Selecting the correct hollow wall anchors is crucial for a secure installation. The object’s weight and the wall’s thickness determine the best choice among the various types of hollow wall anchors available. A custom fasteners manufacturer can supply specific Anchor Bolts or custom anchor bolts for unique projects.

- Plastic expansion drywall anchors support light items under 15 pounds.

- Molly bolts provide reliable strength for medium-duty fixtures up to 50 pounds.

- A toggle bolt is the champion for heavy loads over 50 pounds, such as TV mounts.

Understanding the Basics of Hollow Wall Anchors

Before selecting an anchor, a user must understand why they are essential for any project involving hollow walls. These walls, typically made of drywall, lack the solid structure needed to hold a standard screw under load. Using the correct hardware prevents potential damage and ensures a secure installation.

Why You Can’t Just Use a Screw

The Problem with Hollow Walls

Drywall consists of a soft gypsum plaster core sandwiched between two paper sheets. It is inherently brittle. While a wood screw driven directly into 1/2″ drywall might hold over 50 pounds before failing, the real issue is its tendency to crumble and tear under sustained force or slight movement. The screw’s threads have very little material to grip. Over time, the weight of the object will pull the screw out, leaving a much larger, damaged hole.

How Anchors Create Support

Hollow wall anchors solve this problem by creating a secure bracing point behind the wall. When a user installs an anchor, it expands or deploys on the other side of the drywall. This action distributes the weight of the hanging object over a much larger surface area. Instead of concentrating all the force on the weak gypsum immediately around the screw, the anchor transfers the load to the stronger paper backing and a wider section of the wall, preventing it from tearing.

Key Factors in Choosing an Anchor

Selecting the right anchor involves evaluating a few key variables. The wrong choice can lead to a failed installation.

Weight Capacity is Critical

The most important factor is the weight of the item you intend to hang. Every package of drywall anchors specifies a maximum weight limit. A user must always choose an anchor rated to hold significantly more than the object’s actual weight to ensure a safe margin.

Wall Material and Thickness

The thickness of your drywall affects which anchor will work. In residential construction, 1/2-inch drywall is common, but thicker 5/8-inch boards are also used.

| Region | Common Thicknesses | Other Thicknesses (Specific Applications) |

|---|---|---|

| North America | 1/2 inch (13 mm), 5/8 inch (16 mm) | 1/4, 3/8, 3/4, 1 inch (6, 10, 19, 25 mm) |

| Europe | 9.5 to 25 millimeters (3/8 to 1 inch) | N/A |

Some drywall anchors are designed for a specific range of wall thicknesses, so checking this detail is crucial.

Required Tools and Ease of Use

Different types of hollow wall anchors demand different tools and installation efforts. Some require only a screwdriver, while others need a drill, a hammer, and more careful execution.

Reading the Anchor Packaging

The anchor’s packaging provides all the critical information needed for a successful installation.

Finding the Weight Rating

The weight rating is the most prominent piece of information on the package. It is usually listed in pounds (lbs) or kilograms (kg).

Pro Tip: Always locate the load capacity on the packaging before purchasing. Never guess the strength of an anchor based on its appearance.

Identifying the Required Drill Bit Size

For anchors that require a pilot hole, the packaging will specify the exact drill bit size needed. Using the correct bit is essential; a hole that is too small will prevent the anchor from fitting, while a hole that is too large will not allow the anchor to grip the wall securely.

Light-Duty Solutions: Plastic Expansion Anchors

For hanging lightweight objects, plastic expansion drywall anchors are the most common and accessible solution. They are inexpensive, easy to find, and simple to install, making them a staple in any homeowner’s toolkit for minor decorating tasks.

What They Are and How They Work

The design of these anchors is straightforward yet effective for light loads. Understanding their mechanics helps a user appreciate their function.

The Simple Sleeve and Screw

A standard plastic anchor kit contains two parts: a ribbed plastic sleeve and a corresponding metal screw. The sleeve is designed to fit snugly into a pre-drilled hole in the drywall. The ribs on the outside help prevent the anchor from spinning during installation.

How They Grip the Drywall

The anchor’s holding power comes from expansion. A user inserts the screw into the plastic sleeve after the sleeve is set in the wall. As the screw advances, it forces the end of the sleeve to split and expand. These expanded “wings” press firmly against the back of the drywall, distributing the load over a wider area and creating a secure friction hold.

Best For Items Under 15 Pounds

These drywall anchors are specifically designed for light-duty applications. A user should never exceed the manufacturer’s stated weight limit, which is typically under 15 pounds (about 7 kg).

- Small Picture Frames: They provide ample support for hanging family photos and small pieces of art.

- Smoke Detectors: The light weight of a smoke or carbon monoxide detector makes it a perfect match for a plastic anchor.

- Lightweight Holiday Decor: They are ideal for temporarily hanging items like small wreaths, string lights, or stockings.

