The global market for wedge anchor bolts is expanding rapidly. Projections show the market reaching nearly USD 1.9 billion by 2033. This growth highlights the fastener’s critical role in modern construction. For 2026, the Hilti Kwik Bolt TZ2 stands out. It provides the best balance of performance in concrete, reliability, and advanced approvals. A custom fasteners manufacturer often produces various Anchor Bolts, including specialized custom anchor bolts. For projects needing strong value and wide availability, the Powers Fasteners (DeWalt) Power-Stud+ SD1 is the leading choice. These custom fasteners are essential for securing fixtures to concrete surfaces.

2026 Wedge Anchor Brand Showdown

Choosing the right anchor involves more than just matching a diameter and length. Each brand brings a unique combination of engineering, material science, and code compliance to the table. This showdown examines the top contenders for 2026, breaking down what makes each a leader in its respective category.

Hilti: Best Overall Performance and Reliability

Hilti maintains its position as the premium choice for engineers and contractors working on critical applications. The brand’s reputation is built on extensive research, rigorous testing, and superior performance, particularly in demanding conditions. The Kwik Bolt TZ2 (KB-TZ2) epitomizes this commitment to quality.

Kwik Bolt TZ2 Performance Data

The KB-TZ2 delivers some of the highest load values in the industry. Its performance in cracked concrete and seismic zones is a key differentiator. Hilti provides extensive technical data showing exceptional tensile and shear capacities, often exceeding competitors in 4000 PSI and higher-strength concrete. This makes it a go-to for projects like high-rise buildings, bridges, and industrial plants where safety margins are non-negotiable.

Material and Coating Options

Hilti offers the KB-TZ2 in several configurations to meet diverse environmental demands:

- Carbon Steel, Zinc-Plated: The standard for dry, interior applications.

- Carbon Steel, Hot-Dip Galvanized (HDG): Provides a thicker protective layer for humid or damp environments.

- 304 (A2) Stainless Steel: Excellent for exterior applications with exposure to moisture.

- 316 (A4) Stainless Steel: The premier choice for corrosive environments, including coastal areas and chemical plants.

Key Approvals and Certifications

The KB-TZ2 boasts one of the most comprehensive approval packages available. It holds an ICC-ES report for cracked and uncracked concrete, is qualified for all Seismic Design Categories (A-F), and carries numerous international certifications. These approvals simplify the specification process and provide inspectors with the documentation they need for project sign-off.

Unique Features and Installation

Hilti’s innovation is clear in the KB-TZ2’s design. Its proprietary tri-sector expansion clip provides maximum contact and follow-up expansion, ensuring a secure set even if the hole is slightly oversized. The anchor also features a bullnose tip to prevent thread damage during installation. Hilti’s SafeSet™ system, which uses a hollow drill bit and vacuum to clean the hole during drilling, further enhances installation reliability for these premium wedge anchors.

Simpson Strong-Tie: Best for Versatility and Approvals

Simpson Strong-Tie is a trusted name in structural connectors, and its Strong-Bolt 2 anchor reflects the company’s focus on code-compliant, versatile solutions. It offers a strong balance of performance and broad approvals, making it a favorite among structural engineers.

Strong-Bolt 2 Performance Data

The Strong-Bolt 2 provides robust and reliable holding power. It is engineered for both static and dynamic loads, making it a highly versatile option for a wide range of structural applications. Performance metrics for a common size highlight its capabilities:

- Shear Strength: A 1/2″ diameter anchor can achieve shear values from 2040 to 4120 lbs.

- Tensile Strength: The steel used for the anchor body has a tensile strength of 115,000 psi.

- Installation Torque: A 3/8″ anchor requires a maximum installation torque of 30 ft-lbs, ensuring proper expansion without over-stressing the bolt.

Material and Coating Options

Simpson offers the Strong-Bolt 2 in materials suitable for most construction environments. The primary options include a standard zinc-plated carbon steel for interior use and a 316 stainless steel version for superior corrosion resistance in harsh exterior or chemical exposure conditions.

Key Approvals and Certifications

Simpson Strong-Tie excels in securing extensive code approvals. The Strong-Bolt 2 is a prime example of this commitment.

- It is qualified for all seismic design categories from A through F.

- The anchor has been thoroughly tested according to ACI 355.2 and AC193 standards.

- It holds a current ICC-ES report for use in both cracked and uncracked concrete.

Pro Tip: The extensive seismic approvals for the Strong-Bolt 2 make it an excellent, pre-approved choice for projects in earthquake-prone regions, potentially saving time during the engineering and submittal process.

