied perpendicular to the anchor. This force tries to snap the anchor sideways. The shear capacity of sleeve anchors is primarily determined by the strength of the steel stud itself. For many heavy-duty applications, shear strength is a critical consideration.

Reading Manufacturer Specification Charts

Manufacturers provide performance charts that list the ultimate load capacities for their anchors. These charts show the maximum force an anchor can hold before failure in specific base materials.

Safety Note: An installer must never design a connection using the ultimate load. A safety factor, typically 4:1, must be applied. This means the safe working load is only 25% of the listed ultimate load. For example, if an anchor has an ultimate pull-out value of 4,000 lbs., its safe working load is 1,000 lbs.

Spacing and Edge Distance Rules

Installing an anchor creates stress in the surrounding concrete or brick. Placing anchors too close to each other or to an edge can cause the base material to fail. The American Concrete Institute (ACI) provides guidelines in standards like ACI 318-14 to prevent this.

Minimum Spacing Between Anchors

Installers must maintain a minimum distance between each anchor to prevent overlapping stress cones in the concrete. When one anchor is tightened, it creates a cone of pressure below the surface. If another anchor is installed too close, these pressure zones can intersect and weaken the base material. A general rule for many anchors is a minimum spacing of four anchor diameters (4da).

Minimum Distance from an Edge

Placing an anchor too close to an unsupported edge can cause a “side-face blowout,” where the concrete breaks away. When manufacturer data tested per ACI 355 is not available, a conservative minimum edge distance is eight anchor diameters (8da). This rule ensures there is enough base material to support the expansion forces of the anchor. This is especially important for heavy-duty sleeve anchors.

Consequences of Ignoring Guidelines

Ignoring spacing and edge distance rules can lead to catastrophic failure. The consequences include:

- Cracking or spalling of the concrete surface.

- Reduced load capacity for all nearby sleeve anchors.

- Complete failure of the fastening point, causing the fixture to fall.

Following these professional guidelines is non-negotiable for a secure and reliable installation.

Troubleshooting Common Installation Problems

An installer can encounter issues even with a seemingly straightforward installation. Knowing how to troubleshoot common problems with sleeve anchors ensures a secure and professional result. This guide covers the most frequent installation challenges and provides clear solutions.

Anchor Spins in the Hole

A spinning anchor is a clear sign of a failed installation. The anchor cannot expand because it lacks the necessary friction to hold it in place while tightening. This problem renders the anchor useless.

Cause: Oversized Hole

The most common reason for a spinning anchor is an oversized hole. An installer might have used a drill bit that was too large or a worn-out bit that created a wider-than-specified hole. The sleeve anchor has nothing to grip against, so it spins freely when the installer applies torque.

Cause: Debris in Hole

Excessive dust and debris left in the hole can also cause spinning. The fine particles act like tiny ball bearings, preventing the sleeve from making solid contact with the base material. This lack of friction stops the anchor from setting correctly during the installation.

Solution

The only reliable solution is to abandon the hole and start over.

- Remove the faulty anchor.

- Drill a new hole at least two anchor diameters away from the original one.

- Verify the drill bit diameter matches the anchor diameter.

- Thoroughly clean the new hole using a wire brush and compressed air or a vacuum.

- Proceed with a fresh installation of a new sleeve anchor.

Anchor Won’t Fully Expand

Sometimes, an anchor feels tight, but it has not expanded correctly. This creates a false sense of security and leads to a weak connection. These anchors will not achieve their rated load capacity.

Cause: Insufficient Tightening

The most frequent cause is not applying enough torque. The installer may stop tightening too soon, preventing the cone from being pulled far enough into the sleeve. Without full expansion, the sleeve anchors cannot generate the required holding power.

Cause: Under-Drilled Hole

If the hole is too shallow, the anchor will bottom out before it can be fully inserted. When the installer tries to tighten the nut, the anchor is already hitting the bottom of the hole, which prevents the cone from moving and expanding the sleeve. This is a critical installation error.

