The search for the best exhaust flanges in 2026 leads to the Vibrant Performance T304 Flange. Its superior material and precision surface secure its top position. Other excellent choices cater to specific needs:

- Best Budget: Flowmaster Mild Steel Flange

- Most Durable: ATP Turbo 316L Stainless Steel Flange

- Best for Custom Fab: AP Exhaust Products Unbeveled T304 Flange

Note: A quality bolt casting ensures each Flange Bolt fits securely. For unique needs, a custom fasteners manufacturer can provide specialized custom fasteners.

| Flange Model | Material | Thickness | Price | Key Feature |

|---|---|---|---|---|

| Vibrant Performance | T304 Stainless | 3/8″ | $$$ | Precision CNC Machined |

| Flowmaster | Mild Steel | 1/4″ | $ | Good Value |

| ATP Turbo | 316L Stainless | 1/2″ | $$$$ | Maximum Warp Resistance |

| AP Exhaust | T304 Stainless | 3/8″ | $$ | Ideal for Custom Welding |

Detailed Reviews: The Top 2-Inch 3-Bolt Exhaust Flanges of 2026

An exhaust system is only as strong as its weakest connection. Choosing the right flange is critical for a leak-free, durable, and high-performing setup. This section provides an in-depth analysis of the top contenders for 2026, helping builders select the perfect component for their project.

1. Vibrant Performance T304 Flange – Best Overall

The Vibrant Performance T304 flange earns its top spot through a masterful balance of material science, precision engineering, and proven reliability. It represents the gold standard for most automotive enthusiasts and professional fabricators.

Material Composition and Build Quality

Vibrant constructs this flange from high-quality T304 stainless steel. This material offers excellent corrosion resistance and strength at high temperatures. The flange’s substantial 3/8-inch thickness provides significant rigidity. This thickness, combined with the inherent stability of T304 steel, makes it highly resistant to warping caused by repeated heat cycles from the engine. The build quality is immediately apparent, with clean cuts and a uniform finish that speaks to a superior manufacturing process.

Sealing Performance and Flow

Precision Matters: The key to this flange’s success is its CNC-machined mating surface. This process creates an exceptionally flat and smooth face, which is essential for achieving a perfect, leak-proof seal with a gasket.

The inner diameter is precisely sized for 2-inch tubing, and its beveled edge promotes smooth exhaust gas flow into the connecting pipe. This design minimizes turbulence at the connection point, helping to maintain exhaust velocity and overall engine performance.

Pros and Cons

| Pros | Cons |

|---|---|

| ✅ Excellent corrosion resistance | ❌ Higher price point than mild steel |

| ✅ Precision CNC-machined surface | ❌ May be overkill for basic repairs |

| ✅ 3/8″ thickness resists warping | |

| ✅ Smooth flow characteristics |

Ideal User Profile

This flange is the ideal choice for the serious enthusiast or professional builder. A person restoring a classic car, building a high-performance street machine, or simply wanting a “fit-and-forget” solution will find immense value in the Vibrant flange. Its longevity and sealing capability justify the investment for any high-quality exhaust project.

2. Flowmaster Mild Steel Flange – Best Budget Option

Flowmaster has a long-standing reputation for delivering reliable performance at an accessible price. Their 2-inch 3-bolt mild steel flange continues this tradition, making it the go-to option for builders on a tight budget.

Material Analysis and Cost Savings

This flange uses mild steel for its construction. This material choice is the primary driver of its low cost. Mild steel is easy to source, form, and weld, which keeps manufacturing expenses down. While it lacks the inherent corrosion resistance of stainless steel, it provides more than enough strength for standard exhaust applications. The brand’s reputation for quality parts is strong; for instance, other Flowmaster components like their 50 Series mufflers often receive user satisfaction ratings as high as 4.7 out of 5 stars, reflecting general customer trust in their product line.

Durability for the Price

At 1/4-inch thick, the Flowmaster flange is thinner than its premium counterparts. This can make it slightly more susceptible to warping under extreme heat. However, for a naturally aspirated daily driver or a standard exhaust repair, this thickness provides adequate durability. Applying a coat of high-temperature paint can also significantly extend its service life by protecting it from surface rust.