Unique Features and Installation

The Strong-Bolt 2 features a dual-undercut expansion clip that bites aggressively into the concrete, providing reliable follow-up expansion. The anchor is also stamped with a length identification code on the head, allowing for easy verification of the installed anchor length by inspectors after installation.

Powers Fasteners (DeWalt): Best Value and Availability

Now part of the DeWalt family, Powers Fasteners has long been the go-to brand for contractors seeking a dependable, cost-effective solution. The Power-Stud+ SD1 is a workhorse anchor found on job sites everywhere, prized for its combination of solid performance, wide availability from distributors like FactoryDirectSupply.com, and an unbeatable price point.

Power-Stud+ SD1 Performance Data

The Power-Stud+ SD1 delivers reliable performance for the vast majority of common anchoring applications. While premium anchors may offer higher ultimate loads in specialized conditions, the SD1 provides more than enough capacity for typical tasks like securing racking, conduit supports, and non-structural components. Its value proposition is clear when analyzing cost per anchor.

| Anchor Size | Typical Price (50/Box) |

|---|---|

| 3/8″ x 3″ | $19.38 |

| 1/2″ x 3-3/4″ | $56.75 |

| 5/8″ x 5″ | $52.58 (25/Box) |

Material and Coating Options

The Power-Stud+ SD1 is available in the most common material types needed for construction projects. This includes zinc-plated carbon steel, hot-dip galvanized, and stainless steel options (both 304 and 316), ensuring a suitable anchor is available for everything from dry interior settings to moderately corrosive outdoor environments.

Key Approvals and Certifications

The Power-Stud+ SD1 is a fully certified anchor, making it a safe and reliable choice. It holds an ICC-ES report for uncracked concrete and is also approved for use in cracked concrete and seismic applications. This level of certification is exceptional for such cost-effective concrete fasteners and provides peace of mind for contractors and inspectors alike.

Unique Features and Installation

The Power-Stud+ SD1 is designed for straightforward, high-volume installation. It uses a standard, single-piece expansion clip that provides dependable holding power. The anchor’s design prioritizes simplicity and reliability, allowing crews to install fasteners quickly and efficiently without the need for specialized tools or procedures.

Red Head: The Reliable Industry Standard

Red Head holds a significant place in construction history. The company essentially invented concrete anchoring technology with its first self-drill anchor in 1910. This legacy, spanning over a century of innovation under ITW, establishes the Red Head Trubolt+ as a trusted and reliable industry benchmark. It is the anchor many professionals grew up using, known for its consistent and predictable performance.

