Selecting the right wedge anchor bolts is crucial for successful construction projects in 2026. The global market for concrete fasteners, including custom anchor bolts, shows significant growth projections. This reflects the industry’s demand for reliable performance.

| Source | Projected Market Size (by 2033) | CAGR (2026-2033) |

|---|---|---|

| Verified Market Reports | USD 4.12 Billion | 5.2% |

| LinkedIn Article | USD 8.1 Billion | 6.0% |

For most concrete applications, the Simpson Strong-Tie Strong-Bolt 2 delivers the best overall performance. For heavy-duty needs, the Hilti Kwik Bolt TZ2 stands out as the premier choice among anchors. A custom fasteners manufacturer can also provide specialized custom fasteners.

Top 5 Wedge Anchor Bolts for Concrete: 2026 Review

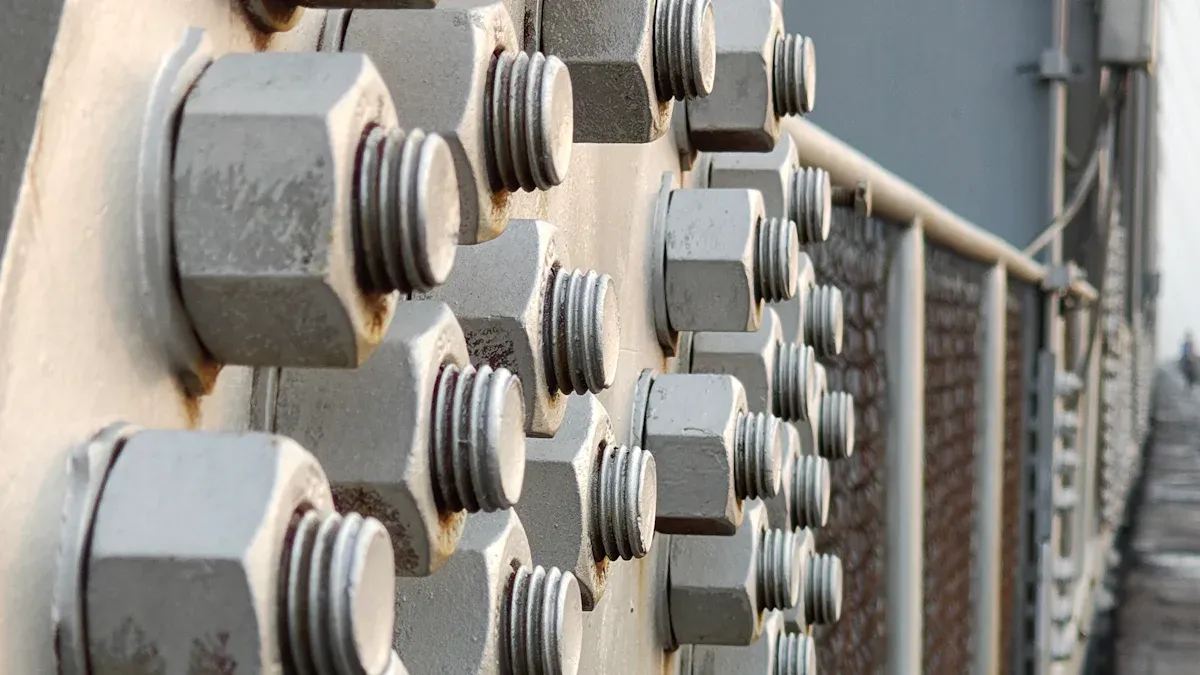

Choosing the correct fastener is a critical decision in any construction project. The performance of an anchor depends on multiple factors, including the quality of the concrete, installation technique, and environmental conditions. This review breaks down the top wedge anchor bolts of 2026 to guide your selection for superior safety and durability.

1. Simpson Strong-Tie Strong-Bolt 2: Best Overall Performance

The Simpson Strong-Tie Strong-Bolt 2 earns its top spot by offering an exceptional balance of strength, reliability, and code-compliant performance. It is a versatile choice for a wide range of construction needs.

