A standard Eye Bolt poses significant safety risks with angular loading, reducing capacity and risking failure. The lifting and rigging industry now considers superior alternatives the standard for angled and heavy lifts. A custom fasteners manufacturer produces advanced rigging hardware, often using superior bolt casting for these components.

Choosing the correct custom fasteners is a critical decision. It ensures operational safety when securing loads and compliance in all lifting operations.

The Hidden Dangers of Standard Eye Bolts in Lifting and Rigging

While common, standard eye bolts introduce significant risks into lifting and rigging operations if misused. Their simple design hides critical limitations that every rigger must understand to ensure worksite safety. Understanding these dangers is the first step toward selecting safer, more appropriate hardware.

Understanding Eye Bolt Design and Limitations

Not all eye bolts are created equal. The manufacturing process and design pattern directly determine an eye bolt’s strength and appropriate application.

Forged vs. Wire Eye Bolts

The manufacturing method is a primary differentiator. Forged eye bolts are made by shaping metal under extreme pressure. This forging process creates a dense, uniform grain structure, resulting in a superior one-piece component. These bolts, often made from hardened steel, possess high tensile strength and resist deformation. In contrast, wire eye bolts are simply bent into shape, making them suitable only for very light-duty, non-lifting applications.

| Feature | Forged Eye Bolts | Wire (Bent) Eye Bolts |

|---|---|---|

| Manufacturing Process | Hammered or pressed into form, altering grain structure | Bending a solid rod into the final eye bolt shape |

| Load Capacity | Heavier-duty lifting applications | Primarily for lighter-duty applications; eye can open or break |

| Angular Loading | Can be used for angular loading (with a shoulder) | Should not be used for angular loads |

Shoulder vs. Plain Pattern

The presence of a shoulder is another critical design feature. A shoulder eye bolt has a reinforced collar between the eye and the threads. This shoulder braces the bolt against the load’s surface, providing crucial support against bending forces during angular lifts. Plain pattern (or non-shouldered) eye bolts lack this feature and are strictly limited to vertical, in-line lifts.

Important Note: A shoulder eye bolt only provides its full rated load capacities when the shoulder is fully and squarely seated against the load surface. Any gap negates its ability to resist angular forces.