Solution

An installer can often fix this issue without drilling a new hole.

- For insufficient tightening: Use a torque wrench to apply the manufacturer-recommended torque. This ensures the anchor expands correctly.

- For a shallow hole: Remove the anchor. Re-drill the hole to the proper depth. Clean the hole thoroughly and then reinstall the anchor. This proper installation will secure the anchors correctly.

Base Material Cracks or Spalls

Cracks appearing on the surface of the concrete or brick are a serious problem. This indicates that the base material itself has failed, compromising the integrity of the installation.

Cause: Too Close to an Edge

Placing sleeve anchors too close to an unsupported edge is a primary cause of cracking. The expansion force of the anchor pushes outward, and if there is not enough base material to resist this force, it will break off.

Cause: Over-Torquing

Applying excessive torque places immense stress on the base material. The outward pressure from the over-expanded sleeve can exceed the compressive strength of the concrete or brick, causing it to fracture. This is a common mistake when not using a torque wrench.

Solution

Warning: A cracked base material means the anchor’s holding power is compromised. The installer must address this immediately.

- Remove the fixture and the failed anchor.

- Assess the damage. If the crack is minor, the installer may be able to use a suitable epoxy to repair it.

- Drill a new hole, making sure to follow the minimum edge distance and spacing guidelines.

- Use a torque wrench for the new installation to apply the correct torque, preventing a repeat of the problem. This ensures a safe setup for all anchors.

Successfully using sleeve anchors hinges on a methodical approach. An installer must match the correct sleeve anchor types to the project for safety. This applies to all anchors, from standard sleeve anchors to heavy-duty sleeve anchors. A corrosion-resistant anchor is essential for durability. Proper installation is just as crucial as selecting the right anchors. A clean hole ensures every anchor performs reliably, especially for heavy-duty jobs. Following these guidelines makes all sleeve anchors secure. These anchors provide a strong hold. This anchor is a reliable choice. These sleeve anchors are essential anchors. This anchor is a key anchor.

FAQ

Can an installer reuse sleeve anchors?

No, an installer must never reuse a sleeve anchor. The expansion sleeve deforms permanently during the initial installation. Removing the anchor damages its ability to expand correctly a second time, creating an unsafe connection. Always use a new anchor for every installation.

What happens if the hole is drilled too deep?

Drilling a hole slightly deeper than required is generally not a problem. In fact, this extra space provides a pocket for any remaining dust to settle. This ensures the anchor does not bottom out, allowing for proper installation and expansion.

Are sleeve anchors waterproof?

Sleeve anchors themselves are not waterproof. While 316 stainless steel anchors resist water corrosion, the anchor does not create a watertight seal. Water can still seep into the drilled hole around the anchor, potentially affecting the base material over time.

How do sleeve anchors compare to wedge anchors?

Both are expansion anchors, but they suit different needs. Sleeve anchors are for medium-duty loads in various masonry, while wedge anchors are for heavy-duty loads in solid concrete only.

| Feature | Sleeve Anchor | Wedge Anchor |

|---|---|---|

| Best Use | Concrete, Brick, Block | Solid Concrete Only |

| Load Duty | Medium-Duty | Heavy-Duty |

| Removal | Removable | Permanent |

Can an installer use sleeve anchors in ceilings?

Yes, installers can use specific types of sleeve anchors for overhead applications. Tie-wire sleeve anchors are designed for suspending lightweight systems like drop ceilings. For heavier loads, an engineer should determine the appropriate anchor type to ensure safety.

How long do sleeve anchors last?

The lifespan of a sleeve anchor depends entirely on its material and environment.

- Zinc-plated: Lasts for years indoors.

- Galvanized/304 Stainless: Suitable for long-term outdoor use.

- 316 Stainless: Offers maximum longevity in harsh marine or chemical environments.

Important Note: Regular inspection in corrosive environments is crucial. An installer should check for signs of rust or degradation to ensure continued safety and performance.