Choosing expansion bolts is a critical task for structural safety. A professional first identifies the project requirements and the key factors to consider when choosing concrete anchors. This process includes calculating loads and selecting the correct anchor type for the application.

Note: Choosing the right anchor also means matching its material to the environment for durability.

For specific needs, a custom fasteners manufacturer can supply custom anchor bolts. The final selection of Anchor Bolts or other expansion bolts must account for concrete condition to prevent failure.

First Steps in Choosing Expansion Bolts

Before selecting a specific product, a professional must understand the fundamental principles of how these fasteners work and the serious implications of getting it wrong. The process of choosing expansion bolts begins with a firm grasp of mechanical theory and safety imperatives.

How Expansion Bolts Create a Secure Hold

Expansion anchors generate immense holding power by leveraging basic physics. They create a secure connection by exerting an outward force against the interior walls of a drilled hole in the concrete. This action transfers the load from the attached fixture directly into the concrete base material.

The Principle of Mechanical Expansion

The core principle is controlled expansion. An installer activates a mechanism that forces parts of the anchor outward, pressing them firmly against the concrete. This creates a powerful mechanical interlock. The two primary methods for achieving this are:

- Torque-Controlled Anchors: An installer applies a specific amount of torque to a nut or bolt head. This action pulls a conical wedge into an expansion sleeve, forcing the sleeve to expand and grip the hole. Wedge anchors are a classic example of this type.

- Displacement-Controlled Anchors: These expansion anchors use an internal plug. An installer uses a setting tool to drive the plug down into the anchor body, which forces the sleeve to expand against the concrete.

The Role of Friction and Keying in Concrete

The expansion force is only half of the story. This outward pressure generates an incredible amount of friction between the anchor and the concrete. The metal sleeve bites into the microscopic pores and aggregate of the concrete, creating a “keyed” or interlocked effect. This combination of friction and mechanical keying is what prevents the anchor from pulling out under tensile (pulling) forces or shifting under shear (sideways) forces.

Why the Right Choice is Critical for Safety

Selecting the correct fastener is not merely a technical detail; it is a critical safety decision. The integrity of the entire assembly, and potentially the structure itself, depends on the performance of each anchor.

Understanding the Risks of Fastener Failure

Fastener failure can have catastrophic consequences. In 2007, a concrete slab at the Pittsburgh Convention Center collapsed near an expansion joint, a failure partly attributed to a bolt contracting in extreme cold and then failing under load. Decades earlier, warehouse roofs at two separate Air Force bases collapsed because defective expansion joints failed to relieve stress from thermal effects, causing massive structural failure. These incidents underscore the importance of following strict safety guidelines when selecting and installing fasteners.

Ensuring Long-Term Structural Integrity

The right choice ensures the stability of a fixture for its entire service life. A successful project depends on an anchor that can withstand not only the initial dead and live loads but also environmental factors like temperature fluctuations and vibration over many years. Proper selection is the first step in building a connection that is both strong and durable, providing peace of mind and ensuring long-term structural integrity.

A Deep Dive into Concrete Anchor Types

Understanding the different concrete anchor types is fundamental to selecting the right fastener. Each design offers unique benefits and is engineered for a specific type of load and base material. A professional evaluates these types of concrete anchors to find the perfect match for the job. This process of matching anchors to applications ensures both safety and efficiency for any project.

Wedge Anchors: The Heavy-Duty Solution

Wedge anchors are the go-to choice for high-strength connections in solid concrete. Professionals often refer to them as heavy-duty anchors due to their exceptional load-bearing capabilities.

Anatomy and Function

A wedge anchor consists of a threaded stud, a nut, a washer, and an expansion clip at the base. An installer drills a hole, cleans it, and hammers the anchor into place. Tightening the nut pulls the stud upward, forcing the expansion clip to flare out and wedge itself tightly against the walls of the hole. This torque-controlled mechanism creates immense friction and holding power.

Best Applications: Structural Steel, Racking

The superior strength of wedge anchors makes them ideal for securing heavy loads. Common uses include fastening structural steel columns, pallet racking, heavy machinery, and support ledgers. Their performance in demanding situations is well-documented. For example, manufacturers provide detailed load charts showing their capacity.

