Proper installation of anchor bolts is a non-negotiable step for structural stability and safety. An improperly installed anchor creates a critical failure point, risking structural collapse and significant financial loss. A flawless concrete anchor bolt installation begins with selecting the right anchor bolts. A custom fasteners manufacturer can provide custom anchor bolts or other custom fasteners for specific needs. Mastering the correct selection and anchor bolt installation guarantees a connection that is both strong and durable, ensuring long-term structural integrity and stability.

Did You Know? Installation errors are a primary cause of anchor failure. Even minor mistakes can have major consequences for the integrity of the bolts.

Statistic Value Anchor bolt failures from installation errors 34% Exceeding shear stress with undersized bolts 22% Load capacity reduction with 1° angular deviation 18%

Understanding and Selecting the Right Anchor Bolts

Choosing the correct anchor is the first step toward ensuring structural integrity. The wide variety of anchor bolts available can be overwhelming, but understanding their fundamental differences simplifies the selection process. Each type of anchor is engineered for specific conditions and load requirements.

What Are Concrete Anchor Bolts and Why Are They Critical?

Concrete anchor bolts are essential fasteners. They provide the critical link between a structural element and its concrete base. The stability of the entire connection depends on the performance of these bolts.

The Fundamental Role in Structural Connections

Anchor bolts are threaded steel bars embedded in concrete. Their primary purpose is to transfer loads, such as tension (pulling) and shear (sideways) forces, from an attached fixture into the concrete foundation. The steel in the bolts provides tensile strength, while the surrounding concrete mass offers stability and resistance. This interaction creates a secure, load-bearing connection that is fundamental to a structure’s overall integrity.

The Consequences of Anchor Failure

An anchor failure can have catastrophic results. Understanding potential failure modes underscores the need for proper selection and installation. Common failures include:

- Steel Failure: The anchor bolt itself breaks under excessive tensile load.

- Pull-Out Failure: The anchor is pulled from the hole, indicating a bond failure.

- Concrete Cone Failure: A cone-shaped piece of concrete breaks away from the surface.

- Splitting Failure: The concrete base material cracks, often when an anchor is too close to an edge.

Key Categories: Cast-in-Place vs. Post-Installed Anchors

There are two primary categories of anchor bolts, each with a distinct installation method and application. The choice between them depends on project timing and design needs.

Cast-in-Place Anchors: The Pre-Pour Solution

Installers place cast-in-place anchor bolts into position before pouring the concrete. These bolts become an integral part of the structure as the concrete cures around them. This method generally provides the highest load capacity and reliability, making it ideal for heavy structural columns and equipment requiring maximum stability.

Post-Installed Anchors: Versatility in Existing Concrete

Installers place post-installed anchor bolts into holes drilled in cured concrete. This method offers excellent flexibility for retrofitting, renovations, and applications where anchor locations were not finalized during the initial pour. The performance of a post-installed anchor depends heavily on correct installation procedures. There are many types of anchor bolts in this category.

A Closer Look at Post-Installed Anchor Types

The different types of anchor bolts offer unique advantages. Selecting the right one is crucial for safety and performance.

Mechanical Expansion Anchors (Wedge, Sleeve, Drop-In)

These common anchor bolts create a connection by expanding against the sides of the drilled hole. They can be loaded immediately after setting. However, the expansion force induces stress in the concrete, requiring careful attention to spacing and edge distance to prevent cracking.

Undercut Anchors for High-Load Applications

Undercut anchor bolts create a mechanical interlock by expanding into a specially drilled “undercut” chamber at the bottom of the hole. This design provides superior performance for high-load and seismic applications.

Concrete Screw Anchors for Temporary and Permanent Use

These versatile bolts, often called screw anchors, cut their own threads into concrete and masonry. They are fast to install and can be removed, making them suitable for both temporary and permanent fixtures.

Adhesive (Chemical) Anchors for Maximum Strength

Adhesive anchor bolts use a two-part epoxy or resin to bond a threaded rod to the concrete. These bolts are “stress-free” during installation, allowing for closer anchor spacing. When installed correctly, adhesive anchor systems provide the strongest possible bond and are excellent for resisting vibratory loads.

