Professionals divide the main types of anchor bolts into two primary groups: mechanical anchor bolts and adhesive anchor bolts. Selecting the correct anchor bolts for any construction project depends on three key factors:

- Load requirements

- Base material (e.g., concrete, brick)

- Installation environment

Mechanical options create a connection through expansion. Adhesive types bond the fastener using a high-strength resin. For unique needs, a custom fasteners manufacturer can produce custom anchor bolts or other custom fasteners.

Mechanical Anchor Bolts: For Speed and Reliability

Mechanical anchor bolts offer a fast and dependable solution for many fastening needs. These expansion bolts work by creating a friction or expansion force against the walls of a pre-drilled hole. Installers often choose mechanical anchor bolts for their straightforward installation process and immediate load-bearing capability.

Wedge Anchors

Wedge anchors are a popular choice for heavy-duty fastening into solid concrete.

How They Work

An installer first drills a hole and cleans it of debris. They then hammer the anchor into the hole. Tightening the nut pulls the anchor body upward, forcing an expansion clip down over a tapered cone. This action wedges the clip firmly against the concrete, creating a secure hold.

Advantages

Wedge anchors provide excellent tensile and shear strength. Their holding power increases with the anchor’s diameter and embedment depth. They are also available in various materials to suit different environments.

| Material Type | Characteristics |

|---|---|

| Zinc-Plated Carbon Steel | Offers good strength for dry, indoor environments. |

| Hot-Dip Galvanized Steel | Provides superior corrosion resistance for outdoor use. |

| 304 & 316 Stainless Steel | Delivers maximum corrosion protection for marine or chemical exposure. |

Disadvantages

These expansion bolts are only suitable for solid concrete. They generate high stress, making them a poor choice for installations near an edge or in brittle materials like brick.

Best Applications

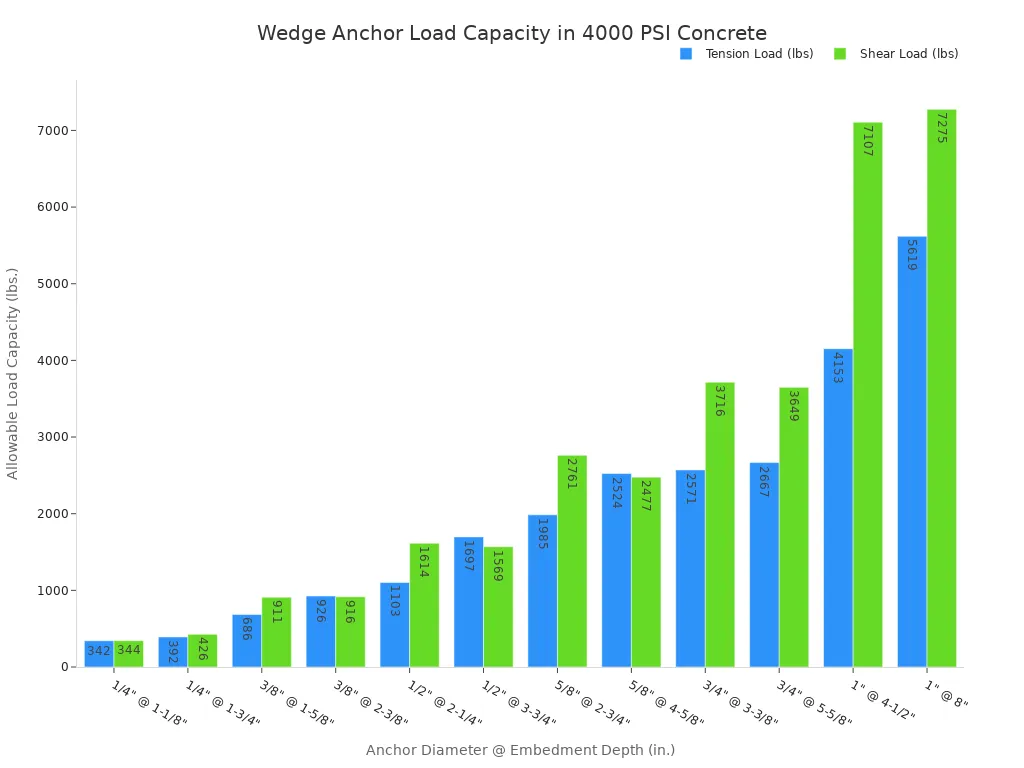

Professionals use wedge anchors to secure structural steel columns, heavy machinery, and racking systems. The load capacity varies significantly by size.

