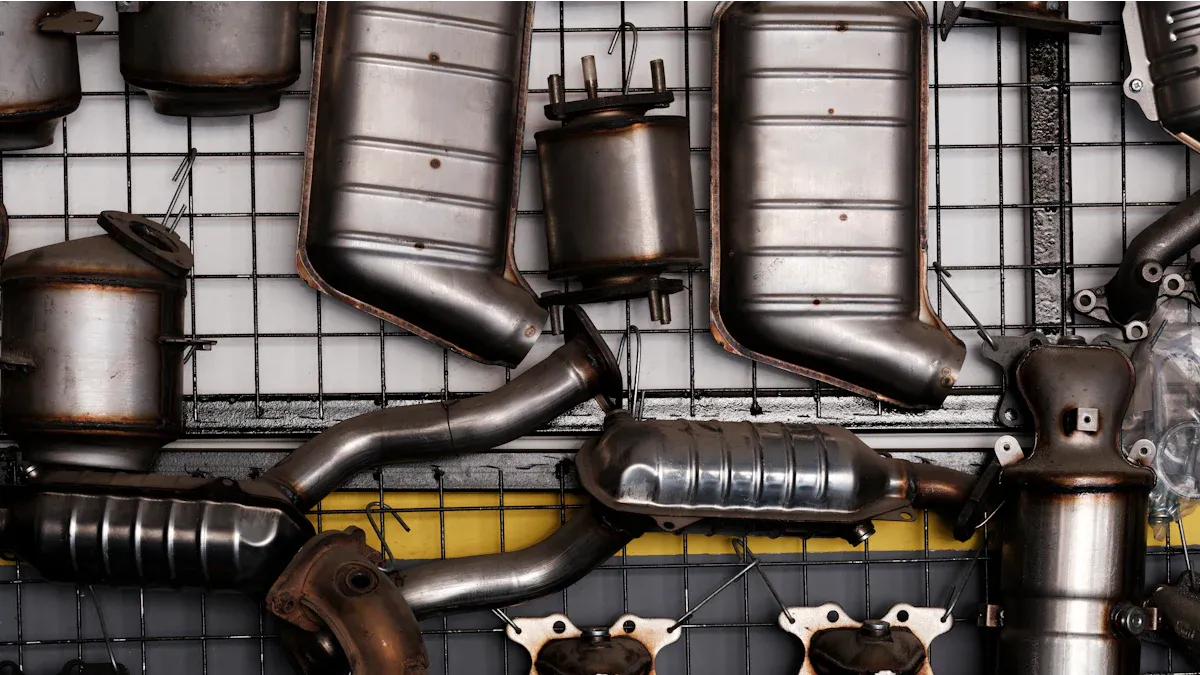

The standard 3-bolt exhaust flange has several effective alternatives. Each flange option provides distinct advantages for an exhaust system. Top choices include V-band clamps, 2-bolt flanges, ball and socket joints, slip-fit connectors, and Marmon flanges. For specialized applications, a custom fasteners manufacturer can supply a superior Flange Bolt or bolt casting. These custom fasteners improve the seal on various exhaust flanges, ensuring optimal performance and durability.

Why Look for an Alternative to the 3-Bolt Exhaust Flange?

The 3-bolt exhaust flange is a common component in many factory and aftermarket exhaust systems. Its design is straightforward and has served its purpose for decades. However, this traditional connection method has several inherent weaknesses that can lead to frustrating and costly repairs. Understanding these drawbacks clarifies why many builders and mechanics now prefer modern alternatives for creating durable, leak-free exhaust systems.

Common Problems with 3-Bolt Flanges

The issues with 3-bolt flanges often compound, where one problem directly causes another. These challenges range from minor annoyances to significant component failures.

Prone to Gasket Blowouts and Leaks

The design relies entirely on a gasket to create a seal between the two mating surfaces. This gasket is a frequent point of failure. Over time, intense heat and pressure cause the gasket material to degrade, compress, and eventually “blow out.” A failed gasket creates an exhaust leak, resulting in excessive noise, harmful fumes entering the cabin, and poor engine performance.

Note: A significant leak from a separated flange can have severe consequences. Hot exhaust gases blowing onto nearby parts have been known to melt components like DEF injectors and wiring harnesses, leading to expensive and complex repairs.

Susceptibility to Warping

Exhaust systems endure constant thermal cycles, heating up to extreme temperatures and cooling back down. This repeated stress can cause the metal of the flange to warp. A warped flange no longer provides a flat, even surface for the gasket to seal against. This condition almost guarantees a persistent leak that cannot be fixed simply by installing a new gasket or tightening the bolts.

Uneven Clamping Pressure

A triangular bolt pattern inherently creates uneven clamping force. The pressure is highest near the bolts and lowest in the areas between them. This inconsistent pressure puts uneven stress on the gasket, accelerating its failure. It also contributes to the warping of the flange itself, as the metal is pulled and stressed unevenly across its surface. This is a fundamental design flaw that more advanced exhaust flanges aim to solve.

Cumbersome Installation and Removal

Working with 3-bolt flanges can be a difficult task, especially on older vehicles. The hardware is exposed to moisture, road salt, and heat, leading to severe corrosion. This makes removal a challenge. Technicians often encounter issues such as:

- Heavy corrosion on bolts, particularly near components like the DPF.

