The role of carriage bolts in demanding woodworking projects is fundamental to creating durable structures. Common applications in wood projects, especially for outdoor structures like decks and fences, typically require a standard 1/2-inch diameter carriage bolt to provide necessary shear strength. While a custom fasteners manufacturer can produce custom fasteners through specialized bolt casting for unique applications, most projects rely on standard hardware.

Note: For most outdoor applications, selecting the correct carriage bolt by evaluating its length and material is as critical as its diameter for ensuring the safety and longevity of your woodworking projects.

Selecting High-Quality Carriage Bolts for 4x4s

The process of selecting high-quality carriage bolts is crucial for the structural integrity of any build. Professionals understand that the fastener’s diameter, length, and material grade directly impact the safety and durability of outdoor structures. Selecting high-quality carriage bolts ensures your woodworking projects withstand the test of time.

Why 1/2-Inch Diameter is the Gold Standard

For connections involving 4×4 posts, a 1/2-inch diameter bolt is the industry benchmark. This standard sizing offers a reliable balance of strength and practicality for most residential construction applications.

Shear Strength and Load-Bearing Capacity

A 1/2-inch diameter carriage bolt provides substantial shear strength. This attribute is critical for preventing the bolt from snapping under lateral forces, such as wind load on a fence or the weight of people on a deck. The material grade of the bolt further defines its capacity. For extreme load-bearing applications, a higher grade of steel is necessary. The quality of the bolt’s grade ensures it meets specific strength requirements for demanding applications.

Compatibility with Standard Hardware

The 1/2-inch diameter is compatible with a wide range of standard hardware. Joist hangers, post bases, and angle brackets are commonly manufactured with 1/2-inch holes. This standardization simplifies the assembly process, as builders do not need to source specialty hardware. Using a common size ensures a proper fit and a more efficient assembly. The quality of the hardware grade should match the bolt’s grade.

How to Calculate the Correct Bolt Length

Sizing your carriage bolt correctly is just as important as choosing the right diameter. A bolt that is too short will not engage the nut properly, while a bolt that is too long can create a snag hazard and looks unprofessional. Selecting high-quality carriage bolts involves precise length calculation.

The Basic Formula: Material Thickness + Washer + Nut

The fundamental rule for calculating bolt length is straightforward. A builder must add the thicknesses of all materials being joined together, then add extra length for the washer and nut.

Formula: Total Lumber Thickness + Washer Thickness + Nut Height = Minimum Bolt Length

Accounting for Washers and Nut Height

A washer is essential; it distributes the load from the nut across the wood’s surface, preventing the nut from crushing the wood fibers as it is tightened. A standard 1/2-inch nut is approximately 7/16-inch tall. A quality installation requires at least two to three full threads to extend past the tightened nut. This ensures the connection utilizes the full strength of the fastener’s grade. Selecting high-quality carriage bolts of the proper grade is key for all woodworking applications.

Example: Bolting Two 4x4s Together

This table shows the calculation for one of the most common applications.

| Component | Actual Thickness |

|---|---|

| First 4×4 Post | 3.5 inches |

| Second 4×4 Post | 3.5 inches |

| Washer + Nut Allowance | ~0.75 inches |

| Total Minimum Length | 7.75 inches |

Recommendation: Choose an 8-inch long carriage bolt for this connection.

Example: Bolting a 2×6 Joist to a 4×4 Post

This calculation is common for deck and pergola projects.

| Component | Actual Thickness |

|---|---|

| 4×4 Post | 3.5 inches |

| 2×6 Joist | 1.5 inches |

| Washer + Nut Allowance | ~0.75 inches |

| Total Minimum Length | 5.75 inches |

Recommendation: Choose a 6-inch long carriage bolt for these carriage bolts applications. The bolt’s grade must be suitable for outdoor use.

Choosing the Best Material for Outdoor Durability

Selecting the correct material is a critical step in choosing the right material and finish for your hardware. The environment where the structure will stand dictates the necessary level of corrosion protection. For outdoor woodworking projects, this choice directly impacts the structure’s safety and lifespan.

Hot-Dipped Galvanized (HDG) Steel Carriage Bolts

Hot-dipped galvanized steel is the workhorse material for most outdoor construction. It offers a fantastic balance of performance, durability, and cost for a wide range of applications.