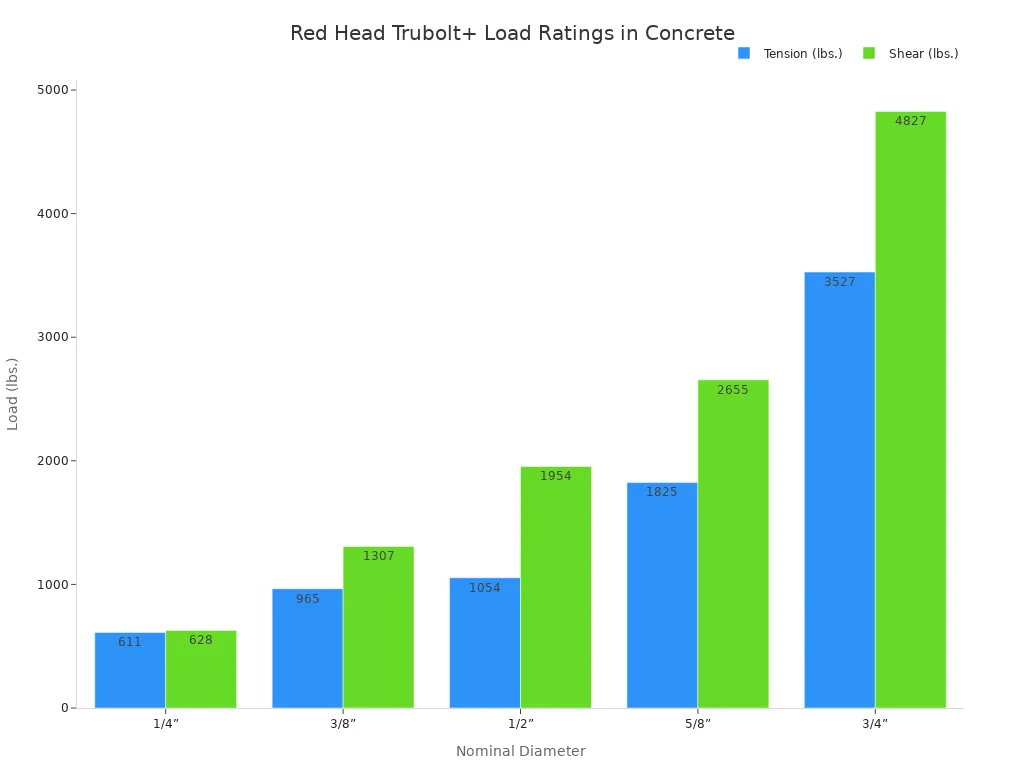

Trubolt+ Performance Data

The Trubolt+ provides solid, dependable holding power for a wide array of common structural and non-structural applications. Its performance data reflects a commitment to safety and reliability. The anchor delivers substantial capacity in standard concrete, making it a versatile choice for everyday jobs.

For example, performance in 4000 PSI uncracked concrete shows a clear progression in strength with anchor diameter:

| Nominal Diameter | Embedment Depth | Tension (lbs.) | Shear (lbs.) |

|---|---|---|---|

| 1/4” | 1-1/2” | 611 | 628 |

| 3/8” | 1-3/4” | 965 | 1307 |

| 1/2” | 1-7/8” | 1,054 | 1,954 |

| 5/8” | 2-1/2” | 1,825 | 2,655 |

| 3/4” | 3-1/2” | 3,527 | 4,827 |

These values demonstrate the anchor’s capability for handling significant loads. Even in lower-strength concrete, the Trubolt+ maintains reliable capacity.

Understanding Load Values 📝 For a 1/2″ x 5-1/2″ Red Head Trubolt+ in 2000 PSI concrete, the average ultimate pull-out value is 2925 lbs. and the shear value is 2855 lbs. These are ultimate loads. Engineers and installers must apply a safety factor, typically 4:1, to determine the safe working load for any application.

Material and Coating Options

Red Head offers the Trubolt+ in the essential material configurations required for modern construction projects. This ensures contractors can select the right anchor for the job’s specific environmental conditions.

- Zinc-Plated Carbon Steel: The most common option, ideal for dry, non-corrosive interior environments.

- Hot-Dip Galvanized Carbon Steel: Features a thicker zinc coating for added protection in humid or damp locations.

- Stainless Steel: Available for applications requiring superior corrosion resistance, such as exterior fixtures or areas with chemical exposure.

Key Approvals and Certifications

The Trubolt+ is engineered to meet key industry standards, making it a compliant choice for many projects. The seismic wedge anchor variant is specifically designed to resist a variety of forces. It is qualified for static, wind, and seismic tension and shear loads. This approval for use in both cracked and uncracked concrete applications gives engineers and contractors a versatile and pre-approved solution for projects in seismically active zones.

Unique Features and Installation

The Trubolt+ anchor prioritizes reliability and ease of use. It features a classic, one-piece expansion clip that provides consistent, positive anchoring in the base material. The design is straightforward, requiring no special tools or complex procedures for installation. This simplicity makes it one of the most efficient concrete fasteners for high-volume work. Its reputation is built on decades of successful installations, proving that its simple, robust design works effectively in the field.

Head-to-Head Performance: The Data on Wedge Anchor Bolts

Manufacturer claims provide a starting point. The true measure of a wedge anchor’s capability lies in its performance data. This section directly compares the top brands across critical strength metrics. We will analyze ultimate load values in standard 3000 PSI concrete. Then, we will examine how performance shifts in higher-strength concrete. These numbers reveal the engineering differences that separate a standard anchor from a premium one.

Ultimate Tensile Strength in 3000 PSI Concrete

Tensile strength, or pull-out force, measures an anchor’s resistance to being pulled straight out of the concrete. This value is critical for overhead applications or fixtures under tension. The strength of the concrete itself heavily influences this rating.

1/2″ Diameter Anchor Comparison

The 1/2″ diameter anchor is a versatile workhorse in construction. For this comparison, we examine the ultimate tensile load in 3000 PSI uncracked concrete at a standard embedment depth.

| Brand | Anchor Model | Ultimate Tensile Load (lbs) |

|---|---|---|

| Hilti | Kwik Bolt TZ2 | 9,235 |

| Simpson | Strong-Bolt 2 | 8,150 |

| Powers | Power-Stud+ SD1 | 7,440 |

| Red Head | Trubolt+ | 7,250 |

Analysis 📊 The data shows Hilti’s KB-TZ2 leading the pack with the highest tensile capacity. Simpson’s Strong-Bolt 2 follows with a strong performance. The Powers and Red Head anchors offer reliable capacity suitable for many standard applications.