Typical Ultimate Load Values in 3000 PSI Concrete The following table shows sample ultimate load values for common wedge anchors. An engineer must apply a safety factor to these numbers to determine the Safe Working Load (SWL) for a specific application.

| Anchor Type | Concrete PSI | Tensile Strength (lb) | Shear Strength (lb) |

|---|---|---|---|

| DeWALT® Power-Stud® 3/8 in Dia | 3000 | 1600 | 1840 |

| Simpson Strong-Tie® WA75812 3/4 in Dia | 3000 | 2840 | N/A |

Limitations: Solid Concrete Only

The primary limitation of a wedge anchor is its reliance on a solid base material. It is designed exclusively for solid, cured concrete. An installer should never use a wedge anchor in block, brick, or other hollow or soft materials, as the expansion force can cause the base material to crack or fail. While many modern wedge anchors are rated for use in both cracked and uncracked concrete, it is crucial to verify this on the product’s technical data sheet.

Sleeve Anchors: The Versatile All-Rounder

Sleeve anchors provide a reliable fastening solution across a wider range of materials than wedge anchors, making them a versatile choice for medium-duty jobs.

Anatomy and Function

A sleeve anchor is a pre-assembled fastener that includes a threaded bolt or stud, a flared cone-shaped nut, a washer, and a full-length expansion sleeve. As an installer tightens the bolt head, the cone is pulled into the sleeve. This action causes the sleeve to expand and press against the interior of the drilled hole, creating a secure hold through friction.

Best Applications: Handrails, Window Frames

The sleeve anchor’s design makes it suitable for fastening items to solid concrete, brick, and concrete block. This versatility makes it a popular choice for securing:

- Handrails and guardrails

- Window and door frames

- Shelving and brackets

- Ductwork straps

When used in exterior settings like handrails, the anchor’s material must resist corrosion. Industry standards like ASTM A153/A153M and AASHTO M 232M/M 232 often govern the hot-dip zinc coatings required for such hardware to ensure long-term durability.

When to Use an Alternative

While versatile, sleeve anchors are not the best choice for every situation. Their holding power is generally lower than that of wedge anchors, making them unsuitable for very heavy structural loads. Furthermore, standard sleeve anchors are not recommended for applications in cracked concrete where seismic activity or significant vibration is a concern. In those cases, an engineer would specify an anchor with a seismic rating.

Drop-In Anchors: For Flush and Overhead Needs

Drop-in anchors are female anchors designed for medium-duty loads in solid concrete. Their key feature is a flush-mount finish, which is ideal for overhead applications and situations where a protruding stud is undesirable.

Anatomy and Function

A drop-in anchor is a cylindrical metal shell with internal threads and a pre-installed internal expander plug. After an installer drills a hole and places the anchor inside, they use a special setting tool to drive the internal plug downward. This forces the sides of the anchor to expand and lock into the concrete. The internal threads are then ready to accept a threaded rod or bolt for the fixture.

Best Applications: Suspending Pipes, Cable Trays

The flush-mount design of drop-in anchors makes them perfect for overhead work. Installers commonly use them for:

- Suspending threaded rod for pipe hangers

- Hanging HVAC ductwork and cable trays

- Attaching strut channel to ceilings

- Anchoring sprinkler systems

This anchor provides a clean, finished look once the bolt is installed, making it aesthetically pleasing for exposed ceilings.

Special Tools: The Drop-In Setting Tool

Proper installation of a drop-in anchor requires a specific tool: a drop-in setting tool. Using this tool correctly is critical for achieving the anchor’s full holding capacity. An installer must follow a precise procedure.

- Drill a hole to the specified diameter and depth using a hammer drill.

- Thoroughly clean all dust and debris from the hole with a wire brush and compressed air.

- Insert the anchor, slotted end first, until it is flush with the concrete surface.

- Place the setting tool into the anchor body and strike it firmly with a hammer until the tool’s shoulder meets the top of the anchor. This ensures the internal plug is fully engaged.

💡 Pro Tip: A professional installer listens for a change in sound when striking the setting tool. A solid, ringing sound often indicates the anchor is fully set. This is one of the most important types of concrete anchors for overhead safety.

Other Common Expansion Anchors

Beyond the primary wedge, sleeve, and drop-in anchors, professionals have other specialized concrete anchor types at their disposal. These fasteners often provide simple, fast solutions for light to medium-duty applications. Understanding these additional options helps a specifier choose the most efficient and cost-effective fastener for the job.

Strike Anchors (Hammer-Set Anchors)

A strike anchor is a displacement-controlled anchor designed for speed and simplicity in medium-duty applications. It consists of a tubular body and a nail-like pin.

- Installation: An installer drills a hole, cleans it, and hammers the anchor into the hole. The installer then drives the internal pin with a hammer until it is flush with the anchor’s head. This action forces the anchor body to expand, creating a secure hold.

- Application: Strike anchors are exclusively designed for use in solid concrete. Their ease of installation makes them a popular choice for fastening wood furring strips, electrical junction boxes, and HVAC strapping.

Note: This anchor is a permanent, non-removable fastener. A professional must be certain of the placement before setting it.