Critical Weakness: Angular Loading

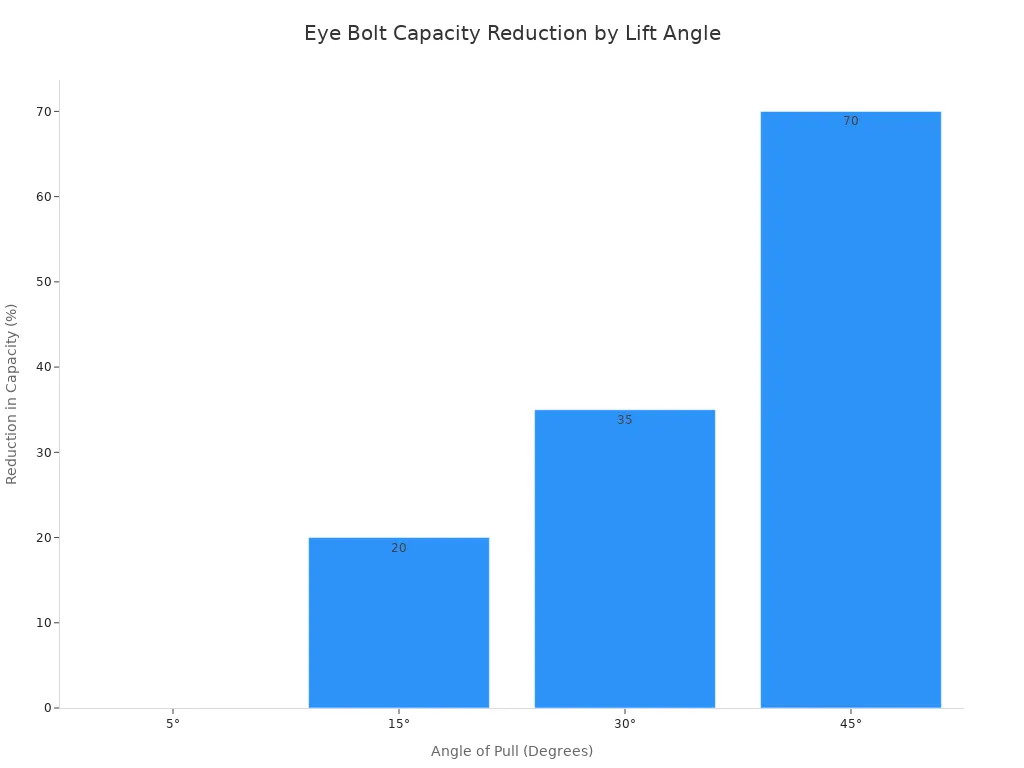

The most significant danger associated with standard eye bolts is their drastically reduced capacity when pulled at an angle.

Drastic Reduction in Working Load Limit (WLL)

An eye bolt’s working load limit applies only to a perfectly vertical (0-degree) lift. As the angle of the sling increases, the capacity plummets due to the introduction of bending forces.

| Angle of Pull (from vertical) | Reduction in Working Load Limit |

|---|---|

| 5° | 0% (Full Capacity) |

| 15° | 20% |

| 30° | 35% |

| 45° | 70% |

| 46°+ | Unsafe – Do Not Use |

Bending Stress and Fracture Risk

When an eye bolt is loaded at an angle, the force tries to bend the shank. This bending stress concentrates at the point where the shank meets the load surface. Eye bolts are not designed to handle this stress, which can lead to bending, metal fatigue, and sudden, catastrophic fracture well below the stated working load limit.

Common Misuses and Failure Scenarios

Human error and a lack of training often lead to eye bolt failures in rigging.

Improper Seating and Orientation

For a shoulder eye bolt to work correctly, it must be screwed in until the shoulder is flush and tight against the load surface. The eye must also be aligned with the direction of the pull. Misalignment puts dangerous bending stress on the bolt.

Shock Loading and Its Consequences

Shock loading occurs from sudden starts, stops, or drops during a lift. This dynamic force can multiply the load’s effective weight, easily exceeding the hardware’s capacity. Shock loads can cause immediate failure or create hidden microfractures that weaken the bolt, setting the stage for a future failure under a normal load. Carbon steel eye bolts are especially vulnerable to shock load failure in cold temperatures.

Using Non-Lifting Grade Hardware

Never use generic, hardware-store eye bolts for any lifting application. These products are not rated for overhead lifting and lack the material strength, traceability, and quality control required for safe operations. Always use hardware specifically designed and rated for lifting and rigging.

Superior Alternative 1: Hoist Rings (Lifting Rings)

When angular lifts are necessary, hoist rings provide an engineered solution that directly overcomes the critical weaknesses of standard eye bolts. These advanced components are designed for safety and versatility, maintaining their rated load capacities in complex lifting scenarios.

What Are Hoist Rings?

A hoist ring, also known as a lifting ring, is a specialized piece of rigging hardware designed to safely handle loads from various angles. Its design is fundamentally different from the fixed loop of an eye bolt.

Defining the Swivel and Pivot Mechanism

The defining feature of a hoist ring is its ability to move dynamically under load. The design incorporates a lifting ring that can swivel a full 360 degrees and pivot 180 degrees. This articulation allows the ring to automatically align itself with the direction of the lifting force.

Key Components: Bail, Bushing, and Bolt

Hoist rings consist of three primary parts working in unison:

- Bail: The D-shaped or pear-shaped steel loop that the sling or hook connects to.

- Bushing: The component that allows the bail and body to rotate smoothly.

- Bolt: A high-strength, threaded fastener that secures the entire assembly to the load.

Core Advantages Over Eye Bolts

The mechanical design of hoist rings offers clear and significant safety advantages over traditional eye bolts, especially when handling heavy loads.