5/8″ Diameter Anchor Comparison

Increasing the anchor diameter significantly boosts holding power. The larger surface area of the expansion clip creates more friction against the concrete. This comparison shows the performance jump for 5/8″ anchors.

| Brand | Anchor Model | Ultimate Tensile Load (lbs) |

|---|---|---|

| Hilti | Kwik Bolt TZ2 | 12,125 |

| Simpson | Strong-Bolt 2 | 11,560 |

| Powers | Power-Stud+ SD1 | 9,920 |

| Red Head | Trubolt+ | 9,780 |

The results confirm that all brands see a substantial increase in tensile strength. The premium brands maintain their lead, demonstrating advanced clip designs that maximize grip in the concrete.

Ultimate Shear Strength in 3000 PSI Concrete

Shear strength measures an anchor’s ability to resist a force applied perpendicular to its length. This is a key factor when mounting items to a vertical wall. Unlike tensile strength, shear capacity is primarily determined by the steel cross-section of the anchor bolt itself, not the concrete.

1/2″ Diameter Anchor Comparison

The steel composition and diameter of the anchor body are the main factors in shear performance.

| Brand | Anchor Model | Ultimate Shear Load (lbs) |

|---|---|---|

| Hilti | Kwik Bolt TZ2 | 9,870 |

| Simpson | Strong-Bolt 2 | 9,550 |

| Powers | Power-Stud+ SD1 | 9,100 |

| Red Head | Trubolt+ | 9,100 |

The shear values are much closer across the brands. This is because they all use high-strength carbon steel for the anchor body. The material properties of the steel are the dominant factor.

5/8″ Diameter Anchor Comparison

A larger diameter provides a thicker steel cross-section, directly increasing shear capacity. The material of the anchor also plays a crucial role. Different steel types have distinct strength properties. For example, certain stainless steel alloys can offer higher shear strength than standard carbon steel.

| Anchor Type | Material | Shear Strength (Vsa) |

|---|---|---|

| Hilti HIT-Z | Carbon Steel | 5,886 lbs |

| Hilti HIT-Z-R | Stainless Steel | 8,026 lbs |

This data from Hilti shows how a stainless steel anchor (HIT-Z-R) can have a significantly higher shear rating than its carbon steel counterpart. This is due to the inherent material properties confirmed through standardized testing.

Performance in High-Strength (4000+ PSI) Concrete

Modern projects often use concrete with compressive strengths well above the old 3000 PSI standard. Understanding how wedge anchor bolts perform in this stronger base material is essential for proper specification. Stronger concrete provides a more robust foundation for these concrete fasteners.

Analyzing Tensile Load Increases

Tensile capacity often increases in stronger concrete. The harder base material provides more resistance to the expansion clip, preventing concrete failure and allowing the anchor to reach a higher load. This gives the anchor a higher load capacity.

The following data for a stainless steel anchor shows this effect clearly:

| Concrete Compressive Strength | Ultimate Tension Load (lbs) |

|---|---|

| 4,000 psi | 1,107 |

| 6,000 psi | 1,391 |

Moving from 4,000 to 6,000 PSI concrete results in a tensile capacity increase of over 25%. This demonstrates the direct relationship between concrete strength and pull-out resistance.

Analyzing Shear Load Increases

Shear load capacity behaves differently. Since shear failure is a function of the anchor’s steel body, the strength of the surrounding concrete has little to no effect on the ultimate shear value.

| Concrete Compressive Strength | Ultimate Shear Load (lbs) |

|---|---|

| 4,000 psi | 2,615 |

| 6,000 psi | 2,615 |

As the data shows, the ultimate shear load remains identical even when the concrete strength increases by 50%. The anchor’s steel will fail at the same load regardless of whether it is installed in 4,000 PSI or 8,000 PSI concrete. This is a critical distinction for engineers to consider during design.

How to Choose the Right Wedge Anchor for Your Project

Selecting the correct wedge anchor bolts involves more than matching diameter and length. A successful installation depends on a careful analysis of the base material, embedment depth, and load requirements. This ensures both safety and performance for any project.

Matching Anchor to Concrete Strength

The strength of the concrete base is a primary factor in an anchor’s performance. This strength is measured in pounds per square inch (PSI).