| Nominal Anchor Diameter (in.) | Minimum Embedment Depth (in.) | Allowable Tension Load (lbs) (4,000 psi) | Allowable Shear Load (lbs) (4,000 psi) |

|---|---|---|---|

| 1/4″ | 1-1/8″ | 342 | 344 |

| 3/8″ | 1-5/8″ | 686 | 911 |

| 1/2″ | 2-1/4″ | 1,103 | 1,614 |

| 3/4″ | 3-3/8″ | 2,571 | 3,716 |

| 1″ | 4-1/2″ | 4,153 | 7,107 |

Sleeve Anchors

Sleeve anchors are versatile fasteners suitable for a range of base materials.

How They Work

Sleeve anchors consist of a threaded bolt inside an expandable sleeve. As the bolt head or nut is tightened, it draws a tapered cone into the sleeve, causing the sleeve to expand and grip the surrounding material.

Advantages

Their main advantage is versatility. Sleeve anchors perform well in concrete, brick, and concrete block (CMU). They distribute the load over a larger area, reducing the risk of cracking the base material.

Disadvantages

Sleeve anchors generally have lower holding values compared to wedge anchors. They are not recommended for applications requiring very high load capacities.

Best Applications

Common uses include fastening handrails, window frames, and light-duty shelving.

Drop-In Anchors

Drop-in anchors are female anchors designed for use in solid concrete.

How They Work

An installer places the anchor into a pre-drilled hole. They then use a special setting tool to drive an internal plug downward, which expands the anchor body against the concrete. A threaded bolt or rod can then be installed.

Advantages

Drop-in anchors sit flush with the concrete surface, creating a clean finish. This design also allows for easy removal of the fixture and bolt without leaving a protrusion.

Disadvantages

They require a specific setting tool for proper installation. Their holding power is also lower than that of wedge anchors. For example, a 1/2″ drop-in anchor in 2000 PSI concrete may have an ultimate pull-out strength of around 2,328 lbs.

Note: Professionals should always apply a safety factor (typically 4:1) to ultimate load values to determine a safe working load.

Best Applications

These anchor bolts are ideal for overhead applications like suspending pipe, conduit, and cable trays.

Strike (Hammer-Set) Anchors

Strike anchors, also known as hammer-set anchors, are light-duty expansion bolts valued for their simple and rapid installation.

How They Work

These anchors are a one-piece assembly consisting of an anchor body and a pre-installed expansion pin. An installer drills a hole to the correct diameter and depth. They then insert the anchor and strike the pin with a hammer. Driving the pin forces the anchor body to expand, creating a friction hold against the walls of the hole.

Advantages

- Speed: Installation is extremely fast, requiring only a drill and a hammer.

- Simplicity: No tightening or special setting tools are necessary.

- Tamper-Resistant: Once set, the anchor cannot be easily removed, providing a secure fastening.

Disadvantages

Strike anchors offer relatively low load capacity. They are not suitable for heavy-duty structural connections. Their permanent nature also means they cannot be removed without damaging the base material.

Best Applications

Installers commonly use these anchor bolts for high-volume, light-duty attachments in concrete or stone. Ideal uses include securing electrical conduit straps, junction boxes, and wood furring strips.

Lag Shield Anchors

Lag shield anchors are two-piece mechanical anchor bolts designed for use with lag screws in a variety of masonry materials.

How They Work

The anchor itself is a metal shield with ribs on the exterior. An installer places the shield into a pre-drilled hole. They then align their fixture and drive a lag screw through it and into the shield. The threads of the lag screw engage the shield, causing it to expand and grip the base material firmly.