How to Choose the Right Anchor for Your Application

Selecting the correct anchor extends beyond just picking one from a box. A professional must evaluate several critical factors to ensure the connection provides lasting stability and safety. The application’s specific demands dictate the ideal type of anchor.

Assessing Load Requirements: Static, Dynamic, and Seismic

An installer must first understand the forces the anchor bolts will resist. These load requirements determine the necessary strength and type of anchor.

- Static Loads: These are constant, unchanging forces, like the weight of a stationary piece of equipment.

- Dynamic Loads: These forces vary, involving vibration or sudden movement, such as from operating machinery.

- Seismic Loads: These are extreme, cyclical forces experienced during an earthquake.

For complex projects, selecting an anchor that meets industry standards like ASTM F1554 is crucial. Wedge anchors can handle both static and dynamic loads, while chemical anchors offer superior strength for critical applications with heavy dynamic forces. A structural engineer should always be involved to verify load calculations and ensure compliance with regional building codes.

Evaluating Concrete Condition: Cracked vs. Uncracked

The condition of the base material is a primary consideration. Concrete can be classified as either cracked or uncracked. Many anchor bolts are only rated for use in uncracked concrete. Using an unrated anchor in cracked concrete significantly reduces its load capacity and can lead to failure. Installers must choose an anchor specifically tested and approved for the concrete’s condition.

Considering Environmental Factors: Corrosion and Temperature

Environmental exposure affects the longevity of anchor bolts. In damp or corrosive environments, such as coastal areas or chemical plants, standard carbon steel bolts will rust and fail. In these cases, stainless steel or hot-dip galvanized bolts are necessary to resist corrosion. Extreme temperatures can also affect the performance of both mechanical and adhesive anchor bolts, making material choice critical for long-term stability.

Matching Anchor to Application: Wall, Floor, and Overhead

The installation orientation influences the forces acting on the anchor. A floor anchor primarily resists shear and tension, while an overhead anchor must support a constant tensile load. Certain bolts are designed with features that make them better suited for overhead use. Matching the anchor to its specific placement is essential for a secure installation.

Sizing Your Anchor: Diameter, Length, and Embedment

Proper anchor bolt sizing is fundamental to achieving the required load capacity. The diameter, length, and embedment depth of the bolts work together to create a strong connection. A failure in anchor bolt sizing can compromise the entire structure.

The Importance of Minimum Embedment Depth

Embedment depth is the distance the anchor is installed into the concrete. Deeper embedment allows the anchor to engage more concrete, which dramatically increases its holding power. Following the manufacturer’s specified minimum embedment depth is non-negotiable. As a general rule, increasing the embedment depth increases the load capacity.

Calculating Required Anchor Diameter and Length

The diameter of the anchor bolts directly impacts their tensile and shear strength. A larger diameter provides greater resistance to a given load. The required length depends on the embedment depth and the thickness of the fixture being attached. Proper anchor bolt sizing requires calculating the expected load requirements and selecting bolts that exceed those needs with an appropriate safety factor.

| Anchor Bolt Type | Diameter (inches) | Tension Capacity (lbs) | Shear Capacity (lbs) |

|---|---|---|---|

| Wedge Anchor | 1/2″ | 2,500 | 3,200 |

| Wedge Anchor | 3/4″ | 4,800 | 5,600 |

| Epoxy Anchor | 1/2″ | 3,000 | 3,500 |

| Epoxy Anchor | 3/4″ | 5,000 | 6,200 |

Note: These values are illustrative and depend on factors like concrete strength and embedment depth. Always consult manufacturer data for specific load capacities.

Critical Spacing and Edge Distance Rules

Installers must respect minimum spacing and edge distance rules. Placing bolts too close to each other or too near a concrete edge can cause the concrete to crack and fail, especially with expansion-style anchor bolts. Adhering to these guidelines prevents overlapping stress cones in the concrete, ensuring each anchor achieves its full load-bearing potential.

The Definitive Guide to Concrete Anchor Bolt Installation

A successful concrete anchor bolt installation depends on precision and adherence to proven procedures. Following a systematic, step-by-step process eliminates guesswork and ensures that every anchor performs to its maximum engineered capacity. From initial preparation to final cleaning, each phase is critical for structural safety.

