Fastener-related failures cause significant project delays and rework. Choosing the right drop in anchor size depends on two primary factors: the diameter of the Anchor Bolts or custom anchor bolts and the required holding strength. A custom fasteners manufacturer provides the correct anchor size for drop in anchors. This makes choosing the right drop in anchors a critical step for structural integrity.

The fundamental rule is simple. An anchor’s internal thread diameter must match the external diameter of the bolt for all drop in anchors.

Step 1: Match Anchor Diameter to Your Bolt or Threaded Rod

An installer’s first step is to match the anchor’s internal diameter to the bolt or threaded rod. This ensures a secure and reliable connection. This initial check prevents most common installation failures.

The First Rule of Choosing the Right Anchor

Understanding Internal vs. External Diameter

Every drop-in anchor has two critical diameters. The internal diameter refers to the size of the threads inside the anchor. The external diameter is the measurement of the anchor’s outer body. The internal diameter must match the bolt’s diameter for proper threading. The external diameter determines the drill bit size needed for installation. Confusing these two measurements leads to incorrect anchor selection.

Why a Mismatched Size Guarantees Failure

Using a bolt that is too small for the drop-in anchor creates a loose connection. The threads will not engage correctly, offering almost no holding power. The fixture will be unstable and unsafe. Conversely, a bolt that is too large will not fit into the anchor at all. This mistake wastes time and materials on site. A proper match is non-negotiable for a secure fastening. For all drop in anchors, the correct pairing is essential for structural integrity.

A Quick-Reference Guide to Common Pairings

Installers frequently use standard sizes for drop in anchors. The following pairings represent the most common applications in construction and fabrication.

Matching a 1/4″ Bolt to a 1/4″ Drop-In Anchor

A 1/4″ drop-in anchor is designed specifically for a 1/4″ diameter bolt or threaded rod. This size is common for light-duty applications like fastening electrical conduit straps or lightweight signage.

Matching a 3/8″ Bolt to a 3/8″ Drop-In Anchor

For medium-duty tasks, a 3/8″ bolt requires a 3/8″ drop-in anchor. This combination is often used for installing cable trays, support brackets, and handrails. It offers a significant increase in holding power over the 1/4″ size.

Matching a 1/2″ Bolt to a 1/2″ Drop-In Anchor

Heavy-duty applications often call for a 1/2″ bolt and a corresponding 1/2″ drop-in anchor. These are suitable for securing machinery, structural supports, and heavy pipe racks. The larger diameter provides substantial load-bearing capacity.

Matching a 5/8″ Bolt to a 5/8″ Drop-In Anchor

When maximum strength is required, a 5/8″ bolt is paired with a 5/8″ drop-in anchor. These robust drop in anchors are used for major structural connections and anchoring heavy industrial equipment.

How to Read Anchor Size Designations

Manufacturers use specific part numbers and sizing conventions. Understanding these helps professionals quickly identify the correct anchor size.

Decoding Manufacturer Part Numbers

Manufacturers often encode size information directly into their part numbers. This system allows for quick identification of different types of concrete drop-in anchors. For example, a manufacturer might use a numerical suffix to denote the size. The size designations for these drop in anchors appear as numerical suffixes within the part numbers.

HAC-V 40HAC-V 50HAC-V-T 30HAC-V-T 70

In this system, numbers like ’40’, ’50’, and ’30’ indicate the specific size. Always consult the manufacturer’s technical data sheet to confirm what each number represents.