Advantages

Lag shield anchors are an excellent choice for brittle or softer base materials like brick, mortar joints, and concrete block. The shield distributes the expansion force more gently than a wedge anchor, reducing the risk of cracking the substrate.

Pro Tip: Always use a lag screw with a diameter that matches the manufacturer’s specification for the shield. Using an undersized screw will result in poor expansion and weak holding power.

Disadvantages

These expansion bolts require a separate lag screw, adding a component to the installation. Their holding values are generally lower than those of heavy-duty anchors designed for solid concrete. The final strength depends heavily on the quality of the base material.

Best Applications

These anchor bolts are well-suited for applications involving fastening items to brick or block walls. Common uses include mounting signs, shelving, and downspout straps.

Chemical (Adhesive) Anchors: For Ultimate Strength and Versatility

When mechanical anchors fall short, professionals turn to chemical, or adhesive, anchors. These systems use a two-part resin to create a bond with the substrate that is often stronger than the base material itself. This makes them ideal for the most demanding situations.

An installer drills a hole, cleans it thoroughly, and injects the resin. They then insert a threaded rod or rebar. The resin cures, creating a powerful bond between the anchor and the base material. This process makes adhesive anchor bolts exceptionally strong and versatile.

Epoxy-Based Adhesive Anchors

Epoxy anchors are the gold standard for high-strength structural connections.

Curing and Properties

Epoxies cure through a chemical reaction between a resin and a hardener. This process is slower than other chemical anchors, often taking several hours to fully cure. The result is an incredibly strong, durable, and waterproof bond. High-performance epoxies, like Simpson Strong-Tie SET-3G, are approved for use in various conditions, including dry, water-saturated, and even submerged concrete, without a loss in performance.

Advantages

- Highest Bond Strength: Epoxies offer the highest load capacities of all post-installed anchor bolts.

- Versatility: They perform exceptionally well in both cracked and uncracked concrete.

- Waterproof: The cured adhesive creates a seal that protects the anchor and hole from moisture ingress.

Disadvantages

The primary disadvantage is the long cure time, which can delay project timelines. They are also more sensitive to temperature, with cold weather significantly extending the curing period.

Best Applications

Engineers specify these anchor bolts for critical applications like securing rebar dowels, anchoring heavy structural steel, and retrofitting structures in seismic zones.

Vinylester and Polyester Anchors

These anchors offer a balance of speed and strength, making them a popular choice for many jobs.

Curing and Properties

Vinylester and polyester resins cure much faster than epoxies, often becoming ready for loading in under an hour. Vinylester, in particular, provides excellent resistance to chemicals. It stands up well against acids, alkalis, and saltwater, making it ideal for industrial or marine environments. Polyester is a cost-effective option for general-purpose anchoring.

Advantages

- Fast Curing: Allows for quicker installation and loading compared to epoxy.

- Chemical Resistance: Vinylester offers superior performance in corrosive environments.

- Good Strength: Provides reliable holding power for a wide range of medium- to heavy-duty applications.

Disadvantages

While strong, they generally do not achieve the ultimate bond strength of high-end epoxies. Their performance can also be more sensitive to improper hole cleaning.

Best Applications

Installers use vinylester adhesive anchor bolts in chemical plants, wastewater facilities, and coastal structures. Polyester anchors are great for general-purpose fastening of railings, gates, and machinery in concrete and masonry.

The Chemical Anchoring Process

Proper installation is critical for all adhesive anchor bolts to achieve their rated strength.

Hole Preparation and Cleaning

This is the most important step. An installer must drill the hole to the specified diameter and depth. Then, they must thoroughly clean it of all dust and debris using a wire brush and compressed air. Failure to clean the hole properly will severely compromise the bond strength.

Resin Injection and Curing

Using a dispensing tool, the installer injects the resin from the bottom of the hole outwards to avoid air pockets. They then insert the anchor element with a twisting motion. The anchor must remain undisturbed for the duration of the cure time specified by the manufacturer.

Temperature and Cure Time

Important: Ambient and base material temperatures directly affect cure times. Colder temperatures slow the chemical reaction, requiring longer cure times, while warmer temperatures speed it up. Always consult the manufacturer’s technical data for specific gel and cure times based on job site conditions.

