A carriage bolt is a fastener distinguished by its smooth, domed head and a square neck. This neck locks into wood, preventing rotation as someone tightens the nut. This design creates a secure fastening solution with a clean, tamper-resistant finish. The demand for reliable carriage bolts and custom fasteners continues to grow. A custom fasteners manufacturer often uses advanced bolt casting techniques to produce these essential carriage bolts.

Market Insight: The global industrial fasteners market reflects this demand. Verified Market Research projects the market will grow from USD 94.56 billion in 2024 to USD 145.11 billion by 2031.

This comprehensive guide explores various carriage bolt applications.

Understanding the Core Carriage Bolt Uses in Woodworking

Woodworking projects demand fasteners that provide strength, security, and a clean appearance. Carriage bolts excel in this role. Their design offers several key advantages over other fasteners.

- Self-Locking Hold: The square neck bites into wood, preventing the bolt from spinning. This allows for one-tool tightening from the nut side.

- Superior Strength: They provide excellent shear strength, making them ideal for joints that bear perpendicular loads.

- Aesthetic Finish: The smooth, domed head offers a visually pleasing, low-profile finish that prevents snagging. This is a distinct advantage over industrial-looking hex bolts.

- Load Distribution: The wide head distributes clamping force over a larger area. This prevents the bolt head from damaging the wood surface.

These features make them a top choice for many carriage bolt uses in both professional construction and home improvement and diy projects.

Deck, Porch, and Patio Construction

Outdoor structures must withstand weather and heavy use. Carriage bolts provide the necessary durability for these demanding environments.

Securing Deck Joists to Support Posts

Builders often use carriage bolts to create strong, load-bearing connections between deck joists and support posts. The bolt passes through the joist and post, where a washer and nut secure it. This method provides immense shear strength, which is critical for deck safety and stability.

Attaching Railing Posts and Balusters

Safety railings require a secure attachment that will not loosen over time. The self-locking neck of a carriage bolt ensures railing posts remain firmly in place. Their smooth heads also eliminate sharp edges, making the railing safer to the touch.

Assembling Pergola and Gazebo Frames

The assembly of large timber frames for pergolas and gazebos is one of the most common uses of carriage bolts. They effectively join heavy beams and posts, creating robust structures that can support significant weight and resist environmental stresses.

Outdoor Furniture and Play Structures

The combination of strength and safety makes carriage bolts essential for building items used daily by families.

Building Picnic Tables and Benches

For picnic tables and benches, carriage bolts fasten legs, seats, and tabletops together. Their smooth heads prevent snagging on clothing, and their strength ensures the furniture remains stable and safe for years. This is a classic example of carriage bolt applications in woodworking and furniture assembly.

Assembling Swing Sets and Playsets

Safety is the top priority for playsets. The smooth, rounded heads of carriage bolts are mandated by safety standards to prevent cuts and scrapes. The square neck’s grip in the wood also resists loosening from the constant vibration of play, a common failure point for other fasteners.

Constructing Raised Wooden Garden Beds

Constructors use carriage bolts to join the corner boards of raised garden beds. This creates a strong frame capable of containing the pressure of soil and water. Hot-dip galvanized or stainless steel carriage bolts are recommended here to prevent corrosion.

Interior Carpentry and Framing

While known for outdoor use, many interior carriage bolt uses exist, especially in heavy-duty construction.

Joining Large Timbers in Post-and-Beam Work

In post-and-beam construction, carriage bolts connect massive timbers. These structural connections must meet strict building codes. Engineers specify carriage bolts for their shear strength when attaching beams to the sides of posts.

Note: Always use code-compliant, rated fasteners for load-bearing structural connections. Verify that the chosen carriage bolts meet local building requirements for strength and corrosion resistance.

Assembling Custom Wooden Furniture

Designers of custom furniture often choose carriage bolts for their rustic aesthetic and reliable strength. These common applications are found in building bed frames, heavy tables, and other pieces where robust joinery is part of the design.

Building Sturdy Workshop Shelving

Workshop shelving must support heavy tools and materials. Using carriage bolts to assemble the frame ensures the unit is strong, stable, and capable of handling significant weight without failure.

Construction and Structural Applications for Carriage Bolts

Beyond woodworking, carriage bolts are fundamental in various construction and structural applications. Their strength and tamper-resistant design make them indispensable for building durable infrastructure. These heavy-duty applications demand fasteners that can withstand significant loads and harsh environmental conditions.