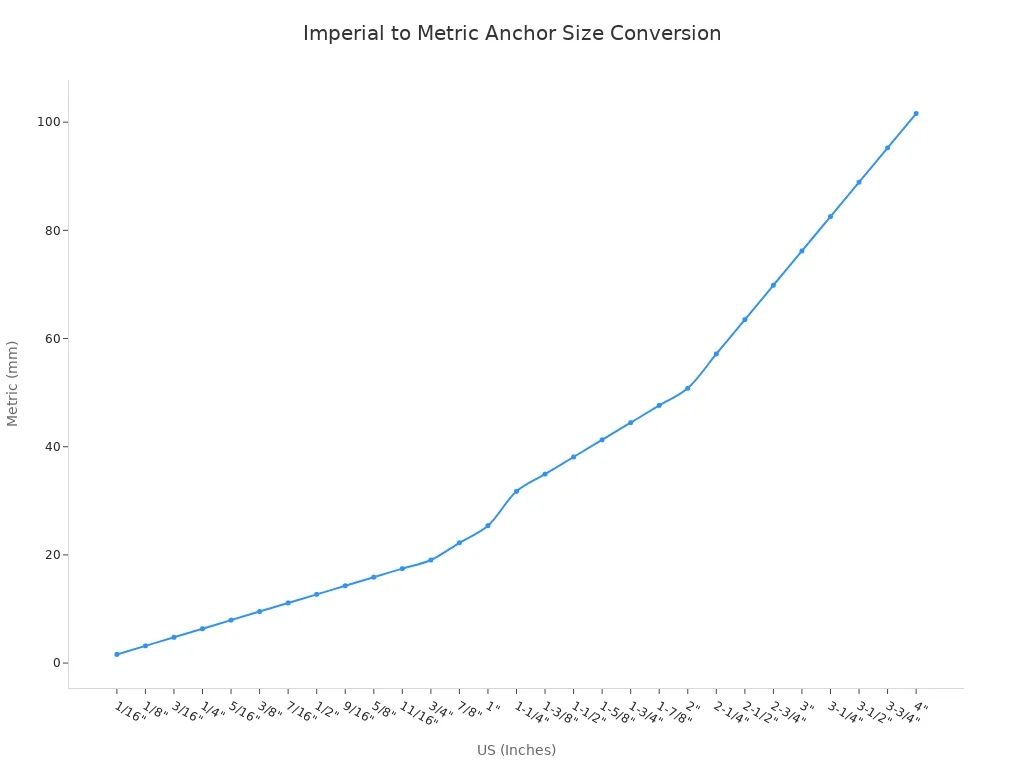

Imperial (Inch) vs. Metric (mm) Sizing

Projects may specify fasteners in either imperial (inch) or metric (mm) units. It is critical to use a consistent system for both the bolt and the drop-in anchor. Mixing these systems will result in a failed connection. For example, a 1/2″ bolt (12.7 mm) is not interchangeable with a 12 mm anchor. The small difference prevents proper thread engagement. The following chart helps convert between common imperial and metric sizes for drop in anchors.

| Standard (SAE) | Metric (mm) | Inches (decimal) |

|---|---|---|

| 1/4″ | 6.35 mm | 0.25″ |

| 5/16″ | 7.9375 mm | 0.313″ |

| 3/8″ | 9.525 mm | 0.375″ |

| 1/2″ | 12.7 mm | 0.5″ |

| 5/8″ | 15.875 mm | 0.625″ |

| 3/4″ | 19.05 mm | 0.75″ |

| 1″ | 25.4 mm | 1″ |

Note: Always double-check project specifications to confirm whether imperial or metric fasteners are required. Using a conversion chart ensures you select the correct drop in anchors for the job.

Step 2: Determine Required Holding Power for Drop in Anchors

After matching the anchor to the bolt, the next critical step is to ensure the chosen anchor can safely support the intended load. The holding power of drop-in anchors is not infinite; it depends on the load type, the anchor’s strength ratings, and its embedment depth in the concrete. A failure to properly assess these factors can lead to a catastrophic connection failure.

Assess Load Weight and Safety Factors

An installer must first understand the forces that will act upon the anchor. These forces determine the minimum strength required for a safe and permanent installation.

Static Loads vs. Dynamic Loads

Loads are categorized into two main types:

- Static Loads: These are constant, unchanging forces. A static load does not move or vibrate. Examples include a wall-mounted cabinet, a stationary pipe rack, or a permanently fixed sign. These loads are predictable and exert a consistent downward or outward force.

- Dynamic Loads: These are variable forces that involve movement, vibration, or shock. Examples include operating machinery, support systems for hoists, or fixtures in high-wind areas. Dynamic loads place significantly more stress on drop in anchors and require a much higher safety margin.

How to Calculate the Total Load

To determine the total load, an installer calculates the combined weight of the object being fastened and any additional weight it will support. For example, when anchoring a storage rack, the calculation must include the weight of the rack itself plus the maximum weight of the items that will be stored on it. This total figure represents the “working load” the anchor must support.

The Importance of Applying a Safety Factor

A safety factor is a crucial multiplier applied to the working load to ensure the anchoring system is strong enough to handle unexpected stresses. It builds a buffer between the expected load and the anchor’s ultimate failure point. For static loads, a standard safety factor is often 4:1. This means the anchor system must be four times stronger than the calculated total load.