Step 1: Pre-Installation Checklist and Preparation

Proper preparation is the foundation of a flawless installation. Before drilling the first hole, an installer must gather the correct tools and materials and thoroughly review all relevant documentation. This initial step prevents costly delays and critical errors.

Essential Tools: Hammer Drill, Bits, Torque Wrench

Having the right equipment on hand is non-negotiable. A professional toolkit ensures efficiency and accuracy throughout the anchor bolt installation process. Key tools include:

- Hammer Drill: A drill with a hammering function is essential for creating holes in concrete efficiently.

- Carbide-Tipped Masonry Bits: These bits are specifically designed to withstand the abrasive nature of concrete.

- Torque Wrench: A calibrated torque wrench is the only tool that can guarantee the bolts are tightened to the manufacturer’s exact specification.

- Hole Cleaning Equipment: A wire brush, compressed air source or blow-out pump, and a vacuum are necessary for removing debris.

- Measurement Tools: A tape measure and a level ensure accurate placement and alignment of the anchor bolts.

Required Materials: Anchors, Adhesives, Cleaning Supplies

The materials list is straightforward but critical. An installer must have the specified anchor bolts for the job, along with any required chemical adhesives for that anchor type. Cleaning supplies, such as nylon brushes and absorbent cloths, are also essential, particularly for adhesive applications.

Always Review Manufacturer’s Installation Instructions (MII)

Every anchor is part of a system, and its performance is only guaranteed when installed according to the Manufacturer’s Installation Instructions (MII). These documents provide non-negotiable specifications for drill bit diameter, hole depth, cleaning procedures, and torque values.

Professional Tip: Before starting, an installer must clean the installation site of all dirt, oil, and contaminants. A clean work surface prevents debris from falling into freshly drilled holes and ensures the fixture seats properly against the concrete. Ignoring the MII is a direct path to anchor failure.

Step 2: Drilling the Hole with Absolute Precision

Drilling is more than just making a hole; it is about creating a perfectly sized and aligned cavity for the anchor. The quality of the drilled hole directly impacts the holding power of the final installation.