- Bolts breaking off during removal, requiring drilling and extraction.

- Fasteners seizing completely, forcing a technician to cut the flange apart.

These problems add significant time and labor costs to what should be a simple service.

Alternative 1: V-Band Clamps

V-band clamps represent a significant upgrade from traditional bolted connections. They are a top choice in performance exhaust systems for their superior sealing, serviceability, and clean appearance. This modern solution eliminates many of the fundamental flaws found in multi-bolt flange designs.

What is a V-Band Clamp Assembly?

A V-band assembly consists of two precision-machined flange rings and a specialized outer clamp. These components work together to create a strong, self-aligning, and gasket-free seal. The design is simple yet highly effective.

The V-Band Flange Rings

The core of the system is a pair of interlocking rings, typically one male and one female. Each flange ring is welded onto the end of an exhaust pipe. The rings feature a unique angled or “V”-shaped surface. When brought together, these surfaces mate perfectly, forming a tight seal without the need for a separate gasket.

The V-Band Clamp Mechanism

The outer clamp is what applies force to the two flange rings. This clamp has a corresponding V-shaped channel that fits over the outside of the mated rings. Tightening a single T-bolt on the clamp draws its ends together, applying uniform 360-degree pressure. This even force pulls the two flange rings into a tight, leak-proof connection.

A typical 2-inch assembly includes the following components:

| Component | Type/Material | Key Feature/Dimension |

|---|---|---|

| V-Band Clamp | Standard T-Bolt Style, 304 Stainless Steel | Included in assembly |

| Male Flange | Interlocking, Mild Steel | Included in assembly |

| Female Flange | Interlocking, Mild Steel | Included in assembly |

| Flange Design | Interlocking | Ensures leak-free seal without gasket |

| Counterbore (on weld side) | Machined | Width: 0.065 inches, aligns with tube ID |

| Assembly Size | 2.000 inches | Matches 2-inch exhaust tubing |

Advantages Over 3-Bolt Exhaust Flanges

The benefits of using v-band exhaust clamps are immediately apparent during both installation and long-term use.

Superior Leak-Free Sealing

The primary advantage is the exceptionally reliable seal. The 360-degree clamping force distributes pressure evenly around the entire circumference of the flange. This eliminates the low-pressure spots found between bolts on a 3-bolt flange, making gasket blowouts a thing of the past.

Quick Release for Easy Service

Servicing an exhaust system becomes incredibly simple. Technicians only need to loosen a single nut to separate the connection. This is a massive improvement over fighting with three rusted, seized, or broken bolts on a conventional flange.

Lighter Weight and Compact Profile

V-band assemblies are more compact and lighter than bulky multi-bolt flanges. This saves valuable space in tight engine bays and reduces overall vehicle weight, a key consideration for performance builds.

Full 360-Degree Rotational Alignment

During installation, the pipes can be rotated a full 360 degrees before the clamp is tightened. This feature allows for perfect alignment of exhaust components, reducing stress on the entire system.

Disadvantages and Considerations

While superior in many ways, V-band clamps have a couple of important considerations.

Higher Initial Cost

The upfront cost of a V-band assembly is higher than that of a simple 3-bolt flange and gasket. However, many users find the long-term reliability and ease of service justify the initial investment.

Requires Precise Welding

Proper installation is critical for a leak-free seal. The flange rings must be welded to the exhaust tubing perfectly straight and flush.

Pro Tip: Misaligned welding can prevent the flange faces from mating correctly, leading to leaks. It is essential that a skilled welder performs this task to ensure the integrity of the connection.

Best Use Cases for V-Band Clamps

V-band clamps excel in specific automotive applications where performance, reliability, and serviceability are paramount. Their design directly addresses the weaknesses of traditional multi-bolt connections, making them the preferred choice for demanding environments. Builders select V-bands when a standard flange will not meet the project’s high standards for sealing and strength.

High-Performance and Racing Builds

In the world of motorsports, every component must deliver maximum performance and reliability. V-band clamps are a staple in this arena for several key reasons:

- Weight Reduction: Racing teams strive to shed every possible ounce. V-band assemblies are significantly lighter and more compact than their bulky 3-bolt counterparts.

- Vibration Resistance: The uniform clamping force of a V-band provides superior resistance to the intense vibrations experienced on a racetrack. This prevents connections from loosening during a race.

- Rapid Service: Pit crews need to make repairs quickly. The single-nut design of a V-band allows for swift disassembly and reassembly of exhaust sections, saving critical time.

Turbocharged and Supercharged Systems

Forced induction systems, such as those with turbochargers or superchargers, generate extreme heat and high exhaust pressures. These conditions are notoriously hard on traditional gaskets and flanges.

Expert Insight: The connection point immediately after a turbocharger turbine housing is one of the hottest and highest-pressure areas in an exhaust system. A V-band clamp is the industry standard here because it creates a robust, gasket-free seal that can withstand the thermal stress without leaking or failing.

Using V-bands throughout a turbo system—from the headers to the downpipe and beyond—ensures a leak-free path for exhaust gases. This maintains boost pressure and allows the turbo to operate at peak efficiency.

Modular or Frequently Serviced Exhausts

V-band clamps are the ideal solution for any exhaust system that requires frequent modification or maintenance. This applies to both professional and hobbyist mechanics who value convenience and flexibility.