For dynamic loads, engineering associations recommend much higher design factors. Rigging systems are often designed with safety factors of 5:1 or even 8:1. Applying a 5:1 factor means the selected drop-in anchors must have a published ultimate load capacity at least five times greater than the expected working load.

Understanding Anchor Strength Ratings

Manufacturers test drop-in anchors to determine their ultimate load capacity. This data is published in two key ratings: tensile strength and shear strength. These values help professionals select an anchor that meets the calculated load requirements.

Tensile Strength (Pull-Out Force)

Tensile strength measures the anchor’s resistance to a direct pulling force. It is the amount of force required to pull the anchor straight out of the base material. This is a primary consideration when hanging objects from a ceiling or fastening items that will experience an upward or outward force.

Shear Strength (Side Force)

Shear strength measures the anchor’s resistance to a side-to-side or perpendicular force. It is the force needed to snap the bolt or cause the anchor to fail from pressure applied parallel to the concrete surface. This is a critical factor for objects mounted on a wall that exert a downward force.

How Anchor Diameter Impacts Strength

There is a direct correlation between an anchor’s diameter and its strength. A larger diameter anchor has more surface area and a larger cross-section, providing significantly higher tensile and shear values. Moving from a 3/8″ to a 1/2″ anchor, for example, can more than double the holding power, creating much stronger holding points for heavy-duty applications.

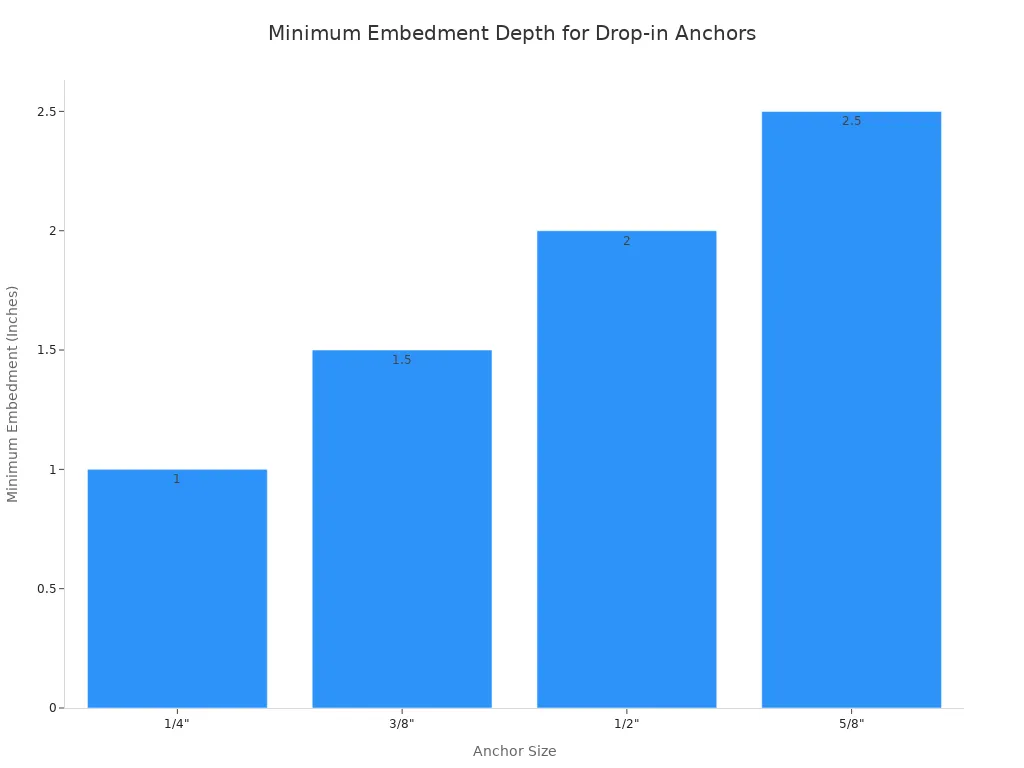

The Critical Role of Embedment Depth

Embedment depth is the distance the anchor is installed into the concrete. This single factor has a massive impact on the performance of all drop in anchors. Proper embedment is non-negotiable for achieving the anchor’s rated capacity.

What is Minimum Embedment Depth?

