The failure of an anchor bolt can lead to significant structural issues, making the process of choosing anchor bolts a critical decision for project safety and longevity. This process involves a systematic evaluation of several key factors. Professionals must first assess the load the Anchor Bolts must support. They then identify the base material and environmental conditions. Finally, they match a specific anchor type to the project’s specific demands. Prioritizing safety by understanding proper installation is the final step to ensure a secure connection.

The global market for these components reflects their importance.

- The anchor bolt market is projected to grow from USD 4.23 billion in 2025 to USD 5.8 billion by 2035.

- This growth represents a Compound Annual Growth Rate (CAGR) of 3.2% over the decade.

This growth highlights the increasing reliance on reliable fastening solutions in construction and industrial applications.

Note: For specialized applications, a custom fasteners manufacturer can produce custom anchor bolts. These custom fasteners meet precise engineering specifications that standard options cannot.

The First Step in Choosing Anchor Bolts: Understanding Loads

A successful installation begins with a thorough analysis of the forces an anchor will endure. Before choosing anchor bolts, professionals must understand the specific load characteristics of the application. This foundational knowledge ensures the selected fastener has the capacity to maintain structural integrity safely and reliably over time.

Differentiating Load Types

Loads are not all the same. They apply force in different ways, and each type requires a different performance consideration from the anchor.

Static Loads (Dead Loads)

Static loads are constant and unchanging forces. They result from the fixed weight of the structure itself, such as a building’s frame, walls, or permanently installed heavy machinery. The force is consistent and comes from a fixed direction.

Dynamic Loads (Live Loads)

Dynamic loads are variable forces that change in magnitude, direction, or both. These can include forces from wind, vehicle traffic, vibrating equipment, or seismic activity. They are less predictable than static loads and place fluctuating stress on an anchor.

The key difference between these loads is clear:

- Static Loads: The force is consistent. An anchor’s yield and tensile strength are the primary limits.

- Dynamic Loads: The force varies. This requires more complex calculations to determine performance limits, especially for seismic events.

Shear Loads

Shear loads apply force perpendicular to the length of the anchor bolt, creating a slicing or cutting action. Under shear forces, anchor bolts generate an internal axial force that increases with displacement. Strengthened anchor bolts show improved shear resistance compared to standard bolts. Failure often occurs at the inflection point from combined tensile and shear stresses.

Tensile Loads (Pull-Out)

Tensile loads apply force along the axis of the anchor, attempting to pull it straight out of the base material. An anchor’s resistance to this force, or its pull-out strength, is critical. This strength is heavily influenced by two factors:

- The anchor’s embedment depth in the base material.

- The diameter of the anchor itself.

How to Calculate Load Requirements

Accurately calculating load requirements is a non-negotiable step for safety and compliance.

Determine the Maximum Weight

The first step is to calculate the total weight of the object being fastened. This provides the baseline static load that the anchoring system must support.

Account for Dynamic Forces

Engineers must add any potential dynamic forces to the static load. This includes variables like wind, vibration, or shock loads, which can significantly increase the total force exerted on the anchor.

Consult Engineering Specifications

Professionals use established standards and software to guarantee precise calculations. The American Concrete Institute’s ACI 318 standard is widely recommended for designing anchors in concrete. Specialized software like MecaStack or Peikko Designer® helps engineers model forces and verify that their anchor selection meets all code-based load requirements.

Applying the Correct Safety Factor

A safety factor provides a crucial buffer between the anchor’s working load and its ultimate failure point.

The Role of a Safety Factor

A safety factor is a multiplier applied to the calculated load. It ensures the anchor can handle forces far greater than what it is expected to encounter, accounting for unforeseen events and material variations.

Standard Safety Factor Ratios

A common safety factor for mechanical anchors in concrete is 4:1. This means the anchor is rated to hold four times the intended maximum load.

When to Use a Higher Safety Factor

A higher safety factor is essential in certain conditions. Applications involving dynamic loads, potential for shock, overhead installations, or locations in seismic zones demand a more conservative approach to ensure life safety.

Evaluating Your Base Material and Environment

After calculating loads, the next critical phase in choosing anchor bolts involves a detailed assessment of the base material and the surrounding environment. The interaction between the anchor, the substrate, and external elements directly dictates the connection’s long-term stability and safety. A failure to match these factors correctly can compromise even the strongest anchor.