- Test Pipes and Catalytic Converters: Swapping between a catalytic converter for street use and a test pipe for track days becomes a simple, one-bolt job.

- Modular Designs: Builders can create modular exhaust systems with interchangeable components, such as different mufflers or resonator sections.

- Drivetrain Access: Placing V-band clamps strategically allows for easy removal of exhaust sections to gain access to other components like the transmission or driveshaft. This simplifies major service tasks.

Alternative 2: 2-Bolt Exhaust Flanges

The 2-bolt exhaust flange is a familiar and straightforward alternative, often seen in both OEM and aftermarket systems. It represents a slight simplification of the 3-bolt design, offering a balance of low cost and wide availability that makes it a practical choice for many standard applications.

Understanding the 2-Bolt Flange Design

The design is exactly what its name implies: two flat plates that are bolted together to join two sections of exhaust pipe. It functions on the same principle as its 3-bolt cousin, relying on a gasket and bolt pressure to create a seal.

How It Differs from a 3-Bolt Flange

The most obvious difference is the reduction from three fasteners to two. This bilateral bolt pattern simplifies the hardware count. While a 3-bolt flange creates a triangular clamping pattern, the 2-bolt flange applies pressure from two opposing sides. This change can make alignment slightly more intuitive in certain situations.

Common Materials and Gaskets

Most 2-bolt exhaust flanges are made from either mild steel for cost-effectiveness or stainless steel for improved corrosion resistance. The gaskets used are typically multi-layer steel (MLS) or composite graphite material. These gaskets are designed to crush slightly when compressed, filling any minor imperfections on the flange surfaces to prevent leaks.

Advantages Over 3-Bolt Flanges

For many repairs and basic custom work, the 2-bolt flange offers several practical benefits.

Simpler Hardware and Installation

With one less bolt and nut to manage, installation is inherently faster. This small change can save valuable time, especially when working in a cramped under-vehicle environment where access is limited.

Wide Availability and Lower Cost

Two-bolt flanges and their corresponding gaskets are mass-produced and readily available at nearly any auto parts store. This makes them an extremely cost-effective solution for repairs or budget-conscious builds.

Easier Alignment in Tight Spaces

The two-bolt pattern can be easier to line up when space is tight. A technician can often hang the gasket and one side of the connection on a single bolt while positioning the other side, simplifying the assembly process.

Disadvantages and Considerations

Despite its simplicity, the 2-bolt design shares the same fundamental weaknesses as the 3-bolt flange. It is still a gasket-dependent system prone to failure under stress.

Similar Risk of Gasket Failure

The gasket remains the most common point of failure. The seal’s integrity depends entirely on maintaining consistent clamping force, which is difficult in a high-heat, high-vibration environment. Common causes of gasket failure include:

- Thermal Cycling: Constant expansion and contraction from heat cycles reduces the preload on the bolts, loosening the clamp on the gasket.

- System Vibrations: Engine and road vibrations can cause bolts to loosen over time, compromising the seal.

- Uneven Flange Loading: The clamping force is concentrated at the two bolts, leaving the areas furthest from the bolts with less pressure. This often causes the gasket to fail at the top or bottom, where the material is thinnest.

- Improper Installation: Insufficient or uneven torque on the bolts can lead to immediate or premature leaks.

Potential for Warping Under Heat

Just like the 3-bolt version, this flange is susceptible to warping from extreme thermal cycles. Once the metal deforms, it can no longer provide a flat surface for the gasket, resulting in a persistent leak that a new gasket cannot fix.

Best Use Cases for 2-Bolt Flanges

The 2-bolt flange serves as a reliable and practical connection in specific scenarios. Its blend of simplicity, low cost, and widespread availability makes it the go-to choice for many common automotive tasks. Mechanics and builders select this option when high-performance sealing is not the primary requirement.

OEM-Style Repairs and Replacements

Many vehicle manufacturers use 2-bolt flanges in their factory exhaust systems, particularly on non-turbocharged vehicles. When a section of the original exhaust, like a muffler or resonator, fails due to corrosion or damage, a 2-bolt connection is the ideal solution for a direct-fit repair.

- Direct Compatibility: Aftermarket replacement parts are designed to match the original factory specifications. This ensures a hassle-free installation without any need for cutting or welding.

- Availability: Technicians can easily find the correct 2-bolt flange and gasket at any local auto parts store. This availability minimizes vehicle downtime.

- Cost-Effectiveness: For a standard repair, this option is significantly cheaper than upgrading to a more complex system like a V-band clamp. It restores the vehicle to its original working condition without unnecessary expense.

Budget-Conscious Custom Builds

Hobbyists and DIY builders often operate with a limited budget. The 2-bolt flange provides a functional and affordable way to construct a custom exhaust system. It allows for modularity without the premium price tag associated with high-performance alternatives. Builders can create custom axle-back or cat-back systems using readily available components. This approach makes custom exhaust work accessible to a wider range of enthusiasts who prioritize affordability and simplicity.

Note: While cost-effective, builders should always use a new, high-quality gasket and apply proper torque to the bolts. This simple step is crucial for preventing leaks in a new custom system.

Low-to-Mid-Power Applications

The potential drawbacks of a 2-bolt connection, such as gasket failure and warping, are most prominent under extreme conditions. For standard passenger cars with naturally aspirated engines, these conditions rarely occur.