Lag Shield Anchors

Lag shield anchors are female-style anchors used to fasten items to concrete, brick, or block using a lag screw. They are available in short and long versions to accommodate different base materials.

- Function: An installer drills a hole and inserts the lag shield anchor until it is flush with the surface. The installer then places the fixture over the anchor and drives a lag screw through the fixture into the shield. As the screw turns, its threads engage the anchor’s internal ribs, causing the shield to expand and grip the base material.

- Use Case: These are intended for light-duty applications. Common uses include attaching signs, pipe clamps, and lightweight brackets. The short version works well in hard, dense materials, while the long version provides more surface area for a better grip in softer or more questionable base materials.

Split Drive Anchors

Split drive anchors are one-piece, light-duty fasteners known for their exceptionally simple installation. They feature a split, expanding base and a rounded or flat head. An installer simply drills a hole of the correct diameter and hammers the anchor in until the head is seated against the fixture. The compression force of the concrete on the split base creates the holding power.

These types of concrete anchors are best for static, light to medium-duty applications in concrete or masonry. Installers often use them for:

- Securing cabinets and shelves

- Attaching electrical fixtures

- Fastening cladding materials

Important Limitation: Split drive anchors have a limited weight capacity compared to other metal anchors. A professional should not use them in outdoor or damp environments, as they are typically made from zinc-plated steel. They also lack high vibration resistance.

The following table summarizes the general load capacities for these concrete anchor types.

| Anchor Type | Common Applications | Typical Load Range |

|---|---|---|

| Strike Anchors | Furring strips, junction boxes | Medium-duty (100-500 lbs) |

| Lag Shield Anchors | Signs, pipe clamps | Light-duty (Under 100 lbs) |

| Split Drive Anchors | Shelves, electrical fixtures | Light to medium-duty |

How to Calculate Load and Select Anchor Size

Properly choosing expansion bolts requires a professional to perform careful calculations. This process ensures the selected fastener can safely handle all anticipated forces throughout its service life. The selection process moves from understanding the load requirements to applying a safety factor and finally to interpreting manufacturer specifications.

Step 1: Determine the Load Requirements

The first step in any fastening project is to quantify the forces the anchor must resist. A professional must identify and calculate all potential loads to determine the maximum weight the anchor needs to support. These loads fall into distinct categories based on their source and direction.

Calculating Dead Loads (Static Weight)

Dead loads are constant, unchanging forces. They include the self-weight of the structure and any permanently attached fixtures. A specifier calculates dead loads by multiplying the volume of an object by the unit weight of its material.

For example, to find the dead load of a concrete slab, an engineer uses a simple formula:

Dead Load per Area = Slab Thickness × Unit Weight of ConcreteA concrete slab that is 0.25 meters thick with a material unit weight of 25 kN/m³ would have a dead load of 6.25 kN/m².

Professionals find the unit weights for common materials in engineering handbooks and building codes.

Identifying Live Loads (Dynamic Forces)

Live loads are temporary or moving forces. They are much more difficult to predict than dead loads. These forces come from furniture, equipment, occupants, snow, and wind. Due to their variable nature, professionals do not calculate live loads from scratch. Instead, they refer to design codes and standards like ASCE 7-16. These documents provide standardized live load values for different types of buildings and occupancies, ensuring a consistent and safe approach.

Understanding Tensile vs. Shear Forces

Forces also act in different directions, which significantly impacts anchor performance. An installer must consider two primary force types:

- Tensile Force: This is a pulling force that tries to pull the anchor straight out of the concrete.

- Shear Force: This is a sideways force that acts perpendicular to the anchor, trying to slice it off.

An anchor’s capacity to resist these forces depends on concrete strength, embedment depth, and spacing. When tensile and shear forces act on an anchor simultaneously, its overall strength is reduced. This interaction is critical; an anchor that is strong enough for a tensile load alone may fail when a shear load is also applied.

Step 2: Apply the 4:1 Safety Factor

Safety is the most important consideration in structural fastening. A professional never designs a connection to meet only the minimum calculated load. Instead, they apply a safety factor to create a crucial buffer between the expected load and the anchor’s breaking point.

What is a Safety Factor?

A safety factor is a multiplier applied to the calculated working load to determine the required minimum strength of a fastener. For static loads, the industry standard is a 4:1 safety factor. This means the anchor must be at least four times stronger than the load it is expected to hold. This accounts for unforeseen circumstances, material variations, and degradation over time.

How to Calculate Your Minimum SWL

To determine the required strength, a professional first calculates the total load. Then, they apply the safety factor.