Identifying the Substrate

The material an anchor fastens into, or the substrate, determines which anchoring mechanism will be effective. Each substrate type has unique properties.

Solid Concrete

Solid concrete is dense and strong, providing an excellent base for high-capacity mechanical and adhesive anchors. Its consistency allows for predictable holding values.

Concrete Masonry Units (CMU)

Often called cinder blocks, CMUs can be hollow or grout-filled. The substrate type dictates the anchor choice. Hollow sections require sleeve-type anchors or screens for adhesive anchors that can span the internal voids.

Brick and Clay Tile

Brick is a brittle material prone to cracking under the expansion forces of some mechanical anchors. Professionals often select sleeve anchors, concrete screws, or adhesive anchors for brick applications to minimize stress.

Natural Stone

Similar to brick, natural stone can be fragile. Its density and integrity vary significantly. A careful evaluation is necessary to prevent splitting the stone during installation.

Analyzing Environmental Factors

The performance of an anchor bolt is heavily influenced by the environmental conditions it will face throughout its service life.

Interior vs. Exterior Use

Interior applications are protected from weather, allowing for standard anchor materials. Exterior installations expose fasteners to moisture, UV radiation, and temperature changes.

Moisture and Corrosion Risk

The presence of water, salt, or humidity accelerates corrosion. This is a primary cause of anchor failure in outdoor or damp settings.

Chemical Exposure

Industrial facilities or treatment plants may expose anchors to harsh chemicals. This requires specialized materials that resist chemical degradation.

Seismic and Vibration Zones

Dynamic forces from seismic activity or machinery require anchors with specific approvals. Additionally, temperature fluctuations cause materials to expand and contract. This thermal cycling puts stress on bolts and can weaken their hold. Continuous exposure to ultraviolet (UV) rays from the sun also degrades anchor materials over time, making them more susceptible to failure.

Matching Anchor Materials to Conditions

Selecting the right material is essential for durability. The choice directly counters the threats identified in the environmental analysis.

- Dry, Indoor Use: Zinc-Plated Carbon Steel

- Outdoor, Humid Use: Hot-Dip Galvanized or 304 Stainless Steel

- Coastal/Marine or Chemical Use: 316 Stainless Steel

Zinc-Plated Carbon Steel

This is the most basic and economical option. A thin layer of zinc provides minimal corrosion protection, making it suitable only for dry, interior environments.

Hot-Dip Galvanized Steel

This material is coated in a thick layer of zinc for significant corrosion resistance. Hot-dip galvanized fasteners are an excellent choice for many outdoor applications, with quality coatings capable of passing salt spray tests for over 1500 hours.

304 Stainless Steel

This stainless steel grade offers very good corrosion resistance. It is ideal for exterior applications, freshwater environments, and areas with high humidity.

316 Stainless Steel

Often called marine-grade, 316 stainless steel contains molybdenum for superior protection against chlorides and acids. It is the premier choice for saltwater coastal areas and chemical processing facilities.

A Guide to Mechanical Anchor Bolts

Mechanical anchors create a secure connection through friction or expansion against the base material. They are installed by drilling a hole and then inserting the anchor, which is then expanded by tightening a nut or driving a pin. This action wedges the anchor firmly into place. Understanding the different types of anchors is key to selecting the right one for a specific task.

Wedge Anchors

Wedge anchors are heavy-duty, non-removable fasteners designed for high-load applications in solid concrete. They are one of the strongest mechanical anchor bolts available.

Mechanism and Holding Principle

A wedge anchor functions through a friction-based holding principle. The anchor body consists of a threaded stud with an expansion clip at the bottom. After insertion into a pre-drilled hole, tightening the nut pulls the stud upward. This action forces the expansion clip down over a tapered cone, wedging it tightly against the walls of the concrete hole. This creates immense friction, providing exceptional tensile and shear strength.

The holding values are significant. For example, a 3/4-inch diameter DeWALT® Power-Stud®+ SD1 anchor in 3000 PSI concrete has an allowable tensile strength of 1,965 lbs and an allowable shear strength of 3,145 lbs at a 3-3/8 inch embedment.

Ideal Applications

Their high load capacity makes wedge anchors ideal for critical structural connections. Common uses include:

- Securing steel columns and beams to concrete foundations.

- Anchoring heavy machinery and industrial equipment.

- Fastening racking systems in warehouses.