The Galvanization Process Explained

The process involves dipping a completed steel bolt into a vat of molten zinc. This creates a thick, durable, and metallurgically bonded coating. The zinc acts as a sacrificial layer, corroding before the steel core does. This method provides a much more robust layer of protection than simple plating.

Pros and Cons of HDG

HDG carriage bolts provide excellent corrosion resistance at a reasonable price point. Their thick coating can even self-heal minor scratches. However, this thick coating results in a rough, matte gray finish and can make threads a bit tight. The quality of the galvanization process determines the fastener’s ultimate longevity.

Best for Pressure-Treated Lumber

Modern pressure-treated lumber contains copper-based chemicals that are highly corrosive to unprotected steel. Hot-dipped galvanized steel fasteners are specifically recommended for these applications. Their zinc coating is compatible with these preservatives, preventing the premature fastener failure that can compromise outdoor projects.

Stainless Steel (Grades 304 and 316)

For maximum corrosion resistance and a clean, bright finish, builders turn to stainless steel carriage bolts. Understanding the different grades is key to using them effectively.

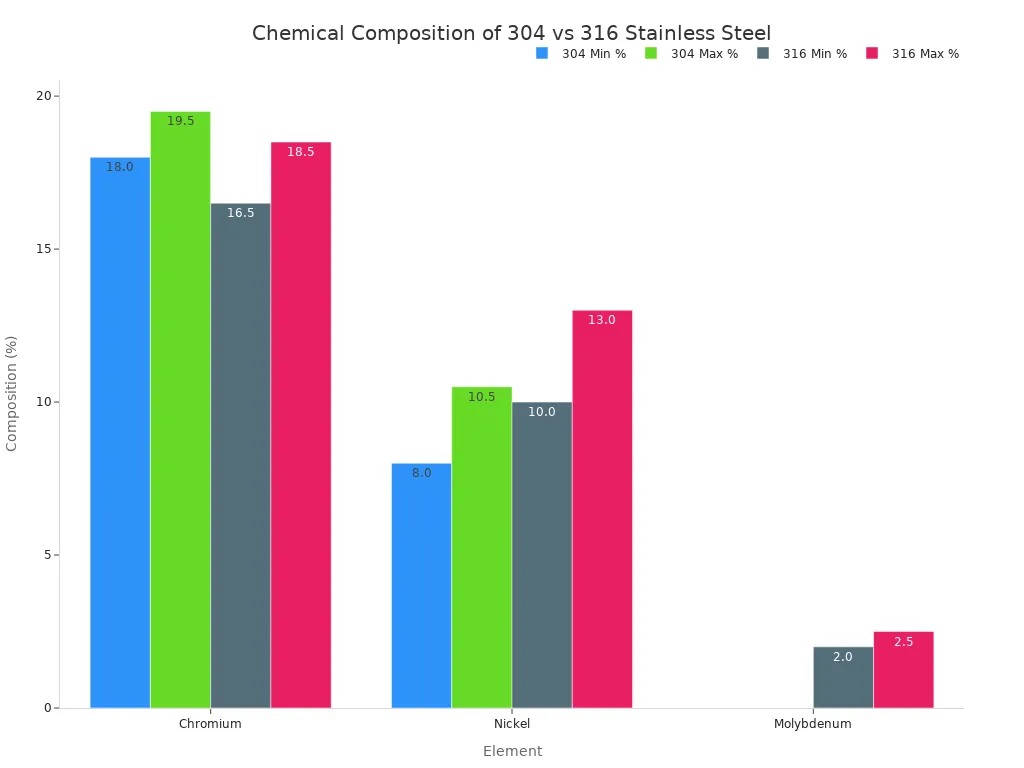

Understanding Stainless Steel Grades

The two most common grades for fasteners are 304 and 316. Grade 304 stainless steel contains 18% chromium and 8% nickel. Grade 316 stainless steel has a slightly different composition, adding molybdenum to the alloy. This addition gives grade 316 significantly enhanced protection against chlorides, like salt. This makes understanding bolt grades and strength essential for material selection in demanding woodworking applications.