Key Specifications

- Materials: Zinc-Plated Carbon Steel, Hot-Dipped Galvanized, 304 & 316 Stainless Steel

- Certifications: ICC-ESR 3037, Cracked and Uncracked Concrete, Seismic (Category C1/C2)

- Sizes: Diameters from 1/4″ to 1-1/4″

Performance in Cracked and Uncracked Concrete

This anchor excels in both cracked and uncracked concrete, a key feature for modern construction where tensile stresses are common. Its tri-segmented clip makes full contact with the hole, ensuring consistent expansion and dependable holding power. This design minimizes the risk of failure in variable concrete conditions.

Load Capacity and Reliability

The Strong-Bolt 2 provides excellent load performance for its class. Its reliability stems from a design that tolerates slight variations in installation. However, achieving maximum strength requires proper technique.

Pro Tip: The holding capacity of any anchor is tied to the concrete quality. For safe working loads, a general rule is to use 25% of the anchor’s ultimate published load value. Deeper embedment also significantly increases holding power.

Ideal Applications

This anchor is a workhorse for general construction. Its versatility makes it suitable for numerous tasks, including:

- Securing structural steel plates

- Anchoring pallet racks in warehouses

- Fastening mechanical and electrical equipment

- General-purpose concrete applications

2. Hilti Kwik Bolt TZ2: Best for Heavy-Duty and Seismic Applications

When a project demands the highest possible strength and safety, the Hilti Kwik Bolt TZ2 is the undisputed leader. This anchor is engineered for the most challenging construction environments and critical connections.

Key Specifications

- Materials: Carbon Steel (Zinc Plated, Hot-Dipped Galvanized), Stainless Steel

- Certifications: ICC-ESR 4266 (Cracked Concrete, Seismic), ETA Approval

- Sizes: Diameters from 3/8″ to 1″

Ultimate Tensile and Shear Strength

The Kwik Bolt TZ2 delivers unmatched tensile and shear strength. Its innovative geometry and advanced expansion mechanism provide superior load transfer into the concrete. This high performance makes it the premier choice for heavy-duty applications where failure is not an option. The anchor’s design ensures maximum load-bearing capacity in demanding construction scenarios.

Seismic and Dynamic Load Ratings

This anchor stands out for its exceptional performance under seismic and dynamic loads. It is rigorously tested and approved for the highest seismic design categories. This makes it essential for construction in earthquake-prone regions or for securing equipment that produces significant vibration, such as heavy machinery and industrial generators.

Recommended Uses

The Kwik Bolt TZ2 is specified for critical construction projects where safety and strength are paramount.

- Structural connections in seismic zones

- Fastening heavy industrial machinery

- Securing roller coasters and amusement park rides

- Nuclear facility construction

3. Powers Fasteners Power-Stud+ SD1: Best for Corrosive Environments

For construction exposed to moisture, chemicals, or saltwater, the Powers Fasteners Power-Stud+ SD1 is the ideal solution. Its material composition provides superior durability and longevity in harsh conditions.

Key Specifications

- Materials: Type 316 Stainless Steel, Zinc-Plated Carbon Steel

- Certifications: ICC-ESR 2818 (Cracked and Uncracked Concrete)

- Sizes: Diameters from 1/4″ to 1-1/4″

Material Composition (316 Stainless Steel)

The key feature of this anchor is its availability in Type 316 stainless steel. This premium material contains molybdenum, which significantly enhances its resistance to chlorides and other corrosive agents. This makes it one of the best anchors for long-term performance in aggressive settings.

Resistance to Rust and Chemicals

The Power-Stud+ SD1 offers first-class protection against rust and chemical corrosion. This quality is vital for maintaining structural integrity over decades, especially in infrastructure and industrial construction where exposure is constant. Its durability ensures a safe and lasting connection.