- Calculate Total Load:

Total Load = Dead Load + Live Load - Apply Safety Factor:

Minimum Required SWL = Total Load × 4

The result of this calculation gives the minimum Safe Working Load (SWL) that the selected anchor must have. This ensures the connection remains secure well below its ultimate failure point.

Step 3: Read Manufacturer Load Charts

After calculating the minimum required SWL, the next step is to consult the technical data sheets provided by the anchor manufacturer. These charts contain the performance data needed to select the correct size and type of anchor for the specific requirements of the job.

Safe Working Load (SWL) vs. Ultimate Load

Manufacturer charts list two important values:

- Ultimate Load: This is the force at which the anchor failed during laboratory testing. A professional should never use this value for design purposes.

- Safe Working Load (SWL): Also called the Allowable or Design Load, this is the maximum load the manufacturer recommends for the anchor. This value already has a safety factor (typically 4:1) built-in.

A specifier must ensure the anchor’s listed SWL is greater than or equal to the minimum required SWL calculated in the previous step.

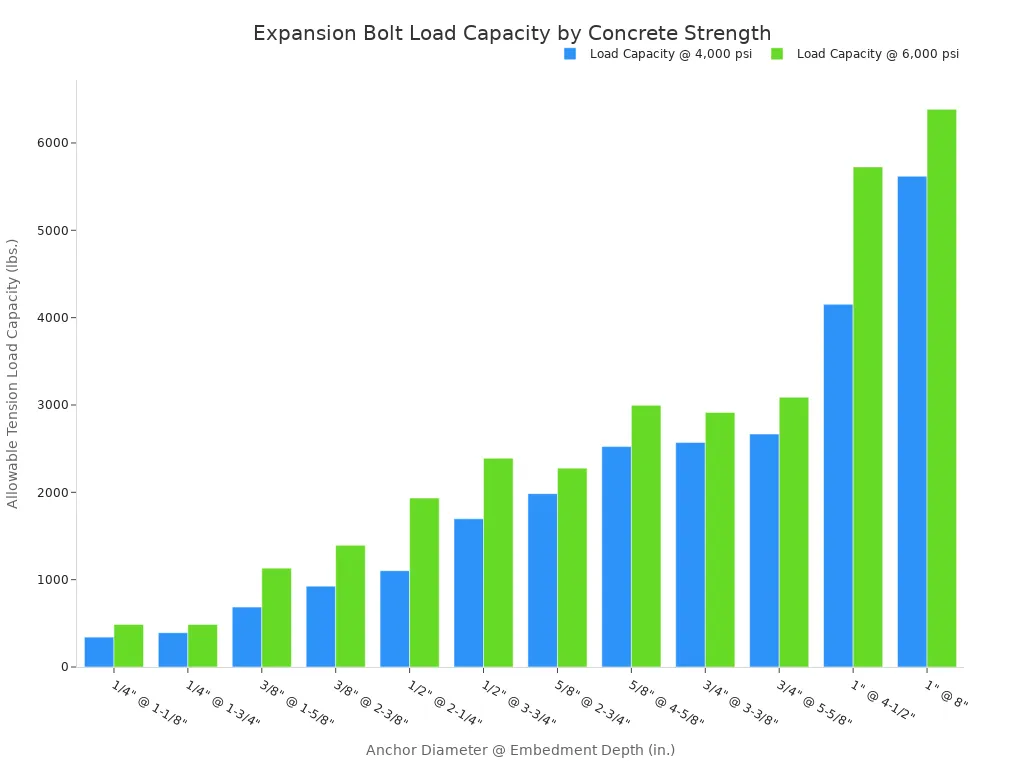

How Embedment Depth Affects Strength

Load charts show that an anchor’s strength is not a single number. It changes based on several factors, primarily embedment depth and the compressive strength of the concrete. Deeper embedment gives the anchor more concrete to grip, increasing its pull-out resistance. Likewise, stronger concrete (measured in PSI) provides a more robust base material, which also increases holding power.

The following chart illustrates how allowable tension loads for an anchor increase with deeper embedment and higher-strength concrete.

As shown, a 1/2″ anchor embedded 2-1/4″ deep in 4,000 PSI concrete has an allowable load of 1,103 lbs. Increasing the embedment to 3-3/4″ raises that capacity to 1,697 lbs. A professional uses these tables to find a diameter and embedment combination that safely exceeds the project’s calculated load.

Assessing Your Concrete and Environment

A successful fastening project depends on more than just the anchor itself. A professional must thoroughly evaluate the concrete base material and the surrounding environment. This assessment ensures the chosen fastener will perform safely and have a long service life.

Evaluating the Base Material

The condition and type of concrete are critical factors that directly influence an expansion bolt’s holding power. An installer must verify the concrete’s suitability before drilling the first hole.