Pros and Cons of Stainless Steel

The primary advantage of stainless steel is its superior corrosion resistance and aesthetic appeal. It will not stain surrounding wood with rust streaks. The main disadvantage is cost, as stainless steel fasteners are considerably more expensive than their galvanized counterparts. The quality of the specific grade is paramount.

When to Choose Stainless Over Galvanized

A builder should choose grade 316 for projects in coastal, saltwater, or other high-moisture environments. It is the best for outdoor structures exposed to salt spray. However, professionals note that even grade 316 can fail rapidly in specific anaerobic conditions, such as being buried in sour mud, where failures have been seen in weeks. For most other outdoor projects away from the coast, grade 304 offers sufficient protection.

Finishes to Avoid for Outdoor Projects

Using the wrong finish on carriage bolts for outdoor projects can lead to rapid failure and create a significant safety hazard. Certain finishes are only suitable for indoor applications.

Why Zinc-Plating Fails Outdoors

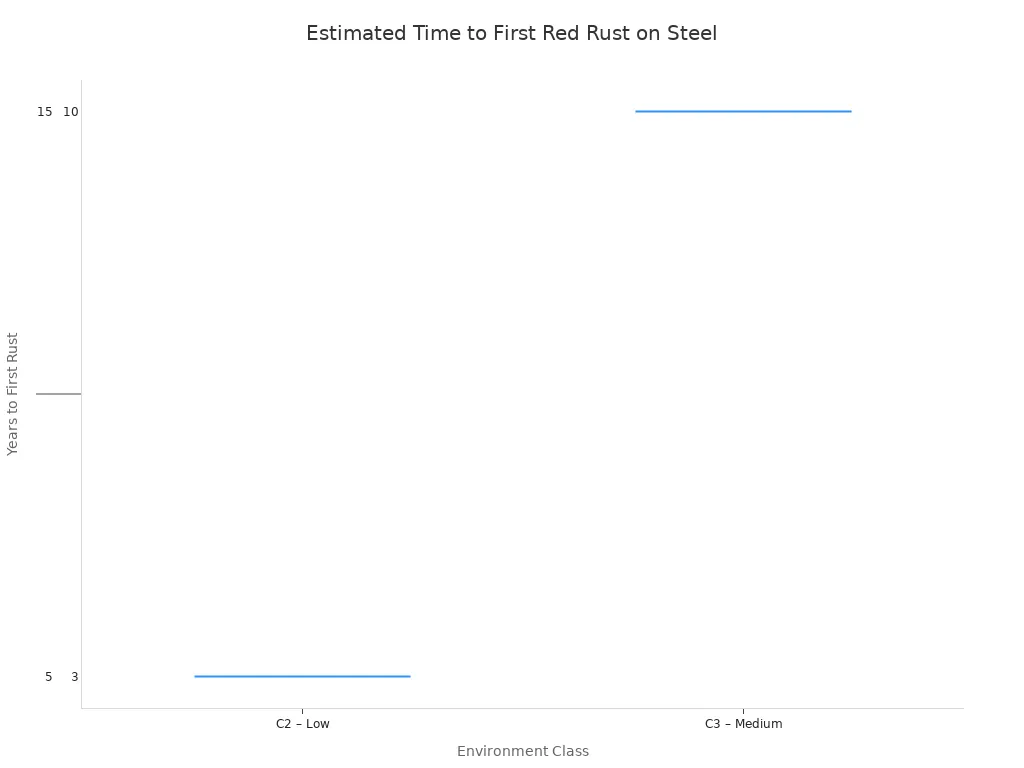

Zinc-plated (or electro-galvanized) fasteners have a very thin, shiny coating of zinc. This finish offers minimal protection and is intended for dry, indoor use. When used outdoors, this thin layer quickly wears away, exposing the steel to moisture and leading to rust. In a moderately corrosive urban or coastal environment (C3-C4), a zinc-plated fastener can show significant rust in as little as 1 to 3 years.

The Risk of Galvanic Corrosion

Galvanic corrosion occurs when two different metals are in contact in the presence of an electrolyte (like moisture). Using a zinc-plated bolt with a hot-dipped galvanized bracket, for example, will cause the less noble metal (the zinc plating) to corrode at an accelerated rate. Always match the fastener material and grade to the hardware being used to ensure the quality and longevity of the connection.