Full WLL at Any Angle

A hoist ring’s ability to swivel and pivot is the key to its superior performance. This movement ensures the lifting force is always channeled through the center of the component. As a result, a hoist ring maintains its full working load limit at any angle up to 90 degrees, eliminating the dangerous capacity reduction seen with eye bolts.

Elimination of Bending Stress

Because the bail aligns perfectly with the sling angle, a hoist ring is not subjected to bending stress. The load force is converted into a pure tensile force along the axis of the bail and bolt, which is exactly what the hardware is designed to handle. This eliminates the primary cause of eye bolt failure in angular lifts.

360° Swivel and 180° Pivot Capability

This full range of motion provides unmatched flexibility. It allows for lifting, turning, and flipping loads without needing to detach and reposition the hardware. This capability is not just convenient; it is a critical safety feature.

| Feature | Hoist Rings | Standard Eye Bolts |

|---|---|---|

| Load Direction | Can handle a load from any angle | Designed for vertical (in-line) pulls only |

| Working Load Limit | Maintains 100% of WLL at any angle | WLL is severely reduced at an angle |

| Articulation | Swivels 360° and pivots 180° | Fixed eye; no pivot action |

| Safety Risk | Low risk of failure in angular lifts | High risk of bending or shearing under side load |

Types of Hoist Rings and Their Applications

Different hoist ring designs are available to suit specific lifting needs. Choosing the correct type is essential for operational safety.

Center-Pull Hoist Rings

These are the most common type. The bail is mounted in the center of the ring’s body, making them ideal for general-purpose lifting from any direction.

Side-Pull Hoist Rings

These rings are specifically engineered for side mounting on a load. They are invaluable when overhead clearance is limited or when a load must be tilted, such as when removing a die from a press.

Weld-On Hoist Rings

Instead of a bolt, these rings have a base that is welded directly onto the load. This creates a permanent, high-strength lifting point on heavy fabrications or large machinery.

Forged Swivel Hoist Rings

The term “forged” refers to the manufacturing process. High-quality hoist rings are forged from alloy steel to create a superior grain structure, ensuring maximum strength and durability for demanding applications.

Best Use Cases for Hoist Rings

The unique design of hoist rings makes them the superior choice for specific, demanding applications where eye bolts would be unsafe or impractical. Their ability to handle complex load dynamics makes them indispensable in modern rigging.

Heavy Die and Mold Handling

The plastic injection mold industry relies heavily on hoist rings for safe and efficient operations. These molds are often extremely heavy, expensive, and have an off-center point of gravity. Hoist rings provide a secure connection point that accommodates these challenges.

- Swivel hoist rings are crucial for safely maneuvering molds, where a drop could cause catastrophic damage and severe injury.

- Unlike eye bolts, hoist rings offer a full range of motion and can be side-loaded without losing capacity.

- They maintain their full Working Load Limit (WLL) even when rotated, making them a safer and more durable option for mold handling.

Complex Machinery and Equipment Lifting

Hoist rings are heavy-duty lifting assemblies engineered for complex commercial applications. They are ideal for moving large, irregularly shaped equipment like generators, turbines, or CNC machines. These items often have multiple attachment points and require precise maneuvering. The hoist ring’s ability to maintain its full WLL across various angles makes it safer for multi-directional pulls and dynamic loads. This versatility ensures that as the machinery is tilted or positioned, the hardware adapts without introducing dangerous bending stress.

Lifts Requiring Load Rotation or Flipping

Many manufacturing and fabrication processes require flipping or rotating large components. Hoist rings excel in these scenarios. Their 360° swivel and 180° pivot capabilities allow riggers to turn a load over without ever disconnecting the rigging. This continuous connection is a significant safety advantage. It eliminates the risks associated with re-rigging a suspended load mid-air.

The ability to pivot under load allows the hoist ring to follow the sling’s angle perfectly. This action prevents the binding and side-loading that would cause a standard eye bolt to fail during a rotational move.

Superior Alternative 2: Lifting Lugs (Pad Eyes)

For heavy-duty and permanent applications, lifting lugs, also known as pad eyes, offer a robust and engineered solution. Unlike threaded hardware, these components are designed to become an integral part of the load itself, providing unparalleled strength and reliability for specific lifting tasks.