Cast-in-Place Anchors: The Pre-Pour Solution

Unlike post-installed anchors, installers place cast-in-place anchors into formwork before pouring concrete. These anchors become an integral part of the foundation, offering unparalleled strength for new construction projects. This method requires careful planning and precise placement.

L-Type and J-Type Anchor Bolts

Bent anchor bolts are a traditional and reliable choice for creating strong connections in concrete.

Design and Function

These fasteners are steel rods bent into an “L” or “J” shape at one end. The bent portion provides mechanical resistance against pull-out forces once embedded in cured concrete. The ASTM F1554 standard governs the manufacturing of these anchor bolts. This specification defines three grades (36, 55, and 105) that correspond to the material’s minimum yield strength, ensuring predictable performance.

Advantages

The primary advantage is their immense holding strength, as they are monolithically bonded with the foundation. They are also a cost-effective solution for planned structural connections in new construction.

Disadvantages

Their main drawback is a complete lack of installation flexibility. Installers must place them with high precision before the concrete pour. Any miscalculation in location is extremely difficult and expensive to correct after the concrete has set.

Best Applications

Engineers commonly specify these for securing structural elements to foundations. Typical applications include anchoring steel building columns, light poles, and heavy machinery bases.

Headed Anchor Bolts (Straight Rods)

Headed anchor bolts offer a modern alternative to bent bolts, providing superior performance in many situations.

Design and Function

These consist of a straight steel rod with a forged head, nut, or plate on the embedded end. The head provides a direct bearing surface against the concrete, creating exceptional resistance to pull-out or tensile loads. This design often provides a more reliable tensile capacity than a bent anchor.

Advantages

Headed anchors typically offer higher tensile strength than equivalent L or J bolts. Their design and performance are well-defined by industry standards, giving engineers confidence.

Code Compliance Note: The design of cast-in-place anchors is governed by key industry standards to ensure safety and reliability.

- ACI 318: Provides the essential design criteria for cast-in-place anchors within concrete structures.

- ASTM F1554: Specifies the material properties and ductility requirements for the steel rods used.

Disadvantages

Like bent bolts, headed anchors require exact placement before pouring concrete and offer no post-pour adjustability. The cost can sometimes be higher than simple bent bolts, depending on the head configuration.

Best Applications

Professionals use these anchor bolts for critical connections subject to high tensile forces. This includes securing large structural steel frames, bridge components, and heavy industrial equipment.

A Guide to the Different Types of Anchor Bolts by Base Material

The base material is a critical factor in selecting the correct fastener. An anchor that performs well in solid concrete may fail completely in hollow brick. Understanding the substrate’s properties ensures a safe and durable connection. Different types of anchor bolts are engineered for specific materials.

Anchoring in Solid Concrete

Solid concrete provides an excellent base for a wide variety of anchor bolts. It offers high compressive strength, allowing for secure anchoring of both light and heavy loads.

Options for Heavy-Duty Loads

For demanding structural applications, installers have several powerful options. Cast-in-place anchors offer the highest stability when planned before a concrete pour. For post-installed solutions, wedge anchors and chemical anchors provide immense holding power.

| Anchor Bolt Type | Key Characteristics | Load Suitability | Ideal Applications |

|---|---|---|---|

| Cast-in-Place Anchor Bolts | Straight bolts with a nut/plate on the embedded end. | Strongest hold, highest stability and strength. | Anchoring heavy machinery to concrete floors, securing buildings to foundations. |

| Wedge Anchors | A slotted sleeve and tapered wedge expand when tightened. | Very strong hold; high load-bearing capacity. | Anchoring heavy equipment in concrete for industrial/commercial use. |

| Chemical (Adhesive) Anchors | Resin adhesive injected into a predrilled hole with threaded rods. | Very strong, permanent hold; suitable for high-load applications. | Securing equipment in concrete, even in cracked areas, for maximum strength. |

| Bent-Bar Anchor Bolts (J/L-Type) | Bent at one end for better grip in wet concrete. | Strong hold for heavy structural elements. | Anchoring columns and structural components to concrete foundations. |

Options for Medium-Duty Loads

Many applications do not require the extreme strength of heavy-duty anchors. For medium-duty tasks, installers often use:

- Sleeve Anchors: Their design distributes load over a larger area, making them reliable for fastening equipment and fixtures.