Reviewing the Top 10 High Quality Carriage Bolt Options

This section begins the process of reviewing the top 10 high quality carriage bolt options available to builders. The analysis focuses on material, features, and ideal use cases to help professionals and DIYers select the perfect fastener for their project.

1. Hillman Group Hot-Dipped Galvanized Carriage Bolt

The Hillman Group offers a go-to fastener that balances performance, cost, and widespread availability, making it a staple in the construction industry.

Material and Finish

These bolts are made from steel and undergo a hot-dipped galvanization (HDG) process. This provides a thick, protective zinc coating that offers excellent corrosion resistance for outdoor structures. The finish is a dull, matte gray, which is characteristic of the HDG process.

Available Sizes

Hillman provides an extensive range of sizes suitable for nearly any project involving 4×4 posts.

- Diameters: Commonly available in the standard 1/2-inch size.

- Lengths: Range from 4 inches up to 12 inches and beyond.

Key Features

- Corrosion Resistance: The HDG coating is specifically designed for use with modern pressure-treated lumber.

- Durability: The thick zinc layer provides a robust barrier against moisture and environmental wear.

- Standard Head Design: Features a traditional domed head with a square neck that seats firmly into wood to prevent turning.

Best For Overall Value and Availability

For builders seeking a reliable, code-compliant, and budget-friendly option, the Hillman HDG carriage bolt represents the best overall value. Its presence in nearly every hardware and home improvement store ensures project timelines are met without a search for specialty parts.

2. Bolt Dropper 316 Stainless Steel Carriage Bolt

Bolt Dropper specializes in high-grade fasteners designed to withstand the harshest conditions, offering a premium solution for long-term durability.

Material and Finish

These carriage bolts are forged from 316 marine-grade stainless steel. This material contains molybdenum, giving it superior protection against chlorides found in saltwater and de-icing salts. The finish is clean and bright, offering a superior aesthetic compared to galvanized options.

Available Sizes

Bolt Dropper offers a solid selection tailored to common construction needs.

| Diameter | Common Lengths |

|---|---|

| 1/2-inch | 4-inch, 6-inch, 8-inch, 10-inch |

Key Features

- Marine Grade: The 316 stainless steel grade provides the highest level of corrosion resistance available in a standard fastener.

- Aesthetic Appeal: The bright, clean finish does not rust or stain surrounding wood, maintaining the visual quality of the project.

- Lifetime Guarantee: Bolt Dropper often backs their 316 stainless products with a no-hassle lifetime guarantee, reflecting confidence in the material’s longevity.

Best For Coastal and High-Moisture Areas

Professionals choose Bolt Dropper 316 stainless steel bolts for projects located in coastal regions, near saltwater, or in environments with constant high humidity. The upfront investment protects against premature failure and ensures the structural integrity of decks, docks, and pergolas exposed to corrosive elements.

3. Simpson Strong-Tie Strong-Bolt 2

The Simpson Strong-Tie Strong-Bolt 2 is an engineered wedge anchor, not a traditional carriage bolt, but it earns its place for its unparalleled strength in specific, demanding connections. It is a top choice for extreme load-bearing applications.

Material and Finish

This anchor is typically made from carbon steel and is available with a zinc-plated finish for interior use or a mechanically galvanized finish for exterior applications. The choice of finish depends entirely on the installation environment.

Available Sizes

The Strong-Bolt 2 comes in a variety of diameters and lengths designed for anchoring into concrete. While not for wood-to-wood connections, it is essential for securing posts to concrete footings. Common diameters include 1/2-inch, 5/8-inch, and 3/4-inch.

Key Features

This anchor is defined by its engineering and code compliance. It provides immense holding power when securing a post base to a concrete foundation.

- Code Compliance: The Strong-Bolt 2 is a pre-approved product listed under ICC-ES ESR-3037, satisfying requirements set by the International Building Code (IBC).

- High-Load Capacity: It is tested according to ACI 355.2 standards for use in cracked concrete and seismic conditions.