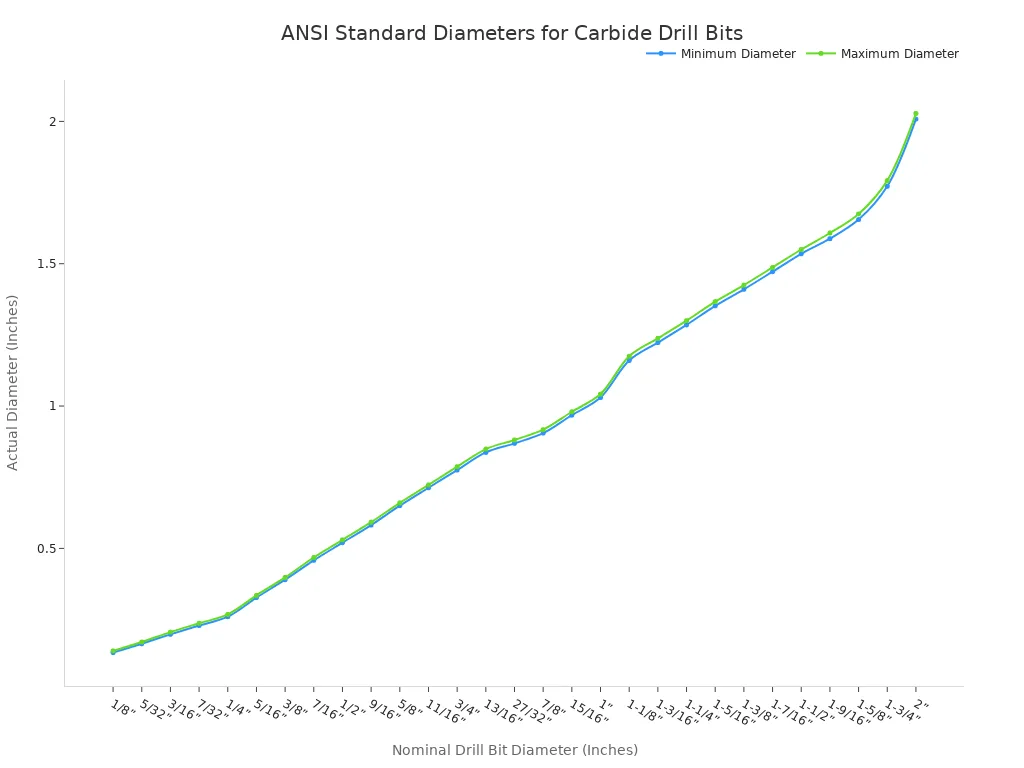

Selecting the Correct ANSI-Standard Carbide Drill Bit

Using the correct drill bit is not optional. For post-installed anchor bolts, installers must use a carbide-tipped masonry drill bit that complies with ANSI Standard B212.15. This standard ensures the bit’s diameter falls within a strict tolerance range, creating a hole that is neither too tight nor too loose for the anchor. An incorrectly sized hole will compromise the anchor’s ability to expand or bond correctly.

| Diameter of Drill Bit | Minimum Diameter | Maximum Diameter |

|---|---|---|

| 1/4” | .260” | .268” |

| 3/8” | .390” | .398” |

| 1/2” | .520” | .530” |

| 5/8” | .650” | .660” |

| 3/4” | .775” | .787” |

| 1” | 1.030” | 1.042” |

Note: This table shows a sample of ANSI B212.15 tolerances. Always verify the required bit diameter in the anchor’s MII.

Techniques for Drilling to the Specified Depth

The hole must be drilled to the depth specified in the MII to achieve the required embedment for the anchor. A simple and effective technique is to use the drill’s depth stop. If one is not available, an installer can mark the correct depth on the drill bit with a piece of tape. It is crucial not to over-drill, as this can interfere with the proper setting of certain types of anchor bolts.

How to Maintain Perpendicularity for Optimal Hold

A hole drilled at an angle reduces the anchor’s performance. The anchor must be installed perpendicular (at a 90-degree angle) to the concrete surface. To ensure a straight hole, professionals use several techniques:

- Start the hole with a center punch to prevent the drill bit from “walking.”

- Use a pre-drilled wooden block or a drill guide to keep the bit steady and perpendicular.

- Periodically pull the bit out while drilling to clear dust, which helps maintain a straighter path.

What to Do When You Hit Rebar

Hitting steel reinforcement (rebar) is a common problem. The first rule is to stop drilling immediately. Never try to power through rebar with a standard hammer drill bit, as this will destroy the bit and may damage the rebar’s integrity. The proper procedure is:

- Relocate: The simplest solution is to move the anchor location by the minimum distance allowed by the project plans and MII.

- Drill Through: If relocating is not an option, a structural engineer must approve cutting the rebar. Specialized tools, such as a diamond core bit or a dedicated “rebar eater” bit, must be used in a rotary-only drill (no hammer function) to cut through the steel. Once through, the installer can switch back to the standard bit and hammer drill to complete the hole.

Step 3: The Critical Hole Cleaning Process

A perfectly drilled hole is useless if it is not perfectly clean. This step is the most frequently skipped and is a leading cause of anchor failure. Dust and debris act as a lubricant, preventing mechanical anchors from gripping and chemical anchors from bonding.

Why Improperly Cleaned Holes Guarantee Failure

Concrete dust left in a hole creates a barrier between the anchor and the base material. For mechanical expansion bolts, this dust crushes and prevents the expansion sleeve from making solid contact with the concrete walls. For adhesive anchors, dust contaminates the epoxy, drastically reducing its bond strength and leading to pull-out failure under a fraction of the expected load.

The Blow-Brush-Blow Method Explained

The industry-standard cleaning procedure is a simple but effective cycle known as the “Blow-Brush-Blow” method. These installation techniques ensure all debris is removed.

- Blow: Use a source of oil-free compressed air or a manual blow-out pump to force loose dust out of the hole from the bottom up.

- Brush: Use a stiff wire or nylon brush with a diameter matched to the hole. Insert the brush to the bottom and twist and pull it out, repeating this several times to dislodge stubborn particles from the sides.

- Blow: Perform a final blow-out to remove all the dust loosened by the brush. The hole is clean only when no more dust emerges.

Essential Tools for Debris Removal: Wire Brushes and Air Nozzles

Professional results require professional tools. A proper cleaning kit includes steel or nylon brushes sized for each hole diameter and an air nozzle long enough to reach the bottom of the deepest hole. Using a brush that is too small or an air source that is too weak will not clean the hole effectively.