What Are Lifting Lugs?

A lifting lug is a plate with a hole, specifically designed as an attachment point for a shackle or hook. Engineers design them to handle specific loads at predetermined angles, making them a custom solution rather than a general-purpose part.

Defining Welded and Bolted Lugs

Lugs are typically attached in one of two ways.

- Welded Lugs: A welder permanently fuses these lugs directly onto a steel structure or piece of equipment. This creates a powerful, seamless connection.

- Bolted Lugs: These lugs are attached using high-strength bolts. This method allows for replacement if the lug becomes damaged and is useful on materials where welding is not practical.

Role in Permanent and Semi-Permanent Lifting Points

Lifting lugs create permanent or semi-permanent lifting points on large assets. They are common on heavy fabrications, offshore equipment, and large machinery. Once installed, they provide consistent and reliable secure anchor points for all future lifts.

Core Advantages of Custom-Engineered Lugs

The true strength of a lifting lug lies in its custom-engineered nature. They are not off-the-shelf solutions but are instead tailored to the exact demands of a specific application.

Designed for Specific Load and Angle Requirements

Engineers design each lug for a precise load weight and sling angle. This eliminates the guesswork and risk associated with angular loading on eye bolts.

According to OSHA regulation §1926.251(a)(4), all special custom design lifting accessories, including lugs, shall be proof-tested to 125 percent of their rated load before use. This mandatory test ensures the component can safely handle its intended forces.

High-Capacity and Robust Construction

Lugs are built for immense loads. Their construction involves careful material selection and fabrication processes. Using qualified welders is critical to ensure proper penetration and fusion, preventing catastrophic weld failure. Weldable steels like ASTM A307 are common, while high-strength, heat-treated bolts such as A325 are generally not welded, as heat can compromise their structural properties.

Integration into the Load’s Structure

When welded or bolted correctly, a lug becomes part of the equipment’s structure. This integration distributes the lifting forces directly into the frame of the load. This method is far more secure than relying on the shear strength of a threaded bolt.

Types of Lifting Lugs

While many lugs are custom-made, several standard types exist for common applications.

Standard Weld-On Pad Eyes

These are pre-manufactured lugs available in various sizes with established rated load capacities. They are a popular choice for general fabrication where lifting requirements are known.

Bolt-On Lifting Lugs

These serve the same function as weld-on lugs but are attached with bolts. They are ideal for adding a lifting point to an existing structure without requiring on-site welding.

Custom-Fabricated Lugs

For unique or extremely heavy projects, engineers design and fabricate lugs from scratch. This process ensures every aspect of the lug—from material thickness to hole diameter—is perfectly optimized for the specific lifting challenge.

Best Use Cases for Lifting Lugs

The engineered nature of lifting lugs makes them the definitive choice for specific, high-consequence applications. They provide unparalleled safety and reliability where standard hardware would fail.

Heavy Fabrication and Structural Steel

In the world of heavy fabrication, engineers incorporate lifting lugs into the design from the very beginning. Welders attach these lugs to massive steel beams, trusses, and plate assemblies in the workshop. This process creates pre-approved, load-tested attachment points. Riggers on the construction site can then confidently connect to these points. This integration eliminates guesswork and ensures the structural components are handled safely during assembly and erection. The lug’s design accounts for the precise weight and intended angle of every lift.

Offshore and Marine Lifting Applications

The offshore and marine industries operate in demanding environments where failure is not an option. Lifting lugs are essential for constructing and maintaining oil rigs, ships, and subsea equipment. They are built to withstand immense forces and corrosive saltwater conditions.

- Specialized lugs, sometimes called ‘tailing lugs,’ help control and stabilize large structural sections during complex lifts.

- They are critical for major operations, such as switching out an 80-ton engine on a bulk carrier, where hydraulic systems need robust points to jack against.

- Their robust, welded design provides the strength needed to move massive, high-value assets safely in challenging sea conditions.