- Attaching support ledgers for decks and balconies.

Key Installation Steps

Proper installation is non-negotiable for achieving the anchor’s rated capacity. The process requires precision.

- Drill a hole into the concrete using an ANSI-standard carbide-tipped drill bit that matches the anchor’s diameter. The hole must be deeper than the intended anchor embedment.

- Clean the hole of all dust and debris using compressed air, a vacuum, or a blow-out pump and wire brush. This step is critical for proper expansion.

- Place the nut and washer on the anchor, leaving the nut flush with the top of the anchor to protect the threads.

- Drive the anchor into the hole with a hammer until the washer and nut are tight against the fixture.

- Tighten the nut to the manufacturer’s specified torque value using a calibrated torque wrench.

Installation Pitfalls and Failure Modes Improper installation directly compromises safety and can lead to failure. Common issues include:

- Concrete Cone Failure: The base material breaks out under tension, often due to insufficient embedment or placement too close to an edge.

- Anchor Pull-Out: The anchor slips out because debris in the hole prevented the clip from fully expanding and gripping the concrete.

- Steel Shear Failure: The anchor rod itself breaks when the applied shear force exceeds the steel’s capacity.

- Concrete Pryout Failure: A short, stiff anchor under a shear load can push against the back of the hole, causing a cone of concrete to break out.

Sleeve Anchors

Sleeve anchors are versatile, medium-duty anchors suitable for a range of base materials, including concrete, brick, and block.

Mechanism and Holding Principle

A sleeve anchor consists of a threaded bolt pre-assembled inside an expansion sleeve. As the bolt’s head or nut is tightened, it pulls a tapered cone on the end of the bolt up into the sleeve. This action forces the sleeve to expand outward, creating pressure and friction against the walls of the hole.

Their performance varies by substrate. Sleeve anchors work well in solid materials but are less ideal in hollow block, where the lack of back pressure can limit their ability to grip effectively. If the sleeve expands within a void, the anchor may hold but could slide back and forth under load.

| Feature | Solid Concrete | Hollow Block |

|---|---|---|

| Holding Action | Sleeve expands fully against dense material. | Sleeve may expand partially or entirely in a void. |

| Performance | Good for medium-duty loads. | Reduced holding power; not ideal. |

| Reliability | Consistent and predictable. | Less reliable due to material inconsistencies. |

Ideal Applications

Sleeve anchors are excellent general-purpose fasteners. Their main advantage is that they are removable, making them perfect for temporary installations.

- Attaching window frames and door frames.

- Securing handrails and guardrails.

- Fastening shelf brackets and light-duty equipment.

- Temporary fixtures like bracing for concrete forms.

To remove one, an installer simply unscrews the bolt or nut, which releases the tension. The entire anchor can often be pulled out, or the sleeve can be tapped flush and patched over.

Key Installation Steps

- Drill a hole with a carbide bit that matches the anchor’s diameter.

- Clean the hole of all debris.

- Insert the sleeve anchor through the fixture and into the hole until the washer and nut are snug against the fixture.

- Tighten the nut or bolt. This expands the sleeve to secure the anchor. Avoid over-tightening, which can damage the base material, especially in brick or block.

Drop-In Anchors

Drop-in anchors are female anchors designed for medium-duty loads in solid concrete. They are intended for overhead applications where a threaded rod will be suspended.

Mechanism and Holding Principle

A drop-in anchor is a hollow cylinder with internal threads and an expansion plug at its base. The anchor is placed (“dropped in”) to a pre-drilled hole. A special setting tool is then inserted into the anchor and struck with a hammer. This drives the internal plug downward, expanding the base of the anchor and wedging it firmly into the concrete. This creates a permanent, flush-mounted threaded socket.