- Sufficient Sealing: In a low-to-mid-power application, the exhaust temperatures and pressures are not high enough to cause frequent gasket blowouts.

- Durability: The flange provides adequate strength and longevity for daily driving and normal vehicle operation.

- Simplicity: The straightforward design is more than capable of handling the demands of a typical commuter vehicle’s exhaust system.

In these contexts, the 2-bolt design offers a dependable seal that will last for many years, making it a smart and economical choice.

Alternative 3: Ball and Socket Joints

Ball and socket joints offer a unique solution focused on flexibility. Unlike rigid flanges, this connection is specifically designed to allow movement within the exhaust system. This makes it an excellent choice for applications where engine torque, chassis flex, or thermal expansion could otherwise place destructive stress on fixed components.

How a Ball and Socket Joint Works

The function of a ball and socket joint is similar to a human shoulder joint. It permits a wide range of angular movement while maintaining a secure connection and a reliable seal. The assembly consists of two distinct, interlocking pipe ends held together by spring-loaded bolts.

The Spherical “Ball” and Flared “Socket”

The design involves two specially formed components that must be welded to the pipe ends.

- The “Ball”: One side of the connection features a pipe end formed into a smooth, spherical, or donut-shaped “ball.”

- The “Socket”: The mating pipe has a flared, concave “socket” that perfectly cups the ball.

When assembled, the ball nests inside the socket, creating a large surface area for both sealing and movement.

The Gasket-Free Sealing Method

The seal is achieved through the precise metal-to-metal contact between the ball and the socket. Spring-loaded bolts are used to pull the two halves together. These springs provide constant, dynamic tension. As the joint moves or as components expand with heat, the springs ensure the ball and socket remain pressed firmly together, preventing leaks. While most modern designs are gasket-free, some variations may use a soft, crushable graphite or metal composite ring to aid sealing. This design is far more durable than a flat gasket used with a typical exhaust flange.

Advantages Over 3-Bolt Flanges

The ball and socket joint directly solves the rigidity problem that plagues standard flange connections.

Allows for System Flex and Movement

This is the primary advantage. The joint acts as a pivot point, absorbing vibrations and movement from the engine and chassis. This flexibility is critical in vehicles that experience significant twisting forces, such as off-road trucks or high-horsepower cars where engine torque causes the powertrain to shift.

Prevents Stress Cracks in Tubing

A rigid exhaust system fights against natural vehicle movement. This resistance concentrates stress at weak points like welds and pipe bends, eventually leading to cracks. A ball and socket joint isolates the rest of the system from these forces.

Key Benefit: By absorbing movement, the joint protects the entire exhaust system from premature failure due to stress fatigue. This significantly increases the longevity of headers, pipes, and mufflers.

No Gaskets to Replace

The metal-on-metal seal, maintained by spring tension, eliminates the need for a traditional flat gasket. This removes the most common failure point of a 3-bolt flange. Technicians will not have to worry about gasket blowouts, which saves time and money on future repairs.

Disadvantages and Considerations

While excellent for flexibility, the ball and socket design has its own set of trade-offs.

Can Wear and Loosen Over Time

The constant movement between the two metal surfaces can cause wear over many thousands of miles. This can eventually create a loose fit, leading to rattling noises or small exhaust leaks. The springs on the bolts can also lose their tension over time, reducing sealing pressure.

Bulkier and Heavier Design

A ball and socket flange assembly is noticeably larger and heavier than a compact V-band clamp or a simple 2-bolt flange. This added bulk and weight can be a disadvantage in performance builds where space is tight and every ounce matters.

Best Use Cases for Ball and Socket Joints

Ball and socket joints are the premier choice for exhaust systems that must endure significant movement and vibration. Their unique design provides a flexible pivot point that protects the entire system from stress-related damage. This makes them indispensable in specific automotive contexts where rigid flanges would quickly fail.

Vehicles with Significant Engine Movement

High-horsepower engines in muscle cars and performance vehicles generate immense torque. This force causes the engine and transmission to twist noticeably under acceleration. Worn or soft motor mounts can amplify this effect even in standard vehicles. A ball and socket joint, placed after the headers or manifold, effectively isolates the rest of the exhaust from this powertrain movement. It absorbs the twisting motion, preventing stress from transferring down the pipes. This protection is crucial for preventing cracks in expensive headers and preserving the integrity of welded connections.

Long Exhaust Systems

Vehicles with long wheelbases, such as pickup trucks and full-size sedans, have extensive exhaust systems. As the exhaust heats up, the metal pipes expand significantly in length. A rigidly mounted system has no way to accommodate this thermal growth, which creates immense stress on hangers and flange connections. A ball and socket joint acts as an expansion joint. It allows the system to lengthen and shorten during heat cycles without binding. This simple addition dramatically increases the durability and lifespan of long exhaust setups by relieving thermal stress.

Expert Insight: Installing a ball and socket joint on a long exhaust system is a proactive measure. It prevents future problems like broken hangers, cracked welds, and warped flanges caused by thermal expansion and contraction.

Off-Road and High-Vibration Applications

No environment tests an exhaust system more than off-road terrain. The constant chassis flex and intense vibrations can tear rigid systems apart. Ball and socket joints are essential for durability in these applications. They allow the exhaust to move independently of the frame, maintaining a secure seal while the vehicle navigates uneven ground. This principle of robust flexibility applies to a wide range of vehicles operating in demanding conditions.