Minimum embedment depth is the shallowest depth at which an anchor must be installed to achieve its published load values. Installing an anchor any shallower than this specified depth will compromise its performance and can lead to failure under load. Manufacturers provide this data for each anchor size.

| Anchor Size | Minimum Embedment |

|---|---|

| 1/4″ | 1″ |

| 3/8″ | 1 1/2″ |

| 1/2″ | 2″ |

| 5/8″ | 2 1/2″ |

How Deeper Embedment Increases Holding Values

Installing drop in anchors deeper than the minimum significantly increases their pull-out strength. As the anchor is set deeper, it engages a larger cone of concrete, distributing the load over a greater area. Performance data clearly shows this benefit. For example, in normal-strength concrete, increasing embedment from 50 mm to 70 mm can boost pull-out strength by over 50%. While complex formulas exist, experimental results show that the relationship between deeper embedment and increased holding power is nearly linear, making it a reliable strategy for enhancing safety and performance.

Where to Find Manufacturer Embedment Data

The most reliable source for performance data is the manufacturer’s technical documentation. Installers should always consult the product’s technical data sheet (TDS) or engineering specifications. These documents provide detailed charts listing the ultimate tensile and shear loads for drop in anchors at various embedment depths and in different strengths of concrete.

Step 3: Evaluate the Concrete for Your Drop-In Anchors

The performance of drop-in anchors depends entirely on the quality of the base material. Even the correct size anchor will fail if the concrete is too thin, too weak, or compromised. A professional installer always evaluates the concrete slab or wall before drilling. This evaluation ensures the concrete can support the loads transferred by the drop in anchors.

Measure Concrete Thickness

The thickness of the concrete member is a primary limiting factor for anchor installation. It directly dictates the maximum allowable embedment depth for all concrete drop-in anchors.

The Rule of Thumb: Thickness vs. Embedment

A fundamental rule is that the concrete’s thickness must be at least 1.5 times the anchor’s embedment depth. This prevents the anchor’s expansion force from cracking or damaging the opposite side of the concrete.

Dangers of Installing in Thin Concrete

Installing drop in anchors in thin concrete slabs is extremely dangerous. Research on anchor performance shows that insufficient thickness leads to a “concrete breakout” failure. The expansion force from the anchor creates a cone-shaped failure in the concrete, causing a section to blow out and the anchor to lose all holding power. This risk increases significantly as the embedment depth approaches the slab’s total thickness.

Simple Methods to Measure Slab Thickness

An installer can determine concrete thickness in several ways. The most reliable method is to consult the project’s structural drawings or building plans. If plans are unavailable, drilling a small test hole completely through the slab and measuring its depth provides an accurate measurement.