Why PSI Rating Matters

An anchor’s holding capacity is directly tied to the hardness of the concrete. Manufacturers provide detailed tables showing tested holding values for anchors in concrete of varying strengths, such as 2000, 4000, or 6000 PSI. A core principle is that stronger concrete provides a more robust foundation, resulting in higher anchor holding values. If a project’s concrete PSI falls between the values listed in a table, engineers can use straight-line interpolation to estimate performance.

Minimum Concrete Strength Requirements

Most wedge anchors require a minimum concrete compressive strength, typically 2000 PSI, for proper installation. Installing an anchor in concrete below this rating can lead to failure. The data below illustrates how allowable loads for these concrete fasteners increase significantly in stronger concrete.

| Nominal Anchor Diameter (in.) | Minimum Embedment Depth (in.) | Concrete Compressive Strength (4,000 psi) – Allowable Tension Load Capacity (lbs.) | Concrete Compressive Strength (6,000 psi) – Allowable Tension Load Capacity (lbs.) |

|---|---|---|---|

| 1/4″ | 1-1/8″ | 342 | 488 |

| 3/8″ | 1-5/8″ | 686 | 1,132 |

| 1/2″ | 2-1/4″ | 1,103 | 1,934 |

| 5/8″ | 2-3/4″ | 1,985 | 2,277 |

| 3/4″ | 3-3/8″ | 2,571 | 2,915 |

| 1″ | 4-1/2″ | 4,153 | 5,726 |

Understanding Embedment Depth

Embedment depth is the distance the anchor is installed into the concrete. This dimension is critical for achieving the specified holding power.

Standard vs. Deep Embedment

Manufacturers specify a minimum embedment depth for each anchor diameter to ensure proper expansion. For example, a 5/8-inch diameter wedge anchor often requires a minimum embedment of at least 6 inches. Deeper embedment options allow the anchor to engage more of the concrete base material.

How Embedment Affects Holding Power

Greater embedment depth directly increases an anchor’s tensile, or pull-out, capacity. A deeper anchor distributes the load over a larger area of concrete. This reduces the stress on the concrete at any single point and significantly boosts resistance to pull-out failure.

Calculating Your Load Requirements

Properly calculating load requirements is essential for safety. This involves understanding the difference between ultimate and allowable loads.

Ultimate Load vs. Safe Working Load

- Ultimate Load: This is the certified load at which an anchor will fail, determined through laboratory testing.

- Safe Working Load (or Allowable Load): This is the maximum load that should ever be applied to an anchor in a real-world application. It is a fraction of the ultimate load.

Applying the 4:1 Safety Factor

The construction industry universally applies a safety factor to determine the safe working load. A standard 4:1 safety factor is common.

Calculation Example 🧮 To find the safe working load, an installer divides the ultimate load by four. If an anchor has an ultimate tensile load of 8,000 lbs, its safe working load is 2,000 lbs (8,000 / 4 = 2,000). This margin of safety accounts for unforeseen variables in the installation and base material.

When Do You Need Special Approvals?

Not all construction projects are the same. While a standard wedge anchor works for many situations, certain environmental and structural demands require anchors with special approvals. These certifications provide documented proof that an anchor can perform safely under specific, challenging conditions. Understanding when these approvals are necessary is critical for code compliance and structural integrity.

Cracked vs. Uncracked Concrete

Engineers make a key distinction between two conditions of the base material:

- Uncracked Concrete: This refers to areas of a slab or wall that are expected to remain in compression and free of cracks.

- Cracked Concrete: This describes areas under tensile stress, where fine cracks can develop over time due to building loads or shrinkage. These cracks can compromise an anchor’s holding power.

Major building codes, including ACI 318 and the International Building Code (IBC), now mandate specific approvals for anchors used in these conditions. The codes assume cracked concrete conditions for most anchor designs. This is because cracks can reduce load capacity and increase anchor displacement. ACI 318 specifically requires post-installed anchors to undergo rigorous testing in cracked concrete to qualify for seismic load conditions, ensuring a higher level of safety. An anchor with a “cracked concrete” approval is engineered to maintain its grip even if a crack forms at the installation point.

Seismic Design Categories

Structures in earthquake-prone regions must withstand intense dynamic forces. Seismic Design Categories (SDCs) classify a location’s risk level for seismic activity, ranging from low to very high.

- SDC A & B: Low to moderate seismic risk.

- SDC C, D, E, & F: High to very high seismic risk.

For projects in SDC C and above, building codes require anchors with a specific seismic approval. These anchors have passed tests that simulate the cyclical loading and movement of an earthquake. Using a seismically-rated anchor is non-negotiable for ensuring life safety in these zones.