- Off-Highway Vehicles: Construction and agricultural equipment operate in harsh environments with constant vibration. Ball and socket joints absorb these shocks, maintaining system integrity and preventing premature failure.

- Commercial Vehicles: Long-haul trucks travel vast distances with heavy loads. These joints compensate for chassis flex and road vibrations, ensuring the robust and reliable exhaust performance needed for commercial operations.

- Passenger Vehicles: Even standard cars and SUVs benefit from the enhanced comfort and durability these joints provide by reducing the transmission of vibrations into the cabin.

In any high-vibration scenario, a ball and socket joint provides a superior, long-lasting connection that a fixed flange cannot match.

Alternative 4: Slip-Fit Connectors with Exhaust Clamps

Slip-fit connectors represent the simplest and most economical method for joining exhaust tubing. This approach abandons the rigid exhaust flange design entirely, relying instead on overlapping pipes secured by external exhaust clamps. While not suitable for high-performance applications, it offers unparalleled simplicity for basic repairs and mock-ups.

What is a Slip-Fit Connection?

A slip-fit connection involves sliding one pipe end over or into another. The joint depends on a tight fit between the two pipes and the clamping force from an external clamp to create a seal and hold the system together.

Expanded vs. Slotted Pipe Ends

Installers create slip-fit joints in one of two ways:

- Expanded End: One pipe end is mechanically stretched to a slightly larger diameter. This allows the normal-sized end of the mating pipe to slide inside it, creating an overlap.

- Slotted End: The outer pipe has several small cuts, or slots, around its circumference. When an exhaust clamp is tightened over these slots, the pipe compresses around the inner pipe to form a tight connection.

The Role of Different Exhaust Clamps

The clamp is the most critical component of this connection. It provides the force needed to secure the joint and prevent leaks. Common types include the standard U-bolt clamp, which is inexpensive but can crush the pipe, and band-style exhaust clamps, which distribute pressure more evenly for a better seal and less pipe deformation.

Advantages Over 3-Bolt Flanges

The primary benefits of a slip-fit connection are its low cost and ease of use during initial assembly.

The Most Cost-Effective Solution

This method is the cheapest way to join two pipes. It eliminates the cost of a multi-part flange assembly and requires only a single, inexpensive clamp. For budget-focused projects, no other option compares in terms of price.

Simple and Highly Adjustable During Install

Slip-fit joints offer excellent adjustability. Installers can easily rotate and change the angle of the pipes before tightening the clamp. This flexibility simplifies the process of routing exhaust tubing and aligning components like mufflers and tips.

Minimal Parts Required

The connection requires only the two pipes and one of the various exhaust clamps. This simplicity reduces the number of components a technician needs to purchase and manage, streamlining straightforward repairs.

Disadvantages and Considerations

The simplicity of the slip-fit design comes with significant drawbacks, primarily related to sealing and serviceability.

High Potential for Leaks

This connection is the most prone to leaks. The seal is often imperfect and can loosen with vibration and thermal cycles.

Pro Tip: To improve the seal, technicians often use additional materials. Applying a thin coat of high-temperature RTV silicone or hardening exhaust paste can fill small gaps. For easier future disassembly, using a high-temperature anti-seize compound on the pipes prevents them from rusting together.

Difficult to Disassemble After Corrosion

Over time, heat and moisture can cause the two pipes to seize together with corrosion. Separating a corroded slip-fit joint is often impossible without cutting the pipe, which negates its initial convenience. This makes it a poor choice for any connection that may need future service.

Can Deform Pipes if Overtightened

Using basic U-bolt clamps often leads to problems. Overtightening the nuts will crush and deform the pipes. This permanently damages the tubing, creates a leak point, and makes removal or reinstallation nearly impossible. Using a wider band-style flange or clamp is a better practice.

Best Use Cases for Slip-Fit Connectors

Slip-fit connectors, despite their potential for leaks, are an excellent choice in specific situations where cost and simplicity outweigh the need for a perfect, high-performance seal. Their practicality shines in non-critical applications, making them a valuable tool for both professional mechanics and DIY enthusiasts.

Budget-Friendly Repairs

When a vehicle needs a simple, low-cost exhaust repair, the slip-fit method is often the most logical solution. It is ideal for fixing common issues without requiring expensive parts or specialized labor.

- Patching Corroded Pipes: A mechanic can cut out a rusted section of pipe and use a slip-fit connector to install a new piece.

- Minimal Cost: The repair requires only a short length of tubing and one or two inexpensive exhaust clamps, making it the most economical fix.

- Quick Turnaround: This type of repair is fast, getting the vehicle back on the road with minimal downtime and labor charges.

For straightforward repairs on a daily driver, this approach restores function without the high cost of replacing an entire exhaust assembly.

Axle-Back or Muffler Swaps

Many car enthusiasts enjoy customizing their vehicle’s sound and appearance by installing an aftermarket muffler or axle-back system. Slip-fit connections are the standard for these popular modifications. The design of these kits often includes an expanded pipe end meant to slide over the factory exhaust pipe after it has been cut. A quality band clamp then secures the new component. This method provides significant adjustability, allowing the installer to perfectly position the new muffler and exhaust tips before final tightening. It makes a popular weekend project accessible to hobbyists with basic tools.