- Tri-Segmented Clip: Each anchor has a unique clip that expands for optimal contact, ensuring maximum holding power.

Best For High-Load Structural Connections

The Strong-Bolt 2 is the premier choice for anchoring post bases to concrete foundations. Its certified performance makes it indispensable for projects where structural safety is paramount and building codes mandate specified, tested anchors. This is not a fastener for joining lumber; it is the fastener for connecting the entire structure to its foundation.

4. National Hardware N222-951 HDG Carriage Bolt

National Hardware provides a classic, dependable fastener trusted for decades in general construction. This bolt is a straightforward, robust solution for a multitude of outdoor wood projects.

Material and Finish

These bolts consist of steel protected by a hot-dipped galvanized coating. The thick, matte gray finish provides substantial corrosion resistance, making it fully compatible with the chemicals in modern pressure-treated lumber. This protection is essential for any outdoor structure.

Available Sizes

National Hardware offers these bolts in sizes that cover the most frequent needs in deck and fence construction.

| Diameter | Common Lengths |

|---|---|

| 1/2-inch | 4-in, 5-in, 6-in, 7-in, 8-in, 10-in, 12-in |

Key Features

The N222-951 model is defined by its traditional design and reliable performance. It features a smooth, rounded head and a square neck that bites into the wood to prevent the bolt from spinning during tightening. Its heavy-duty construction makes it suitable for demanding tasks like securing gates and heavy doors to 4×4 posts or assembling robust deck framing.

Best For General Fencing and Decking

Professionals and DIYers select this bolt for its proven reliability in standard outdoor applications. It is an excellent, cost-effective choice for building fences, pergolas, and completing most deck framing connections where a standard, code-compliant fastener is required.

5. Everbilt Hot-Dipped Galvanized Carriage Bolt

Everbilt is the house brand for The Home Depot, making its hardware one of the most accessible options on the market. These bolts offer a convenient and reliable solution for projects requiring immediate material sourcing.

Material and Finish

Similar to other workhorse bolts, Everbilt uses steel with a hot-dipped galvanized finish. This ensures the necessary durability and corrosion protection for outdoor use, especially when in direct contact with pressure-treated wood. The quality of the finish provides a dependable barrier against the elements.

Available Sizes

Everbilt provides a comprehensive range of sizes directly on store shelves, minimizing project delays.

- Diameter: The 1/2-inch diameter is standard.

- Lengths: Typically available in one-inch increments from 4 inches to 12 inches.

Key Features

The primary feature of Everbilt carriage bolts is their immediate availability. A builder can easily acquire them in various quantities, from single units to project-sized boxes. This accessibility is invaluable for professionals managing tight schedules and for DIYers starting a weekend project. They are a go-to for all types of deck framing.

Best For Big Box Store Accessibility

When project timelines are critical and a trip to the local home improvement store is necessary, Everbilt is the top choice. It provides a dependable, code-compliant fastener for deck framing without the need to order from a specialty supplier.

6. GRK Fasteners RSS Structural Screw

The GRK Fasteners RSS screw is an engineered fastener that serves as a modern, high-performance alternative to traditional carriage bolts. It is designed for strength and installation speed.

Material and Finish

These screws are made from specially hardened steel to handle high torque and heavy loads. They feature GRK’s proprietary Climatek™ coating, which provides corrosion resistance suitable for outdoor use with pressure-treated lumber. This advanced finish offers protection without the thick, thread-clogging nature of HDG. The fastener’s high-quality grade ensures structural reliability.

Available Sizes

RSS screws come in a wide array of lengths, from 3 1/8 inches up to 16 inches. This range allows them to replace bolts in nearly any deck framing application, from attaching joists to laminating beams.

Key Features

The RSS screw’s main advantage is speed. Its design often eliminates the need for pre-drilling, a significant labor-saving feature. The built-in washer head and aggressive thread design provide immense clamping force. Its structural grade is recognized by major building codes.

- GRK Fasteners RSS screws have been evaluated for structural and corrosion resistance to comply with the International Building Code (IBC).

- They also comply with the International Residential Code (IRC).

- The ICC-ES/ESR-2442 report confirms their compliance, making them a trusted bolt replacement for deck framing.