Special Cleaning Needs for Adhesive Anchor Installation

Adhesive anchors are the most sensitive to hole cleanliness. Because their capacity relies entirely on the chemical bond, the hole must be pristine. Manufacturers often require a more rigorous cleaning cycle, such as a “2x2x2” method (Blow-Brush-Blow, repeated twice).

Important: For many high-strength adhesive anchors, manufacturers specify compressed air at a minimum of 90 PSI. A hand pump or vacuum cleaner is not an acceptable substitute. Some modern systems, like the Hilti SafeSet, use a hollow drill bit connected to a vacuum to clean the hole simultaneously as it is drilled, satisfying these stringent requirements in one step.

Step 4: Anchor Installation Techniques by Type

With a clean, precisely drilled hole, the installer can proceed with the final installation. The specific installation techniques vary significantly depending on the type of anchor being used. Each method requires careful execution to ensure the anchor functions as designed.

Installing Mechanical Expansion Anchors

Mechanical expansion anchors, like wedge and sleeve anchors, rely on friction to achieve their holding power. The installation process is straightforward but demands precision.

An installer follows these critical steps for a successful installation:

- Drill the Hole: Use a hammer drill and a carbide-tipped bit matching the anchor diameter. The hole must be drilled at least 1/2-inch deeper than the required embedment to provide space for dust and debris.

- Clean the Hole: Remove all dust and debris from the hole. A combination of a wire brush and compressed air or a vacuum is essential for a clean surface.

- Prepare the Anchor: Position the washer on the anchor and thread the nut just a few turns. This protects the threads during installation.

- Drive the Anchor: Insert the anchor through the fixture and into the hole. Gently tap it with a hammer until the washer and nut are snug against the fixture.

- Set the Anchor: Use a calibrated torque wrench to tighten the nut. This action pulls the anchor shaft up, forcing the expansion clip to wedge itself firmly against the concrete walls.

⚠️ Caution: Over-tightening a mechanical anchor can cause the concrete to crack or lead to steel failure in the bolt itself. Always stop at the manufacturer’s specified torque value.

Driving and Setting Screw Anchors

Concrete screw anchors, like Tapcon® bolts, cut their own threads into the base material. This makes them fast to install, but they are susceptible to stripping if not driven correctly.

To prevent stripping and ensure a secure hold, professionals follow these guidelines:

- Use the Correct Driver: Match the driver bit to the screw head. Using the wrong size can strip the head, making proper tightening impossible.

- Drive Slowly: Use a rotation drill (not a hammer drill) on a low-speed setting. Drive the screw steadily with minimal downward pressure, allowing the threads to do the work.

- Avoid Over-Torquing: Overtightening is the primary cause of failure. It will strip the threads cut into the concrete, causing the anchor to spin freely and lose all holding value.

- Finish by Hand: For the final few rotations, switch to a hand wrench. This gives the installer a better feel for when the anchor is tight against the fixture, preventing over-torquing.

Injecting and Setting Adhesive Anchors

Adhesive anchors offer the highest load capacities but are the most technique-sensitive. The process creates a chemical bond between the threaded rod and the concrete.

The installation of adhesive anchor bolts involves several unique steps:

- Prepare the Cartridge: Attach the mixing nozzle to the adhesive cartridge. Dispense the initial amount of adhesive (typically the first two or three trigger pulls) onto a piece of scrap material until the color is uniform. This ensures the two parts of the epoxy are properly mixed.

- Inject the Adhesive: Insert the nozzle to the bottom of the clean hole. Slowly inject the adhesive while withdrawing the nozzle to avoid creating air pockets. Fill the hole approximately two-thirds full.

- Insert the Anchor Rod: Push the threaded rod into the adhesive-filled hole with a slow, twisting motion. This ensures the adhesive fully coats the threads and eliminates any remaining voids.

- Let it Cure: Allow the anchor to cure undisturbed for the manufacturer-specified time. Do not move, adjust, or apply any load to the bolts during this critical period.

Step 5: Setting, Tightening, and Curing for a Secure Hold

The final steps of the concrete anchor bolt installation lock in the anchor’s performance. Proper tightening and curing are non-negotiable for achieving the specified load capacity and ensuring long-term safety.