Performance and Potential Compromises

The primary compromise with this flange is its long-term durability against corrosion. In regions with heavy road salt use or high humidity, it will rust much faster than a stainless steel alternative. Performance-wise, its sealing surface is typically stamped or laser-cut, not machined. This may require more careful surface preparation and a high-quality gasket to ensure a leak-free seal.

Ideal User Profile

The ideal user for the Flowmaster flange is the DIY mechanic or budget-conscious builder. It is perfect for quick repairs, custom exhaust work on a project car where cost is a major factor, or for vehicles operated in dry climates. It delivers dependable function without the high cost of premium materials.

3. ATP Turbo 316L Flange – Most Durable / Heavy-Duty

When an exhaust system faces extreme temperatures and corrosive gases, such as in a high-horsepower turbocharged application, the ATP Turbo 316L flange is the undisputed heavy-duty champion. It is engineered specifically for the most demanding environments.

Heavy-Duty Construction Features

This flange’s durability stems from two key features:

- Material: It uses 316L stainless steel. The “L” denotes low carbon content, which improves weldability and reduces carbide precipitation, enhancing corrosion resistance after welding. More importantly, 316-grade steel contains molybdenum, giving it superior resistance to heat and chlorides compared to T304.

- Thickness: An immense 1/2-inch thickness makes this flange virtually immune to warping. This is critical in turbo applications where exhaust gas temperatures can spike dramatically, placing immense thermal stress on the manifold and downpipe connections.

Performance in High-Stress Applications

In a high-boost, high-EGT (Exhaust Gas Temperature) scenario, this flange excels. Its massive thermal mass and superior material composition ensure the sealing surface remains flat, preventing dangerous and power-robbing exhaust leaks. While some general ATP exhaust components receive mixed reviews, with certain manifolds averaging 3.5 out of 5 stars, this specialized flange is designed for a niche, high-performance purpose where its extreme durability is the paramount feature, valued highly by professional tuners and racers. It is one of the best exhaust flanges available for withstanding the rigors of motorsport.

Pros and Cons

| Pros | Cons |

|---|---|

| ✅ Maximum warp resistance (1/2″ thick) | ❌ Highest price point |

| ✅ Superior 316L stainless steel | ❌ Extreme overkill for most applications |

| ✅ Excellent for turbo/race use | ❌ Added weight from thickness |

| ✅ Elite heat and corrosion resistance |

Ideal User Profile

This flange is built for a specific user: the serious performance builder. Anyone with a high-horsepower turbocharged or supercharged engine, or a dedicated race car that sees intense track use, should consider this flange a necessary investment. It provides peace of mind that the exhaust connection will not fail under the most extreme conditions.

4. AP Exhaust Unbeveled Flange – Best for Custom Fabrication

The AP Exhaust Unbeveled Flange is a specialized component designed for the true fabricator. It forgoes some finishing touches in favor of maximum adaptability, making it the top choice for custom exhaust projects where welding precision is paramount.

Material and Design for Weldability

AP Exhaust Products constructs this flange from quality T304 stainless steel. This material provides a great foundation of strength and corrosion resistance. The flange’s defining feature, however, is its unbeveled inner edge. Unlike other flanges with a pre-chamfered or beveled opening, this one presents a flat, 90-degree surface where the pipe meets the flange.

A Fabricator’s Advantage: This “blank canvas” design gives a welder complete control. The fabricator can grind a custom bevel to match the specific wall thickness of their pipe, ensuring optimal weld penetration and a stronger, more reliable joint.

This design choice makes it one of the best exhaust flanges for those who demand full control over their weld prep and execution.

Versatility for Custom Projects

This flange’s simplicity is its greatest strength. Its universal design makes it incredibly versatile for a wide range of applications. Fabricators can use it for:

- Building a custom downpipe for a unique turbo setup.

- Creating a full cat-back or axle-back exhaust system from scratch.