- Drop-In Anchors: These provide a flush finish, perfect for overhead applications like suspending conduit and cable trays.

- Strike Anchors: Installers choose these for their speed when securing light items like electrical boxes.

Anchoring in Cracked Concrete

Concrete can develop hairline cracks over time due to tension, shrinkage, or seismic activity. These cracks can severely compromise an anchor’s performance.

Why Chemical Anchors Are Preferred

Standard expansion anchors rely on consistent pressure against the hole walls. A crack creates a void, preventing the anchor from expanding properly and drastically reducing its holding power. Chemical anchors solve this problem. The adhesive resin fills the crack and the entire hole, bonding with the concrete on a molecular level. This creates a monolithic, stress-free connection that is often stronger than the concrete itself.

Qualified Mechanical Anchors

Some specialized mechanical anchors are engineered and tested for use in cracked concrete. These anchors often feature unique sleeve or clip designs that can bridge a crack and maintain their load capacity.

Important: Always verify that a mechanical anchor is explicitly rated for “cracked concrete” in the manufacturer’s technical data before using it in such conditions.

Anchoring in Concrete Block (CMU)

Concrete Masonry Units (CMUs), or concrete blocks, present unique challenges due to their hollow or filled nature.

Hollow vs. Grout-Filled Blocks

Hollow blocks have thin walls and large voids. Anchors must grip these thin walls without breaking them. Grout-filled blocks are solid and behave more like solid concrete, allowing for a wider range of anchor choices.

Recommended Anchor Solutions

For hollow blocks, sleeve anchors are an excellent choice. Their long expansion sleeve distributes the load across a wider area of the block’s thin wall, preventing blow-out. Lag shield anchors also work well in this material. For grout-filled blocks, installers can use many of the same anchors as in solid concrete, including wedge anchors for heavier loads.

Anchoring in Brick and Masonry

Brick and masonry are common construction materials, but their brittle nature presents unique anchoring challenges. Unlike solid concrete, brick can easily crack or spall under the high expansion forces of certain anchor bolts. The key to a secure connection lies in understanding the type of brick and choosing an anchor that distributes load without damaging the substrate.

Solid vs. Hollow Brick Considerations

Installers must first identify whether the brick is solid or hollow.

- Solid Brick: This material provides a consistent, dense base for anchoring. It can support higher loads than hollow brick, but it is still more brittle than concrete. Anchors that create localized high-stress points can still cause cracking.

- Hollow Brick: This type contains voids, or cells, with relatively thin walls. Standard expansion anchors are unsuitable as they can easily break through the thin internal walls or crush the brick. The anchor must be able to either grip the thin face wall securely or span the internal void.

Pro Tip: When possible, drilling into the mortar joint instead of the brick face can reduce the risk of cracking the brick itself. However, the strength of the mortar must be sufficient for the load requirement.

Recommended Anchor Solutions

The correct choice from the various types of anchor bolts depends entirely on the brick’s structure. For solid brick, lag shield anchors are a reliable choice. They expand gently, distributing pressure to minimize the risk of cracking.

For hollow brick and other hollow masonry, installers must use anchors specifically designed for these conditions.

- Hollow Wall Anchors: These expand behind the face of the wall to create a solid grip inside the void.

- Toggle Bolts: A spring-loaded toggle passes through the hole and flips open inside the cavity, providing excellent holding power for heavy items.

- Self-Drilling Anchors: These are versatile for lighter loads and expand to create a secure hold.

- Molly Bolts: A metal sleeve expands and grips the back of the wall as the screw is tightened, suitable for light to medium loads.

For the highest strength in hollow materials, professionals often turn to chemical solutions. An installer drills a hole, inserts a mesh or screen tube, and injects an adhesive resin. The screen tube contains the resin, allowing it to ooze through the mesh and form a solid, custom-fitted plug inside the void. This creates an incredibly strong, stress-free bond between the threaded rod and the brick. These chemical anchor bolts are ideal for securing heavy fixtures where mechanical options might fail.