Fencing and Gate Installation

Proper fencing relies on strong connections that resist weather and physical stress. Carriage bolts provide the necessary stability for long-lasting fence and gate systems.

Attaching Fence Rails to Posts

Contractors use carriage bolts to securely fasten horizontal fence rails to vertical posts. The bolt’s square neck digs into the wooden post, preventing it from turning during tightening. This creates a solid connection that can support the weight of the fence panels and resist force from wind or impact. This is one of the most common carriage bolt uses.

Mounting Hinges and Latches on Wooden Gates

Gate hardware requires a secure mounting that will not loosen with repeated use. The smooth, domed head of a carriage bolt is ideal for this task. It provides a clean look and prevents tampering from the outside, enhancing the security of the gate.

Assembling Gate Frames

Builders assemble the frames of heavy wooden gates using carriage bolts. These fasteners provide the shear strength needed to keep the gate square and prevent sagging over time. For agricultural equipment and fencing, selecting the right material is crucial.

| Feature | Galvanized Carriage Bolts | Stainless Steel Carriage Bolts |

|---|---|---|

| Corrosion Resistance | Moderate (zinc layer) | High (throughout material) |

| Ideal Use Case | General outdoor wood structures | Marine, coastal, decorative |

| Lifespan | 10+ years (mild exposure) | 20+ years (harsh conditions) |

| Price Range | More budget-friendly | Higher cost, premium durability |

Dock, Pier, and Marina Construction

Marine environments are exceptionally corrosive, making fastener selection a critical safety decision. The right carriage bolt uses ensure structural integrity against constant moisture and chemical exposure.

Assembling Dock Frames and Walkways

Crews assemble the primary framework of docks and piers with heavy-duty carriage bolts. These connections must handle constant loads and the dynamic forces of water. For freshwater, hot-dip galvanized steel is a suitable choice.

Fastening Bumper Guards and Cleats

Bumper guards and mooring cleats are attached to docks using carriage bolts. The bolts must endure direct impact and high tensile loads. The smooth head minimizes snagging on ropes and equipment.

Securing Floating Dock Sections

Connecting floating dock sections requires fasteners that can withstand constant movement. For these carriage bolt applications, material choice is paramount.

In saltwater environments, 316 marine-grade stainless steel is not optional—it’s mandatory. The added molybdenum in 316 stainless steel provides true saltwater resistance. Never compromise on fastener quality in saltwater; the cost difference is minimal compared to reconstruction costs from premature failure.

Concrete Formwork and Scaffolding

Temporary structures in construction also rely on the strength of carriage bolts for safety and reliability.

Securing Wood Forms for Concrete Pours

Workers use carriage bolts to assemble and secure wooden forms for concrete foundations and walls. The bolts hold the forms together against the immense pressure of wet concrete.

Temporary Bracing and Support Structures

On job sites, crews erect temporary bracing for walls and other structural elements using carriage bolts. Their strength and ease of installation and removal make them ideal for these heavy-duty applications.

Specialized and Niche Carriage Bolt Applications

The utility of carriage bolts extends far beyond large-scale construction into specialized fields. Their unique design solves specific challenges in security, manufacturing, and equipment repair. These niche carriage bolt uses highlight the fastener’s versatility.

Security and Tamper-Resistance

The primary security feature of a carriage bolt is its head design. The smooth, domed head offers no purchase for standard tools like screwdrivers or wrenches. This simple characteristic makes it incredibly difficult to remove the bolt from the head side, deterring theft and vandalism.

Securing Public Fixtures and Park Benches

Municipalities frequently choose carriage bolts to install park benches, trash receptacles, and other public fixtures. Their tamper-resistant nature ensures these items remain securely in place. The design provides several key advantages for public infrastructure:

- It offers a low-profile, smooth finish.

- It reduces the risk of snagging on clothing.

- It prevents loosening from vibration or tampering.

Fastening Public Signage and Information Boards

Public signs must remain in place to convey important information. Using carriage bolts to mount signs to wooden or metal posts prevents their unauthorized removal. This ensures that street signs, trail markers, and public notices serve their intended purpose without interruption.

Reinforcing Garage Door Hardware

For home security, installers use carriage bolts to attach exterior hinges, handles, and locks on garage doors. An intruder cannot simply unscrew the hardware from the outside. This simple upgrade adds a significant layer of protection against forced entry.