Building codes allow for such innovations when they meet or exceed the performance of traditional methods.

The 2012 International Residential Code, Section R104.11, states that its provisions are not intended to prevent the installation of any material or to prohibit any design or method of construction not specifically prescribed by this code, provided that any such alternative has been approved.

Best Bolt-Alternative for Speed

For professional builders where time is money, the GRK RSS screw is the best alternative to conventional carriage bolts. It dramatically accelerates the deck framing process by removing the pre-drilling step, delivering powerful, code-approved connections with unmatched efficiency.

7. Power-Fast Hot-Dipped Galvanized Carriage Bolt

Power-Fast offers a line of fasteners that provides reliable performance for large-scale construction. Their HDG carriage bolts are a practical choice for professionals who prioritize efficiency and cost-effectiveness.

Material and Finish

These bolts are manufactured from steel and receive a hot-dipped galvanized coating. This process ensures a thick, protective layer of zinc. The finish is designed to withstand outdoor elements and is fully compatible with the corrosive chemicals found in pressure-treated lumber.

Available Sizes

Power-Fast supplies a standard range of sizes to meet the demands of most framing projects.

- Diameter: The 1/2-inch diameter is readily available.

- Lengths: Common lengths include 6-inch, 8-inch, and 10-inch options.

Key Features

The main feature of Power-Fast bolts is their availability in large-quantity packaging. This approach reduces the cost per unit and ensures crews have enough hardware on hand to complete extensive projects without interruption. The bolts feature a standard square neck for a secure, non-spinning fit in wood.

Best For Bulk Purchases

For contractors and builders undertaking large projects like extensive fencing or multi-level decks, Power-Fast is the superior choice. Purchasing these fasteners in project-sized boxes delivers significant cost savings without compromising on the necessary quality and corrosion resistance.

8. Deck-Drive DCU Composite Screw

The Simpson Strong-Tie Deck-Drive DCU is a specialized fastener, not a structural bolt. It is engineered specifically for attaching composite or PVC decking boards to the underlying structure, including 4×4 posts used for stairs or landings.

Material and Finish

These screws are made from high-quality Type 305 stainless steel. This material grade offers excellent corrosion resistance. The screws also feature a painted head, available in various colors to match popular decking brands.

| Specification | Detail |

|---|---|

| Material | Type 305 Stainless Steel |

| Drive Style | T-20 6-Lobe (Torx) |

| Common Size | #10 x 2-3/4 in. |

| Head Style | Cap Head |

Available Sizes

The DCU screw is primarily available in the size most commonly required for face-fastening deck boards. The #10 diameter and 2-3/4 inch length are standard for securing 1-inch thick composite boards to wood joists or posts.

Key Features

The DCU screw is packed with features designed for a clean and secure installation on high-end decking.

- Inverted Upper Threads: These clear excess material, ensuring the screw seats cleanly and tightly.

- Tri-Lobe Thread Design: This feature reduces the torque needed to drive the screw, making installation faster.

- Type-17 Point: The sharp point allows the screw to engage the wood quickly without pre-drilling.

- Trex® Approved: It is an officially approved fastener for use with Trex composite decking, ensuring compatibility.

Best For Attaching Composite Decking to Posts

When a project involves attaching composite deck boards directly to the face of a 4×4 post, such as for stair stringers or picture-frame borders, the Deck-Drive DCU is the premier choice. Its design prevents mushrooming and provides a clean, color-matched finish that other carriage bolts cannot offer.

9. FastenMaster ThruLOK Bolt-Replacement System

The FastenMaster ThruLOK system is an innovative, engineered solution that replaces traditional carriage bolts. It combines the strength of a bolt with the installation speed of a screw.

Material and Finish

The ThruLOK screw is made from high-strength steel. It features a galvanized coating that is ACQ-approved, making it safe for use with all types of pressure-treated lumber. The nut has a black e-coat finish for additional corrosion protection.

Available Sizes

ThruLOKs are sold in specific lengths designed to fasten common lumber combinations without any measuring or cutting.

- 6 1/4″ (for two 2x boards to a 4×4)

- 7″ (for a 2x board to a 6×6)

- 8″ (for three 2x boards to a 4×4)

Key Features

This all-in-one system includes the screw, a washer, and a nut that is driven by the same drill bit, eliminating the need for wrenches.