Permanent Lifting Points on Large Equipment

Manufacturers often install lifting lugs as permanent features on heavy machinery and equipment. This practice ensures the asset can be handled correctly throughout its entire service life. These integrated lugs provide designated and engineered secure anchor points for maintenance, transportation, and installation.

Common Examples: You will find lifting lugs, or pad eyes, as standard components on many types of industrial equipment. They are essential for the safe lifting of these items.

These devices are commonly found on:

- Equipment skids used in the oil and gas industry

- Large industrial storage tanks

- Structural elements and modules

- Intermodal shipping containers

By including these lugs, manufacturers remove the risk of users attaching rigging to unsafe points on the equipment.

Superior Alternative 3: Shackles as Critical Connectors

While not a direct replacement for an eye bolt screwed into a load, shackles are indispensable connectors in nearly every complex rigging plan. They provide a secure and rated link between lifting hardware, slings, and the load itself. Understanding their function and types is essential for building a safe lifting assembly.

What Are Shackles in Lifting?

Shackles are fundamental components used to connect different parts of a lifting system. Their simple design provides a strong, reliable link for transferring force.

Defining the Role as a Connector

A shackle is a U-shaped metal piece secured with a pin. Its primary job is to connect a sling to a lifting lug, a hook to a sling, or various other hardware components together. They act as the crucial link in the chain of equipment.

Key Components: Body, Pin, and Shoulder

Every shackle consists of a few key parts:

- Body: The main U-shaped or O-shaped part, often called the bow.

- Pin: The steel bolt that passes through the eyes of the body to close the shackle.

- Shoulder: The part of the pin that contacts the shackle body, ensuring it seats correctly.

When to Use Shackles as a Lifting Point Alternative

A shackle rarely serves as the primary lifting point itself. Instead, it functions as a vital intermediary component that enables safer connections.

Connecting Slings to Lifting Lugs

Shackles are the standard method for attaching a sling to a welded or bolted lifting lug (pad eye). The shackle’s rounded surface provides a smooth, wide bearing point for the sling eye, preventing damage and ensuring proper load distribution.

Use with Spreader Beams and Rigging Assemblies

In complex lifts involving multiple slings or spreader beams, shackles connect all the components. They allow riggers to create secure, multi-leg bridle assemblies and attach them to a single hook.

Not a Direct Replacement, but a Critical Component

It is critical to understand that a shackle does not thread into a load like an eye bolt or hoist ring. It connects to an existing, engineered lifting point. Its role is to complete the connection safely and efficiently.

Types of Shackles and Their Functions

Shackles come in different shapes and pin styles, each designed for specific tasks. Choosing the correct type is vital for safety.

Anchor (Bow) Shackles

These shackles have a large, O-shaped body. The rounded design provides ample space and is ideal for connecting multiple slings. The bow shackle’s shape allows it to handle angular loads from multiple directions, making it perfect for multi-leg sling assemblies where forces come from different angles.

Chain (Dee) Shackles

These have a narrower, D-shaped body. Their design is optimized for single, in-line pulls. The straight sides prevent unwanted rotation and keep the load aligned.

Chain shackles, also referred to as D shackles, have a D-shaped bow that is narrower than anchor shackles. Because these shackles are designed and rated for in-line tension, they should not be side loaded, as side loading can twist or bend the bow of the shackle.

Screw Pin vs. Bolt-Type Pins

The pin type determines the shackle’s suitability for different applications.

- Screw Pin: This pin threads directly into the shackle body. It is excellent for temporary applications or jobs that require quick and repeated connection and disconnection.

- Bolt-Type Pin: This design uses a bolt, nut, and cotter pin. This secure system prevents the pin from loosening due to vibration or load rotation. Bolt-type shackles are the required choice for semi-permanent or long-term installations.

Best Use Cases for Shackles in a Rigging Plan

Shackles are fundamental to safe rigging practices. Their proper application ensures that lifting assemblies are strong, secure, and configured correctly for the specific task. They are the go-to hardware for creating reliable connections within a larger system.