Securing Shed and Barn Doors

Similar to garage doors, shed and barn doors are common targets for theft. Fastening hasps, hinges, and slide bolts with carriage bolts makes these entry points much more secure. The bolt’s square neck bites into the wood, while the smooth exterior head leaves no vulnerability.

Automotive and Trailer Assembly

The field of automotive and trailer manufacturing finds many uses for these fasteners. Strength and appearance are both critical considerations in these applications.

Fastening Trailer Bed Flooring

In automotive and trailer manufacturing, workers use carriage bolts to fasten wooden planks or metal plates to a trailer’s frame. The low-profile head creates a smooth, snag-free floor, which is essential for easily sliding cargo on and off. The bolt’s strength ensures the floor can handle heavy loads.

Securing Body Panels on Vintage Vehicles

Restorers of classic cars and trucks often seek out carriage bolts. They use them to secure body panels, running boards, and fenders. This specific carriage bolt application provides a strong connection while maintaining a period-correct, vintage aesthetic that is crucial for authentic restorations.

Agricultural Equipment Repair

Farm equipment endures constant vibration and high stress. The robust nature of carriage bolts makes them ideal for repairs in this demanding environment.

Pro Tip: When repairing farm implements, always use Grade 5 or higher carriage bolts with locking nuts to resist loosening from constant machine vibration.

Attaching Components on Farm Implements

One of the most common agricultural carriage bolt uses involves securing components in farm machinery. They are used to attach guards, plates, and wear parts on plows, cultivators, and harvesters. Their durability ensures repairs hold up through long seasons of hard work.

Repairing Wooden Crates and Bins

Farmers often use large wooden crates and bins for harvesting and transport. Over time, these containers can weaken. Using carriage bolts to reinforce corners and replace old fasteners is a cost-effective way to extend the life of these essential items.

A Deep Dive into Carriage Bolt Types

Selecting the correct fastener goes beyond just size and material. Installers must understand the different types of carriage bolts available to ensure optimal performance. Each design variation offers unique advantages for specific materials and applications. Exploring these types of carriage bolts reveals how specialized engineering solves common fastening challenges.

Standard Round Head, Square Neck

This is the most common and widely recognized carriage bolt. Its simple, effective design has made it a staple in construction and woodworking for decades.

The Universal Choice for Wood

The standard carriage bolt is engineered primarily for wood. As a user tightens the nut, the square neck pulls into the wood fibers. This action locks the bolt in place, preventing it from spinning. This self-locking feature allows for easy, one-person installation with a single wrench.

Best for Wood-to-Wood and Wood-to-Metal

These carriage bolts excel at joining two wooden components, such as a beam to a post. They are also highly effective for fastening wood to a metal plate. In this case, the bolt passes through the wood first, allowing the square neck to lock securely before the bolt goes through the metal component.

Ribbed Neck (Finned Neck) Carriage Bolts

A ribbed neck carriage bolt replaces the single square neck with a series of fins or splines around the bolt shank, just under the head. This design provides a different kind of grip.

Designed for Softer Materials

The fins on a ribbed neck bolt are less aggressive than a square neck. This design feature makes them ideal for use in softer materials that might split under the pressure of a traditional square neck.

Gripping in Plywood and Particle Board

Plywood, OSB, and particle board are prone to splitting and delamination. The multiple points of contact from the ribbed neck distribute the locking force more evenly. This allows the bolt to grip securely without damaging the integrity of these engineered wood products.

Use in Thin Gauge Metal Sheets

The fins can also effectively lock into pre-punched holes in thin sheet metal. The splines bite into the edges of the hole, providing the anti-rotation grip needed to tighten the nut securely.

Short Neck Carriage Bolts

As the name implies, these bolts feature a significantly shorter square neck compared to the standard version. This modification is a specific solution for applications where material thickness is minimal.

Applications in Sheet Metal

Short neck carriage bolts are preferred in many sheet metal applications. A standard neck is often too long and would create an obstruction, preventing the bolt head from seating flush against the metal surface. The short neck design avoids this blockage, ensuring a tight and proper fit.

Use with Pre-Drilled Metal Channels

These bolts are ideal for use in pre-drilled metal channels or tracks where clearance is limited. The design allows for convenient single-side installation because it prevents the bolt from turning as someone tightens the nut, even in a confined space.