- No Pre-Drilling: The screw installs with a standard cordless drill, dramatically increasing job site speed.

- Self-Tightening: The nut tightens itself as the screw is driven, creating a secure through-bolted connection.

- Code Compliant: The ThruLOK system is fully tested and code-compliant, meeting IBC/IRC standards. Its performance is documented in reports like ICC-ES ESR-1078 and TER 1308-11.

Best All-in-One System

For builders who want the strength of a through-bolted connection with maximum efficiency, the ThruLOK system is unmatched. It eliminates the need for multiple tools and pre-drilling, making it the fastest and easiest way to create code-compliant connections for deck posts and beams.

10. Boltmaster Zinc-Plated Carriage Bolts for Woodworking Projects

Boltmaster offers a line of zinc-plated carriage bolts tailored for specific indoor applications. These fasteners are a common sight in hardware bins and are useful for a range of light-duty woodworking projects where corrosion is not a concern.

Material and Finish

These bolts are made from steel and feature a zinc-plated finish. The electro-plating process applies a thin, shiny layer of zinc that offers minimal protection against moisture. This finish is purely cosmetic and provides a clean look for interior projects. The material grade is suitable for non-structural loads.

Available Sizes

Boltmaster provides these fasteners in a wide variety of smaller diameters and lengths. This makes them ideal for fine woodworking and assembly projects where larger structural bolts would be excessive. Common sizes cater to joining thinner materials like 1x lumber and plywood.

Key Features

The primary feature is the bright, shiny finish that gives a clean, manufactured look to assemblies. They are an economical choice for projects where aesthetics are more important than structural strength or weather resistance. The quality of the finish is consistent for indoor use.

- Aesthetic Finish: The bright zinc plating provides a clean look for visible connections.

- Cost-Effective: They are an inexpensive option for light-duty tasks.

- Wide Availability: These bolts are easily found in most hardware stores in various small sizes.

Best For Indoor or Dry-Use Projects Only

Important: Professionals use these carriage bolts for woodworking projects strictly in dry, indoor environments. The thin zinc plating offers no meaningful protection against outdoor elements and will rust quickly when exposed to rain or humidity.

These fasteners are the correct choice for:

- Building shop furniture and storage racks.

- Assembling indoor playhouses or children’s furniture.

- General furniture and cabinet assembly.

Never use this grade of bolt for decks, fences, or any outdoor structure. Their use in such projects creates a significant safety hazard due to rapid corrosion and failure.

How to Properly Install Carriage Bolts for Deck Building

Proper installation is essential for leveraging the full strength of carriage bolts for deck building. A precise and methodical approach ensures a secure assembly and a long-lasting structure. Following the correct steps for deck framing prevents common failures and guarantees professional results for all outdoor projects.

Tools and Materials Needed

A builder must gather the right tools before beginning the assembly. Having everything on hand streamlines the workflow for all deck framing applications. Professionals recommend a specific set of tools for accuracy.

- Power drill

- Drill bits (a spurred wood bit creates the cleanest holes)

- Wrench or socket set

- Rubber mallet or hammer

- Washers and nuts

- Pencil and ruler

- Safety goggles

Drill and Auger or Spade Bit

A sharp drill bit is critical. For the highest level of accuracy in woodworking, a spurred wood bit is recommended. It reduces splintering and ensures a clean entry and exit hole, which is vital for a quality assembly.

Wrench or Socket Set

A builder needs a wrench or socket set that matches the nut size. This allows for controlled and consistent tightening during the final assembly of the deck framing.

Mallet or Hammer

A mallet or hammer is used to seat the square neck of the bolt into the wood. A rubber mallet is preferable as it minimizes damage to the bolt’s protective coating.

Washers and Nuts

Every bolt requires a corresponding nut and at least one washer. The washer is crucial for distributing pressure and protecting the wood during tightening in all deck framing applications.

Step-by-Step Installation Guide

This guide outlines the four essential steps for a perfect installation in deck framing projects.

Step 1: Mark Your Hole Location

A builder first uses a pencil and ruler to mark the exact center point for the bolt hole. Precision at this stage ensures proper alignment for the entire deck framing assembly.