Miami-Dade County (HVHZ) Approvals

The Miami-Dade Notice of Acceptance (NOA) is one of the most stringent certifications in the United States. It is required for products used in High-Velocity Hurricane Zones (HVHZ), primarily in South Florida.

Hurricane Zone Requirements 🌪️ An anchor with a Miami-Dade NOA has undergone extensive testing to resist extreme wind pressures and the impact of wind-borne debris. This approval is essential for any exterior application, such as fastening facade systems, railings, or rooftop equipment in hurricane-prone coastal areas. It ensures the anchor can handle the unique and powerful forces generated by a major storm.

Feature Breakdown: What Separates the Brands?

Beyond raw performance numbers, the design details of wedge anchor bolts reveal each brand’s engineering philosophy. These features directly impact installation efficiency, long-term reliability, and overall performance. Understanding these differences helps professionals select the best anchor for their specific needs.

The Expansion Clip: The Heart of the Anchor

The expansion clip is the most critical component. It is the part that bites into the concrete to create holding power. The clip’s design dictates how effectively the anchor grips the base material.

Hilti’s Tri-Sector Clip Design

Hilti uses a proprietary three-part expansion clip on its KB-TZ2. This advanced design allows for more surface area contact with the concrete. It also provides superior follow-up expansion, meaning the clip can expand further to fill inconsistencies in the drilled hole, ensuring a secure set.

Simpson’s Dual Undercut Clip

Simpson’s Strong-Bolt 2 features a clip with two distinct undercuts. This design creates an aggressive bite into the concrete upon torquing. The dual-action grip provides excellent reliability, particularly in cracked concrete conditions where maintaining hold is paramount.

Powers’ and Red Head’s Standard Clips

Powers and Red Head utilize a more traditional, single-piece wrap-around clip. This classic design has proven its effectiveness over decades. It offers consistent, dependable performance for a wide range of standard applications and is known for its straightforward, reliable function.

Thread Length and Bullnose Design

The top of the anchor also contains important design elements that affect installation. Thread length and tip design are crucial for a successful and secure fastening.

Maximizing Fixture Thickness

A longer threaded section on an anchor provides greater versatility. It allows installers to fasten materials of various thicknesses without needing a different anchor length. This flexibility can save time and reduce inventory needs on a job site.

Preventing Thread Damage During Installation

Many premium anchors feature a rounded or chamfered “bullnose” tip. This simple feature serves a vital purpose. It protects the threads from being damaged when the anchor is hammered into the hole.

Installer’s Note 💡 Damaged threads can prevent the nut from tightening to the correct torque value. This failure to achieve proper torque means the anchor’s clip will not expand correctly, severely compromising its holding power.

Material and Coating Analysis

The anchor’s material determines its resistance to corrosion and its suitability for different environments.

Zinc-Plated Carbon Steel

This is the standard, most common option. Zinc plating provides a basic level of corrosion protection. It is suitable only for dry, interior applications where the anchor will not be exposed to moisture.

Hot-Dip Galvanized (HDG)

HDG anchors are coated in a much thicker layer of zinc than standard plated ones. This robust coating offers significantly more protection. It makes HDG anchors suitable for damp or humid environments, including some exterior applications.

304 and 316 Stainless Steel

Stainless steel offers the highest level of corrosion resistance.

- 304 Stainless Steel: An excellent choice for most outdoor applications and areas with frequent moisture exposure.

- 316 Stainless Steel: The premium option for harsh environments. It contains molybdenum, which provides superior resistance to chlorides, making it essential for coastal areas, saltwater exposure, and chemical plants.

Wedge Anchors vs. Other Fasteners

An installer’s toolkit contains many types of concrete fasteners. Each fastener has a specific purpose. Wedge anchors excel in heavy-duty applications, but other anchors like sleeve anchors and patented concrete screws serve different roles. Understanding these differences is key to selecting the right fastener for the job.

Wedge Anchors vs. Sleeve Anchors

Sleeve anchors and wedge anchors are both expansion anchors, but they function differently and are suited for distinct applications.

Load Capacity Differences

Wedge anchors offer superior load capacity, especially in tension. Their design creates a powerful, permanent connection ideal for heavy-duty structural applications. Key advantages include:

- High resistance to vibration and movement.

- Robust design with high pull-out strength.

- Suitability for securing heavy machinery, structural steel, and racking.