Applying Correct Torque with a Calibrated Wrench

Applying the correct torque is essential for setting mechanical anchor bolts and for the final tightening of all anchor types. Torque creates the clamping force that holds the fixture in place and, for expansion anchors, generates the expansion that grips the concrete.

An installer must use a calibrated torque wrench to apply the precise torque value listed in the Manufacturer’s Installation Instructions (MII).

For many general-purpose anchor bolts, the American Institute of Steel Construction (AISC) specifies a ‘snug tight’ condition. However, for proprietary post-installed anchors, the manufacturer’s specified torque value is the only acceptable standard. An engineer must provide specific torque information if a value beyond ‘snug tight’ is required.

Understanding Proof Loading and Tensioning

For critical applications, an engineer may specify proof loading to verify the installation quality. Proof loading is a non-destructive test that confirms an anchor was installed correctly. The process involves applying a specified tension load to the anchor to check for any movement or signs of failure.

Key aspects of proof loading include:

- Purpose: To verify proper installation without damaging a correctly set anchor.

- Frequency: Testing frequency depends on the job’s criticality. It can range from a 5% random sample for redundant applications to 100% for safety-critical connections.

- Load Level: The proof load is typically a percentage of the anchor’s ultimate capacity (e.g., 50%), high enough to detect installation errors but low enough to avoid damaging the anchor or concrete. This load verifies the anchor bolt tension capacity.

- Equipment: Testing requires specialized, calibrated equipment, such as hydraulic rams or torque wrenches, to apply a precise and measurable anchor bolt tension.

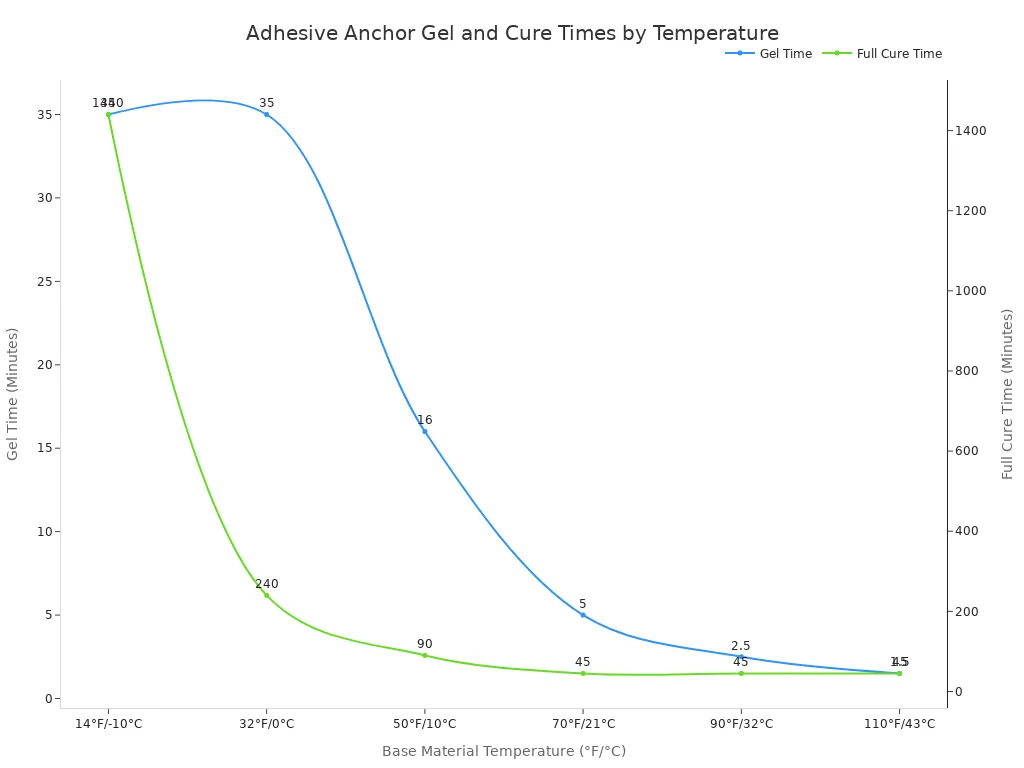

Adhering to Adhesive Anchor Gel and Cure Times

Adhesive anchors derive their strength from a chemical reaction that is highly dependent on temperature. Installers must respect two critical timeframes:

- Gel Time (Working Time): The period after injection during which the threaded rod can be inserted and adjusted.