Installation Steps and Required Tools

The installation process is quick and requires only basic hand tools. Proper execution ensures the anchor performs as expected.

Tools: Drill, Hammer, Screwdriver

A user will need the following tools for a successful installation:

- Power Drill

- Drill bit (size specified on the anchor packaging)

- Hammer

- Screwdriver (Phillips or flat-head, depending on the screw)

Step-by-Step Installation Guide

Following these steps will result in a secure mount.

Note: Using the exact drill bit size specified on the packaging is critical. A hole that is too large will prevent the anchor from gripping, while a hole that is too small can damage the anchor or the wall during insertion.

- Mark the Location: Use a pencil to mark the precise spot on the wall for the anchor.

- Drill a Pilot Hole: Drill a hole at the marked spot using the drill bit size recommended by the anchor manufacturer.

- Insert the Anchor: Gently tap the plastic sleeve into the hole with a hammer until its head is flush with the wall surface.

- Drive the Screw: Place the item over the anchor, align the holes, and drive the screw into the sleeve until it feels snug. Do not overtighten, as this can strip the anchor or damage the drywall.

Pros and Cons of Plastic Anchors

Plastic anchors are a popular choice for many homeowners, but they have a specific set of strengths and weaknesses. A user must understand these to decide if they are the right fit for a particular project.

Key Advantages

The widespread use of plastic anchors stems from several key benefits that make them ideal for simple, everyday tasks.

- Low Cost: They are extremely economical, often sold in large multi-packs for just a few dollars. This makes them a budget-friendly option for numerous small projects.

- Wide Availability: A user can find plastic anchors at any hardware store, home improvement center, or even most supermarkets. Their ubiquity ensures they are always on hand when needed.

- Ease of Installation: The installation process is straightforward and forgiving for beginners. It requires only basic tools that most people already own, such as a drill, hammer, and screwdriver.

- Minimal Wall Damage: The small pilot hole required for a plastic anchor is easy to patch and paint over if the item is removed later. This makes them suitable for renters or for hanging decor that might be moved frequently.

Common Limitations

Despite their convenience, plastic anchors have significant limitations that a user must respect to avoid installation failure and potential damage. Their primary drawback is their very low weight capacity. Exceeding this limit can lead to several types of failure.

The most common issue is anchor pull-out, where the anchor simply fails to grip and pulls out of the wall, leaving a torn, enlarged hole. Overloading causes mechanical stress that can result in visible fractures or deformation of the plastic sleeve itself. In other cases, a user might over-tighten the screw during installation. This action can cause steel rupture, where the screw head snaps off, or it can strip the anchor’s internal threads, rendering it useless.

Caution: Never use plastic expansion drywall anchors for valuable, heavy, or critical items like televisions, large mirrors, or safety grab bars. The risk of failure is too high.

These anchors also perform poorly in old or brittle drywall. The material may crumble during installation or lack the structural integrity to support the anchor’s expansion, leading to a weak hold from the start. For any application beyond the lightest decorative items, a stronger anchor type is a much safer choice.

Medium-Duty Workhorses: Molly Bolts (Sleeve-Type Anchors)

When a project requires more holding power than a plastic anchor can provide, molly bolts are the ideal upgrade. These sleeve-type drywall anchors offer significantly more strength, making them a reliable choice for a wide range of household fixtures. They are the go-to solution for most medium-duty jobs.

What They Are and How They Work

The robust design of a molly bolt is what gives it superior holding capacity. Its all-metal construction provides a secure and permanent mounting point in hollow walls.

The Expanding Metal Sleeve

A molly bolt consists of a machine screw threaded into a metal sleeve. This sleeve has slits that allow it to collapse and expand. When a user installs the anchor, the sleeve is inserted into a pre-drilled hole. Turning the screw then draws the head of the screw inward, causing the slitted portion of the sleeve to compress and flare out like a spider’s legs behind the drywall.

Why They’re Stronger Than Plastic

The mechanical design of molly bolts offers much greater strength than plastic alternatives. The expanding metal legs create a wide, rigid brace against the back of the wall, distributing the load far more effectively. This mechanism provides a few key advantages:

- The metal construction resists stripping and deformation under load.

- It creates permanent, reusable screw threads within the wall. A user can remove and reinstall the bolt without losing holding power.

- Unlike plastic anchors that can collapse or pull through, the metal legs lock firmly in place.

These features allow molly bolts to support up to 50 pounds in standard drywall, a significant increase over most plastic drywall anchors.

Best For Items From 20 to 50 Pounds

These anchors are perfectly suited for common household items that carry a moderate but consistent load. Their reliability makes them a safe choice for fixtures that see regular use.

Towel Bars and Curtain Rods

The constant pulling and weight from wet towels or heavy curtains require a secure anchor. A molly bolt prevents these fixtures from loosening over time.

Medium-Sized Mirrors

A medium-sized mirror can weigh between 20 and 40 pounds. Using these anchors ensures the mirror stays safely on the wall.