Flat Head Carriage Bolts

Flat head carriage bolts represent a significant design evolution from the standard domed-head version. This specialized fastener features a flat top surface and a tapered, conical shape under the head. This design allows the bolt head to sit perfectly flush with the material’s surface, creating a smooth, seamless finish. The square neck remains beneath the conical section, providing the same anti-rotation function as other carriage bolts.

Achieving a Completely Flush Finish

The primary purpose of a flat head carriage bolt is to create a surface with no protrusions. Installers achieve this by using a countersink bit to drill a cone-shaped recess into the material. The bolt head then fits perfectly into this recess. This method is essential for applications where a smooth surface is critical for function or safety.

Installation Tip: For a perfect fit, the angle of the countersink bit must match the angle of the bolt’s head, which is typically 82 degrees. Proper depth control is crucial. A recess that is too shallow leaves the head proud, while one that is too deep can weaken the material.

This flush finish prevents snagging on clothing, skin, or other objects. It also allows for other components to be placed directly over the fastener head without any gaps. The result is a clean, professional, and integrated connection that looks intentional and well-executed.

Ideal for Concealed Fastening in Fine Woodworking

Fine woodworking and high-end furniture making demand both strength and aesthetic perfection. Flat head carriage bolts provide an elegant solution for joining components where the fastener head must be invisible or unobtrusive. Their ability to disappear into the wood surface makes them a superior choice for premium projects.

Woodworkers use these specialized carriage bolts in several key areas:

- Tabletops and Countertops: They secure tops to frames without creating bumps on the usable surface.

- Stair Treads and Risers: They provide immense structural strength for staircases while ensuring a smooth, trip-free walking surface.

- Custom Cabinetry: They can join cabinet frames or attach hardware in a way that is both strong and visually clean.

- Architectural Millwork: They fasten decorative wood elements where visible hardware would detract from the design.

In these applications, the fastener provides the robust clamping force of a bolt without the industrial look of a hex head or the bump of a domed head.

Choosing the Right Material and Finish for Your Carriage Bolts

The longevity and safety of a connection depend heavily on the bolt’s material and finish. An installer must match the fastener’s properties to the project’s environmental and structural demands. This selection process is critical for ensuring a durable and reliable assembly.

Common Steel Grades and Their Uses

Steel carriage bolts are categorized by grade, which indicates their tensile strength. Higher grades signify greater strength.

Grade 2 Low Carbon Steel for Light-Duty Use

Grade 2 bolts are the most common and economical option. They are made from low-carbon steel. These fasteners are suitable for light-duty, non-structural projects like assembling garden beds or workshop shelving where high load capacity is not a primary concern.

Grade 5 Medium Carbon Steel for Structural Loads

Grade 5 bolts are heat-treated for increased strength. They are the standard for most structural woodworking, including deck frames, pergolas, and playsets. Their strength makes them reliable for connections that bear significant weight and stress.

Grade 8 Alloy Steel for High-Stress Applications

Grade 8 bolts are made from a quenched and tempered alloy steel. This process gives them the highest tensile strength. They are specified for heavy-duty applications where extreme stress and load are expected, such as automotive suspensions or heavy machinery repair.

Corrosion-Resistant Coatings

A protective coating is essential for preventing rust on steel bolts, especially in outdoor or damp environments.

Zinc-Plated Steel for Indoor/Dry Use

Zinc plating provides a thin, bright coating that offers minimal corrosion resistance. It is adequate for indoor applications like furniture assembly where the bolts will not be exposed to moisture.