Outdoor and Marine Applications

These wedge anchor bolts are perfectly suited for outdoor and marine environments. Their ability to withstand constant exposure to rain, humidity, and saltwater makes them a top choice for:

- Coastal construction and docks

- Wastewater treatment plants

- Chemical processing facilities

- Exterior structural steel and facade systems

4. Red Head Trubolt+: Best Budget-Friendly Option

For construction professionals and DIYers who need a reliable fastener without the premium price tag, the Red Head Trubolt+ is the leading choice. It provides dependable performance for a wide array of everyday applications.

Key Specifications

- Materials: Zinc-Plated Carbon Steel

- Certifications: ICC-ESR 2251 (Uncracked Concrete)

- Sizes: Diameters from 1/4″ to 1-1/4″

Cost vs. Performance Analysis

The Trubolt+ anchor excels in its value proposition. It delivers solid performance for light to medium-duty loads at a fraction of the cost of high-end seismic anchors. This makes it an economical solution for large-scale construction projects where thousands of fasteners are needed for non-structural elements. While it lacks the cracked concrete ratings of premium options, its performance in standard concrete is more than sufficient for its intended uses.

Pro Tip: When evaluating budget-friendly wedge anchor bolts, focus on the application. For non-critical tasks in stable, uncracked concrete, the Trubolt+ offers the best balance of cost and security in the construction industry.

Reliability for General Use

Red Head has built a reputation for consistent quality, and the Trubolt+ is no exception. These anchors provide predictable holding power for general-purpose fastening. Their straightforward design ensures a secure connection when installed correctly in solid concrete. This reliability makes them a staple on many construction sites for tasks that do not require specialized dynamic or seismic ratings. The quality of the anchor is dependable for standard construction needs.

Best for DIY and Light Commercial Projects

The accessibility and affordability of the Trubolt+ make it ideal for a specific range of construction projects. It is a go-to choice for:

- Fastening shelving and racking in garages and workshops.

- Securing 2×4 lumber for wall framing to a concrete slab.

- Anchoring handrails and posts in non-critical areas.

- General repairs and installations in residential construction.

5. CONFAST Zinc Plated Wedge Anchors: Best for Ease of Installation

CONFAST has carved out a niche by focusing on simplicity and efficiency. Their Zinc Plated Wedge Anchors are designed for rapid, hassle-free installation, saving valuable time on the job site. This makes them a favorite for high-volume construction work.

Key Specifications

- Materials: Zinc-Plated Carbon Steel

- Certifications: Meets GSA Specification FF-S-325, Group II, Type 4, Class 1

- Sizes: Diameters from 1/4″ to 1-1/4″

Simple and Effective Design

These anchors ship fully assembled with the nut and washer in place, eliminating extra steps during installation. The expansion clip is engineered for consistent engagement within the concrete hole. This simple, effective design minimizes the chance of user error and ensures a smooth workflow, a significant advantage in fast-paced construction environments. The design prioritizes speed without sacrificing fundamental performance.

Required Hole Depth and Diameter

Proper installation starts with the correct hole. For CONFAST anchors, the hole diameter must match the anchor diameter. The minimum hole depth depends on the anchor length, ensuring adequate embedment.

| Anchor Diameter | Required Drill Bit |

|---|---|

| 1/4″ | 1/4″ |

| 3/8″ | 3/8″ |

| 1/2″ | 1/2″ |

| 5/8″ | 5/8″ |

Drilling the hole to the correct depth and cleaning it thoroughly is essential for achieving the anchor’s full holding capacity in concrete.

User Feedback on Installation

Professionals consistently praise CONFAST anchors for their straightforward installation process. The pre-assembled nature allows workers to move quickly from one anchor to the next. This efficiency is a major benefit in commercial construction where labor costs are a primary concern. Users report fewer issues with binding or improper setting compared to other multi-piece anchors.

User Note: The simple installation process reduces the learning curve for new construction workers, leading to higher quality and more consistent results across a team.