Small Floating Shelves

Floating shelves intended to hold books, plants, or decorative objects need a strong foundation. Molly bolts provide the necessary support to prevent sagging or failure.

Installation Steps and Required Tools

Installing these anchors requires precision, but the process is straightforward with the right tools and technique.

Tools: Drill, Hammer, Screwdriver

For a standard installation, a user will need:

- Power Drill

- Drill bit (sized according to the package)

- Hammer

- Screwdriver (Phillips or flat-head)

A Guide to Installing Molly Bolts

- Drill the Pilot Hole: After marking the location, drill a hole matching the diameter specified on the anchor’s packaging.

- Insert the Anchor: Gently tap the anchor into the hole with a hammer until the flange is flush with the drywall. The small teeth on the flange will bite into the wall to prevent spinning.

- Expand the Sleeve: Turn the screw clockwise. A user will feel resistance as the sleeve begins to expand. Keep turning until the screw feels very snug. This action sets the anchor.

- Mount the Item: Unscrew the bolt, position the fixture’s bracket over the anchor, and then re-insert the bolt and tighten it to secure the item.

Pro Tip: Stop turning the screw as soon as it becomes firmly snug. Over-tightening can damage the drywall or strip the anchor’s threads.

Pointed vs. Non-Pointed Molly Bolts

Molly bolts come in two primary designs: a pointed-tip version for self-starting and a standard non-pointed version that requires a pilot hole. A user’s choice between them depends on the wall material, the need for precision, and the desired installation speed. Each type offers distinct advantages for different situations.

When to Use Pointed-Tip Mollies

Pointed-tip molly bolts are designed for speed and convenience. The sharp, reinforced tip allows a user to create the installation hole without a drill. This design streamlines the process into fewer steps, making it an attractive option for quick jobs.

The installation process is direct:

- A user positions the sharp point on the wall.

- They firmly tap the anchor head with a hammer, driving the point through the drywall.

- They then expand the anchor by turning the screw, just like a standard molly.

This type is best suited for standard 1/2-inch drywall where the exact placement is not hyper-critical. It is an excellent choice for projects where a user needs to install several anchors quickly and does not have a drill readily available. However, the hammering action can sometimes create a less clean entry point compared to a drilled hole.

When a Pilot Hole is Better

The traditional non-pointed molly bolt, used with a pre-drilled pilot hole, offers superior precision and control. This method is the professional standard for ensuring a clean, secure installation, especially in more challenging conditions. Drilling a pilot hole guarantees the opening is the perfect size, which prevents the anchor from fitting too loosely or damaging the wall upon insertion.

Expert Tip: Always opt for a pilot hole when working with older, brittle drywall or thicker 5/8-inch panels. Hammering a pointed anchor into these materials can cause the wall surface to crack, crumble, or “blow out” on the back side, severely weakening the anchor’s hold.

Using a pilot hole is the recommended approach for any application where strength and a clean finish are top priorities. It is essential when hanging valuable items or when the anchor must align perfectly with a mounting bracket. The extra step of drilling provides peace of mind that the anchor has the most stable foundation possible.

| Feature | Pointed-Tip Molly | Non-Pointed Molly (with Pilot Hole) |

|---|---|---|

| Speed | 🏃♂️ Faster | Slower |

| Precision | Good | ✅ Excellent |

| Tools Needed | Hammer, Screwdriver | Drill, Hammer, Screwdriver |

| Best For | Standard 1/2″ drywall | All drywall types, plaster, critical loads |

| Wall Damage Risk | Higher | Lower |

Heavy-Duty Champions: Classic Toggle Bolts

For hanging the heaviest and most critical items, the classic toggle bolt is the undisputed champion of hollow wall anchors. Its simple yet powerful design provides exceptional holding strength, making it the only safe choice for loads exceeding 50 pounds. A user relies on this anchor when failure is not an option.

What They Are and How They Work

The strength of a toggle bolt comes from its unique two-part mechanical design, which creates an incredibly secure brace inside the wall.

The Spring-Loaded Wing Mechanism

A classic toggle consists of two components: a machine bolt and a spring-loaded metal wing nut. The wings are designed to fold flat against the bolt. A user pushes them through a pre-drilled hole in the drywall. Once clear of the wall’s back surface, the springs force the wings to open, creating a solid T-brace.

How Toggles Distribute Weight

The anchor’s immense strength comes from this T-brace. The open wings create a very large contact area against the back of the drywall. This design distributes the heavy load over a wide surface, preventing the anchor from pulling through the wall. Instead of relying on friction, it uses direct mechanical bracing for maximum support.

Best For Items Over 50 Pounds

A user should always choose a toggle bolt for any item that is heavy, valuable, or related to safety. Its high weight capacity provides the necessary security and peace of mind.

Heavy Shelving Units

Shelves intended for books, kitchen supplies, or heavy decorative pieces require robust support. Toggles ensure the shelves and their contents remain firmly attached to the wall without risk of collapse.