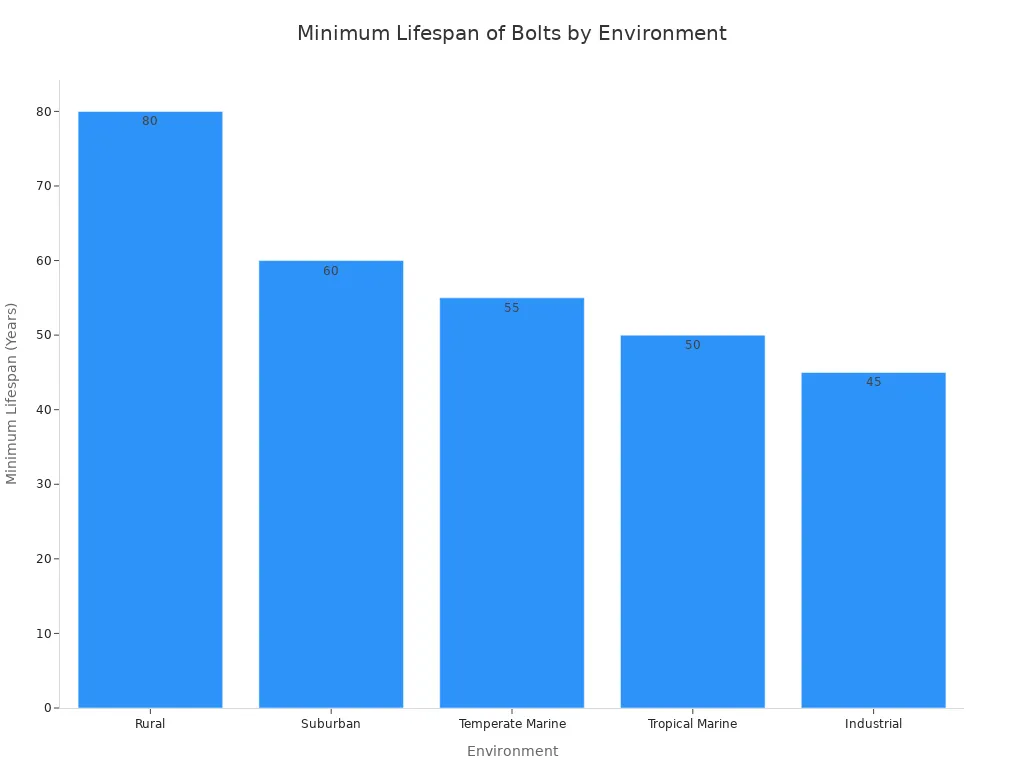

Hot-Dip Galvanized Steel for Outdoor Exposure

Hot-dip galvanizing creates a thick, durable layer of zinc that metallurgically bonds to the steel. This process offers superior, long-term protection for outdoor structures. Galvanized carriage bolts are the standard choice for decks, fences, and docks. The coating’s lifespan varies by environment but consistently provides decades of protection.

Ceramic and Polymer Coatings for Extreme Environments

Specialized ceramic or polymer coatings offer maximum protection in harsh conditions. These advanced finishes resist chemicals, abrasion, and extreme temperatures. They are often used in industrial or marine heavy-duty applications.

Stainless Steel Options for Longevity

Stainless steel contains chromium, which creates a passive, corrosion-resistant layer on the surface. It is an ideal material for long-lasting connections.

18-8 (304) Stainless Steel for General Corrosion Resistance

18-8 stainless steel, also known as Type 304, contains approximately 18% chromium and 8% nickel. It offers excellent corrosion resistance in most atmospheric conditions. 18-8 stainless steel carriage bolts are a great choice for outdoor furniture and freshwater applications.

316 Marine-Grade Stainless Steel for Saltwater Exposure

Type 316 stainless steel provides the ultimate corrosion resistance. Its key advantage comes from a simple but crucial chemical addition.

The primary distinction is the inclusion of 2-3% molybdenum in 316 stainless steel, which is absent in 304. This molybdenum content significantly boosts resistance to pitting and crevice corrosion, especially in chloride-rich environments like saltwater.

This makes 316 stainless steel carriage bolts the only acceptable choice for projects in or near saltwater, such as coastal docks, piers, and boats.

Specialty Materials for Specific Needs

While steel is the workhorse of the fastener world, certain projects demand materials with unique properties. Specialty materials provide solutions where standard steel falls short in terms of corrosion resistance, weight, or aesthetic appeal. Installers select these advanced options to meet very specific engineering and design requirements.

Silicon Bronze for Marine and Aesthetic Applications

Builders and artisans choose silicon bronze for its combination of strength, exceptional corrosion resistance, and visual beauty. This copper-based alloy possesses unique properties that make it a premium choice for specialized carriage bolts. It naturally resists corrosion in harsh marine environments, often outperforming even some grades of stainless steel, especially in underwater applications.

Silicon bronze carriage bolts are a top choice for traditional wooden boat building and high-end architectural restoration. Their warm, golden hue deepens to a rich patina over time, adding a distinguished look that cannot be replicated by coated steel fasteners.

This material provides the necessary strength for structural connections while delivering an unmatched aesthetic finish. Its use signifies a commitment to both longevity and superior craftsmanship, making it ideal for projects where every detail matters.