Multi-Leg Sling Connections

One of the most common and critical uses for shackles is to gather multiple slings at a single lifting point. When a lift requires a two, three, or four-leg sling bridle, a shackle provides a master link to connect them all to the crane hook. This application demands careful shackle selection.

- For multi-leg slings or any side-loading situation, riggers must use Anchor (Bow) Shackles.

- The wide, rounded body of a bow shackle provides ample room for multiple sling eyes and is specifically designed to accommodate the angular forces they create.

Choosing the correct shackle type is crucial for safety and performance under specific rigging conditions. Using a narrow Chain (Dee) shackle in a multi-leg bridle can cause dangerous side-loading and potential hardware failure.

Attaching Hardware to Pad Eyes

Shackles are the industry-standard method for connecting a sling to a lifting lug or pad eye. A rigger should never attach a sling’s soft eye directly over the sharp edges of a lug. The shackle acts as a perfect intermediary component. The rounded bow of the shackle provides a smooth, broad surface for the sling eye to rest on. This design prevents the sling from being cut or damaged while ensuring the load is distributed evenly. This connection method protects the sling, prolongs its service life, and maintains the integrity of the entire lifting assembly.

Temporary and Adjustable Connection Points

Shackles provide excellent versatility for creating temporary and adjustable connection points. Screw pin shackles are particularly useful for these applications. Their design allows for quick assembly and disassembly, making them ideal for jobs that require frequent changes or adjustments to the lifting setup. For example, a rigger can easily use a screw pin shackle to attach a block, hoist, or other hardware for a short-term task. For longer-term or semi-permanent connections where vibration is a concern, a bolt-type shackle offers superior security, as the nut and cotter pin system prevents the pin from backing out.

Decision Matrix: Choosing the Right Hardware for Securing Loads

Selecting the correct hardware is a critical safety decision. Riggers must evaluate several key factors to match the component to the specific demands of the lift. This decision matrix simplifies the process of choosing between eye bolts, hoist rings, and lifting lugs for securing loads safely.

Factor 1: Load Angle

The angle of the sling relative to the load is the most important factor. It directly impacts the hardware’s ability to handle the force.

0-5 Degrees: Eye Bolts (with caution)

For straight, vertical lifts, a properly installed shoulder eye bolt can be used. However, riggers must exercise extreme caution. Even a small deviation from vertical drastically reduces the working load limit.

Riggers must always use shoulder nut eye bolts for any potential angular lift and never use regular nut eye bolts. The working load limit must be adjusted for any angle greater than 5 degrees.

| Direction of Pull (from vertical) | Adjusted Work Load |

|---|---|

| 45 degrees | 30% of Work Load Limit |

| 90 degrees | 25% of Work Load Limit |

5-90 Degrees: Hoist Rings

Hoist rings are the engineered solution for any angular lift. Their design allows them to pivot 180° and swivel 360°. This range of motion ensures the lifting point aligns perfectly with the sling’s angle, maintaining 100% of its rated load capacities. This eliminates the dangerous bending stress that causes eye bolt failure.

Pre-determined Angles: Lifting Lugs

For heavy, repetitive lifts where the angle is known and fixed, lifting lugs are the superior choice. Engineers design these components for a specific load and angle, building the safety factor directly into the equipment.

Factor 2: Load Capacity

The weight of the object being lifted narrows the hardware options.

Low to Medium Capacity: Eye Bolts, Hoist Rings

Both eye bolts and hoist rings are available for low to medium capacity lifts. While an eye bolt may have a high stated working load limit, its actual load capacity is only valid for a perfect vertical lift. Hoist rings provide a much safer alternative in this range because they maintain their full load capacity at any angle.

High to Very High Capacity: Hoist Rings, Lifting Lugs

For securing loads with very high weights, the choice is between high-capacity hoist rings and custom-fabricated lifting lugs. Lugs are integrated into the load’s structure for maximum strength, while hoist rings offer versatility for complex maneuvers.

Factor 3: Permanence of Installation

The duration and frequency of the lifting operation influence the best type of attachment.