Cured vs. “Green” Concrete

Expansion anchors require fully cured concrete to achieve their specified strength. Concrete cures over time, gaining compressive strength in the process. Installing an anchor in “green” or uncured concrete is a critical error. The expansion forces can easily damage the soft material, leading to a weak connection or complete failure.

💡 Rule of Thumb: Most concrete requires at least 28 days to reach its designed compressive strength. Always verify the concrete’s age and cure status before installation.

Checking for Cracks, Voids, or Spalling

A visual inspection of the concrete surface is essential. An installer looks for pre-existing cracks, voids (hollow spots), or spalling (flaking or chipped surfaces). Fastening into or near these defects significantly compromises the anchor’s capacity. If the concrete quality is questionable, a professional may need to select a different location or use a specialized anchor designed for cracked concrete.

Light vs. Normal Weight Concrete

Concrete is not all the same. It can be normal weight or lightweight, which affects its density and strength. Lightweight concrete has lower compressive strength, which reduces the holding power of expansion anchors. As the concrete’s compressive strength increases, so does the anchor’s tension capacity.

| Anchor Size | Embedment Depth | Concrete Strength (PSI) | Tension Capacity (lbs) | Shear Capacity (lbs) |

|---|---|---|---|---|

| 3/8-inch | 2-3/8 inch | 2,500 | 3,485 | 2,540 |

| 3/8-inch | 2-3/8 inch | 6,000 | 5,400 | 2,540 |

The Importance of Concrete Thickness

The thickness of the concrete slab or wall limits the anchor’s embedment depth. This relationship is crucial for preventing base material failure.

Matching Embedment Depth to Thickness

An installer must select an anchor with an embedment depth appropriate for the concrete’s thickness. A general guideline is that the concrete thickness should be at least 1.5 times the anchor embedment depth. This ensures there is enough material to support the stress cone created by the anchor.

How to Prevent Concrete “Blowout”

Concrete “blowout” occurs when an anchor is installed too deep in thin concrete. The expansion force pushes a cone of concrete out from the opposite side, causing a catastrophic failure. Adhering to the manufacturer’s minimum thickness requirements is the only way to prevent this.

Choosing the Right Material for Durability

The anchor’s material must be able to withstand the environmental conditions of the installation site. Choosing the wrong material can lead to premature corrosion and failure.

Indoor Use: Zinc-Plated Carbon Steel

For dry, indoor applications, zinc-plated carbon steel is the standard and most economical choice. The zinc coating provides a minimal layer of corrosion protection suitable for controlled interior environments.

Outdoor/Wet Use: Hot-Dip Galvanized Steel

When fasteners are exposed to moisture or outdoor elements, hot-dip galvanized steel is necessary. This process applies a thick, durable layer of zinc that offers substantial protection against rust and corrosion.

Corrosive Environments: Stainless Steel (304 & 316)

For the harshest conditions, stainless steel is the superior choice.

- Type 304 Stainless Steel is ideal for freshwater environments and areas with chemical exposure.

- Type 316 Stainless Steel contains molybdenum, giving it maximum corrosion resistance. It is essential for saltwater and coastal marine environments.

In marine settings, a galvanized fastener may only last a few years, while a Type 316 stainless steel fastener can last for a decade or more. This longevity makes it the safest choice for critical applications near the coast.

A Guide to Proper Expansion Bolt Installation

Selecting the right anchor is only half the battle; its performance depends entirely on correct installation. A professional follows a meticulous process, using specific tools and techniques to ensure the connection is safe and achieves its full engineered strength. This commitment to proper installation is what separates a reliable fixture from a potential failure.

Essential Tools for the Job

Using the correct equipment is the first step toward a successful outcome. A professional installer’s toolkit contains specific items designed for precision and safety. Major manufacturers recommend a core set of tools for any expansion bolt project.