Aluminum for Lightweight, Corrosion-Resistant Fastening

Aluminum offers an excellent solution when weight is a primary concern. This material is significantly lighter than steel but still provides good strength and natural corrosion resistance. An invisible layer of aluminum oxide forms on its surface, protecting the metal from environmental factors. This makes aluminum carriage bolts a practical choice for specific, non-structural uses.

Key benefits of aluminum fasteners include:

- Excellent Strength-to-Weight Ratio: It provides reliable fastening without adding significant mass to an assembly.

- Natural Corrosion Resistance: It performs well in damp environments without needing an additional coating.

- Non-Magnetic Properties: It is suitable for use in sensitive electronic or scientific equipment.

Important Note: Professionals must prevent galvanic corrosion when using aluminum. Direct contact between aluminum and a dissimilar metal, like steel, can cause the aluminum to corrode rapidly in the presence of an electrolyte. Using nylon washers or other insulators is a common practice to prevent this issue.

How to Select the Correct Carriage Bolt Size

Choosing the correct size is a critical step for any project involving carriage bolts. The bolt’s dimensions directly impact the connection’s strength, security, and overall integrity. A precise selection ensures a safe and durable final assembly.

How to Measure a Carriage Bolt Correctly

Accurate measurement is the foundation of proper bolt selection. An installer must understand how to measure a carriage bolt according to industry standards to avoid errors. The two primary dimensions are diameter and length.

Measuring Diameter (Shank, Not Threads)

The diameter of a carriage bolt refers to the thickness of its shank, which is the unthreaded portion of the bolt shaft. A common mistake is measuring the outer threads. For an accurate reading, a professional uses a caliper to measure the smooth shank. This measurement determines the bolt’s fundamental strength and the required pilot hole size.

Measuring Length (From Under the Head to the End)

The length measurement for carriage bolts follows a specific rule. The measurement starts from the flat surface directly beneath the domed head and extends to the very tip of the threaded end.

The domed head itself is never included in the official length measurement. This standard ensures consistency, as the head’s function is to distribute load, not contribute to the bolt’s reach through materials.

A tape measure or caliper can provide this measurement.

Understanding Diameter and Load Capacity

A bolt’s diameter is directly proportional to its ability to handle stress and weight. Selecting the appropriate diameter is a non-negotiable aspect of structural safety.

Matching Bolt Diameter to Project Load

A larger diameter provides greater shear strength and tensile strength. For light-duty projects like assembling a small planter box, a smaller diameter bolt may suffice. For structural applications like deck framing or playset assembly, a larger diameter is essential to support the expected loads safely.

Common Diameters: 1/4″ to 3/4″

Carriage bolts are available in a range of standard diameters. Each size is suited for different levels of stress.

- 1/4″ to 3/8″: Used for light-duty applications, furniture, and general repairs.

- 1/2″: A common choice for deck railings, fences, and moderately loaded structures.

- 5/8″ to 3/4″: Reserved for heavy-duty construction, such as post-and-beam connections and dock framing.

Determining the Correct Bolt Length

Calculating the required bolt length prevents issues like insufficient thread engagement or excessive protrusion. The calculation is a straightforward process.

Calculating Length for Material Thickness

The first step is to sum the thickness of all materials the bolt will pass through. For example, joining two 2×4 boards (each 1.5 inches thick) requires a bolt that can pass through at least 3 inches of material.

Accounting for Washer and Nut Height

The bolt must be long enough to extend beyond the materials to accommodate the hardware. An installer must add the thickness of the washer and the height of the nut to the initial material thickness measurement. A properly sized bolt will have at least two full threads showing past the tightened nut.

Thread Pitch Explained (UNC vs. UNF)

Thread pitch is a critical specification that defines the distance between threads on a bolt’s shank. It determines how a nut tightens and how securely the fastener holds. In the Unified Thread Standard (UTS) system, pitch is expressed as threads per inch (TPI). The two most common classifications are UNC and UNF.

- UNC (Unified National Coarse): These bolts have fewer threads per inch. The threads are deeper and have a steeper angle.

- UNF (Unified National Fine): These bolts have more threads per inch. The threads are shallower and more closely spaced.

Understanding this difference is essential for selecting the right fastener for the job.

Why Coarse Threads (UNC) are Standard for Carriage Bolts

Professionals overwhelmingly choose UNC threads for the vast majority of carriage bolt applications. This preference is based on several practical advantages, especially when working with wood. Coarse threads are the default for nearly all general-purpose carriage bolts found in hardware stores.