How to Choose the Right Wedge Anchor Bolts for Your Project

Selecting the correct wedge anchor bolts for your construction project is a critical step. The right choice ensures safety, durability, and long-term performance. This guide breaks down the key factors to consider, from material types to anchor dimensions, helping you make an informed decision for your concrete fastening systems.

Understanding Anchor Materials

The environment of your construction project dictates the best material for your concrete fasteners. Each material offers a different level of corrosion resistance.

Zinc-Plated Carbon Steel

Zinc-plated anchors are the most common and economical choice. They are best suited for indoor, dry applications where moisture is not a concern. The thin zinc coating provides minimal rust protection.

Hot-Dipped Galvanized Steel

For outdoor construction projects exposed to moisture, hot-dipped galvanized fasteners are a reliable option. These anchors have a thicker zinc coating, offering moderate corrosion resistance. They are a step up in protection for exterior use.

304 Stainless Steel

304 stainless steel offers good corrosion resistance and is suitable for humid or damp environments. It is a solid choice for many outdoor construction applications where longevity is important.

316 Stainless Steel

316 stainless steel provides the highest level of corrosion resistance. It contains molybdenum, making it ideal for marine environments, wastewater treatment plants, and areas with chemical exposure.

| Anchor Type | Corrosion Resistance | Primary Application | Material Composition |

|---|---|---|---|

| Zinc Plated | Low | Indoor, dry environments | Carbon steel with a thin zinc coating |

| Hot-Dip Galvanized | Medium | Outdoor, moist environments | Carbon steel with a thick zinc coating applied through hot-dipping |

| Stainless Steel | High | Wet, corrosive environments (e.g., marine, chemical) | Stainless steel (e.g., 304 or 316 grade) |

Selecting the Correct Diameter and Length for Concrete Fasteners

The size of the anchor directly impacts its performance in concrete. Choosing the right diameter and length is essential for a secure installation.