- Cure Time (Loading Time): The total time required for the adhesive to reach its full load capacity.

Applying a load before the anchor is fully cured will lead to bond failure. Both gel and cure times decrease as the ambient and concrete temperature increases.

Typical Adhesive Anchor Cure Times (Epoxy-Acrylate)

| Base Material Temperature (°F/°C) | Gel Time | Full Cure Time |

|---|---|---|

| 110°/43° | 1.5 minutes | 45 minutes |

| 90°/32° | 2.5 minutes | 45 minutes |

| 70°/21° | 5 minutes | 45 minutes |

| 50°/10° | 16 minutes | 90 minutes |

| 32°/0° | 35 minutes | 4 hours |

| 14°/-10° | 35 minutes | 24 hours |

Note: The table above is an example. Always consult the specific manufacturer’s data sheet for the adhesive product being used, as times can vary significantly between formulations.

Strict adherence to these final setting, tightening, and curing procedures transforms a collection of individual components into a secure, reliable, and safe structural connection.

Essential Safety Protocols and Avoiding Common Mistakes

A successful concrete anchor bolt installation extends beyond technical skill; it requires a deep commitment to safety and an awareness of common errors. Following established best practices protects workers from immediate safety hazards and ensures the long-term stability and integrity of the structure.

Personal Protective Equipment (PPE) for Anchor Bolt Installation

Proper PPE is the first line of defense against job site injuries. Each piece of equipment addresses a specific risk associated with drilling concrete and installing anchor bolts.

Eye and Face Protection from Debris

Drilling concrete sends chips and dust flying at high speeds. An installer must wear safety glasses or goggles that meet ANSI Z87.1 standards to protect their eyes from impact. A full-face shield offers additional protection when working overhead.

Respiratory Protection from Crystalline Silica Dust

Concrete dust contains respirable crystalline silica, a hazardous substance that can cause severe and irreversible lung diseases. Inhaling this dust poses significant health risks.

- Silicosis: A preventable but incurable lung disease that causes scarring and stiffening of the lungs.

- Lung Cancer: A serious disease linked to occupational exposure to silica dust.

- Chronic Obstructive Pulmonary Disease (COPD)

- Kidney Disease

To mitigate these risks, installers must use a NIOSH-approved respirator, often in conjunction with a dust-collection system attached to the drill. This is a non-negotiable safety measure.

Hand and Hearing Protection During Drilling

A hammer drill generates intense vibrations and noise. Padded, anti-vibration gloves protect an installer’s hands from fatigue and nerve damage. Earplugs or earmuffs are essential for protecting hearing from the high-decibel noise produced during drilling.

Top 5 Common Installation Mistakes and How to Avoid Them

Even experienced professionals can make mistakes. Recognizing these common errors is the key to preventing them and ensuring a flawless installation.

Mistake 1: Incorrect Hole Diameter or Depth

Using a worn or wrong-sized drill bit creates an improperly sized hole, compromising the anchor’s performance. A hole that is too shallow prevents the anchor from reaching its required embedment depth, drastically reducing its load capacity.

Solution: Always use an ANSI-standard carbide bit specified in the MII and measure the hole depth before cleaning.

Mistake 2: Inadequate or Skipped Hole Cleaning

Debris left in the hole prevents the anchor from making solid contact with the concrete. This is a leading cause of anchor failure, as the resin bonds to dust instead of the substrate. The 2006 “Big Dig” tunnel collapse in Boston was a tragic example, where faulty epoxy application led to a 26-ton ceiling section falling.

Solution: Strictly follow the “Blow-Brush-Blow” cleaning method until the hole is completely free of dust.

Mistake 3: Over-Torquing or Under-Torquing the Bolt

Applying the wrong amount of torque can be disastrous. Under-torquing leaves the connection loose, while over-torquing can strip the threads or fracture the concrete, leading to a loss of stability.

Solution: Always use a calibrated torque wrench to tighten bolts to the manufacturer’s exact specification. This ensures proper tension without damaging the anchor or the concrete.