- Adapting an aftermarket muffler to a stock or custom mid-pipe.

- Repairing or modifying an existing stainless steel exhaust system.

The 3/8-inch thickness provides a solid, warp-resistant base for welding, giving builders confidence that their custom creation will have a durable and leak-free connection point.

Pros and Cons

| Pros | Cons |

|---|---|

| ✅ Unbeveled edge offers total welding control | ❌ Requires more prep work than beveled flanges |

| ✅ T304 stainless steel resists rust | ❌ Not ideal for beginners or quick repairs |

| ✅ Excellent value for a stainless flange | ❌ Mating surface may lack CNC precision |

| ✅ Highly versatile for custom projects |

Ideal User Profile

The ideal user for the AP Exhaust flange is the hands-on builder, the custom exhaust shop, or the advanced DIY enthusiast with welding skills. This individual prioritizes the ability to create perfect, customized weld joints over the convenience of a pre-finished part. If your project involves cutting, fitting, and welding pipes to create a one-of-a-kind exhaust system, this flange provides the ideal starting point.

Buyer’s Guide: How to Choose the Right Flange

Selecting the right flange involves more than just matching the bolt pattern. A builder must consider the material, thickness, and manufacturing quality. These factors directly impact the exhaust system’s durability, seal integrity, and overall performance. This guide breaks down the critical elements to help you make an informed decision.

Material Deep Dive: Stainless vs. Mild Steel

The material of a flange determines its lifespan and resistance to the elements. The choice between stainless and mild steel is the most significant decision a builder will make.

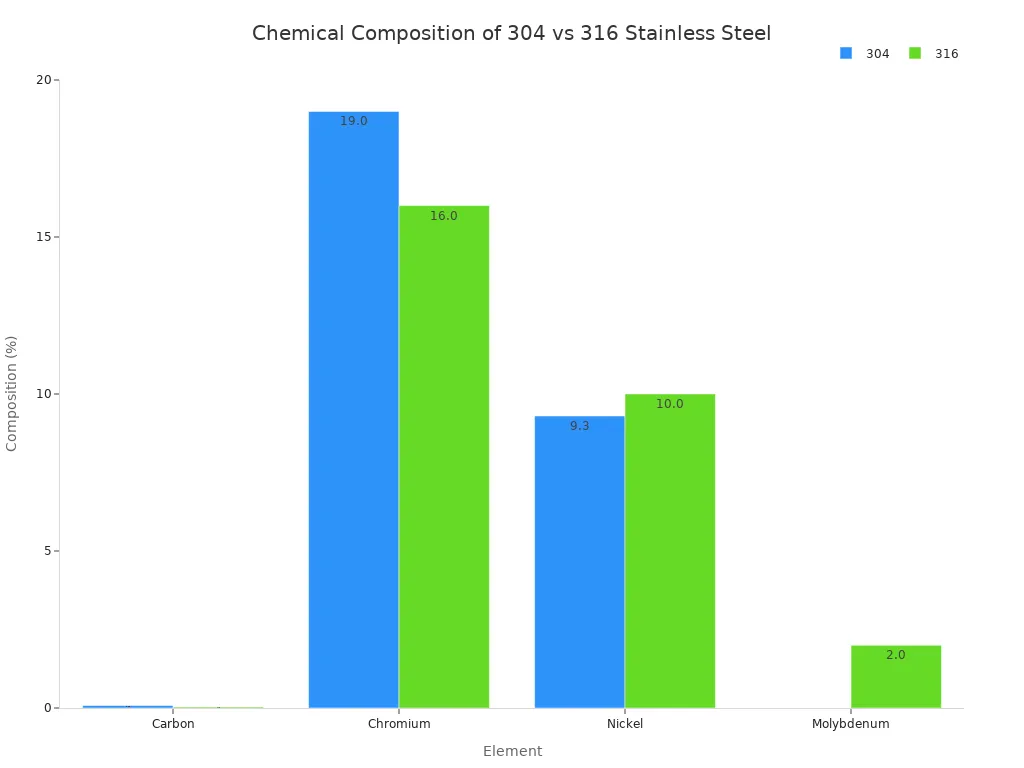

T304 Stainless Steel

T304 is the industry standard for high-quality exhaust components. It typically contains 18% chromium and 8% nickel. This composition gives it excellent resistance to rust and corrosion from moisture and road grime. It is a durable choice for most street and performance applications, offering a long service life.