Wall-Mounted TV Brackets

Modern televisions are large and heavy. A secure mount is essential to protect the investment and ensure safety. A toggle bolt provides the strength needed to support typical full-motion mounts and large screens.

| Feature | Specification |

|---|---|

| Model | MD2617 |

| Type | Full motion TV wall mount |

| TV size | 42”-84” |

| Weight capacity | 100 lbs. |

| Material | Cold Rolled Steel |

Grab Bars and Handrails

Safety fixtures like grab bars must withstand sudden, significant force. Their installation is often governed by strict safety codes, such as the Americans with Disabilities Act (ADA), which specifies precise placement and length.

- Toilet Stalls: Side wall grab bars must be at least 42 inches long, while rear wall bars must be 36 inches long.

- Shower Stalls: Bars are required on the control and back walls, with specific placement rules depending on the shower type.

- Bathtubs: Multiple bars are required on the back and control end walls, with lengths of at least 24 inches.

Using toggles ensures these critical safety devices meet structural requirements.

Installation Steps and Required Tools

Installing a toggle requires a larger hole than other anchors, but the process is straightforward.

Tools: Drill, Screwdriver

A user only needs two basic tools for the job:

- Power Drill with a bit sized for the folded toggle

- Screwdriver (Phillips or flat-head)

Step-by-Step Toggle Bolt Installation

- Drill the Hole: Drill a pilot hole large enough for the folded wings to pass through. The packaging will specify the required bit size.

- Assemble the Toggle: Remove the wings from the bolt. Thread the bolt through your item’s mounting bracket first, then re-thread the wings onto the bolt.

- Insert into Wall: Pinch the wings flat against the bolt and push them completely through the hole. A user will hear or feel them spring open inside the wall.

- Tighten the Bolt: Pull the bolt outward to seat the wings against the back of the wall. While pulling, tighten the bolt with a screwdriver until the fixture is secure.

Important: A user must pass the bolt through the fixture before inserting the toggle into the wall. The wings will fall off if the bolt is removed after installation.

The Downsides of Toggle Bolts

While toggle bolts offer unmatched strength, their design presents several notable disadvantages. A user must consider these drawbacks before committing to an installation, as they impact both the initial process and any future wall modifications. These limitations make the classic toggle bolt a permanent solution rather than a flexible one.

The Large Hole Requirement

The primary functional drawback of a toggle anchor is the large pilot hole required for installation. A user must drill a hole wide enough for the entire folded wing mechanism to pass through. This opening is often 1/2 inch or larger, significantly bigger than holes for other anchor types.

This large hole creates a few challenges:

- Difficult Repairs: Patching a large hole is more involved than filling a small screw hole. It requires more spackle, careful sanding, and precise paint matching to conceal the repair.

- Permanent Commitment: The significant wall alteration makes toggles unsuitable for temporary hangings or for renters who may need to restore walls to their original condition.

- Reduced Placement Options: The hole size may limit placement near wall edges or other fixtures where the drywall could be structurally weaker.

The need for such a large opening makes the installation a more destructive and permanent decision compared to other anchor systems.

One-Time Use Limitation

The most significant operational flaw of a classic toggle is its single-use nature. The design that provides its strength is also its biggest weakness upon removal. Once the anchor is installed, the bolt holds the wings tight against the wall. If a user completely removes this bolt for any reason—such as to repaint the wall or relocate the item—the spring-loaded wing nut immediately drops down into the wall cavity.

Classic toggle bolts, once inserted into a wall, cannot be removed without causing damage. This design directly impacts future wall repairs or item relocation, as the anchor cannot be salvaged or reused. The lost wing leaves an empty hole, and the user must install a brand-new anchor to re-hang the item. This limitation is a critical factor for any installation that might need future adjustment.

| Action | Result |

|---|---|

| Screw is in place | ✅ Wings are braced, fixture is secure. |

| Screw is removed | ❌ Wings fall inside the wall, anchor is lost. |

This one-time use characteristic makes simple tasks more complicated and forces a user to plan for a permanent installation from the start.

The Modern Upgrade for Heavy Loads: Strap Toggles

Strap toggles represent a significant evolution in heavy-duty anchoring technology. They address the primary weaknesses of the classic toggle bolt while delivering even greater holding power. This modern design offers a more user-friendly and reliable solution for the most demanding home installation projects.

How Strap Toggles Improve on the Classic

These anchors refine the traditional toggle concept with clever engineering, resulting in a superior installation experience and functionality.

The Plastic Strap Advantage

A strap toggle anchor combines a high-strength metal channel with a plastic strap assembly. A user inserts the metal channel through a pre-drilled hole. The plastic straps allow the user to pull the channel snug against the back of the wall. This design prevents the anchor from falling into the wall cavity, a common frustration with spring-wing toggles. It simplifies the installation of items with multiple mounting points by keeping all anchors perfectly aligned and ready for the bolts.