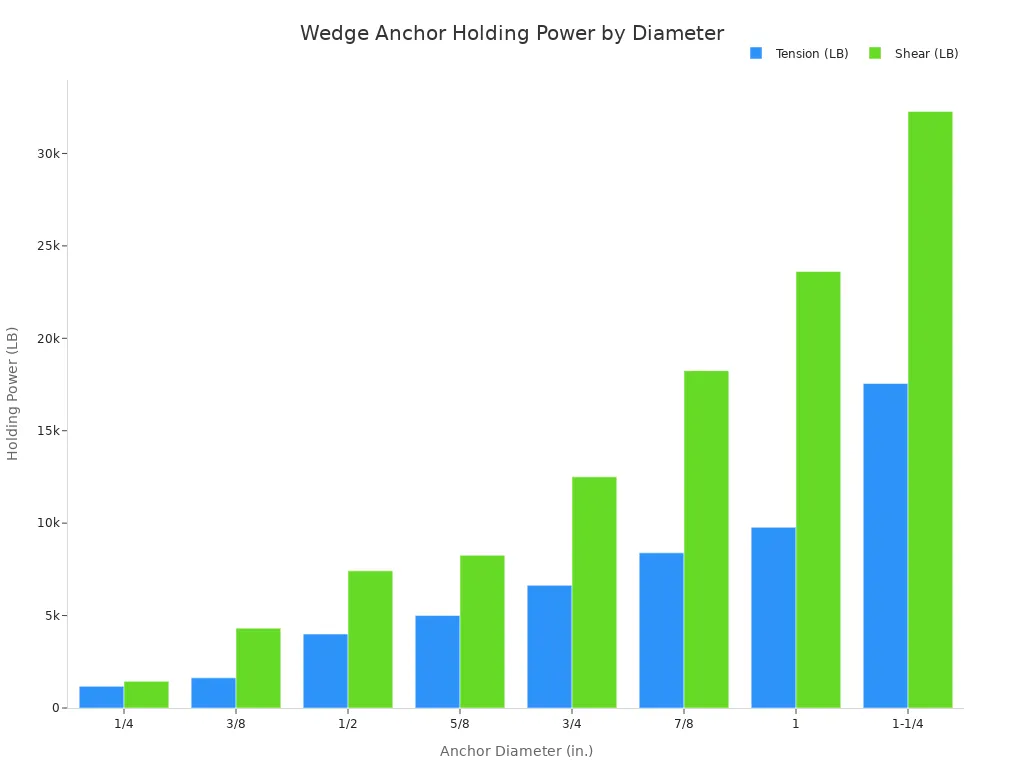

How Diameter Affects Holding Power

An anchor’s diameter is a primary factor in its holding strength. A larger diameter increases the surface area engaging with the concrete, resulting in significantly higher tensile and shear load capacities. This is crucial for heavy-duty construction.

Calculating Required Anchor Length

To determine the minimum anchor length, you must account for the fixture, embedment, and hardware. The formula is straightforward:

Fixture Thickness + Minimum Embedment + Nut & Washer Thickness = Minimum Anchor Length

For example, to fasten a 1.5-inch thick item with a 1/2-inch diameter anchor requiring 2.25 inches of embedment, the calculation is: 1.5″ + 2.25″ + 0.5″ = 4.25″. You would need wedge anchors at least 4.25 inches long.

Common Diameters for Specific Tasks

Different construction tasks require different anchor diameters.

- 1/4″ & 3/8″: Light-duty tasks like securing electrical boxes or conduit straps.

- 1/2″ & 5/8″: Medium-duty applications such as anchoring pallet racking or machinery.

- 3/4″ and larger: Heavy-duty structural connections in major construction projects.

Embedment Depth: Standard vs. Deep

Embedment depth is the length of the anchor installed into the concrete. It plays a vital role in the performance of all concrete fasteners.

What is Embedment Depth?

Embedment depth measures how deep the anchor sits within the concrete base material. Manufacturers specify a minimum embedment for their anchors to achieve published load values.

Benefits of Deeper Embedment

Deeper embedment significantly increases an anchor’s pull-out strength. It allows the anchor to distribute forces over a larger cone of concrete. This enhances load resistance and the overall reliability of the connection, a key consideration in demanding construction.

When to Use Standard Embedment

Standard embedment is sufficient for many light to medium-duty applications where the load requirements are not extreme. Always follow the manufacturer’s guidelines to ensure the anchors perform as expected for your construction needs.

Concrete Condition and Type

The state of the concrete base material is a fundamental factor in any construction project. The performance of concrete fastening systems depends heavily on whether the concrete is cracked, its density, and its curing stage. Proper evaluation ensures a secure and lasting installation.

Cracked vs. Uncracked Concrete

Uncracked concrete is solid, without any fractures. Cracked concrete, however, develops fine fissures due to tensile stresses from structural loads or shrinkage. Modern construction standards often assume concrete will crack over its service life. Therefore, selecting an anchor rated for cracked concrete is a critical safety measure.

- Power-Stud+ SD1 Concrete Wedge Anchors are designed for consistent performance in both cracked and uncracked concrete.

- The Power-Stud+ SD2, SD4, and SD6 models also provide reliable holding values in cracked concrete conditions.

Professional Insight: Always use anchors with an ICC-ES approval for cracked concrete in applications where tensile loads are present. This ensures the anchor maintains its grip even if the concrete fractures around it, a vital consideration for safe construction.

Lightweight vs. Normal-Weight Concrete

Normal-weight concrete has a density of approximately 150 pounds per cubic foot (pcf). Lightweight concrete has a lower density, which reduces its compressive strength. This reduction directly impacts the holding power of wedge anchors. For any construction involving lightweight concrete, professionals must consult the anchor manufacturer’s technical data to confirm suitability and obtain reduced load capacity values.

Cured vs. Green Concrete Considerations

Green concrete is newly poured concrete that has not yet reached its full design strength. Wedge anchors rely on the compressive strength of fully cured concrete to function correctly. Installing anchors into green concrete can cause catastrophic failure, as the expansion forces can easily break the weak material. For safe construction, professionals must wait until the concrete has cured for at least 28 days before installing any mechanical anchors.