316L Stainless Steel

316L stainless steel represents a step up in performance. The key difference from T304 is the addition of molybdenum. This element significantly enhances its resistance to chlorides (like road salt) and high temperatures.

This makes 316L the superior choice for turbocharged engines or vehicles in harsh, salt-heavy climates.

Mild Steel

Mild steel is a basic carbon steel alloy. Its main advantage is its low cost. However, it lacks the chromium and nickel content of stainless steel. This makes it highly susceptible to rust. Salt-spray tests confirm that stainless steel vastly outperforms carbon steel in corrosion resistance. A mild steel flange will require protective coatings like high-temp paint to slow down inevitable corrosion.

Which Material is Right for You?

- Daily Drivers/Dry Climates: T304 stainless offers the best balance of cost and longevity.

- Budget Builds: Mild steel is a functional, low-cost option if rust is not a primary concern.

- High-Performance/Harsh Climates: 316L stainless provides the ultimate protection against heat and corrosion.

Critical Features for a Perfect Seal

A perfect seal prevents power-robbing exhaust leaks. Several physical features of a flange contribute to its sealing capability. Finding the best exhaust flanges means paying close attention to these details.

Flange Thickness and Warp Resistance

A thicker flange has more thermal mass and structural rigidity. This makes it less likely to warp from the intense heat cycles of an engine. A 3/8-inch or 1/2-inch flange will resist distortion better than a thinner 1/4-inch flange, ensuring the mating surface stays flat.

Machining Quality and Surface Finish

A flat, smooth surface is essential for a good seal. Premium flanges often feature a CNC-machined face. This process creates a nearly perfect surface that mates cleanly with a gasket. Stamped or laser-cut flanges may have minor imperfections that require more care during installation.

Bolt Hole Sizing and Alignment

The bolt holes must be precisely sized and positioned. Oversized or misaligned holes can cause the flange to shift during tightening. This leads to a poor seal and potential leaks. Quality flanges have tight tolerances to ensure perfect alignment with the mating pipe.

Inner Diameter and Pipe Fitment

The inner diameter (ID) of the flange should closely match the outer diameter (OD) of the exhaust pipe. A snug fit simplifies the welding process and ensures a smooth transition for exhaust gases, minimizing turbulence.

Finding the Best Exhaust Flanges: A Performance Breakdown

A flange’s performance extends beyond its basic function of connecting pipes. Key design characteristics directly influence sealing effectiveness, exhaust flow dynamics, and long-term durability. Understanding these factors helps builders find the best exhaust flanges for their specific performance goals.

Sealing Capability Analysis

A perfect seal is non-negotiable for preventing leaks, which can rob power and create unwanted noise. Two primary design elements determine a flange’s ability to create this seal.

Flat vs. Recessed Designs

Most exhaust flanges feature a simple, flat mating surface. This design relies entirely on the gasket and clamping force to create a seal. A recessed, or “fire ring,” design incorporates a groove for the gasket to sit in.

Tip: A recessed design offers superior gasket alignment and can provide a more reliable seal by concentrating clamping force around the gasket ring. However, it requires a specific gasket type.

The Role of Surface Finish

A smooth, flat surface is critical for an effective seal. A precision-machined face provides maximum contact area for the gasket, minimizing microscopic gaps where exhaust can escape. A rougher, stamped surface may require a thicker, more compliant gasket to fill imperfections.

Exhaust Flow Characteristics

The shape and size of the flange opening can impact engine performance by influencing how smoothly exhaust gases exit the system.