Reusability and Easier Installation

The most significant improvement is reusability. The anchor remains securely in place even when the bolt is completely removed. This feature allows a user to take down a fixture for painting or cleaning and then easily reinstall it. Installation is also simpler, often requiring a smaller pilot hole (typically 1/2 inch) than other commercial anchors with similar weight ratings. The user drills the hole, inserts the anchor, and zips the strap tight for a secure mount.

When to Choose a Strap Toggle

A user should select a strap toggle for any application where maximum strength and future flexibility are required.

For Very Heavy or Critical Items

Modern strap-type toggles can hold up to twice the load of a traditional toggle of the same bolt size, making them the superior choice for safety-critical installations. A user should always opt for this anchor when mounting:

- Large televisions, especially on full-motion mounts

- Safety grab bars in bathrooms

- Heavy mirrors or artwork

- Wall-mounted cabinets and heavy shelving

- Overhead fixtures like projectors, as they are easier to install on ceilings

When You Might Need to Remove the Bolt

The ability to remove and replace the bolt without losing the anchor makes strap toggles ideal for any item that may need to be temporarily moved. This feature provides long-term value and convenience that older anchor designs cannot match.

Installing a Strap Toggle Anchor

The installation process is efficient and requires minimal tools, delivering a professional-grade result.

Tools and Preparation

A user will typically only need two items for the job:

- A power drill

- A drill bit (usually 1/2 inch, but always check the packaging)

The Strap Toggle Installation Process

Note: Unlike classic toggles, a user installs the strap toggle anchor into the wall before positioning the fixture.

- Drill the Hole: Drill a hole of the size specified by the manufacturer at the desired location.

- Insert the Anchor: Hold the metal channel parallel to the plastic straps and push it through the hole.

- Set the Anchor: Pull on the plastic straps until the metal channel sits flat against the inside of the wall.

- Secure the Cap: Slide the plastic cap along the straps until it is flush with the outer wall. Snap the excess strap length off at the side.

- Mount the Item: Place the fixture over the anchor cap, insert the provided bolt, and tighten until snug.

Quick and Easy Jobs: Self-Drilling Anchors

When speed and simplicity are the top priorities, self-drilling anchors are an excellent choice. These innovative fasteners eliminate the need for pre-drilling, streamlining the installation process significantly. They are a favorite for quick household tasks and light-duty mounting jobs.

What They Are and How They Work

The design of these anchors is focused on efficiency, combining the anchor and the drill bit into a single component.

The All-in-One Threaded Design

A self-drilling anchor features a sharp, drill-like tip and coarse, deep threads along its body. This design allows the anchor to bore its own hole directly into the drywall. As a user drives it in, the threads cut into the gypsum and paper, creating a secure grip without the need for a separate pilot hole. The center of the anchor is hollow to accept the mounting screw.

Plastic vs. Metal Self-Drilling Anchors

These anchors are available in both plastic and metal, each offering different characteristics. Plastic versions are non-conductive and resist corrosion, making them a cost-effective choice. Metal self drilling anchors, typically made of a zinc alloy, provide greater durability and are less prone to breaking during installation into dense drywall.

| Feature | Plastic Self-Drilling Anchor | Metal Self-Drilling Anchor |

|---|---|---|

| Material | Nylon or Plastic | Zinc Alloy (Zamak) |

| Durability | Good | ✅ Excellent |

| Strength | Less prone to stripping the wall | Less prone to breaking during install |

| Conductivity | Non-conductive | Conductive |

While both types are intended for similar light to medium loads, the metal variant offers superior stability and is a better choice when a user needs a more robust mechanical connection.

Best For Light to Medium Loads

These drywall anchors are ideal for items that do not carry significant weight. A user should always check the packaging for the specific weight rating, which is typically under 40 pounds.

- Bulletin Boards and Whiteboards: Their large size but light weight makes them perfect candidates for this anchor type.

- Thermostats and Doorbells: These small electronic devices require a secure mount that this anchor can provide quickly.

- Lightweight Shelving: They can support small decorative shelves intended for holding picture frames or other light objects.

Installation Steps and Required Tools

The biggest advantage of these anchors is the minimal tool requirement and the rapid installation process.

Tool: Screwdriver or Drill

A user only needs one tool for the job:

- A Phillips head screwdriver for manual installation.

- A power drill with a Phillips driver bit for faster installation.

How to Install a Self-Drilling Anchor

- Mark the Location: Use a pencil to mark the spot on the wall.

- Position the Anchor: Place the sharp tip of the anchor on the mark.

- Drive the Anchor: Using firm, steady pressure, drive the anchor into the drywall with a screwdriver or drill. Continue until the head of the anchor is flush with the wall surface.

- Mount the Item: Place the fixture over the anchor, insert the provided screw, and tighten until it is snug.

Pro Tip: Avoid over-tightening the anchor when driving it into the wall. If the anchor head breaks the paper surface of the drywall, its holding power will be severely compromised. Stop as soon as it is flush.