Temporary Exhaust Mock-Ups

Custom exhaust fabrication requires careful planning and precise measurements. Slip-fit joints are indispensable during the mock-up phase of a custom build. Fabricators use them to temporarily assemble the entire system under the vehicle.

Fabricator’s Tip: During mock-up, use high-quality band-style exhaust clamps to hold slip-fit joints together securely. This allows for precise adjustments to pipe routing and component placement before committing to final welds, ensuring a perfect fit and avoiding costly mistakes.

This process allows the builder to check for clearance around suspension components, the driveshaft, and the chassis. Once the fabricator confirms the alignment of every piece, they can mark the joints, remove the system, and perform the final welding on a workbench. This temporary assembly method is a critical step for achieving professional results in custom exhaust work.

Alternative 5: Marmon Flanges

Marmon flanges represent the ultimate solution for heavy-duty and industrial applications. They are essentially an overbuilt, more robust version of a V-band clamp, engineered for maximum strength and sealing performance in the most demanding environments.

Defining the Marmon Flange

A Marmon flange is a specialized, high-strength connector used where standard flanges would fail. Its design prioritizes durability above all else.

Heavy-Duty Flange Profile

The profile of a Marmon flange is noticeably thicker and more substantial than other connectors. These flanges are typically machined from a single piece of 304 Stainless Steel, which ensures they will not rust and can withstand extreme conditions. A common design features a bevel V-Band flange with a specific Marmon Type Seal. This robust construction is available across a vast range of industrial sizes.

| Size (inches) | Part Number |

|---|---|

| 2.00 | 55000-200S |

| 3.00 | 55000-300S |

| 4.00 | 55000-400S |

| 5.00 | 55000-500S |

| 6.00 | 55000-600S |

| 8.00 | 55000-800S |

Key Differences from V-Bands

While a Marmon flange looks similar to a V-band, there are critical differences. Marmon flanges have a much heavier cross-section and a wider sealing surface. This added mass provides superior strength and heat resistance. The clamp used with a Marmon flange is also significantly more robust to handle the higher clamping forces required for a secure seal in high-pressure systems.

Advantages Over 3-Bolt Flanges

The benefits of a Marmon flange are most apparent in extreme-use cases where a 3-bolt connection is not a viable option.

Extreme Durability and Strength

The solid, single-piece construction makes this flange incredibly resistant to warping, cracking, and fatigue. It easily handles the intense physical stresses that would deform or break a standard multi-bolt flange.

Superior Sealing for High Pressure

The design creates an exceptionally tight and reliable seal. This makes it the preferred choice for high-pressure turbocharged diesel engines and industrial machinery, where any leak results in a significant loss of performance and efficiency.

Excellent Resistance to Heat and Vibration

Marmon flanges excel in high-vibration environments like commercial trucking and agricultural equipment. Their massive construction and strong clamping force prevent loosening and ensure a consistent seal despite constant shaking and thermal cycling.

Disadvantages and Considerations

The industrial-grade performance of a Marmon flange comes with significant trade-offs in cost and accessibility.

Highest Cost and Weight

This is the most expensive and heaviest option. The materials and manufacturing process result in a premium price point and substantial weight, making it impractical for most consumer vehicles.

By the Numbers: A single 5.75-inch Marmon exhaust flange can weigh approximately 2 lbs (907 grams) and cost upwards of $90. This highlights the significant investment in both weight and budget required.

Limited Availability for Consumer Cars

These flanges are produced primarily for commercial and industrial markets. Finding a Marmon flange in sizes suitable for standard passenger cars (e.g., 2.00 to 3.00 inches) is difficult, and they are generally considered overkill for such applications.

Best Use Cases for Marmon Flanges

Marmon flanges are engineered for scenarios where failure is not an option. Their selection signifies a commitment to maximum durability and sealing performance, making them the default choice in several demanding industries.

Heavy-Duty Diesel and Commercial Trucks

The world of commercial trucking relies on absolute reliability. A Class 8 truck’s turbocharged diesel engine generates immense heat, pressure, and vibration. Standard connections would quickly fail under these conditions. Marmon flanges provide the necessary strength to maintain a perfect seal at the turbocharger outlet and other critical junctions. This robust connection prevents boost leaks, ensures engine efficiency, and minimizes costly downtime for fleet operators. Their ability to withstand constant thermal cycling and road vibrations makes them essential for long-haul vehicles.

Industrial and Agricultural Equipment

Beyond public roads, Marmon connections are a staple in heavy machinery. These applications demand components that can endure harsh operating environments and continuous use. The superior strength of a Marmon connection is vital for equipment that experiences constant shaking and physical stress. Common industrial and agricultural uses include:

- Large stationary power generators

- Marine propulsion systems

- Earth-moving and construction equipment

- Farming tractors and combines

In these fields, the robust design ensures that exhaust systems remain intact and leak-free, protecting both the machinery and its operators.

Expert Insight: The use of Marmon connections in marine applications is critical. A failed exhaust joint at sea can release hazardous fumes into enclosed spaces and disable the vessel, making their reliability a matter of safety.