Beveled vs. Non-Beveled Edges

A beveled, or chamfered, inner edge creates a funnel-like transition from the flange into the pipe. This simple feature significantly reduces turbulence. Computational Fluid Dynamics (CFD) models show that a beveled flange design can dramatically increase airflow velocity compared to a standard non-beveled flange, promoting more efficient exhaust scavenging.

Impact of Inner Diameter on Performance

The flange’s inner diameter must match the exhaust pipe to maintain consistent flow. An oversized pipe and flange can decrease exhaust gas velocity. This reduction weakens the scavenging effect that helps pull spent gases from the cylinders, potentially hurting low-end torque. Conversely, a diameter that is too small increases backpressure and engine pumping losses.

Durability and Longevity Factors

An exhaust flange must withstand extreme conditions to provide a long service life. Its material and thickness are key to its resilience.

Heat Cycling and Warp Resistance

Exhaust components endure constant thermal fatigue. The metal expands when hot and contracts when cool. Material science studies show this repeated heat cycling can force the metal into plastic deformation, where it exceeds its elastic limit and permanently changes shape. A thick flange (3/8″ or 1/2″) has greater thermal mass and structural rigidity, making it far more resistant to warping from these extreme temperature swings.

Corrosion Resistance in Different Climates

The flange’s environment dictates its required corrosion resistance.

- Dry Climates: Mild steel may suffice with proper coating.

- Wet/Salty Climates: T304 or 316L stainless steel is essential to prevent rust and premature failure.

Choosing a flange with the right material for the climate ensures a durable, long-lasting connection.

Installation Guide: Achieving a Leak-Free Seal

An exhaust flange’s performance depends heavily on correct installation. A flawed procedure can lead to leaks, negating the benefits of a high-quality component. This guide provides a systematic approach to achieving a durable, leak-free seal.

Pre-Installation: Tools and Parts

Proper preparation is the first step toward a successful installation. Gathering the right tools and components beforehand ensures a smooth and efficient process.

Essential Tool Checklist

A professional-grade installation requires specific tools. A builder should have the following items ready:

- A calibrated torque wrench

- A socket set with appropriate sizes for the hardware

- Wire brushes (both hand and drill-mounted)

- Brake cleaner or a similar degreasing agent

- Safety glasses and gloves (gloves emoji)

Choosing the Right Gasket

The gasket is a critical sealing component. A wide variety of materials are available for 2-inch 3-bolt flanges.

- Composite

- Graphite

- Flexible graphite core with an elastomer coating

- Graphite coated steel core laminate

- Solid steel

For example, the Vibrant Performance 1461 gasket uses a graphite core with an elastomer coating, offering excellent compliance. The choice depends on the application’s heat and pressure. For most street cars, a high-quality composite or graphite gasket provides a reliable seal.

Selecting Appropriate Hardware

Hardware is not a place to cut corners. High-grade bolts and nuts (Grade 8 or stronger) are essential for maintaining proper clamping force. Stainless steel hardware is recommended for use with stainless flanges to prevent galvanic corrosion. Always use new hardware for a new installation.

Step-by-Step Installation Process

Following a precise sequence ensures the flange seats correctly and the gasket seals effectively.

Step 1: Preparing the Mating Surfaces

Begin by thoroughly cleaning both flange mating surfaces. Use a wire brush to remove all old gasket material, carbon buildup, and rust. After brushing, wipe the surfaces with a degreaser to eliminate any oils or contaminants. The goal is a clean, bare-metal surface.

Step 2: Aligning the Gasket and Flange

Place the new gasket onto one of the flanges, ensuring the bolt holes align perfectly. Carefully bring the two exhaust sections together, making sure the gasket does not shift. Insert the bolts by hand to hold the assembly in place.

Step 3: The Correct Bolt Tightening Sequence

Do not tighten one bolt completely at a time. Instead, use a star or crisscross pattern.

- Snug all bolts by hand.

- Tighten each bolt a half-turn at a time, following the star pattern.

- Repeat this process until the bolts are uniformly snug.

Professional Tip: This sequence draws the flanges together evenly, preventing the gasket from being pinched or crushed on one side.