Environmental Factors to Consider

The surrounding environment determines the necessary corrosion resistance for your fasteners. Choosing the wrong material can compromise the structural integrity of a construction project over time.

Interior, Dry Conditions

For indoor construction projects shielded from moisture, zinc-plated carbon steel anchors offer a cost-effective and reliable solution. The thin zinc coating provides basic rust protection suitable for controlled, dry environments.

Exterior, Wet or Humid Conditions

Outdoor construction exposes fasteners to rain, humidity, and temperature fluctuations. In these conditions, hot-dipped galvanized or stainless steel anchors are necessary.

- Hot-dipped galvanized anchors are suitable for general water exposure.

- However, the galvanized zinc coating wears down over time, leaving the steel vulnerable to corrosion.

- Stainless steel offers superior longevity for durable construction in wet environments.

Exposure to Chemicals or Saltwater

The most aggressive environments demand the highest level of protection.

- Type 304 stainless steel degrades with exposure to salt and chlorine. This makes it unsuitable for marine construction, pools, or wastewater treatment plants.

- Type 316 stainless steel contains molybdenum, which provides excellent resistance to chlorides and acids. It is the premier choice for highly corrosive settings, including coastal areas and chemical facilities.

Wedge Anchor Installation Guide: A Step-by-Step Process

Proper installation is paramount for the safety and performance of wedge anchors. A correct procedure ensures the fastener achieves its maximum load capacity, a non-negotiable requirement in professional construction. This guide covers the essential installation basics for a secure and reliable connection in any construction project. Following these steps guarantees a successful installation.

Required Tools and Safety Gear

Professionals begin every task by gathering the correct tools and safety equipment. This preparation is a hallmark of quality construction work.

Essential Tools List

A successful installation requires specific tools. Workers should have these items ready before starting.

- Rotary Hammer Drill

- ANSI-Standard Carbide Drill Bit

- Wire Brush and Compressed Air (or high-velocity blower)

- Hammer

- Calibrated Torque Wrench

Personal Protective Equipment (PPE)

Safety is the top priority on any construction site. All personnel must wear appropriate PPE during the installation process.

- Eye Protection: Safety glasses or goggles are mandatory. 👓

- Hand Protection: Work gloves protect against abrasion.

- Hearing Protection: Earplugs or muffs are necessary when using a hammer drill.

Step 1: Drilling the Hole in Concrete

The first active step in the installation process is creating a precise hole. The quality of the hole directly impacts the anchor’s performance.

Choosing the Right Drill Bit

Selecting the correct drill bit is a critical construction detail. The diameter of the carbide drill bit must match the diameter of the anchor.

Rule of Thumb: A 1/2″ anchor requires a 1/2″ drill bit. Using the wrong size will compromise the entire installation.

Proper Drilling Technique

Workers should use a rotary hammer drill set to hammer-and-rotation mode. They must drill the hole perpendicular to the concrete surface. The hole must be drilled to a depth greater than the required minimum embedment. This extra space accommodates any dust that cannot be removed, ensuring the anchors can be set properly. This technique is standard in modern construction.

Step 2: Cleaning the Hole

A clean hole is essential for a strong connection. This step is one of the most important aspects of the entire installation. Many failures in construction are traced back to improperly cleaned holes.

Importance of a Clean Hole

Concrete dust and debris act as a lubricant. This dust prevents the anchor’s expansion clip from making solid contact with the base material. A dirty hole can reduce an anchor’s holding power by over 50%, creating a significant safety hazard in any construction application.

Methods for Cleaning

The industry-standard method ensures a perfectly clean hole. Professionals follow a simple, effective sequence.

- Insert a wire brush and scrub the sides of the hole to loosen debris.

- Use compressed air or a blower to force all dust out of the hole.

- Repeat the brush-and-blow process until the hole is completely clean. This fundamental step is vital for all construction.