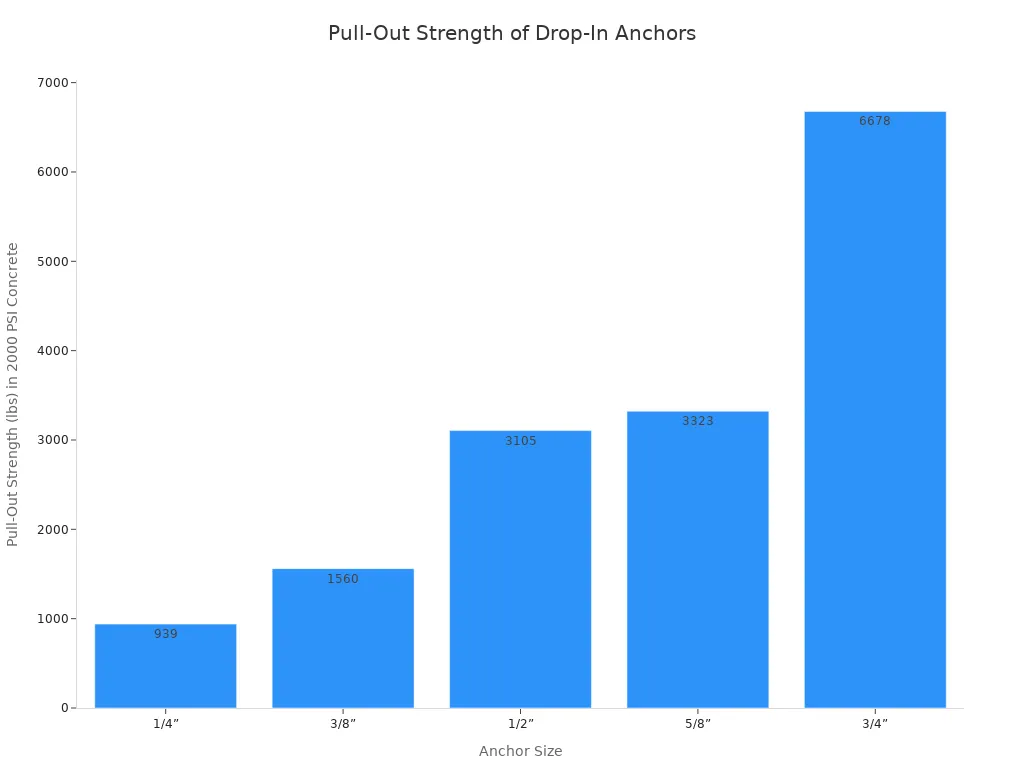

Assess Concrete Quality and Strength

The compressive strength of concrete, measured in pounds per square inch (PSI), directly impacts the holding power of concrete drop-in anchors. Manufacturer load data is based on specific PSI values.

Minimum Concrete PSI Requirements (2000 PSI+)

Most manufacturers base their published load values on tests conducted in normal-weight concrete with a minimum compressive strength of 2000 PSI. Using drop in anchors in concrete with a lower PSI will significantly reduce their pull-out and shear strength.

| Anchor Size | Minimum Embedment | Pull-Out (lbs.) in 2000 PSI Concrete |

|---|---|---|

| 1/4” | 1” | 939 |

| 3/8” | 1-9/16” | 1560 |

| 1/2” | 2” | 3105 |

| 5/8” | 2-1/2” | 3323 |

| 3/4” | 3-3/16” | 6678 |

Issues with Uncured or “Green” Concrete

Installers must never install drop-in anchors into “green” or uncured concrete. Fresh concrete has not yet reached its designed compressive strength. Setting an anchor prematurely will damage the concrete and result in extremely low holding values. Professionals should always wait for the concrete to cure fully, which typically takes at least 28 days.

Why Cracked or Low-Quality Concrete Reduces Holding Power

Published strength ratings for concrete drop-in anchors assume installation in solid, uncracked concrete. Cracks, voids, or low-quality aggregate compromise the integrity of the base material. An anchor installed near a crack cannot develop its full holding power because the concrete’s stress-bearing “cone of influence” is incomplete.

Maintain Critical Edge and Spacing Distances

Proper placement of drop in anchors is just as important as the concrete’s quality. American Concrete Institute (ACI) guidelines specify minimum distances to prevent premature failure.

Defining Minimum Edge Distance

Minimum edge distance is the shortest distance allowed between the center of an anchor and the nearest free edge of the concrete slab. Installing an anchor too close to an edge can cause the side of the concrete to break away.

Defining Minimum Anchor Spacing

Minimum anchor spacing is the shortest distance allowed between the centers of two adjacent drop in anchors. A common guideline for non-torqued anchors is a minimum spacing of four times the anchor diameter (4da).

How These Distances Prevent Concrete Blowout

When a load is applied to a drop-in anchor, it relies on a cone-shaped area of concrete below it for pull-out resistance. This is known as the “cone of influence.”

- Spacing: If two concrete drop-in anchors are installed too close together, their stress cones overlap. This means both anchors are competing for the same area of concrete, which significantly reduces the capacity of the entire connection.

- Edge Distance: Placing an anchor too close to an edge truncates this cone, removing a large portion of the supporting concrete and drastically reducing its tensile strength. This can lead to a “side-face blowout” failure under load.

Step 4: Select the Correct Drill Bit for Concrete Drop-In Anchors

After an installer confirms the anchor size, load capacity, and concrete condition, the final step is preparing for a flawless installation. The success of all concrete drop-in anchors hinges on drilling a hole with the correct diameter and depth. Using the right drill bit and associated tools is not just a recommendation; it is a requirement for safety and performance.

Match the Drill Bit to the Anchor’s Outer Diameter

The drill bit size must correspond to the anchor’s outer body diameter, not its internal thread size. This ensures a snug fit, which is essential for the anchor’s expansion mechanism to work correctly.

The Most Common Installation Mistake

The most frequent installation error is using the wrong size drill bit. This simple mistake has significant consequences.

- A hole that is too large prevents the anchor from gripping the concrete effectively. The anchor will spin in the hole or fail to expand properly, resulting in drastically reduced holding power.