Step 4: Applying Final Torque Specifications

Use a torque wrench for the final tightening. Follow the star pattern again, bringing each bolt to the manufacturer’s specified torque value. For a typical 2-inch pipe flange using 5/16-inch bolts, a final torque of around 17 ft-lbs is common.

| Nominal Pipe Size (in) | Size of Bolts (in) | Preferred Torque (ft. lbs.) |

|---|---|---|

| 1.50 | 0.50 | 28 |

| 2.00 | 0.63 | 49 |

| 2.50 | 0.63 | 67 |

Common Installation Mistakes to Avoid

Avoiding common pitfalls is just as important as following the correct steps. These errors are frequent causes of exhaust leaks.

Over-Torquing Bolts

Excessive force is a primary cause of flange-related leaks. Industry guidelines show that over-tightening can cause excessive flange stress and crush the gasket. This leads to permanent distortion of the flange and a guaranteed leak path. Always adhere to the recommended torque specifications.

Reusing Old Gaskets or Hardware

Automotive experts strongly advise against reusing old components. Gaskets are single-use items; they compress and deform to create a seal. Once compressed, they cannot properly reseal. Similarly, old bolts can stretch or corrode, compromising their ability to maintain clamping force.

Ignoring Surface Imperfections

A clean surface is non-negotiable. Failing to remove all old gasket material or rust creates high spots. These imperfections prevent the new gasket from seating flat, creating small gaps for exhaust to escape.

Misaligning the Flange

Improper alignment during assembly can damage the gasket and prevent a proper seal. Ensure the flanges and gasket are perfectly centered before tightening the bolts. A misaligned flange will apply uneven pressure, leading to a failed connection.

For 2026, the Vibrant Performance T304 Flange is the top overall choice for its balance of quality, performance, and durability. The Flowmaster Mild Steel Flange offers dependable performance for the budget-conscious builder. For high-horsepower applications, investing in the superior ATP Turbo 316L Flange is the smartest choice.

A builder must weigh initial cost against long-term value. Stainless steel’s higher upfront price often leads to lower total ownership costs over time due to minimal maintenance needs.

Ultimately, a builder should assess their specific needs for material and budget to select the flange that guarantees a reliable, leak-free exhaust system.

FAQ

Can a builder reuse an old exhaust flange or gasket?

No. A builder should never reuse these parts. Flanges can warp from heat, preventing a proper seal. Gaskets are single-use components designed to crush once. Reusing them almost always results in an exhaust leak.

What is the best gasket material for a 2-inch flange?

The best choice depends on the application.

- Standard Use: High-quality composite gaskets work well.

- High-Performance: Multi-layer steel (MLS) or graphite gaskets offer superior heat resistance and sealing for demanding conditions.

Is a thicker flange always better?

Yes, a thicker flange provides better performance. Flanges measuring 3/8-inch or 1/2-inch have more thermal mass. This quality makes them significantly more resistant to warping from extreme heat cycles, ensuring a reliable, flat sealing surface.

Why would someone need a 316L stainless steel flange?

A builder chooses 316L stainless steel for extreme environments. Its molybdenum content offers superior resistance to heat and salt corrosion. This makes it the ideal material for high-horsepower turbocharged engines or vehicles operated in harsh winter climates.

Does a beveled inner edge really matter for performance?

A beveled edge significantly improves exhaust flow. It creates a smooth transition for gases entering the pipe, which reduces turbulence. This helps maintain exhaust velocity and can contribute to better engine scavenging and overall performance.

How can a builder prevent exhaust bolts from seizing?

Applying a thin layer of high-temperature anti-seize lubricant to the bolt threads before installation is the best method. This simple step prevents the hardware from corroding and seizing, making future removal much easier. (wrench emoji)

Can a fabricator weld a stainless steel flange to a mild steel pipe?

Yes, this is a common practice in custom exhaust work.

A fabricator must use a specific filler wire, such as 309L stainless steel, to create a strong and crack-resistant weld between the two dissimilar metals.