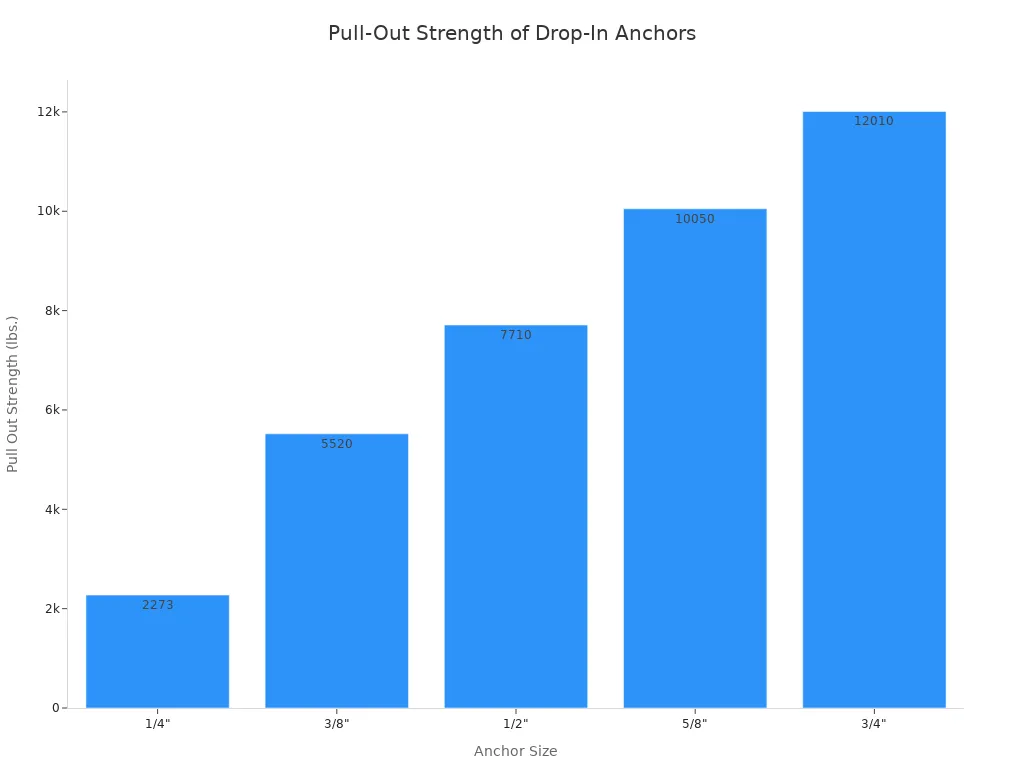

Their pull-out strength is substantial, making them reliable for overhead use. The holding power increases significantly with anchor diameter.

Note: The values above are from tests in 3000 PSI concrete. Professionals must apply a safety factor. A 4:1 ratio is common, but critical overhead applications may require a 10:1 safety factor.

Ideal Applications

The flush-mount design makes drop-in anchors perfect for applications requiring a clean surface finish after installation.

- Suspending threaded rod for hanging pipe, conduit, and HVAC ductwork.

- Anchoring cable trays and strut channel.

- Overhead lighting and fire sprinkler systems.

Key Installation Steps

- Drill a hole in the concrete to the specified diameter and depth.

- Thoroughly clean the hole of all dust and debris.

- Drop the anchor into the hole, ensuring the threaded end is up.

- Insert the correct-sized drop-in anchor setting tool into the anchor.

- Strike the setting tool firmly with a hammer until the tool’s shoulder meets the top of the anchor. This ensures the anchor is fully and properly set.

- The anchor is now ready to receive a threaded bolt or rod.

Using the correct setting tool is not optional; it is essential. The tool is specifically designed to drive the internal plug to the correct depth for full expansion. Failure to use the proper tool will result in an unsecured anchor.

Strike Anchors (Hammer-Set)

Strike anchors, also known as hammer-set anchors, are one-piece, tamper-proof fasteners for light to medium-duty applications in solid concrete. Professionals favor them for their simple and rapid installation. The anchor’s design provides a permanent connection, making it a secure choice for fixtures that do not require future removal.

Mechanism and Holding Principle

A strike anchor operates on a simple expansion principle. The anchor consists of a cylindrical body with a pre-installed nail-like pin. After an installer places the anchor into a pre-drilled hole, they drive the pin into the anchor body with a hammer. This action forces the lower, slotted portion of the anchor body to expand outward. The expansion creates a strong compression force against the walls of the concrete hole, generating the friction needed to resist pull-out and shear forces.

Professionals often compare strike anchors to wedge anchors for similar applications. While their holding values are comparable, key differences influence selection.

| Feature | Wedge Anchor | Strike Anchor |

|---|---|---|

| Holding Values | Essentially the same as strike anchors. | Essentially the same as wedge anchors. |

| Pull-out & Shear | Slightly better and more consistent. | Less consistent than wedge anchors. |

| Popularity | More popular due to a wider variety of sizes and materials. | Less popular, but preferred for aesthetics. |

| Aesthetics | Can be difficult to achieve a consistent look. | Preferred for a clean, consistent protrusion. |

The choice often comes down to the need for consistent aesthetics, where the strike anchor excels, versus the broader availability and slightly more consistent performance of the wedge anchor.