- Hammer drill

- Correctly sized carbide drill bit

- Hammer

- Properly sized machine bolt/screw

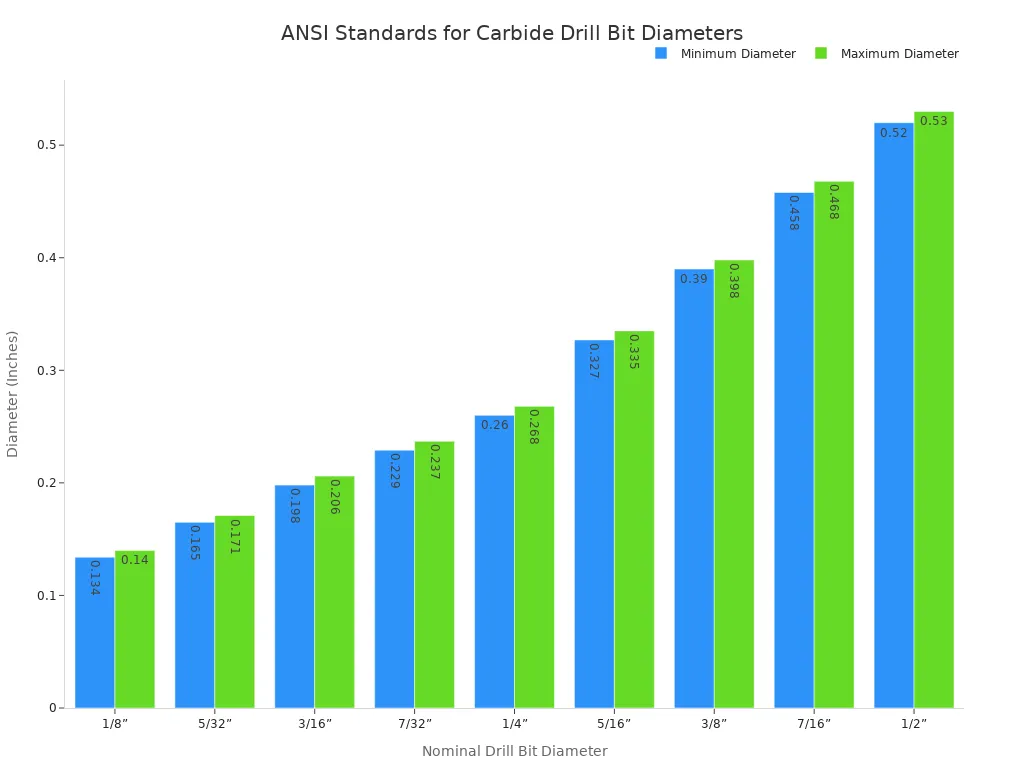

Hammer Drill and ANSI-Standard Carbide Bits

A rotary hammer or hammer drill is essential for efficiently drilling into concrete. The quality of the drill bit is equally important. Professionals use carbide-tipped bits that meet the American National Standards Institute (ANSI) standard B212.15. This standard dictates a very tight tolerance for the bit’s diameter, ensuring the drilled hole is not too large or too small for the anchor.

Hole Cleaning Tools: Wire Brush and Air Blower

A wire brush and a source of compressed air (like a hand pump or air blower) are non-negotiable. These tools remove the concrete dust and debris left behind after drilling. A clean hole is critical for achieving the anchor’s maximum holding power.

Calibrated Torque Wrench

For torque-controlled anchors like wedge anchors, a calibrated torque wrench is mandatory. It allows the installer to apply the exact amount of rotational force specified by the manufacturer, ensuring the expansion mechanism is properly engaged without over-stressing the bolt or the concrete.

The Drilling Process

The drilling phase requires precision. The diameter and depth of the hole must perfectly match the requirements of the selected fastener.

Matching Drill Bit Diameter to the Anchor

The relationship between the drill bit diameter and the anchor diameter is critical. For many common fasteners, such as wedge and sleeve anchors, the rule is simple: the drill bit diameter is the same as the anchor diameter. However, this is not a universal rule. Other types of anchors require a hole that is larger than the fastener itself. An installer must always follow the manufacturer’s directions, as the specified hole size is integral to the product’s performance testing.

| Anchor Type | Anchor Size | Drill Bit Size |

|---|---|---|

| Wedge Anchors | Any | Same as Anchor |

| Sleeve Anchors | Any | Same as Anchor |

| Drop-In Anchors | 1/4″ | 3/8″ |

| 3/8″ | 1/2″ | |

| Lag Screw Shields | 1/4″ | 1/2″ |

| 3/8″ | 5/8″ |

Drilling to the Correct Depth

An installer must drill the hole to the minimum depth specified in the anchor’s technical data. This ensures the fastener achieves the required embedment. Drilling too shallow prevents the anchor from being set correctly, while drilling too deep can be inefficient and may cause issues with setting certain anchor types.

The Critical Step: Cleaning the Drilled Hole

Many fastener failures can be traced back to a single, overlooked step: cleaning the hole. This simple action has a massive impact on the final strength of the installation.

Why Debris Reduces Holding Power

Concrete dust acts as a lubricant. If left in the hole, it prevents the expansion sleeve from making solid contact with the base material. This dramatically reduces the friction needed for the anchor to resist pull-out forces, compromising its load capacity.

The Brush-Blow-Brush-Blow Method

Professionals use a simple yet effective procedure to guarantee a clean hole. An installer inserts a wire brush to the bottom of the hole and scrubs the sides. Then, they use an air blower to force all the loose dust out. They repeat this process—brush, then blow—at least twice to ensure the hole is completely free of debris.