Temporary Lifts: Threaded Hoist Rings

For temporary jobs or one-time lifts, threaded hoist rings offer the ideal combination of safety and convenience. They can be easily installed into a tapped hole and removed once the task is complete, providing superior angular lifting performance compared to an eye bolt.

Semi-Permanent/Permanent: Weld-On Hoist Rings, Lifting Lugs

For equipment that requires frequent handling or has designated lifting points, welded solutions provide the highest level of safety and durability.

- Weld-on points offer permanent and secure integration into the load-bearing structure.

- Their fixed installation reduces the risk of human error, such as improper tightening.

- They are engineered for dynamic use, with load-bearing components that are 100% crack-tested to ensure reliability.

Factor 4: Load Movement and Rotation

The dynamic behavior of the load during the lift is a final, critical consideration. Whether a load remains static or needs to be moved and repositioned determines the appropriate hardware for securing loads safely.

Static Vertical Lifts: Eye Bolts

Eye bolts are only suitable for a very limited scenario: a perfectly static, vertical lift. This means the load is lifted straight up and set straight down without any turning, flipping, or horizontal movement. In these simple lifts, a properly seated shoulder eye bolt can perform its function. Any deviation, however, introduces dangerous forces the hardware is not designed to handle.

Dynamic Lifts with Rotation/Pivoting: Hoist Rings

Dynamic lifts involve any movement beyond a simple vertical pull. Hoist rings are the only appropriate choice for these complex operations. Their design provides a higher safety factor during any lifting, turning, or flipping maneuver.

- The hoist ring’s ability to move with the load prevents dangerous shock loading.

- Its articulation allows for the safe manipulation of loads without introducing side-loading stress.

- The 360° swivel and 180° pivot action enables the hardware to articulate safely, preventing the unthreading or shearing that can occur with fixed eye bolts.

- This ensures a stable and secure connection throughout the entire operation, which is crucial for tasks like handling large dies and molds.

Comparative Summary Table

This table provides a clear summary to help riggers choose the correct component for the job. It compares the key features of eye bolts, hoist rings, and lifting lugs.

Feature Comparison: Eye Bolt vs. Hoist Ring vs. Lug

| Feature | Eye Bolt (Shouldered) | Hoist Ring (Swivel) | Lifting Lug (Pad Eye) |

|---|---|---|---|

| Angular Lifting | Unsafe. Drastic WLL reduction beyond 5°. | Safe. Maintains 100% WLL up to 90°. | Safe. Engineered for a specific, fixed angle. |

| Load Rotation | No. Can unscrew or fracture. | Yes. Swivels 360° and pivots 180°. | No. Fixed point for a specific lift plan. |

| Load Capacity | Low to Medium (vertical only). | Low to Very High. | High to Extremely High. |

| Installation | Temporary (threaded). | Temporary (threaded) or Permanent (weld-on). | Permanent (welded) or Semi-Permanent (bolted). |

| Best Use Case | Strictly vertical, static lifts with no side load. | Complex, dynamic lifts requiring rotation or pivoting. | Permanent, engineered points for securing loads on heavy equipment. |

Installation, Inspection, and Safety Compliance

Selecting the right hardware is only the first step. Proper installation, diligent inspection, and adherence to industry standards are essential for safe lifting and rigging operations. These practices ensure that components perform as designed and prevent catastrophic failures.

Proper Installation Procedures

Correct installation is the foundation of a safe lift. A small mistake at this stage can compromise the entire system.

Thread Engagement and Surface Preparation

For threaded hardware like hoist rings, the load surface must be clean, flat, and perpendicular to the bolt hole. The bolt must have full thread engagement in the hole to achieve its rated strength. Any debris or unevenness can prevent proper seating and introduce dangerous stress.

Applying Correct Torque Specifications

Manufacturers provide specific torque values for their hardware. Applying the correct torque ensures the component is secure without over-tightening, which can stretch the bolt and lead to failure. A calibrated torque wrench is a necessary tool for this task.

Welding Procedures for Lugs and Weld-On Rings

Only a qualified welder should attach weld-on lugs or hoist rings. The welder must follow specific procedures to ensure proper fusion and prevent heat from compromising the structural integrity of the load or the lifting point.