Step 3: Installing and Tightening the Anchor

The final phase of the installation process involves setting the anchor and applying the correct torque. This step transforms a drilled hole into a secure fastening point. Proper execution is essential for a safe and durable construction project. This part of the installation demands precision from every construction professional.

Setting the Anchor

Setting the anchor correctly ensures it engages properly with the concrete. This is a critical step for a secure installation. Professionals in the construction field follow a clear sequence for this task.

- Drive the anchor through the fixture and into the clean hole with a hammer.

- Continue tapping until the nut and washer are snug against the surface of the fixture.

- Ensure the anchor is driven to a depth that meets or exceeds the minimum embedment requirement. This action is fundamental to achieving the anchor’s designed holding strength.

This straightforward process positions the wedge anchors for the final, crucial step of tightening. The quality of this installation step impacts the entire construction’s integrity.

Applying the Correct Torque

Applying the correct torque expands the clip and locks the anchor into the concrete. This is the most critical part of the installation. Using a calibrated torque wrench is non-negotiable in professional construction. It is the only way to ensure the fastener is tightened to the manufacturer’s specifications. Incorrect torque can lead to catastrophic failure in a construction setting.

Professional Tip: Always refer to the manufacturer’s technical data sheet for the specific torque value required for the anchor’s diameter and embedment depth. Never guess or rely on feel. This precision is a hallmark of quality construction.

Failing to apply the specified torque has serious consequences for any construction project.

- Over-torquing can damage the concrete base material, the anchor itself, or the fixture. Applying excessive force can cause stress fractures, weaken the secured material, and reduce the anchor’s load-bearing capacity.

- Under-torquing results in an insecure connection. The anchors will not achieve full expansion, leading to a loose fixture that could rattle, become misaligned, or fail completely under load.

Proper torque is the final guarantee of a successful installation in any construction application.

2026 Wedge Anchor Bolts Comparison Table

To simplify the selection process for your next construction project, these tables provide a direct comparison of our top 5 wedge anchor bolts. This quick-reference guide highlights key performance metrics and features, helping professionals choose the right concrete fasteners for the job. The overall performance of any fastener depends on correct installation and a suitable environment.

Quick-Reference Performance Ratings

These ratings offer a high-level overview to guide your initial selection. The quality of the installation directly impacts the final performance.

Load Capacity Comparison

This table compares the general load-bearing capabilities of each anchor. Higher ratings indicate suitability for heavy-duty construction.

| Anchor Model | Load Capacity Rating |

|---|---|

| Hilti Kwik Bolt TZ2 | ★★★★★ (Ultimate) |

| Simpson Strong-Bolt 2 | ★★★★☆ (Excellent) |

| Powers Power-Stud+ SD1 | ★★★★☆ (Excellent) |

| Red Head Trubolt+ | ★★★☆☆ (Good) |

| CONFAST Zinc Plated | ★★★☆☆ (Good) |

Corrosion Resistance Score

This score reflects the anchor’s ability to withstand moisture and chemicals, a critical factor in durable construction.

| Anchor Model | Corrosion Resistance |

|---|---|

| Powers Power-Stud+ SD1 | ★★★★★ (Superior – 316 SS) |

| Simpson Strong-Bolt 2 | ★★★★☆ (Excellent – Multiple SS options) |

| Hilti Kwik Bolt TZ2 | ★★★★☆ (Excellent – SS options) |

| Red Head Trubolt+ | ★★☆☆☆ (Limited – Zinc only) |

| CONFAST Zinc Plated | ★★☆☆☆ (Limited – Zinc only) |

Price Point Index

This index provides a relative cost comparison for budget planning in construction.

| Anchor Model | Price Point |

|---|---|

| Hilti Kwik Bolt TZ2 | $$$$$ (Premium) |

| Simpson Strong-Bolt 2 | $$$$ (High) |

| Powers Power-Stud+ SD1 | $$$$ (High) |

| Red Head Trubolt+ | $$ (Budget-Friendly) |

| CONFAST Zinc Plated | $$ (Budget-Friendly) |

Feature-by-Feature Breakdown

This section details the specific materials, certifications, and sizes available for each of our top concrete fasteners. This information is vital for technical specifications in any construction plan.