Extreme Motorsport Applications

In top-tier racing, every component operates at its absolute limit. High-performance turbocharged engines in motorsports generate extreme exhaust gas temperatures and pressures that would destroy lesser connections. A Marmon flange provides a secure, leak-proof seal that can withstand the violent vibrations and heat of a racetrack. Fabricators use them in custom exhaust systems for everything from turbo connections to downpipes. The strength of this connection ensures that a critical joint will not fail during a race, which could otherwise lead to a catastrophic loss of power or a fire.

Comparison Chart: Choosing Your 3-Bolt Flange Alternative

Selecting the right connection involves balancing performance, cost, and installation difficulty. This chart breaks down how the alternatives compare across key categories, helping builders and mechanics choose the best option for their specific project.

Sealing Performance

V-Band vs. Ball and Socket vs. Flanges

The reliability of the seal is often the most critical factor. The options vary significantly in their ability to prevent leaks.

- Best Seal (Gasket-Free): V-band and Marmon flanges provide the most reliable, leak-proof seal. Their 360-degree clamping force creates even pressure that is not possible with multi-bolt exhaust flanges.

- Good Seal (Flexible): A ball and socket joint offers a very good, dynamic seal. It uses spring tension on a metal-to-metal surface, effectively preventing leaks while allowing for system movement.

- Adequate Seal (Gasket-Dependent): The 2-bolt exhaust flange relies on a gasket. It provides an adequate seal for many stock applications but shares the same risk of blowouts and leaks as the 3-bolt flange it replaces.

- Lowest Seal Performance: A slip-fit connection is the most prone to leaks. It depends entirely on clamp pressure and pipe overlap, often requiring sealant for a decent seal.

Cost Comparison

Budget vs. Premium Options

The budget for a project often dictates the choice of connection. The alternatives span a wide price range.

Premium Tier: V-band clamps and Marmon flanges represent the highest initial investment. Their precision manufacturing and superior materials contribute to a higher price point. Mid-Tier: Ball and socket joints typically fall in the middle. They cost more than a simple flange but are generally less expensive than a full V-band assembly. Budget Tier: Slip-fit connectors and 2-bolt flanges are the most cost-effective solutions. The parts are inexpensive and widely available at most auto parts stores.

Ease of Installation

DIY-Friendly vs. Professional Install

Installation complexity ranges from simple bolt-on tasks to jobs requiring specialized welding skills.

V-band clamps offer significant advantages for a DIY mechanic. The single-nut design eliminates the need for two hands to stop a bolt from free-spinning, a common issue with a traditional flange. Their compact nature also allows for easy rotation into the perfect position, making them simpler to work with in tight spaces. In contrast, removing a corroded multi-bolt flange can be a frustrating and time-consuming task.

| Flange Type | Estimated Removal Time (Rusted) |

|---|---|

| V-Band Clamp | Approximately 2 minutes |

| 2-Bolt or 3-Bolt Flange | Over 30 minutes |

- DIY-Friendly: Slip-fit connectors and 2-bolt flanges are the easiest to install for basic repairs, requiring only simple hand tools.

- Professional Install Required: V-band and Marmon flanges must be welded onto the pipe ends. This task requires a skilled welder to ensure the flange faces are perfectly aligned for a leak-free seal.

Durability and Longevity

The lifespan of an exhaust connection depends heavily on its design, materials, and the conditions it endures. A component that lasts for years on a daily driver might fail quickly in a high-performance or industrial setting. Choosing the right alternative requires matching its durability to the specific demands of the vehicle.

Heavy-Duty vs. Standard Use

The operational environment dictates which connection will provide the best long-term service.

Heavy-Duty Champions (Marmon & V-Band): Marmon and V-band flanges offer the highest level of durability. Their robust, gasket-free designs make them exceptionally resistant to heat, pressure, and vibration. A Marmon flange is the top choice for industrial equipment and commercial trucks where reliability is paramount. V-band clamps provide similar strength in a more compact package, making them ideal for high-performance and turbocharged applications. Both are engineered to outlast the vehicle itself.

The Flexible Contender (Ball & Socket): A ball and socket joint provides excellent durability by managing stress. It allows for movement, which protects the entire system from fatigue cracks. A standard exhaust flex coupler, which serves a similar purpose, is expected to last between 50,000 to 100,000 miles. However, factors like worn engine mounts or constant chassis flex can significantly reduce this lifespan. The ball and socket joint offers a more robust and serviceable version of this flexible technology.

Standard Use Workhorses (2-Bolt & Slip-Fit): Two-bolt flanges and slip-fit connectors are designed for standard, less demanding applications. Their longevity is tied directly to the life of the gasket or sealant used. In a low-power, daily-driven vehicle, a 2-bolt flange can last for many years. A slip-fit connection is the least durable, as it is prone to corrosion and leaks over time.

Environmental Impact: The vehicle’s operating environment plays a massive role in the lifespan of any exhaust component. Road salt, humidity, and even the length of daily trips can accelerate corrosion.

The following table illustrates how location and material affect the life of a typical muffler, a principle that also applies to flange connections.

| Component Material | Location/Conditions | Estimated Lifespan | Key Factor |

|---|---|---|---|

| Plain Steel | Buffalo, NY (Short Trips) | ~1 Year | Road salt and internal condensation |

| Regular Steel | Colorado (Snow/Salt) | 5-6 Years | Harsh winter climate |

| Stainless Steel | Buffalo, NY (Snow/Salt) | 15+ Years | Superior corrosion resistance |

| Original Stainless | Coastal California | 200,000+ Miles | Mild, salt-free climate |

Ultimately, for maximum longevity in any condition, stainless steel options like V-band or Marmon flanges are the superior investment. For standard use, a 2-bolt flange offers a predictable service life appropriate for most passenger cars.