Ideal Applications

The speed of installation and tamper-proof nature of strike anchors make them ideal for specific jobs. They are excellent for repetitive fastening tasks.

- Securing electrical conduit straps and junction boxes.

- Fastening wood furring strips or sill plates to concrete.

- Anchoring lightweight machinery guards.

- Attaching HVAC strapping and brackets.

A Note on Permanence 📝 Strike anchors are permanent fasteners. Once the pin is set, the anchor cannot be removed without destroying it or causing significant damage to the surrounding concrete. This makes them highly tamper-proof but unsuitable for temporary fixtures.

Key Installation Steps

Correct installation is straightforward but requires attention to detail to ensure safety and holding power.

- Drill a hole in the solid concrete using a carbide-tipped bit that matches the diameter of the strike anchor. The hole depth must be at least the minimum required embedment.

- Clean the hole of all dust and debris using compressed air or a vacuum. A clean hole is essential for proper expansion.

- Insert the strike anchor through the fixture and into the hole.

- Hammer the pin into the anchor body until its head is flush with the top of the anchor head. This final action expands the anchor and secures the connection.

⚠️ Critical Step: The installer must drive the pin completely flush. An incompletely set pin means the anchor has not fully expanded, severely compromising its load-bearing capacity and creating a safety hazard.

Exploring Screw-Type and Specialty Anchors

Beyond traditional expansion anchors, a category of screw-type and specialty fasteners offers unique solutions for various base materials. These anchors rely on different mechanisms, from cutting their own threads to expanding behind hollow surfaces. They provide installers with versatile options for both solid and problematic substrates.

Concrete Screw Anchors

Concrete screw anchors, often known by brand names like Tapcon®, are self-tapping fasteners that provide a strong, removable connection in concrete, brick, and block.

Mechanism and Holding Principle

These anchors function by cutting their own threads into the base material. Unlike expansion anchors, they create a secure interlock without exerting outward pressure. This non-expanding characteristic makes them an excellent choice for applications close to edges or near other anchors. The holding power comes directly from the engagement of the hardened threads with the concrete.

Ideal Applications

Concrete screws are highly valued for their versatility and ease of use, especially for projects that may require future changes. Their primary benefits include:

- Fast installation with a power tool, which minimizes downtime.

- The ability to be easily removed or adjusted.

- An immediate capacity to be loaded after installation.

These features make them a preferred choice for temporary installations like formwork, bracing, or shelving that might be reconfigured later.

Key Installation Steps

- Drill a pilot hole to the specified diameter and depth using a compatible carbide-tipped bit.

- Clean the hole thoroughly of all dust and debris.

- Drive the screw anchor with a drill or impact driver through the fixture and into the hole until it is securely seated.

Edge and Spacing are Critical 📐 Installers must maintain proper spacing to prevent base material failure. A general guideline suggests a minimum distance of 12 times the anchor’s diameter between anchors and from any concrete edge. This spacing allows the cone-shaped stress zone around each anchor to form completely, preventing cracks and ensuring the connection achieves its full strength.

Lag Shield Anchors

Lag shield anchors are two-piece expansion shields used with lag screws to fasten objects to masonry materials like brick, block, and concrete.

Mechanism and Holding Principle

A lag shield anchor consists of a zinc alloy shell that is inserted into a pre-drilled hole. As an installer drives a lag screw into the shield, the two halves of the shell expand outward. This expansion creates a powerful compression force against the walls of the hole, providing reliable holding power. They are particularly effective in the mortar joints of brick or block walls.

| Load Type | Ultimate Capacity (lb) | Allowable Capacity (lb) |

|---|---|---|

| Tensile | 1190 | 240 |

| Shear | 1620 | 325 |

Note: Values are for a 1/4″ short lag shield in 1500 PSI brick masonry. A safety factor has been applied to determine allowable capacity.

Ideal Applications

Their simple design and solid performance in brittle materials make them suitable for a variety of light to medium-duty tasks.

- Attaching signs and downspouts to brick facades.

- Securing electrical boxes and conduit clamps.