- A hole that is too small makes it difficult or impossible to insert the anchor. Forcing an anchor into an undersized hole can damage the anchor body or the internal plug, preventing a secure installation.

Why Hole Diameter is Non-Negotiable

The holding power of drop in anchors comes from the friction created when the internal plug expands the anchor’s slotted sleeve against the walls of the concrete. This action requires a precise hole diameter. An incorrect fit compromises this entire mechanical process. The connection will be unreliable and unsafe, regardless of the anchor’s quality.

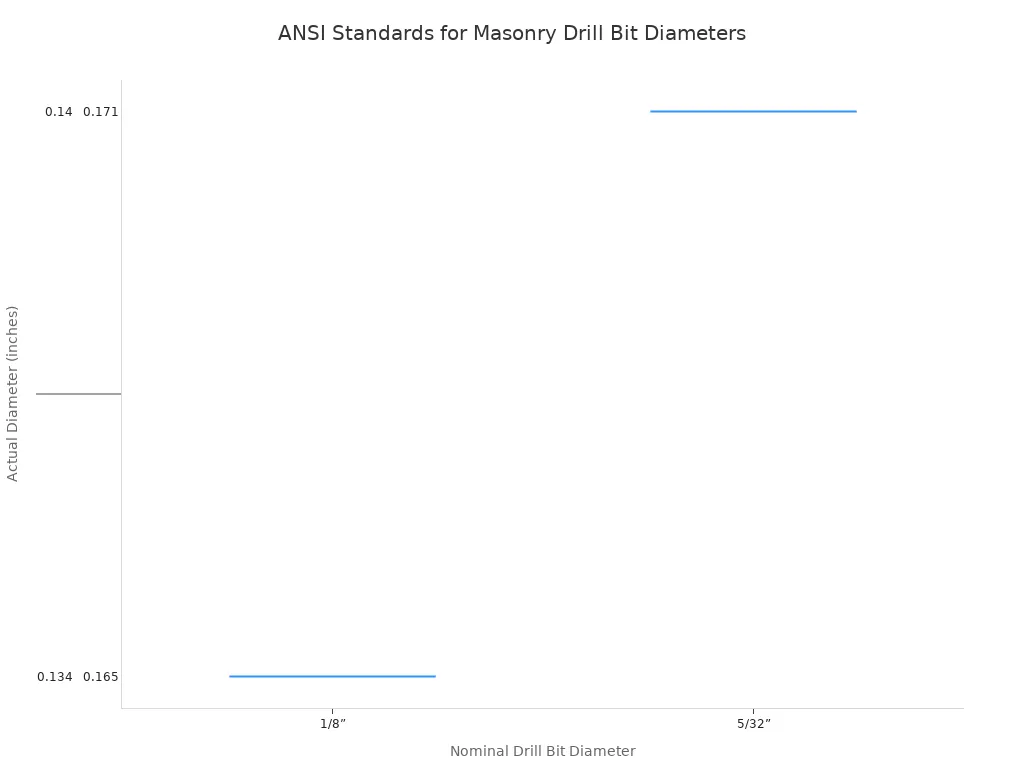

The Right Tool: Carbide-Tipped Masonry Bits

Professionals must use a hammer drill equipped with a carbide-tipped masonry bit for drilling into concrete. These bits are specifically designed to withstand the abrasive nature of concrete. To ensure consistency, drill bits must meet American National Standards Institute (ANSI) standard B212.15. This standard dictates the precise diameter ranges for bits, guaranteeing that a bit from any compliant manufacturer will create a hole with the correct tolerance for a secure installation.

| Diameter of Drill Bit | Minimum Diameter | Maximum Diameter |

|---|---|---|

| 1/4” | .260” | .268” |

| 5/16” | .327” | .335” |

| 3/8” | .390” | .398” |

| 1/2” | .520” | .530” |

Drill Bit Size Chart for Drop-In Anchors

To simplify the process, installers can refer to a standard pairing chart. The drill bit diameter is always larger than the anchor’s designated thread size because it must match the anchor’s outer body.

| Drop-In Anchor Size (Internal Thread) | Required Carbide Drill Bit Diameter |

|---|---|

| 1/4″ | 3/8″ |

| 3/8″ | 1/2″ |

| 1/2″ | 5/8″ |

| 5/8″ | 3/4″ |

Pro Tip: The required drill bit size is almost always printed on the anchor’s packaging. Always verify the size before drilling to prevent errors when you install drop in anchors.