When Not to Use Self-Drilling Anchors

While self-drilling anchors offer unmatched convenience for many tasks, a user must recognize their specific limitations. These fasteners are not a universal solution. Using them in the wrong situation can lead to a failed installation and significant wall damage. Understanding when to choose a different type of anchor is just as important as knowing how to install these correctly. Their effectiveness depends heavily on both the condition of the wall and the weight of the object being mounted.

Avoiding Brittle or Old Drywall

The primary weakness of a self-drilling anchor is its reliance on the structural integrity of the drywall itself. The anchor’s threads must cut cleanly into the gypsum core to create a firm hold. This process works well in modern, stable drywall panels. However, older homes often have drywall that has become brittle or soft over time due to age or humidity.

Warning: Attempting to drive a self-drilling anchor into old or compromised drywall often results in failure. Instead of cutting clean threads, the anchor’s tip can shatter the brittle gypsum, creating a soft, crumbly pocket. The threads will have nothing to grip, and the anchor will either spin in place or pull out easily under minimal load.

A user can test the wall’s condition in an inconspicuous area. If the drywall feels soft or crumbles easily, a different anchor type is necessary. A molly bolt or a toggle bolt, which brace against the back of the wall, provide a much more secure solution in these circumstances. They do not depend solely on the quality of the gypsum core for their holding power.

Understanding Their Weight Limits

A user must strictly adhere to the weight ratings specified on the anchor’s packaging. These limits are not suggestions; they are the maximum load the anchor can safely support under ideal conditions. Exceeding this capacity is a common and dangerous mistake. The holding power of these anchors is derived entirely from the threads gripping the soft drywall material. This connection is far weaker than the mechanical bracing provided by molly or toggle bolts.

The table below illustrates the typical failure points when these anchors are overloaded.

| Load Type | Potential Failure | Result |

|---|---|---|

| Static Load (Constant Weight) | Shear Failure | The anchor’s threads slowly tear through the drywall, causing the fixture to sag and eventually fall. |

| Dynamic Load (Vibration/Movement) | Material Fatigue | The drywall around the threads crumbles, causing the anchor to loosen and pull out from the wall. |

For any item approaching the anchor’s maximum limit, or for anything valuable or heavy, a user should always upgrade to a stronger anchor. The small amount of time saved during installation is not worth the risk of a falling fixture, property damage, or potential injury.

Comparing All Types of Hollow Wall Anchors

Choosing the right anchor requires a direct comparison of their core attributes. A user must weigh strength, installation effort, and cost to find the best fit for their project. This head-to-head analysis simplifies the decision-making process for all types of hollow wall anchors.

Head-to-Head: Strength and Capacity

The primary function of an anchor is to support weight safely. The differences in load capacity among hollow wall anchors are significant and directly tied to their design.

Light vs. Medium vs. Heavy-Duty

- Light-Duty (Under 15 lbs): Plastic expansion anchors are designed for simple decorative items. Their holding power is limited and suitable only for objects with minimal weight.

- Medium-Duty (20-50 lbs): Molly bolts provide a substantial increase in strength. Their metal construction and expanding sleeve design make them reliable for medium-duty jobs like hanging shelves and towel bars.

- Heavy-Duty (Over 50 lbs): Toggle bolts and strap toggles are the champions of strength. They create a solid brace behind the wall, making them the only safe option for heavy items like TVs, cabinets, and grab bars.

Shear vs. Tensile Strength Explained

Understanding how forces affect an anchor is key to appreciating its strength. Tensile strength is an anchor’s ability to resist being pulled straight out of the wall. Shear strength is its capacity to resist a downward, slicing force parallel to the wall surface. While both are important, tensile failure is a common concern. When an object pulls downward, the force often translates into an axial (tensile) pull on the screw. If this force exceeds the anchor’s limit, it will fail. Toggle bolts excel because their wide brace distributes these forces over a large area, providing superior resistance to both shear and tensile loads.

Head-to-Head: Installation Difficulty

The time and tools required for installation vary greatly between anchor types.

Easiest: Self-Drilling

Self-drilling anchors offer the fastest installation. A user only needs a screwdriver to drive them directly into the wall, making them perfect for quick, simple tasks.

Moderate: Plastic and Molly Bolts

Plastic anchors and non-pointed molly bolts represent a moderate level of difficulty. They require a user to drill a precise pilot hole before inserting the anchor, adding an extra step to the process.

Most Complex: Toggle Bolts

Classic toggle bolts are the most complex to install. They demand a large pilot hole and require the user to assemble the bolt through the fixture before inserting it into the wall. This multi-step process requires careful execution.

Head-to-Head: Cost and Value

Cost is often a deciding factor, but it should be balanced against the need for security.

Most Economical Options

Plastic expansion anchors are the cheapest option, often sold in bulk for a few dollars. Self-drilling anchors are also very affordable. These are excellent for low-risk, lightweight applications where budget is a primary concern.