The primary reasons for this standard include:

- Faster Installation: Fewer threads per inch mean a nut travels further with each rotation. This significantly speeds up assembly on a job site.

- Reduced Cross-Threading: The wider spacing between threads makes it more difficult to accidentally cross-thread the nut, preventing damage to the bolt.

- Superior Grip in Wood: The deeper, more aggressive threads bite securely into soft materials like wood without stripping the fibers.

- Debris Tolerance: UNC threads are less likely to get clogged with dirt, rust, or wood fibers, ensuring a smoother and more reliable tightening process.

When Fine Threads (UNF) Might Be Used

While less common, UNF threads have a distinct role in specialized applications. Their unique characteristics make them the superior choice where precision and vibration resistance are paramount. Installers might seek out fine-threaded carriage bolts for specific mechanical or automotive projects.

Pro Tip: In applications involving constant vibration, such as mounting components on engines or heavy machinery, UNF threads offer a distinct advantage. The increased surface area contact between the nut and bolt threads creates more friction, making the connection naturally more resistant to loosening over time.

Fine threads are also preferred for tasks requiring precise tension adjustments. The smaller pitch allows for finer control over the clamping force. Because they have a slightly larger minor diameter (the diameter at the root of the threads), they also offer a marginal increase in tensile strength, making them suitable for high-stress metal-to-metal connections.

A Step-by-Step Installation Guide

Proper installation ensures that carriage bolts provide maximum strength and security. Following a systematic process guarantees a professional result and a durable connection. This guide outlines the essential steps for a successful and easy installation.

Tools and Preparation

Thorough preparation is the first step toward a flawless installation. Gathering the correct tools and marking the materials accurately prevents mistakes and saves time.

Marking and Drilling the Pilot Hole

An installer first marks the precise center point for the bolt. For the cleanest and most accurate holes in wood, professionals often use a spurred wood bit. This type of bit reduces splintering at the entry and exit points of the hole.

Selecting the Correct Drill Bit Size

Choosing the right drill bit is critical. The drill bit must have the same diameter as the shank of the carriage bolt. For instance, a 1/2-inch diameter bolt requires a 1/2-inch drill bit. This ensures a snug fit that allows the square neck to grip the wood properly.

Gathering Washers, Nuts, and Wrenches

Before starting, an installer should gather all necessary components. A complete toolkit prevents interruptions during the assembly process.

- Drill and appropriate wood drill bit

- Hammer or rubber mallet

- Correctly sized carriage bolts

- Washers and nuts

- Spanner or ratchet with a socket

The Installation Process

With the materials prepared, the installation itself is a straightforward procedure. Each step builds upon the last to create a secure joint.

Inserting the Bolt Through the Hole

The installer inserts the bolt through the pre-drilled hole. The bolt should pass through all layers of material without excessive force.

Seating the Square Neck with a Mallet

A gentle tap with a mallet on the domed head seats the square neck into the wood. This action engages the anti-rotation feature, which is the key function of all carriage bolts.

Installing the Washer and Nut

A washer is placed over the threaded end of the bolt. The washer distributes the load from the nut. The nut is then threaded onto the bolt by hand until it is snug.

Tightening to the Correct Torque

The installer uses a wrench to tighten the nut. The goal is a firm fit where the washer is pressed flat against the surface. Tightening should stop once the wood under the washer begins to compress slightly. This visual cue is a more reliable indicator of tightness than a specific torque value.

Common Installation Mistakes to Avoid

Avoiding common errors is essential for the structural integrity of the connection. Awareness of these pitfalls helps ensure a long-lasting and safe assembly.

Over-tightening and Crushing Wood Fibers

Excessive force when tightening can crush wood fibers. This action permanently damages the material and weakens the joint. An installer should watch for signs of a deforming washer or compressed wood and stop tightening immediately.

Drilling an Oversized Pilot Hole

A pilot hole that is too large prevents the square neck from locking into the material. The bolt will spin freely as someone tries to tighten the nut. This mistake completely defeats the primary benefit of using carriage bolts.

Forgetting to Use a Washer Under the Nut

A washer is not an optional component. It prevents the nut from digging into the wood surface during tightening. Forgetting the washer concentrates pressure in a small area, which can damage the material and compromise the connection’s strength.