Setting the Anchor and Applying Torque

With the hole drilled and cleaned, the final steps of the installation involve physically setting the fastener and applying the precise amount of torque. This stage activates the anchor’s expansion mechanism, creating the secure connection that will support the intended load. A professional executes this phase with precision to guarantee a safe and reliable outcome.

Tapping the Anchor into Place

An installer first positions the fixture over the drilled hole. They then insert the anchor through the fixture and into the concrete. For a wedge anchor, the installer gently taps the nut end with a hammer. This drives the fastener into the hole until the washer rests firmly against the surface of the fixture. This process should be done carefully to avoid damaging the threads on the bolt. For a drop-in anchor, the installer uses a setting tool to expand the anchor before inserting a bolt.

💡 Pro Tip: When setting a wedge anchor, an installer should leave the nut on the end of the threads. This protects the threads from being damaged by the hammer strikes.

Following Manufacturer Torque Specifications

Applying the correct torque is the most critical part of the installation for torque-controlled fasteners. This rotational force pulls the expansion clip into the sleeve, generating the outward pressure that locks the anchor into the concrete. Using a calibrated torque wrench is not optional; it is essential for meeting the manufacturer’s requirements.

- Under-torquing fails to expand the sleeve sufficiently, resulting in a weak hold that could pull out under load.

- Over-torquing can stress the bolt beyond its yield point, causing it to break. It can also crack the surrounding concrete, leading to a complete failure of the connection.

Torque values are not universal. They vary based on the anchor’s diameter, material grade, and surface coating. A galvanized coating, for example, increases friction and requires a higher torque value than a plain or lubricated bolt. A professional always consults the technical data for the specific fastener.

| Bolt Size | Material Grade | Tightening Torque (ft lbs) – Plain | Tightening Torque (ft lbs) – Galv | Tightening Torque (ft lbs) – Galv+Waxed |

|---|---|---|---|---|

| 3/8″ | ASTM A307 | 12 | 15 | 6 |

| 1/2″ | ASTM A307 | 29 | 37 | 15 |

| 3/8″ | ASTM A449 / SAE Grade 5 | 31 | 39 | 15 |

| 1/2″ | ASTM A449 / SAE Grade 5 | 75 | 94 | 38 |

| 5/8″ | ASTM A325 | 198 – 240 | N/A | 99 – 120 |

Following these specifications ensures the fastener performs exactly as engineered, completing a safe and durable installation.

Best Practices for Installation Spacing

A professional understands that the placement of an expansion bolt is as critical as the installation technique. The concrete surrounding the fastener must be sufficient to handle the immense expansion forces. Following best practices for installation spacing ensures the base material does not become the point of failure. This involves respecting two key measurements: the distance from an edge and the spacing between adjacent fasteners.

Maintaining Minimum Edge Distance

The location of an anchor relative to the edge of a concrete slab or wall directly impacts its performance. Placing a fastener too close to an unsupported edge is a common and dangerous mistake.

What is Edge Distance?

Edge distance is the measurement from the centerline of an anchor to the nearest free edge of the concrete. When an expansion bolt is tightened, it exerts outward pressure, creating a cone of stress in the concrete. If this stress cone reaches an edge, it can cause the concrete to crack and break away, a failure known as “blowout.” To prevent this, installers must adhere to minimum edge distance requirements.

- A general guideline for wedge anchors suggests a minimum edge distance of 5 anchor diameters from an unsupported edge.

- Inadequate edge distance can lead to severe concrete cracking and a drastic reduction in load capacity.

- Ultimately, failing to maintain proper distance can cause a complete anchor failure.

Finding Edge Distance on a Technical Data Sheet

Manufacturers provide precise minimum edge distance values on the technical data sheet for each product. A professional always consults this document before drilling. These specifications are not suggestions; they are requirements based on extensive laboratory testing. Following these values is essential for a safe and reliable connection.

Ensuring Minimum Anchor Spacing

When a project requires multiple fasteners in a group, the distance between them becomes just as important as the edge distance. This measurement is known as anchor spacing.

Why Spacing Between Anchors Matters

Each anchor creates its own cone of stress within the concrete. If two fasteners are installed too close together, their stress cones will overlap. This overlap creates a weak point between the fasteners, significantly reducing the pull-out capacity of the entire group. The concrete in the overlapping zone is essentially being pulled in two different directions, making it highly susceptible to failure under load.