When to Invest in a Stronger Anchor

Investing in a stronger anchor like a molly bolt or strap toggle is a wise decision for valuable or heavy items. While the initial cost is higher, the value comes from security and peace of mind. The cost difference is minimal compared to the potential expense of a failed installation, which could involve property damage or personal injury. A user should always prioritize safety over small savings.

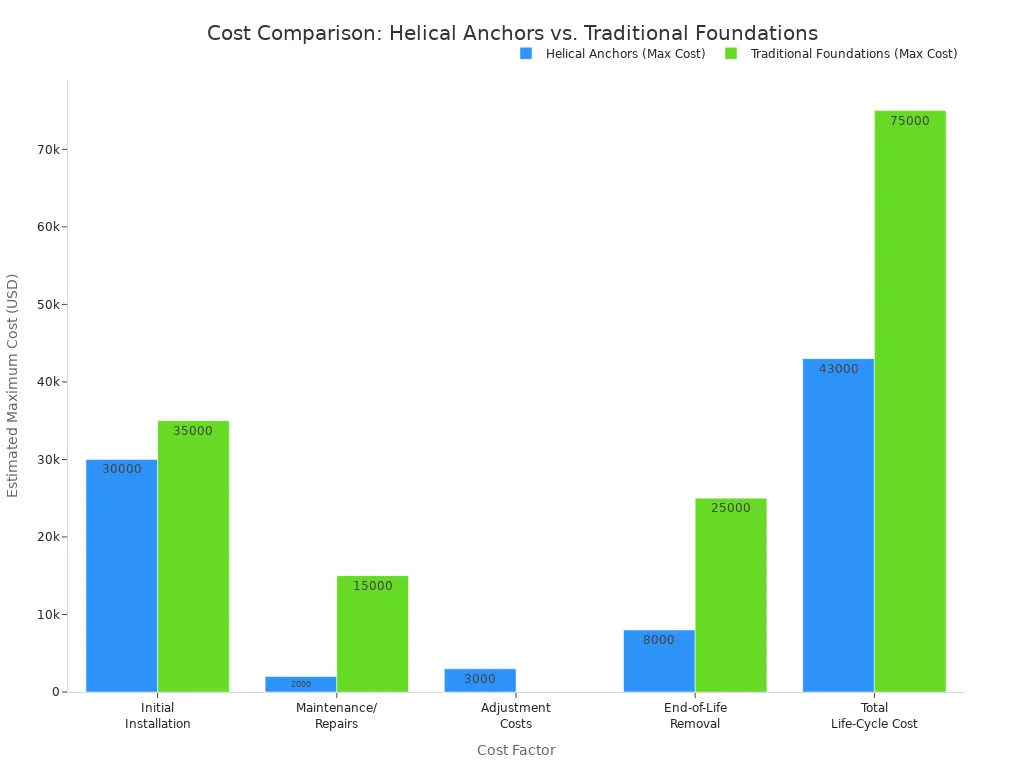

The following chart illustrates how a higher initial investment in a superior anchoring system can lead to lower long-term costs by preventing failure and the need for repairs.

Common Mistakes to Avoid When Using Wall Anchors

A successful installation depends on proper technique. A user can avoid most failures by sidestepping a few common errors. Understanding these pitfalls ensures that fixtures remain secure and walls stay intact. Proper use of drywall anchors is critical for safety and reliability.

Choosing the Wrong Anchor for the Weight

Selecting an anchor without considering the load is the most frequent and dangerous error. The anchor’s capacity must always exceed the object’s weight.

The Dangers of Underestimating Weight

A user might guess an object’s weight and choose an insufficient anchor. This mistake leads to anchor failure. The fixture can pull out of the wall, causing property damage or injury. A falling mirror, shelf, or television creates a significant safety hazard. The resulting wall damage is often a large, torn hole that is difficult to repair.

Always Read the Packaging

The anchor’s packaging provides its certified weight rating. A user must always consult this information before making a purchase.

Safety First: Always select an anchor rated for at least twice the weight of the item you plan to hang. This safety margin accounts for unexpected stress or vibrations.

Drilling the Wrong Size Pilot Hole

Many drywall anchors require a pilot hole. The size of this hole is not a suggestion; it is a precise requirement for the anchor to function correctly.

What Happens if the Hole is Too Big

A pilot hole that is too large prevents the anchor from gripping the drywall. The anchor will spin in place when the user tries to drive the screw. It will not expand correctly and will offer very little holding power, pulling out under even a light load.

What Happens if the Hole is Too Small

A hole that is too small creates a different set of problems. The user may damage the anchor or the wall while trying to force it into place.

| Hole Size | Result |

|---|---|

| Too Big | 😵 Anchor spins, no grip. |

| Too Small | 🔨 Anchor breaks, wall cracks. |

| Correct Size | ✅ Snug fit, secure hold. |

Over-Tightening the Screw

A user might think that tighter is always better. With wall anchors, over-tightening is a destructive mistake that compromises the entire installation.