Techniques for Removing Carriage Bolts

While installing carriage bolts is straightforward, removal can sometimes present challenges, especially after years of exposure to the elements. Professionals use a range of techniques, from simple procedures to more advanced methods for stubborn fasteners.

Standard Removal Procedure

For most situations, removing a carriage bolt is the reverse of its installation. This process requires only basic hand tools.

Loosening and Removing the Nut

An installer uses a socket or spanner wrench to turn the nut counter-clockwise. The bolt’s square neck should hold it steady in the wood. The professional continues turning until the nut is completely off the bolt’s threads.

Tapping the Bolt Out from the Threaded End

Once the nut and washer are removed, the installer gently taps the threaded end of the bolt with a hammer. This action pushes the bolt back through the hole. The bolt should slide out without significant force.

Removing Difficult, Stripped, or Rusted Bolts

Corrosion or damaged wood can cause the bolt to spin in its hole, making removal difficult. In these cases, a technician must employ more advanced methods.

Pro Tip: Before attempting forceful removal, apply a penetrating oil like WD-40 or Kroil to the nut and threads. Allowing it to soak can help break the bonds of rust and make the process much easier. Applying heat to the nut can also expand it, helping to break a corrosion seal.

Using a Locking Wrench on the Domed Head

If the square neck no longer grips the wood, the entire bolt will spin. A technician can clamp a pair of locking pliers or a large wrench onto the domed head to hold it steady. This provides the necessary counter-force to loosen the nut. Another technique involves using a rotary tool to cut a deep groove into the head, allowing a large flathead screwdriver to hold the bolt.

Cutting the Bolt with an Angle Grinder or Saw

When a nut is completely seized, destructive removal may be the only option. An operator can use an angle grinder or a reciprocating saw with a metal-cutting blade to cut through the bolt. The most common method is to cut the bolt shaft in the gap between the two pieces of material being joined.

Using a Nut Splitter for Seized Nuts

A nut splitter is a specialized tool designed for this exact problem. It works by applying precise pressure to crack the seized nut open without damaging the bolt’s threads.

- The tool is placed over the nut.

- A screw on the splitter is tightened against the nut.

- The immense pressure forces a wedge into the side of the nut, splitting it open.

As a final resort for stubborn carriage bolts, a technician can drill through the center of the bolt. This heats the fastener and relieves pressure, often allowing it to be extracted. These techniques ensure that even the most difficult carriage bolts can be removed effectively.

In 2026, carriage bolts remain a superior fastener. They provide security, strength, and a clean finish for countless projects. Successful carriage bolt applications depend on correctly selecting the bolt’s type, material, and size for specific demands. This comprehensive guide explains the principles of various carriage bolt uses. Mastering these concepts allows professionals and DIYers to achieve durable and reliable results with carriage bolts.

FAQ

Why is the head of a carriage bolt smooth?

The smooth, domed head provides a safe, low-profile finish. It prevents snagging on clothing or skin. This design also makes the fastener tamper-resistant from the head side, as a wrench cannot grip it.

What is the purpose of the square neck?

The square neck locks into the wood or a square hole in metal. This action prevents the bolt from spinning. An installer can then tighten the nut from one side with a single tool.

Do you always need a washer with a carriage bolt?

Yes, a professional always places a washer under the nut. The washer distributes the clamping force over a wider area. This prevents the nut from damaging the material surface during tightening and improves the connection’s strength.

How do you stop a carriage bolt from spinning during removal?

An installer can grip the domed head with locking pliers. This provides the necessary counter-force to loosen a rusted or stripped nut. Applying a penetrating oil beforehand often helps break the corrosion seal.

Can you use carriage bolts in metal?

Yes, installers can use carriage bolts in metal. The application requires a pre-punched square hole that matches the size of the bolt’s neck. This allows the neck to lock securely, preventing rotation during tightening.

What is the difference between galvanized and stainless steel bolts?

Galvanized bolts have a protective zinc coating for outdoor use. Stainless steel has corrosion resistance throughout the entire material. Professionals use 316 stainless steel for saltwater environments, as it offers superior, long-term protection.

What does the “grade” of a carriage bolt mean?

The grade indicates the bolt’s tensile strength. Higher grades signify stronger bolts.

- Grade 2: For light-duty, non-structural use.

- Grade 5: For most structural applications like decks.

- Grade 8: For high-stress, heavy-duty connections.

See Also

Page Not Found: Navigating The Digital Void Of Missing Content