Critical Inspection Checklist

Regular inspection is a non-negotiable part of any rigging program. A qualified person must inspect all equipment before each shift or use.

Pre-Use Visual Inspection

A daily visual check is the first line of defense. Riggers must look for any obvious signs of damage before the hardware is put into service.

- Confirm that identification tags with load ratings are present and legible.

- Check that hooks have functional safety latches.

- Ensure all components are free of dirt or debris that could hide a defect.

Identifying Wear, Deformation, and Cracks

A thorough inspection looks for specific signs of damage. Any rigging hardware showing the following defects must be removed from service immediately:

- Cracks, nicks, or gouges in the metal.

- Visible bending, twisting, or stretching.

- Excessive corrosion or pitting.

- Wear on any part of the component that exceeds 10% of the original dimension.

Periodic Inspection Requirements (ASME B30.26)

In addition to daily checks, a complete and documented inspection must be performed periodically. The frequency depends on the service conditions, but it provides a thorough assessment of the equipment’s condition over time.

Understanding and Adhering to Standards

Compliance with established standards is mandatory. These regulations provide a framework of safety precautions for the entire lifting and rigging industry.

ASME B30.26: Rigging Hardware

This standard from the American Society of Mechanical Engineers covers detachable rigging components. It provides key requirements for the construction, installation, operation, inspection, and maintenance of items like shackles, eyebolts, and hoist rings.

ASME BTH-1: Design of Lifting Devices

This standard applies to the design of custom equipment, including engineered lifting lugs. It ensures that custom-fabricated devices are designed with appropriate safety factors for their intended lifting task.

OSHA Regulations for Rigging Equipment

The Occupational Safety and Health Administration (OSHA) sets federal laws for workplace safety. Key regulations for rigging state that a qualified rigger must inspect all gear before each shift. The total load must never exceed the rated capacity of the equipment, and any deficient gear must be removed from service immediately.

Modern rigging demands a commitment to safety that moves beyond outdated hardware. Choosing the correct rigging hardware is a critical decision for all lifting operations.

- Hoist rings and lifting lugs provide engineered solutions for complex rigging applications.

- Proper selection, installation, and inspection protect both personnel and assets.

- Personnel should always consult a qualified rigging engineer when any doubt exists about a lift.

FAQ

Why can’t I just use a bigger eye bolt for an angled lift?

A larger eye bolt still suffers from drastic capacity reduction at an angle. The bending stress remains the primary failure risk. Hoist rings are the engineered solution. They eliminate this dangerous side-loading stress and maintain their full capacity.

What does “WLL” mean?

WLL stands for Working Load Limit. It is the maximum mass or force that a piece of lifting equipment can safely handle. Riggers must never exceed the manufacturer’s specified WLL for any component in the lifting assembly.

Is a hoist ring always better than an eye bolt?

For angular lifts, yes. Hoist rings provide superior safety. For a perfectly vertical, static lift, a properly installed shoulder eye bolt can be adequate. However, hoist rings offer a much higher safety factor for almost all lifting scenarios.

When is a bolt-type shackle required over a screw pin?

Riggers must use bolt-type shackles for long-term or semi-permanent installations. The nut and cotter pin design prevents the pin from loosening due to vibration. Screw pins are suitable only for temporary, quick-connection tasks where removal is frequent.

Can I weld a standard bolt to make a lifting lug?

No. 🚫 Welding can compromise the heat treatment and strength of standard bolts. Lifting lugs require specific weldable materials and engineering design. Only qualified welders should attach approved weld-on hardware following proper procedures.

What is the most important rule for using shoulder eye bolts?

The shoulder must be fully and squarely seated against the load surface. Any gap negates the shoulder’s ability to resist bending forces. This proper seating is critical for the hardware to function safely, even at very small angles.

Who is a “qualified person” for inspections?

A qualified person possesses a recognized degree, certificate, or professional standing. They have extensive knowledge, training, and experience. This background allows them to solve problems related to the subject matter, work, or project successfully.