Available Materials

The material composition determines the anchor’s suitability for different environments. The quality of the material is key to long-term performance.

| Anchor Model | Available Materials |

|---|---|

| Simpson Strong-Bolt 2 | Zinc, Hot-Dip Galvanized, 304 & 316 Stainless Steel |

| Hilti Kwik Bolt TZ2 | Zinc, Hot-Dip Galvanized, Stainless Steel |

| Powers Power-Stud+ SD1 | Zinc, 316 Stainless Steel |

| Red Head Trubolt+ | Zinc Plated Carbon Steel |

| CONFAST Zinc Plated | Zinc Plated Carbon Steel |

Key Certifications (ICC-ES, Seismic, ETA)

Certifications provide third-party verification of an anchor’s performance, a crucial requirement in modern construction. These approvals ensure the fasteners meet stringent safety standards.

Professional construction standards often require concrete fastening systems to have an ICC-ES approval. For example, ETB-Z Wedge Expansion Anchors hold ICC ESR-4346 approval for use in both cracked and uncracked concrete, verifying their reliable performance.

Using certified fasteners is essential for code compliance and structural integrity.

Available Sizes

The range of available diameters dictates the applications for which an anchor is suitable. Heavy-duty construction demands larger diameter fasteners.

| Anchor Model | Available Diameters |

|---|---|

| Simpson Strong-Bolt 2 | 1/4″ to 1-1/4″ |

| Hilti Kwik Bolt TZ2 | 3/8″ to 1″ |

| Powers Power-Stud+ SD1 | 1/4″ to 1-1/4″ |

| Red Head Trubolt+ | 1/4″ to 1-1/4″ |

| CONFAST Zinc Plated | 1/4″ to 1-1/4″ |

For most construction, the Simpson Strong-Tie Strong-Bolt 2 provides an excellent combination of strength and reliability. When construction projects demand ultimate strength, the Hilti Kwik Bolt TZ2 is the superior choice for heavy-duty construction. A successful installation in concrete requires matching the anchors to the job. This step ensures the durability and safety of the construction. Proper installation is vital for all construction, guaranteeing the final strength and durability of the concrete construction.

FAQ

Can you reuse wedge anchors?

No, professionals should never reuse wedge anchors. The anchor’s expansion clip deforms permanently during the initial installation. Removing and reinstalling it compromises its holding power and creates a significant safety risk in any construction project. Always use a new anchor for every installation.

What is the difference between a wedge anchor and a sleeve anchor?

Wedge anchors provide superior strength in solid concrete. Sleeve anchors are more versatile and function in base materials like brick or block. The wedge anchor’s clip creates a stronger grip, while the sleeve anchor’s expansion mechanism works better in hollow or weaker materials.

How close to the edge of concrete can you install a wedge anchor?

The minimum edge distance depends on the anchor’s diameter and embedment depth. Professionals must consult the manufacturer’s technical data. A general rule suggests a minimum distance of five anchor diameters from any unsupported edge to prevent concrete blowout during installation.

Do wedge anchors work in concrete block (CMU)?

Wedge anchors are designed specifically for solid concrete. Their high expansion forces can crack or break hollow concrete blocks (CMU). Professionals should use sleeve anchors or other fasteners specifically rated for hollow base materials to ensure a secure connection in block walls.

How long does concrete need to cure before installing wedge anchors?

Professionals must wait for the concrete to reach its specified compressive strength. This typically requires a minimum curing time of 28 days. Installing anchors in “green” or uncured concrete will result in a failed connection and is a major safety violation in construction.

Why is cleaning the hole so important for wedge anchor installation?

Concrete dust inside the hole prevents the anchor’s clip from gripping the base material properly. This can reduce the anchor’s holding capacity by more than 50%.

- A clean hole ensures maximum friction.

- It allows the anchor to achieve its full, published load value.