- Fastening handrails and brackets to concrete or block.

Key Installation Steps

- Drill a hole to the correct diameter and depth for the shield.

- Insert the lag shield into the hole until it is flush with the surface.

- Place the fixture over the hole, insert the lag screw, and tighten it until secure.

Toggle and Winged Anchors

Toggle and winged anchors are specialty fasteners designed specifically for securing items to hollow walls, such as drywall, plaster, or hollow block.

Mechanism and Holding Principle

These anchors feature wings or a toggle bar that folds flat to pass through a pre-drilled hole. Once behind the wall, the wings spring open. Tightening the bolt pulls the wings tight against the interior surface of the wall. This action distributes the load over a much larger area than the hole itself, preventing the anchor from pulling through the fragile wall material. A heavy-duty toggle bolt, for example, can support over 200 lbs. in standard 1/2-inch drywall.

Ideal Applications for Hollow Walls

They are the go-to solution for mounting objects on surfaces that cannot support traditional anchors.

- Hanging heavy mirrors, artwork, and televisions.

- Installing shelving, curtain rods, and cabinets.

- Securing grab bars and towel racks in bathrooms.

Key Installation Steps

- Drill a hole large enough for the folded toggle or wings to pass through.

- Fold the wings flat and push the anchor head through the hole.

- Listen or feel for the wings to spring open behind the wall.

- Pull back on the screw to engage the wings, then tighten the screw to clamp the fixture firmly to the wall.

Chemical (Adhesive) Anchors for Ultimate Strength

When a project demands the highest possible load capacity and reliability, professionals turn to chemical or adhesive anchoring systems. These systems create a bond that can be stronger than the base material itself. Unlike mechanical fasteners that rely on friction, chemical anchor bolts form a monolithic connection with the substrate, offering unparalleled strength for the most demanding jobs.

How Adhesive Anchoring Systems Work

Adhesive anchors achieve their strength through a chemical reaction that bonds a steel element, like a threaded rod or rebar, to the surrounding concrete or masonry. This process creates a continuous, stress-free connection.

The Bonding Process

The holding power of an adhesive anchor comes from a powerful chemical bond. The system transfers loads through the adhesive to the base material. This process involves two key actions: adhesion and micro-keying. The resin adheres directly to the anchor element and the walls of the hole. It also flows into the microscopic pores and imperfections of the concrete, creating a mechanical interlock that dramatically increases pull-out resistance.

This method provides a distinct advantage over mechanical expansion anchors.

- Chemical anchors use resin adhesives to create a durable bond with the concrete.

- This bond is often stronger than the concrete itself, ensuring a robust connection.

- They are highly effective in challenging conditions, such as cracked or uneven concrete.

- Mechanical anchors, which rely on friction, can be less reliable in compromised concrete or areas with heavy vibration.

Epoxy vs. Acrylic vs. Polyester

Installers have three primary types of adhesives to choose from, each with different characteristics. The selection depends on the required bond strength, working time, and environmental conditions.

| Adhesive Type | Pot Time (Working Time) | Cure Time | Bond Strength |

|---|---|---|---|

| Polyester | A few minutes | Short (minutes to hours) | Good |

| Acrylic | 5-7 minutes | Fast (minutes to hours) | Very Good |

| Epoxy | A few minutes to over an hour | Moderate to long (hours to days) | Excellent |

Acrylic adhesives are often favored for their rapid curing properties. They offer:

- Increased bonding strength compared to standard polyester adhesives.

- The fastest cure times at room temperature.

- A working time of approximately 5-7 minutes.

- A tack-free surface in 10-20 minutes, allowing for faster project progression.

Epoxies, while slower to cure, provide the highest ultimate bond strength, making them the top choice for critical, heavy-duty anchors.

Understanding Cure Times

Cure time is the period required for the adhesive to harden and reach its full load-bearing capacity. This time varies significantly based on the adhesive type and ambient temperature. Installers must strictly follow the manufacturer’s guidelines for cure times. Applying a load to an anchor before it has fully cured will lead to bond failure and create a severe safety risk.

When to Use Chemical Anchor Bolts

Adhesive anchors are the solution for specific, challenging applications where mechanical anchors may not be suitable.

Critical Structural Connections

For connections that are essential to a structure’s stability, chemical anchors provide the necessary security and peace of mind. This includes securing steel columns, large beams, and seismic retrofitting components. To ensure safety, professionals must select products that meet rigorous standards.