Stripping the Anchor

Excessive force can strip the internal threads of an anchor, especially plastic or self-drilling types. Once stripped, the screw can no longer tighten. It will just spin, and the anchor becomes useless. This action ruins the anchor’s ability to hold any weight.

Damaging the Drywall

Over-tightening also puts immense pressure on the wall itself. The anchor’s flange can crack the surrounding gypsum or break through the wall’s paper surface. This damage destroys the structural integrity at the mounting point, causing the anchor to loosen and fail.

Ignoring Wall Thickness

A user often overlooks the thickness of their wall, a mistake that can completely undermine an anchor’s performance. The mechanical function of many anchors depends on a specific wall thickness. An anchor designed for standard drywall may fail in a thicker wall, and vice versa. This factor is just as critical as weight capacity for a secure installation.

Standard vs. Thicker Drywall

Most residential homes use 1/2-inch thick drywall for interior walls. However, builders use thicker 5/8-inch drywall (often called Type X) in certain areas for specific reasons.

- 1/2-inch Drywall: The common standard for walls and ceilings in living rooms, bedrooms, and hallways.

- 5/8-inch Drywall: Typically required for garages, furnace rooms, or multi-family dwellings to provide increased fire resistance and sound dampening.

A user must identify the wall’s thickness before selecting an anchor, as a 1/8-inch difference is enough to cause installation failure.

How Thickness Affects Anchor Choice

Wall thickness directly impacts how an anchor deploys and grips. Molly bolts, for example, have a specific grip range. A molly bolt designed for 1/2-inch drywall will not expand correctly in a 5/8-inch wall because its sleeve is too short to clear the material and flare out properly.

Thicker drywall provides a more stable base, which significantly increases the holding power of heavy-duty anchors. Manufacturers’ technical data sheets are crucial for determining detailed load capacities. For heavy equipment, strap-style toggle bolts are the ‘gold standard’ due to their excellent load distribution. For instance, a heavy-duty strap toggle like the SNAPTOGGLE® can support up to 238 lbs in 1/2-inch drywall. Its holding power in 5/8-inch Type X drywall can even rival fastening directly to a stud for certain load types.

The strength increase in thicker walls is dramatic. The wider bracing surface allows toggle bolts to handle much greater forces. The difference in ultimate load capacity for standard toggle bolts is significant.

| Toggle Bolt Size | 1/2-inch Drywall (Ultimate Load) | 5/8-inch Drywall (Ultimate Load) |

|---|---|---|

| 3/16-inch | 430 lbs | 700 lbs |

| 1/4-inch | 310 lbs | 830 lbs |

Pro Tip: 🧐 Before buying anchors, measure your wall’s thickness. Drill a small, inconspicuous test hole and use a bent paperclip to hook the back edge and measure the depth. This simple check guarantees you purchase an anchor that will perform correctly.

A user must prioritize the object’s weight when selecting an anchor. The correct choice ensures a secure and lasting installation. By matching the hardware to the load, a user can hang almost anything with confidence.

- Light Loads (Under 15 lbs): Simple plastic expansion anchors are sufficient for small decor.

- Medium Loads (20-50 lbs): Reliable molly bolts provide the necessary strength for fixtures like shelves.

- Heavy Loads (Over 50 lbs): Toggle bolts are the safest choice for critical items like TV mounts or grab bars.

FAQ

Can a user reuse a wall anchor?

Most anchors are for single use. A user cannot reuse plastic anchors or classic toggles. However, molly bolts and strap toggles leave a threaded insert in the wall. This feature allows a user to remove and re-insert the bolt multiple times, making them reusable.

What should a user do if they hit a wood stud?

Hitting a wood stud is good news. 🥳 A user should abandon the anchor and drive a screw directly into the stud. Wood provides a much stronger hold than any hollow wall anchor. No anchor is necessary when a stud is present.

How does a user remove an old plastic anchor?

A user has two options for removing an old plastic anchor:

- Pull it out: Use pliers to grip the anchor’s head and pull it straight out.

- Push it in: Tap the anchor with a hammer until it falls behind the wall.

Both methods leave a small hole that a user can easily patch.

Are metal anchors always better than plastic ones?

Not necessarily. The best anchor depends on the object’s weight. Metal anchors like molly bolts and toggles offer superior strength for heavy loads. Plastic anchors are economical and perfectly suitable for lightweight items under 15 pounds. A user should match the anchor to the job.

Can a user install anchors in a ceiling?

Yes, but with extreme caution. Ceilings experience a direct downward pull (tensile force). A user must only use heavy-duty toggle-style anchors for ceiling installations. Plastic or self-drilling anchors are unsafe for this purpose and will fail under load.

Why did the anchor just spin in the hole?

A spinning anchor almost always means the pilot hole is too large. The anchor’s threads or wings have nothing to grip. A user must always drill the exact hole size specified on the anchor’s packaging to ensure a snug, secure fit.