Critical Factors for Selecting Anchor Bolts

Choosing the right anchor involves more than just matching a bolt to a hole. Professionals must analyze several critical factors to ensure a safe and lasting connection. These factors fall into two main categories: the loads the anchor must resist and the environment where it will be installed.

Analyzing Load Requirements

The forces acting on an anchor dictate the required strength and type. An engineer calculates these loads to prevent failure during the structure’s service life.

Tensile Load (Pull-Out Force)

Tensile load is the force that tries to pull an anchor straight out of its base material. This is a primary consideration for overhead applications or for fixtures that hang from a wall. The anchor’s resistance to this force is known as its pull-out strength.

Shear Load (Side Force)

Shear load is a force that acts perpendicular to the anchor, trying to slice it sideways. An example is a ledger board attached to a wall. When an anchor experiences both tensile and shear forces simultaneously, its capacity for each is reduced. Engineers use an interaction equation to verify that the combined loads do not exceed the anchor’s design strength.

Dynamic, Vibratory, and Seismic Loads

Static loads are constant, but many applications involve changing forces.

- Vibratory Loads: Machinery and equipment can create constant vibrations that may loosen standard expansion anchors over time.

- Seismic Loads: In earthquake-prone regions, the design of anchor bolts is highly regulated. Building codes like the International Building Code (IBC) reference standards such as ACI 318, which often require assuming the concrete is cracked. Per ASCE 7, anchors in these applications must be specifically pre-qualified for seismic use and designed for ductile, not brittle, failure.

Environmental and Installation Conditions

The job site itself presents another set of crucial variables for any construction project.

Interior vs. Exterior Exposure

Anchors used indoors in a dry, climate-controlled environment have different material requirements than those exposed to rain, humidity, and temperature swings outdoors. Exterior exposure demands higher corrosion resistance.

Corrosion Resistance and Material Choice

Corrosion can severely weaken an anchor over time. The material choice is critical for longevity. While zinc-plated steel is suitable for dry indoor use, exterior applications require more robust protection.

| Material | Key Characteristics | Best Use Case |

|---|---|---|

| 304 Stainless Steel | Good corrosion resistance. | General outdoor use, food processing areas. |

| 316 Stainless Steel | Contains molybdenum for superior resistance to chlorides. | Marine environments, chemical plants, coastal areas. |

Note: For the most severe environments, 316 stainless steel provides the best defense against corrosion, especially from salt and industrial chemicals.

Edge Distance and Spacing

Installers must maintain a minimum distance from the anchor to the edge of the concrete and between adjacent anchors. Placing an anchor too close to an edge or another anchor can cause the concrete to break out under load. ACI 318 provides specific calculations for these distances to prevent this type of failure.

Embedment Depth Requirements

Embedment depth is the distance the anchor is installed into the base material. Deeper embedment generally provides significantly higher pull-out strength. Studies show a direct relationship; doubling the embedment depth can nearly double an anchor’s pull-out capacity by increasing the bond strength and engaging a larger cone of concrete.

Head-to-Head Comparison: Mechanical vs. Chemical Anchors

Choosing between mechanical and chemical anchor bolts involves a trade-off between strength, speed, and cost. Each system has distinct advantages that make it suitable for different phases of a construction project.

Load Capacity and Performance

Ultimate Strength Comparison

Chemical anchors generally provide the highest possible load capacity. The adhesive resin creates a bond with the concrete that is often stronger than the base material itself. This results in superior pull-out strength, especially with high-performance epoxies. While heavy-duty mechanical anchors like wedge anchors are very strong, they typically cannot match the ultimate bond strength achieved by a properly installed chemical anchoring system.

Performance in Weaker Materials

In weaker or more brittle base materials, chemical anchors have a clear performance advantage.

- They are versatile and perform well in both cracked and uncracked concrete, as well as masonry.

- They do not induce expansion stress, which prevents cracking or crushing of materials like brick or blockwork.