Installation Tips for Flange Alternatives

Proper installation is crucial for getting the most out of any exhaust connection. Each alternative to the 3-bolt flange has its own set of best practices. Following these tips ensures a durable, leak-free seal and maximizes the lifespan of the components.

Welding V-Band and Marmon Flanges

V-band and Marmon flanges require precise welding for a perfect seal. The process demands attention to detail to prevent warping and ensure structural integrity.

TIG vs. MIG Welding

Both TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding can produce strong results. TIG welding offers superior control and creates cleaner, more precise welds, making it the preferred method for high-end stainless steel systems. MIG welding is faster and easier for many fabricators, providing a strong weld that is perfectly suitable for most applications.

Ensuring Proper Alignment

Proper alignment is non-negotiable for a leak-free seal. A warped flange will not seal correctly, regardless of the clamp’s quality.

Pro Tip: To minimize warping from heat, a welder should clamp the mating half of the V-band flange to the one being welded. This technique allows the second piece to act as a heat sink.

For best results when welding stainless steel components:

- Use a high-quality filler rod like 308 or 309L, which contains nickel and manages different metal expansion rates well.

- If the parts are zinc-plated, a technician must grind off the coating completely before welding to avoid contamination.

Sealing Slip-Fit and 2-Bolt Connections

These common connections rely on proper assembly techniques to prevent frustrating leaks. A few extra steps during installation make a significant difference.

Using High-Temp Sealant

For slip-fit joints, applying a thin layer of high-temperature exhaust sealant inside the outer pipe helps fill minor gaps. This creates a much more reliable seal than a dry fit. For a 2-bolt flange, sealant can be a useful aid, but it should never be a substitute for a high-quality gasket and flat flange surfaces.

Correct Bolt Tightening Patterns

Uneven torque is a primary cause of leaks in 2-bolt connections. A progressive tightening method is essential.

- Snug both nuts to a low initial torque, such as 10-20 in-lbs.

- Tighten the nuts in stages, alternating between them. For example, tighten to 20 ft-lbs, then 40 ft-lbs, and finally to the manufacturer’s specified final torque.

- This gradual process ensures the gasket compresses evenly, creating a durable seal.

Assembling Ball and Socket Joints

The key to a successful ball and socket joint is achieving the correct spring tension, which allows for movement while maintaining a seal.

Proper Spring-Bolt Tension

These joints use special shouldered bolts. The correct tension is achieved when the shoulder of the bolt seats firmly against the flange. This design prevents over-tightening and ensures the springs can do their job.

Checking for Full Range of Motion

After assembly, a technician should confirm the joint can move freely. The connection should pivot smoothly without binding. It is critical to use hardware designed for the application, as standard bolts and springs from a hardware store cannot withstand the intense heat and will fail quickly.

Choosing the right connection requires balancing project needs. Each alternative to the standard 3-bolt exhaust flange offers specific benefits for builders.

- A V-band flange provides the best performance and serviceability.

- A 2-bolt flange offers a simple swap for standard repairs.

- A slip-fit connector with quality exhaust clamps is the top choice for budget solutions; good exhaust clamps are critical.

- A Marmon flange is the ultimate solution for heavy-duty applications.

A builder’s final decision on a flange balances performance, budget, and durability.

FAQ

Can a V-band clamp be installed without welding?

No, proper installation requires welding. A skilled technician must weld the V-band flange rings onto the pipe ends. This process ensures the flange faces are perfectly straight and flush, which is essential for creating the strong, leak-free seal that V-band clamps are known for.

Should a new gasket always be used with a 2-bolt flange?

Yes, mechanics should always install a new gasket. Reusing an old, compressed gasket almost guarantees an exhaust leak. A new gasket ensures a fresh sealing surface. For best results, technicians should also confirm the flange surfaces are clean and flat before assembly.

When is a flexible connection like a ball and socket necessary?

A flexible connection is crucial when the exhaust system must absorb significant movement. High-horsepower engines, vehicles used for off-roading, and trucks with long exhaust systems all benefit. This flexibility prevents stress cracks in headers and pipes caused by engine torque or chassis flex.

Can exhaust sealant fix a warped flange?

No, sealant is not a permanent solution for a warped flange. While high-temperature sealant can fill minor imperfections, it cannot compensate for a deformed flange surface. The only reliable repair for a warped flange is to replace it to ensure a proper, long-lasting seal.

What is the main difference between a V-band and a Marmon flange?

The main difference is strength and application. A Marmon flange is a heavier, more robust version of a V-band.

- V-Band: Ideal for high-performance automotive use.

- Marmon: Engineered for extreme-duty industrial, commercial truck, and marine applications where maximum durability is required.

Is stainless steel always the best material for a flange?

Stainless steel offers the best corrosion resistance and longevity, making it ideal for harsh climates or high-performance builds. However, mild steel is a cost-effective and suitable choice for standard repairs in drier climates where road salt is not a major concern.