Certification is Key 🛡️ For critical applications, always choose an anchor with a European Technical Assessment (ETA) or an ICC-ES evaluation. These certifications are the gold standard, confirming the product has passed extensive testing for load capacity, durability, and performance in various conditions, including fire exposure.

Anchoring in Cracked Concrete

Concrete can develop hairline cracks under tension, which can compromise the holding power of expansion anchors. Chemical anchors excel in this environment. The adhesive fills the cracks and bonds with the surrounding material, ensuring a stable and reliable connection.

| Concrete Condition | Mechanical Anchors | Chemical Anchors |

|---|---|---|

| Cracked/Weak Concrete | Poor performance; relies on friction. | Strong performance; bonds with the substrate. |

| Uncracked Concrete | Good performance. | Excellent performance. |

This makes chemical anchors the superior choice in seismic zones or areas subject to heavy vibration, where their ability to bond with both cracked and uncracked concrete ensures structural integrity.

Securing Rebar Dowels

Chemical adhesives are the industry standard for retrofitting rebar into existing concrete structures. Installers use them to create extensions for walls, slabs, and columns. The adhesive forms a continuous bond, making the new rebar function as if it were cast into the concrete from the beginning.

Oversized or Irregular Holes

Drilling errors can sometimes result in holes that are too large or uneven for a mechanical anchor to work properly. Chemical anchors solve this problem. The adhesive fills the entire void, regardless of its shape, creating a solid, custom-fitted connection that compensates for imperfections in the hole.

The Chemical Anchor Installation Process

Proper installation is paramount to achieving the full strength of a chemical anchor. Every step must be executed with precision.

Critical Hole Preparation

The success of an adhesive anchor installation begins with the hole. An improperly prepared hole is the leading cause of failure.

- Drill the hole to the diameter and depth specified by the adhesive manufacturer.

- Clean the hole meticulously. Use a combination of compressed air and a stiff wire brush. Repeat the process (blow, brush, blow) until no dust or debris emerges from the hole.

The cleanliness of the hole is arguably the most important step in the entire installation. Any remaining dust will prevent the adhesive from bonding directly to the concrete, severely reducing the anchor’s holding capacity.

Dispensing and Injection Technique

Proper dispensing ensures the adhesive components mix correctly. Before injecting into the hole, an installer must purge the cartridge.

- Attach the mixing nozzle to the adhesive cartridge.

- Dispense the initial amount of adhesive onto a piece of cardboard or scrap material.

- Continue dispensing until the color of the adhesive is uniform and consistent, with no streaks.

⚠️ Warning: Failing to purge the initial material can trap air or create an off-ratio mix. This leads to an uneven cure, significantly reduced bond strength, and potential anchor failure.

Once purged, insert the nozzle to the bottom of the clean hole. Inject the adhesive, slowly withdrawing the nozzle as the hole fills to about two-thirds full. This technique prevents air pockets from forming.

Setting the Anchor Rod or Rebar

Immediately after injecting the adhesive, insert the threaded rod or rebar into the hole. Use a slow, twisting motion as you push the element to the bottom. This ensures the adhesive fully coats the threads and eliminates any remaining air voids. Brace the anchor in place and allow it to cure undisturbed for the manufacturer’s specified time.

Best Practices for Anchor Bolt Installation

Choosing the correct fastener is only half the battle. Proper installation is essential to ensure anchor bolts perform to their rated capacity and maintain structural integrity. A precise and clean installation process prevents premature failure and guarantees a safe, reliable connection.

Preparing the Hole Correctly

The foundation of a secure anchor is a perfectly prepared hole. Installers must pay close attention to every detail of this initial step.

Selecting the Right Drill Bit

Professionals must select a drill bit that meets ANSI standards and matches the anchor’s requirements. Carbide-tipped drill bits are recommended for concrete because they resist wear and maintain sharpness for precise drilling. A properly sized hole ensures the anchor fits snugly, which is crucial for its holding capacity. For example, a 1/2-inch concrete anchor may require a 5/8-inch drill bit to facilitate better alignment and achieve a snug fit. A hole that is too small can cause anchor failure, while an oversized hole compromises strength.