Mechanical expansion anchors create high compression forces. These forces can damage weaker substrates. Chemical anchors bond without stress, making them the ideal solution for securing loads in delicate masonry.

Installation Process

Speed and Simplicity

Mechanical anchor bolts offer unmatched installation speed. An installer can drill a hole, set the anchor, and apply the load almost immediately. This simplicity makes them a favorite for projects with tight deadlines. Chemical anchors require a more methodical, multi-step process that takes longer.

Required Tools and Expertise

Installing mechanical anchors typically requires only a drill and a wrench or hammer. Chemical anchoring demands more specialized equipment. Installers need:

- A blow-out pump or compressed air for thorough hole cleaning.

- A stiff wire brush to remove all dust and debris.

- A specialized resin injection gun or dispensing tool to mix and inject the adhesive.

Proper training is crucial for chemical anchor installation to avoid common errors like air pockets or incomplete bonding.

Time-to-Load Differences

The most significant installation difference is the time until the anchor can be loaded. Mechanical anchors are ready for immediate loading once tightened. Chemical anchors require a specific cure time, which can range from under an hour to over 24 hours, depending on the resin type and ambient temperature.

Cost Considerations

Per-Unit Anchor Cost

On a per-unit basis, most mechanical anchors are less expensive than chemical anchoring systems. A standard wedge or sleeve anchor costs less than a cartridge of adhesive and a threaded rod.

Associated Labor and Equipment Costs

The overall cost can shift when factoring in labor and equipment. The rapid installation of mechanical anchors reduces labor time and costs. The slower, more specialized process for chemical anchors increases labor hours. Additionally, the need for dispensing tools and cleaning equipment adds to the upfront equipment cost for chemical systems.

Selecting the correct anchor bolts is non-negotiable for ensuring structural stability in any construction project. While mechanical anchors offer speed in solid materials, chemical anchors provide superior strength for demanding jobs. Professionals must remember the consequences of poor selection, as seen in failures like Boston’s Big Dig tunnel collapse.

Key factors in that failure included:

- Use of an epoxy with poor long-term load resistance.

- Improper hole cleaning procedures.

- Lack of follow-up inspections.

Installers must always verify their choice against manufacturer specifications, engineering documents, and local building codes to prevent such catastrophic outcomes.

FAQ

Can installers reuse anchor bolts?

Most anchor bolts are single-use items. Mechanical anchors deform during installation, and chemical anchors create a permanent bond. Removing them typically damages the anchor and the base material, making reuse unsafe and impractical for any structural application.

What is the most important step for installing chemical anchors?

Hole preparation is the most critical step. Installers must thoroughly clean the drilled hole of all dust and debris using a wire brush and compressed air. Proper cleaning ensures a strong bond between the adhesive and the concrete.

Why is embedment depth so important?

Embedment depth directly impacts an anchor’s holding power. A deeper embedment engages a larger area of the base material. This significantly increases the anchor’s resistance to pull-out forces, creating a much stronger and more reliable connection.

Which anchor is best for cracked concrete?

Chemical (adhesive) anchors are generally the best choice for cracked concrete. They fill the crack and bond with the substrate without creating expansion stress. Some specialized mechanical anchors are also rated for cracked concrete, but professionals must verify this rating.

How do temperature changes affect chemical anchors?

Temperature significantly impacts the curing time of chemical anchors.

- Cold temperatures slow the chemical reaction, requiring a longer cure time.

- Warm temperatures speed up the reaction, shortening the cure time.

Note: Installers must always consult the manufacturer’s data sheet for specific cure times based on job site conditions.

What does the ASTM F1554 standard specify?

The ASTM F1554 standard governs cast-in-place anchor bolts. It defines three material grades (36, 55, and 105) based on minimum yield strength. This standard ensures that the anchor bolts have predictable and reliable mechanical properties for engineering design.

Can you install an anchor in a mortar joint?

Installers can place anchors in mortar joints, but the mortar’s strength must be sufficient for the load. This practice can prevent cracking the brick. However, the holding power will be lower than an anchor set in solid brick or concrete.