Essential Tools for a Proper Installation

A successful installation requires more than just the right drill bit. Using the complete toolset ensures that each step, from drilling to setting, is performed correctly. This is key when installing drop in anchors.

Selecting the Right Hammer Drill

A rotary hammer drill is essential for efficiently drilling into concrete. Its hammering action pulverizes the material while the rotation clears it away. For overhead applications, specialized tools like an Overhead Drill Machine (ODM) with extension poles reduce operator fatigue and improve safety by allowing work from the ground. This makes installing drop in anchors in ceilings much safer.

Using the Correct Drop-In Anchor Setting Tool

A drop-in anchor setting tool is a mandatory piece of equipment. This steel punch is specifically designed to drive the internal plug down and properly expand the anchor.

Never use a bolt, screwdriver, or other makeshift object to set the anchor. These items can damage the threads or fail to expand the anchor fully, leading to a weak connection.

The setting tool has a shoulder that stops it at the top of the anchor, ensuring the plug is driven to the correct depth. An installer simply inserts the tool and strikes it with a hammer until the tool’s shoulder sits flush against the top of the anchor.

Why You Must Clean the Hole (Brushes and Air)

After drilling, the hole must be completely cleaned of all dust and debris. Technical guidelines show that uncleaned holes significantly diminish the holding capacity of concrete drop-in anchors. The dust prevents the anchor from making full contact with the concrete, reducing friction and compromising its grip.

A proper step-by-step anchor installation cleaning process involves:

- Blowing: Use a blow bulb, compressed air, or a vacuum to remove the bulk of the loose dust.

- Brushing: Use a wire brush with a diameter matching the hole to scrub the interior walls. This dislodges any remaining fine particles.

- Blowing Again: Perform a final blow-out to remove the dust loosened by the brush.

This simple but critical procedure ensures the drop-in anchors can achieve their maximum published holding power. A clean hole is a prerequisite to correctly install drop in anchors.

Choosing the right drop-in anchor size prevents common installation failures, such as underestimating load capacity or damaging the base material. An installer ensures a secure connection by verifying these final points. This checklist is the key to choosing the right anchor for the job.

- Bolt/Rod Diameter: Have you matched the anchor’s internal thread to your bolt’s diameter?

- Load Weight: Have you calculated the total load and applied a safety factor?

- Embedment Depth: Does the anchor meet the manufacturer’s minimum embedment for your required load?

- Concrete Condition: Is your concrete thick enough, strong enough, and are you maintaining proper edge/spacing distances?

- Drill Bit Size: Is choosing the right drill bit part of your final check?

FAQ

What is the first rule of drop-in anchor sizing?

An installer must always match the anchor‘s internal thread diameter to the bolt’s external diameter. This fundamental pairing ensures the threads engage correctly for a secure connection. A mismatch guarantees failure.

Can an installer reuse a drop-in anchor?

No. Drop-in anchors are permanent, single-use fasteners. The expansion process deforms the anchor body. Removing and attempting to reinstall a used anchor results in a complete loss of holding power and is extremely unsafe.

What happens if the drilled hole is too large?

An oversized hole prevents the anchor from working correctly. The consequences include:

- The anchor spinning during bolt installation.

- The expansion sleeve failing to grip the concrete.

- A drastic reduction in pull-out and shear strength.

Why is cleaning the drilled hole so important?

Concrete dust acts as a lubricant, preventing the anchor from achieving full friction against the hole’s walls. A professional cleaning process (blow-brush-blow) is mandatory to ensure the anchor meets its published load ratings.

How long should an installer wait to anchor into new concrete?

Installers must wait for the concrete to reach its specified compressive strength. This curing process typically takes a minimum of 28 days. Anchoring into “green” or uncured concrete will result in connection failure.

What is the difference between tensile and shear strength?

Tensile strength measures resistance to a direct pull-out force (⬆️). Shear strength measures resistance to a side-to-side force parallel to the surface (↔️). Both values are critical for selecting the right anchor for the load.

Is a special tool needed to set a drop-in anchor?

Yes, a dedicated drop-in anchor setting tool is mandatory. This tool ensures the internal plug is driven to the correct depth for full expansion. Using a screwdriver or bolt will damage the anchor and create a weak connection.