Mistake 4: Ignoring Edge and Spacing Distance Requirements

Placing anchor bolts too close to an edge or to each other creates overlapping stress zones in the concrete. This can cause the concrete to crack and spall, a failure known as “concrete cone breakout,” which compromises the stability of the entire connection.

Solution: Adhere to the minimum edge and spacing distances detailed in the anchor’s technical data sheet.

Mistake 5: Using the Wrong Anchor Type for the Load or Concrete

Not all anchor bolts are created equal. Using an anchor not rated for cracked concrete in a tension zone, or a light-duty anchor for a heavy dynamic load, is a recipe for failure.

Solution: Carefully assess the load requirements, concrete condition, and environmental factors before selecting an anchor. When in doubt, consult a structural engineer.

Post-Installation Inspection and Long-Term Maintenance

The job is not finished after the final torque. Regular inspection and maintenance are crucial for ensuring the continued safety and integrity of the anchor system.

The Initial Post-Installation Inspection Checklist

Immediately after installation, a qualified person should conduct a visual inspection. This check confirms that the correct anchor was used, spacing and edge distances are correct, and the bolts have been tightened properly. For adhesive anchors, the inspector verifies that the epoxy has cured correctly with no voids.

How to Conduct Long-Term Maintenance Checks

The frequency of maintenance depends on the structure’s risk level. High-risk structures like bridges may require checks every six months, while low-risk residential applications might be inspected every two years. The basic maintenance practices involve:

- Cleaning: Remove any dirt or debris from around the bolts with a brush.

- Tightening: Check the torque on the bolts to ensure they have not loosened over time.

- Coating: Reapply protective coatings or corrosion inhibitors as needed, especially in coastal or industrial environments.

Identifying Early Signs of Potential Anchor Failure

Vigilance can prevent catastrophic failure. Installers and maintenance personnel should look for tell-tale signs of distress:

- Corrosion: Rust stains on the concrete or visible rust on the anchor itself.

- Cracking: Fine cracks radiating from the anchor location.

- Spalling: Chipped or flaking concrete around the anchor head.

- Looseness: Any movement in the fixture or the anchor when tested.

Identifying these issues early allows for timely repairs, preserving the structure’s stability and safety.

The foundation of structural integrity lies in selecting the correct anchor bolts for the specific load and environment. A meticulous installation ensures these bolts achieve full capacity, which is critical for the structure’s stability and integrity. Consistent adherence to safety protocols and manufacturer guidelines, like those reflected in ACI 318, guarantees the long-term integrity of the anchor system. This commitment to the bolts’ integrity preserves the building’s overall structural integrity and stability.

FAQ

Can an installer reuse a concrete anchor?

Most mechanical anchors are single-use items. Removing them damages the expansion mechanism, making reinstallation unsafe. Concrete screw anchors are an exception, as manufacturers design some for temporary use and removal. An installer should always check the product specifications before attempting to reuse any anchor.

What is the best anchor for overhead applications?

Adhesive anchors and undercut anchors provide the highest reliability for overhead use. Their design creates a strong bond or mechanical interlock, making them ideal for sustained tension loads. Installers must select an anchor specifically rated for overhead applications to ensure safety and long-term performance.

Why is a calibrated torque wrench so important?

A calibrated torque wrench guarantees the correct clamping force. It prevents under-tightening, which leaves the connection loose. It also avoids over-tightening, which can damage the anchor or crack the concrete. Proper torque is essential for achieving the anchor’s specified load capacity and ensuring a secure installation.

How long do adhesive anchors need to cure?

Cure times vary significantly based on the adhesive type and the concrete’s temperature. Colder conditions require much longer cure times.

Important: An installer must always consult the Manufacturer’s Installation Instructions (MII) for the specific gel and full cure times. Applying a load prematurely will cause failure.

What should an installer do when the drill hits rebar?

The installer must stop drilling immediately. The best practice is to abandon the hole and relocate the anchor according to the project plans. If relocation is not possible, a structural engineer must approve cutting the rebar with a specialized rebar-cutting or diamond core drill bit.

Can anchors be installed in lightweight concrete?

Yes, but an installer must use anchors specifically tested and rated for lightweight concrete. This material has a lower compressive strength, which reduces the holding power of standard anchors. Using the wrong anchor type in lightweight concrete can lead to a significant loss of capacity and potential failure.