How to Avoid Overlapping Stress Cones

Professionals use established guidelines to prevent stress cone overlap. A common rule recommends a minimum spacing of 3 times the effective embedment depth (3*hef). Other guidelines suggest a minimum spacing of at least 12 times the fastener’s diameter. For full load capacity, some manufacturers recommend a spacing of 16 times the diameter. These best practices for installation ensure each fastener can develop its full holding power without interfering with its neighbors. A specifier must always check the manufacturer’s data for the exact spacing requirements for the specific anchor being used.

Comparing Alternatives When Choosing Concrete Anchors

A professional specifier understands that expansion anchors are not the only solution for fastening to concrete. The selection process often involves comparing different concrete anchor types to find the best fit for a project’s specific demands. Two common alternatives are concrete screws and adhesive anchors, each with distinct advantages and limitations.

Expansion Anchors vs. Concrete Screws

Concrete screws, often known by brand names like Tapcon®, offer a different fastening mechanism than expansion bolts. A professional evaluates their unique characteristics for light to medium-duty tasks.

Strength and Application Differences

Concrete screws are designed for light and medium-duty loads. They function by cutting their own threads directly into the concrete, creating a secure connection. This makes them ideal for fastening electrical boxes, furring strips, and window frames. In contrast, expansion anchors generate much higher holding power through friction and are necessary for heavy structural loads like pallet racking or support columns.

Removability and Reusability

A primary advantage of concrete screws is their removability. An installer can easily back them out, making them perfect for temporary installations or fixtures that may need adjustment. Most expansion anchors, once set, create a permanent connection and cannot be removed without damaging the concrete.

Expansion Anchors vs. Adhesive (Epoxy) Anchors

Adhesive anchors, also known as epoxy anchors, use a chemical bond to secure a threaded rod into concrete. They represent one of the strongest concrete anchor types available.

Load Capacity and Performance

Adhesive anchors often provide superior load capacity, particularly in challenging conditions. Professionals recognize their enhanced security, as the adhesive distributes stress throughout the anchor, rather than concentrating it at one point. This characteristic significantly reduces the likelihood of the base material cracking. Adhesive anchors are highly effective in cracked concrete because their resin forms a powerful bond with the existing aggregate. While mechanical anchors provide a robust initial interlock, adhesive systems are often preferred in high-vibration environments because they are less prone to loosening over time.

Installation Complexity and Cure Time

The installation of an adhesive anchor is more involved. It requires meticulous hole cleaning, injecting the two-part epoxy, and inserting the threaded rod. The most significant difference is the need for cure time.

⏱️ Cure Time is Critical: An adhesive anchor cannot be loaded until the epoxy has fully hardened, a process that can take from a few hours to over a day depending on the product and ambient temperature. This contrasts with expansion anchors, which can handle their full load immediately after proper torquing, making them a better choice for a time-sensitive application.

A successful project hinges on a clear formula when choosing expansion bolts: correct selection, precise calculation, and meticulous installation. A professional prioritizes safety, applying a 4:1 safety factor and matching the anchor material to the environment for long-term durability. Ultimately, proper installation is non-negotiable. Even the best anchor fails without it, making correct drilling, cleaning, and torquing essential for optimal performance.

FAQ

Can an expansion bolt be reused?

A professional should never reuse an expansion bolt. Once set, the anchor’s expansion mechanism permanently deforms. Removing and reinstalling it compromises its holding power and creates a significant safety risk. A new anchor is always required for a new installation.

What happens if the hole is not cleaned?

Failure to clean the drilled hole drastically reduces an anchor’s strength. Concrete dust acts as a lubricant, preventing the anchor from properly gripping the base material. This can lead to the anchor pulling out under a much lower load than its design capacity.

Why is a torque wrench necessary?

A calibrated torque wrench ensures an installer applies the precise rotational force specified by the manufacturer.

- Under-torquing results in a weak hold.

- Over-torquing can break the bolt or crack the concrete. Proper torque is essential for activating the anchor correctly and safely.

Can expansion bolts be used in brick?

Some expansion bolts, like sleeve anchors, are suitable for brick or block. However, heavy-duty wedge anchors are not. A professional must always verify the anchor’s specifications. Using the wrong anchor in a hollow or soft material can cause the base material to fail.

How long do expansion bolts last?

The lifespan of an expansion bolt depends on its material and environment.

A zinc-plated bolt may last for decades indoors. In a wet or coastal setting, a hot-dip galvanized or stainless steel anchor is necessary to prevent corrosion and ensure long-term structural integrity.

What is the strongest type of concrete anchor?

For pure strength, adhesive (epoxy) anchors often provide the highest load capacities. They distribute stress over a large area and bond chemically with the concrete. Among mechanical anchors, heavy-duty wedge anchors are typically the strongest option for solid concrete applications.