Step 2: Drill a Straight Hole

A builder drills the hole through the lumber. For a 1/2-inch carriage bolt, the recommended drill bit size is also 1/2-inch to ensure a snug fit. Drilling a straight, perpendicular hole is critical for the structural integrity of all outdoor applications.

Step 3: Insert and Seat the Bolt Head

The builder inserts the carriage bolt through the hole. A few firm taps with a mallet will seat the square neck into the wood, preventing the bolt from spinning during tightening. This is a key step in woodworking.

Step 4: Add Washer and Tighten the Nut

On the threaded end of the bolt, the builder places a washer over the threads and then hand-tightens the nut. A wrench is then used to secure the nut until it is snug, completing the connection for the deck framing.

Common Installation Mistakes to Avoid

Avoiding simple errors is key to the success of outdoor projects. These mistakes can compromise the strength and safety of the deck framing.

Drilling an Oversized Hole

Drilling a hole larger than the bolt diameter prevents the square neck from seating properly. The bolt will spin during tightening, making a secure connection impossible for these applications.

Over-Tightening the Nut

Excessive force when tightening a nut can crush or split the wood fibers. This damage directly compromises the structural integrity of the wood, weakening the connection. A quality installation requires a snug fit, not maximum force.

Forgetting the Washer Under the Nut

Forgetting the washer allows the nut to dig into the wood. This concentrates pressure on a small area, which can lead to wood failure over time in many applications. The correct grade of hardware includes a washer.

Using the Wrong Bolt Material

Using an indoor-grade zinc-plated bolt for outdoor deck framing is a critical error. The fastener will corrode and fail rapidly. A builder must always use the correct grade of hot-dipped galvanized or stainless steel carriage bolts for these applications.

Professionals find the best value in 1/2-inch hot-dipped galvanized carriage bolts for most outdoor projects. Successful woodworking projects demand correct length calculations for all applications. For coastal outdoor applications, an upgrade to stainless steel carriage bolts provides superior value. Investing in quality hardware is essential for the safety of all outdoor structures. The quality of these fasteners ensures the long-term integrity of outdoor structures like decks and fences, making them suitable for demanding woodworking applications and projects that require lasting value. These diverse applications for outdoor projects confirm their utility.

FAQ

Can a builder reuse old carriage bolts?

Professionals advise against reusing structural bolts. Old fasteners may have unseen stress fractures or compromised coatings from a previous installation. For safety and structural integrity, a builder should always use new, high-quality carriage bolts for any load-bearing project.

What is the difference between a carriage bolt and a lag bolt?

A carriage bolt passes completely through the wood and is secured with a nut and washer. A lag bolt, or lag screw, is a heavy-duty screw that threads directly into the wood. Carriage bolts provide superior clamping force for structural connections.

Does a builder need a washer on both ends of the bolt?

A builder must always place a washer under the nut. This distributes the load and prevents wood damage. Placing a washer under the bolt’s head is generally not necessary, as the domed head is designed for this purpose.

Pro Tip: For softwoods like cedar, a washer under the head can provide extra protection against the head pulling through the wood over time.

Why is the drill bit size so important?

A builder must use a drill bit that matches the bolt’s diameter (e.g., a 1/2-inch bit for a 1/2-inch bolt).

- An oversized hole prevents the square neck from seating, causing the bolt to spin.

- An undersized hole makes installation difficult and can damage the wood.

Can structural screws always replace carriage bolts?

Engineered structural screws like the GRK RSS are excellent, code-approved alternatives for many applications. They offer speed and strength. However, a builder must verify that the specific screw is rated for the intended structural load and meets local building codes.

What should a builder do if a carriage bolt is too long?

A bolt that is too long creates a snag hazard. After tightening the nut, a builder can cut the excess length with a hacksaw or an angle grinder with a metal-cutting disc. It is important to leave at least two threads showing past the nut.

How does a builder remove a rusted carriage bolt?

Removing a rusted bolt requires effort. A builder can first apply a penetrating oil to the threads. If a wrench fails, an impact wrench may provide the necessary torque. As a last resort, cutting the bolt off is often the most efficient solution.