Achieving Proper Embedment Depth

Embedment depth directly influences an anchor’s pull-out strength. Installers must drill the hole to the exact depth specified by the manufacturer. A hole that is too shallow will not allow the anchor to develop its full holding power, creating a significant safety risk.

The Importance of Cleaning the Hole

Drilling debris is the enemy of a strong connection. A clean hole is non-negotiable for both mechanical and chemical anchors.

- Professionals use compressed air and a wire brush to remove all dust and loose material.

- The industry-standard cleaning sequence is ‘blow/brush/blow’.

- An installer repeats this process until no more dust emerges from the hole, ensuring the anchor can achieve its full design capacity.

Proper Setting and Torquing

Setting the anchor correctly transfers the load safely to the base material. This step requires precision and the right tools.

Using a Calibrated Torque Wrench

Guesswork has no place in anchor installation. A calibrated torque wrench is the only tool that can apply the precise rotational force needed to set a mechanical anchor correctly without causing damage.

Following Manufacturer Specifications

Every anchor has a specific torque value provided by the manufacturer. Professionals must adhere to this specification strictly. This value ensures the anchor is tight enough to engage its holding mechanism but not so tight that it damages the anchor or the concrete.

The Danger of Over-Torquing

Applying too much torque is a common and dangerous mistake. Over-torquing adds excessive stress to the fastener, pushing it closer to its failure point.

⚠️ Over-Torquing Risks:

- It can strip threads or snap the anchor head.

- It permanently deforms the bolt, reducing its load-bearing capacity.

- It can cause micro-fractures in the concrete, leading to eventual failure.

- Improperly tightened fasteners can trigger machine malfunctions or structural collapses, creating severe safety hazards.

Common Installation Mistakes to Avoid

Avoiding simple errors is key to a successful installation. Professionals must be vigilant to prevent these common issues.

Incorrect Hole Dimensions

Drilling a hole that is too wide, too narrow, or too shallow is a primary cause of anchor failure.

Insufficient Cleaning

Leaving dust and debris in the hole prevents the anchor from making full contact with the base material, severely reducing its holding power.

Violating Edge and Spacing Distances

Placing anchors too close to an edge or to each other can cause the concrete to crack and break out under load.

Ignoring Adhesive Cure Times

For chemical anchors, applying a load before the adhesive has fully cured according to the manufacturer’s instructions will result in a complete bond failure.

The process of choosing anchor bolts involves a clear, three-step evaluation: assessing loads, analyzing the environment, and selecting the correct anchor type. This systematic approach to choosing anchor bolts is fundamental to the safety, reliability, and longevity of any construction project. A successful installation depends on this careful planning.

Professionals must always consult manufacturer data sheets for specific anchor bolts. For critical applications, seeking guidance from a structural engineer ensures maximum safety and compliance.

FAQ

Can installers reuse mechanical anchor bolts?

Most mechanical anchors, like wedge and strike anchors, are permanent and not designed for reuse. Removing them often damages the anchor or the concrete. Sleeve anchors are an exception; professionals can remove them, making them suitable for temporary applications.

Why is the drill bit size different from the anchor size?

The drill bit must create a hole that matches the anchor’s required nominal diameter. For some anchors, the hole needs to be slightly larger than the threaded portion to accommodate the anchor’s expansion mechanism or body. Always follow the manufacturer’s specifications for the correct bit size.

When should professionals choose chemical over mechanical anchors?

Professionals select chemical anchors for the highest load requirements, for anchoring in cracked concrete, or for securing rebar. They choose mechanical anchors for most general-purpose applications in solid concrete that require fast, reliable installation with immediate loading capability.

What happens if an anchor is installed too close to a concrete edge?

Placing an anchor too close to an edge concentrates stress on a small area of concrete. This can cause the concrete to crack and break away, a failure known as “concrete breakout.” This failure prevents the anchor from supporting its intended load and creates a serious safety risk.

What is torque and why is it important for installation?

Torque is the rotational force applied when tightening the anchor’s nut or head. Applying the correct, specified torque is critical. It properly sets the expansion mechanism of a mechanical anchor, ensuring it achieves its full holding power without over-stressing the bolt or damaging the concrete.

How important is cleaning the hole before installing an anchor?

Cleaning the hole is one of the most critical steps. Dust and debris prevent both mechanical and chemical anchors from making full contact with the base material.

This lack of contact severely reduces the anchor’s load capacity and is a leading cause of anchor failure. A clean hole ensures a safe connection.