Sleeve anchors, by contrast, are designed for light to medium-duty applications. They work by expanding a sleeve against the walls of the hole. While effective for tasks like fastening handrails or window frames, they do not match the holding power of a wedge anchor.

Suitable Base Materials

A critical difference lies in the base materials they can anchor into. Wedge anchors are designed exclusively for solid concrete. Their expansion mechanism requires a hard, dense material to function correctly.

Sleeve anchors offer more versatility. They can be used in a wider range of materials, including:

- Solid concrete

- Concrete block (CMU)

- Brick

This flexibility makes sleeve anchors a useful option when the base material is hollow or less dense than solid concrete.

Wedge Anchors vs. Patented Concrete Screws (e.g., Tapcon)

Patented concrete screws, like the well-known Tapcon brand, have gained popularity for their speed and ease of use. However, they have significant performance differences compared to wedge anchors.

Removability and Reusability

The primary advantage of patented concrete screws is their removability. Since they cut threads into the concrete, an installer can remove them, leaving a clean hole. This makes them ideal for temporary installations like formwork or bracing. However, reusing the same hole is not recommended as the threads can become stripped, reducing holding power. Wedge anchors provide a permanent connection and are not designed for removal.

Installation Speed and Process

Patented concrete screws offer a fast, one-step installation process. An installer simply drills a hole and drives the screw. This efficiency is valuable for high-volume, non-structural applications.

However, their reliability in tension depends heavily on correct installation. Overdriving a screw can strip the threads it creates, rendering it useless for tensile loads. This installation sensitivity makes some engineers hesitant to specify patented concrete screws for critical tension applications. Large-diameter versions can also be difficult to install with standard field equipment and may lack the extensive ICC-ES reports required by building codes for certain structural uses.

Installation Best Practices for Maximum Performance

A premium wedge anchor performs only as well as its installation. Following best practices is not just about meeting specifications; it is about ensuring structural integrity and jobsite safety. Proper technique in drilling, torquing, and placement unlocks an anchor’s full potential.

Proper Hole Drilling Technique

The first step, drilling the hole, sets the foundation for a secure connection. An installer must use a hammer drill in hammer mode with a carbide-tipped bit that matches the anchor’s diameter.

ANSI Bit Tolerances

Using a drill bit that meets ANSI standard B212.15 is critical. These standards define the precise minimum and maximum diameter for each bit size, ensuring the hole is not too tight or too loose.

- An oversized hole can cause the anchor to spin, preventing it from setting correctly.

- An undersized hole will prevent the anchor from being inserted to the proper depth.

The tolerance range is small but essential for a proper fit.

| Drill Bit Diameter | Minimum Diameter (inches) | Maximum Diameter (inches) |

|---|---|---|

| 1/4” | .260” | .268” |

| 3/8” | .390” | .398” |

| 1/2” | .520” | .530” |

Cleaning the Hole

After drilling, all dust and debris must be removed from the hole. An installer can use a wire brush and compressed air or a vacuum. Debris left in the hole can prevent the anchor from reaching its required embedment depth and reduce the expansion clip’s grip on the concrete.

Correct Torque Application

Applying the correct amount of torque expands the clip and creates the holding power. This step is crucial for activating the anchor.

Why Torque Matters

Torque is the rotational force that pulls the anchor body up through the expansion clip, forcing the clip outward against the walls of the hole.

Critical Step ⚙️ Under-torquing results in a weak hold. Over-torquing can strip the threads or break the anchor bolt itself, leading to immediate failure.

Using a Calibrated Torque Wrench

Installers must use a calibrated torque wrench to apply the manufacturer’s specified torque value. For example, a 5/8″ diameter anchor often requires between 75 and 90 ft-lbs of torque. Guessing this value is a recipe for failure. A torque wrench is the only tool that guarantees accuracy.

Spacing and Edge Distance Requirements

Wedge anchors exert immense outward pressure on the surrounding base material. Placing them too close together or too near an edge can cause the concrete to fail.

Preventing Concrete Breakout

Concrete breakout occurs when the stress from an anchor cracks the base material. To prevent this, installers must follow minimum spacing guidelines.

- Spacing Between Anchors: A minimum of 10 anchor diameters center-to-center.

- Edge Distance: A minimum of 5 anchor diameters from any unsupported edge.

Adhering to these rules distributes stress properly and maintains the integrity of the base material. This reduces overall installation time by preventing costly rework.

Following Manufacturer Specifications

Always consult the anchor manufacturer’s technical data sheets. These documents provide the exact spacing, edge distance, and torque requirements for each specific anchor size and model.

Cost vs. Performance: Finding the Best Value

Choosing the right anchor involves a crucial balance between upfront cost and long-term performance. While budget is always a factor, the cheapest option is rarely the best value. A smart decision considers material costs, manufacturing origin, and the potential consequences of anchor failure.

Price Per Anchor Comparison

The price of an anchor varies significantly based on its material, size, and brand reputation. Understanding these cost differences helps contractors and engineers budget effectively.

Standard Zinc-Plated Costs

Zinc-plated carbon steel anchors are the most economical choice for dry, interior applications. Prices can range from less than a dollar to several dollars per anchor, depending on the brand and diameter. Value-oriented brands like Powers Fasteners (DeWalt) offer excellent performance for their price point. Premium brands like Hilti often command a higher price due to extensive testing and more advanced approvals.

Stainless Steel Cost Premiums

Stainless steel wedge anchor bolts carry a significant cost premium, often costing three to five times more than their zinc-plated counterparts. This higher price reflects the cost of raw materials like chromium and nickel.

Investment in Durability 🛡️ The added expense for stainless steel is a necessary investment for projects exposed to moisture, chemicals, or coastal air. It prevents corrosion that could lead to catastrophic failure, making it the most valuable choice for harsh environments.

Domestic vs. Imported Manufacturing

The origin of an anchor is a common point of discussion. Both domestic and imported products can offer high quality, but traceability is a key differentiator.

Does Origin Impact Quality?

A product’s country of origin does not solely determine its quality. Reputable brands maintain strict quality control standards regardless of where their factories are located. The critical factor is the brand’s commitment to material specifications, manufacturing processes, and consistent testing, not the factory’s address.

Traceability and Mill Certifications

Domestic manufacturers and premium brands often provide superior traceability. They can supply mill certifications (certs) upon request. These documents trace the steel back to its original heat lot, verifying its chemical composition and mechanical properties. For critical structural applications, this documentation is often a requirement for project approval.

Long-Term Value and Reliability

The true value of an anchor is measured over the life of the structure, not by its initial price tag.

The Cost of Anchor Failure

An anchor failure can have devastating consequences. The costs extend far beyond the price of the fastener itself and may include:

- Expensive structural repairs

- Project delays and rework

- Potential for catastrophic accidents and liability

Saving a few dollars on uncertified concrete fasteners is a poor trade-off against these immense risks.

Investing in Certified Anchors

Investing in anchors with current ICC-ES reports and other key approvals is the smartest financial decision. These certifications guarantee that the anchor has been independently tested to perform as specified. This assurance provides peace of mind, ensures code compliance, and represents the best long-term value for any construction project.

For 2026, the choice in concrete fasteners is clear. The Hilti Kwik Bolt TZ2 stands as the premier option for critical applications, justified by its superior performance and extensive approvals. For general-purpose projects where value is key, the Powers Fasteners Power-Stud+ SD1 provides a reliable and widely available solution.

Final Takeaway 📌 The most critical factor for a successful installation is matching the specifications of the wedge anchors—strength, material, and approvals—to your project’s specific demands. Always verify compliance with local building codes and the project engineer’s specifications.

FAQ

Can you reuse a wedge anchor?

No. Wedge anchors are permanent, single-use fasteners. An installer must use a new anchor for every application. Removing an anchor damages it and the concrete, making reuse unsafe and compromising the connection’s integrity.

What happens if you over-torque an anchor?

Over-torquing a wedge anchor can cause immediate failure. The excessive force may strip the threads or break the bolt. This action prevents the expansion clip from setting correctly, which severely compromises the anchor’s holding power.

Can wedge anchors be used in brick or block?

Wedge anchors are designed exclusively for solid concrete. Their expansion mechanism requires a dense base material to function. Using them in hollow or brittle materials like brick or concrete block can cause the base material to crack and fail.

How do you choose the right anchor length?

An installer selects an anchor length by adding the fixture’s thickness to the required minimum embedment depth. The total length must also account for the nut and washer. This calculation ensures the anchor achieves proper embedment for full holding capacity.

Why is cleaning the hole so important? 🧹

Debris in a drilled hole prevents the anchor from reaching its full embedment depth. It also reduces the expansion clip’s grip on the concrete. Installers must clean the hole thoroughly with a brush and compressed air to achieve specified load values.

What is the difference between ultimate load and safe load?

Ultimate Load: The laboratory-tested failure point of an anchor. Safe Working Load: The maximum force an anchor should support in an application. Engineers calculate this by dividing the ultimate load by a safety factor, typically 4.