Engineers select the correct flange bolts by consulting dimensional tables in governing standards like ASME B16.5. These charts specify bolt requirements based on the flange’s pipe size and pressure rating. For a unique rating, a custom fasteners manufacturer can produce custom fasteners.

The industry-standard Flange Bolt for carbon steel applications is the ASTM A193 Grade B7. Its specification ensures performance far superior to a generic bolt casting.

Finally, one calculates the required bolt length from the combined thickness of the flanges, gasket, and nuts, adding a small allowance for thread protrusion.

The Critical Role of Correct Flange Bolts in Joint Integrity

A bolted flange joint is more than just a connection point; it is a complex mechanical system responsible for maintaining the integrity of a piping network. The fasteners may seem like simple hardware, but correct bolt selection is a critical engineering decision that directly impacts safety, reliability, and operational performance. Neglecting this step introduces significant risk into any pressurized system.

Why Proper Bolt Selection is Non-Negotiable

Choosing the wrong fasteners can have immediate and severe consequences. The bolts are the active components that generate the clamping force, and their specifications must match the demands of the service.

Guaranteeing a Leak-Proof Seal

A joint’s primary function is to prevent leaks. Properly tightened bolts create a compressive load on the gasket, causing it to deform and fill imperfections on the flange faces. This action forms a tight seal. Failure analysis reveals a startling statistic. Up to 85% of gasket failures result from incorrect installation procedures, where improper bolting is a primary factor. Using bolts with the wrong material or diameter prevents the joint from achieving the necessary clamping force to seal correctly.

Preventing Catastrophic Joint Failure

The bolts must withstand the total force exerted by the internal fluid pressure and maintain sufficient residual load on the gasket. An undersized or incorrect grade of bolt can stretch beyond its elastic limit (yield) or fracture under operational stress. This failure leads to a sudden and catastrophic loss of pressure containment, posing a severe hazard to personnel and the environment.

Adhering to ASME and API Code Compliance

Piping codes like ASME B31.3 and flange standards like ASME B16.5 exist to ensure safety and interoperability. These documents explicitly define the required bolt material, size, and quantity for specific pressure classes. Using non-compliant fasteners violates industry regulations, invalidates system integrity, and can lead to significant legal and financial liability.

Core Components of a Bolted Flange Connection

Engineers design flanged connections as a complete system. Each component has a distinct role, and they must all work together to achieve a reliable, leak-free joint.

The Flange, Gasket, and Bolt System

This three-part system functions in unison to contain pressure.

- Flanges: Provide the structural connection point.

- Gasket: Creates the physical seal between the two flange faces.

- Bolts: Supply the clamping force (preload) needed to compress the gasket.

A change in any one component affects the performance of the entire system.

Stud Bolts vs. Machine (Hex) Bolts

Two main types of flange bolts are used in industrial piping:

- Stud Bolts: A threaded rod with two heavy hex nuts.

- Machine Bolts: A bolt with a hexagonal head on one end and a single nut on the other.

For through-bolted flanged connections, stud bolts are the preferred choice. They ensure more accurate and uniform loading during tightening because the entire fastener can be tensioned evenly. Machine bolts are typically reserved for situations where one flange has tapped (threaded) bolt holes.

Understanding Tensile Strength and Preload

Tensile strength is the maximum stress a bolt can withstand before it breaks. Preload is the tension created in a bolt when the nut is tightened. This tension is what creates the clamping force on the flanges. The goal of tightening is to apply enough preload to seat the gasket and maintain a seal without stretching the bolt beyond its elastic limit.

Step 1: Identify Flange Standard and Pressure Rating

Before selecting any bolts, an engineer must first determine the flange’s governing standard and its designated pressure rating. This critical information is the foundation for all subsequent choices, from bolt diameter to material grade. Fortunately, the flange itself holds all the necessary clues, stamped directly onto its surface for clear identification.

How to Read Markings Stamped on a Flange

Industrial flanges feature permanent markings that provide essential data about their specifications. Learning to read these markings is a fundamental skill for any piping professional.

Locating Manufacturer, Material, and Size

A quick inspection of the flange’s outer rim reveals several key identifiers. You will typically find:

- Manufacturer’s Name or Logo: Identifies the company that produced the flange.

- Material Grade: Specifies the material composition, such as

ASTM A105(carbon steel) orA182 F316(stainless steel). - Nominal Pipe Size (NPS): Indicates the pipe size the flange is designed to fit, for example,

4for a 4-inch pipe. - Heat Code: A traceability number linking the flange back to its manufacturing batch and material test reports.

Identifying the Pressure Rating (Class)

The most crucial marking for bolt selection is the pressure rating, often called the “Class.” This number is usually stamped prominently on the flange. It will appear as a number like 150, 300, 600, or higher. This rating signifies the maximum pressure the flange can safely withstand at a given temperature.

Key Flange Standards in the Industry

Different industries and applications use specific flange standards. The three most common standards governing pipe flanges are ASME and API.

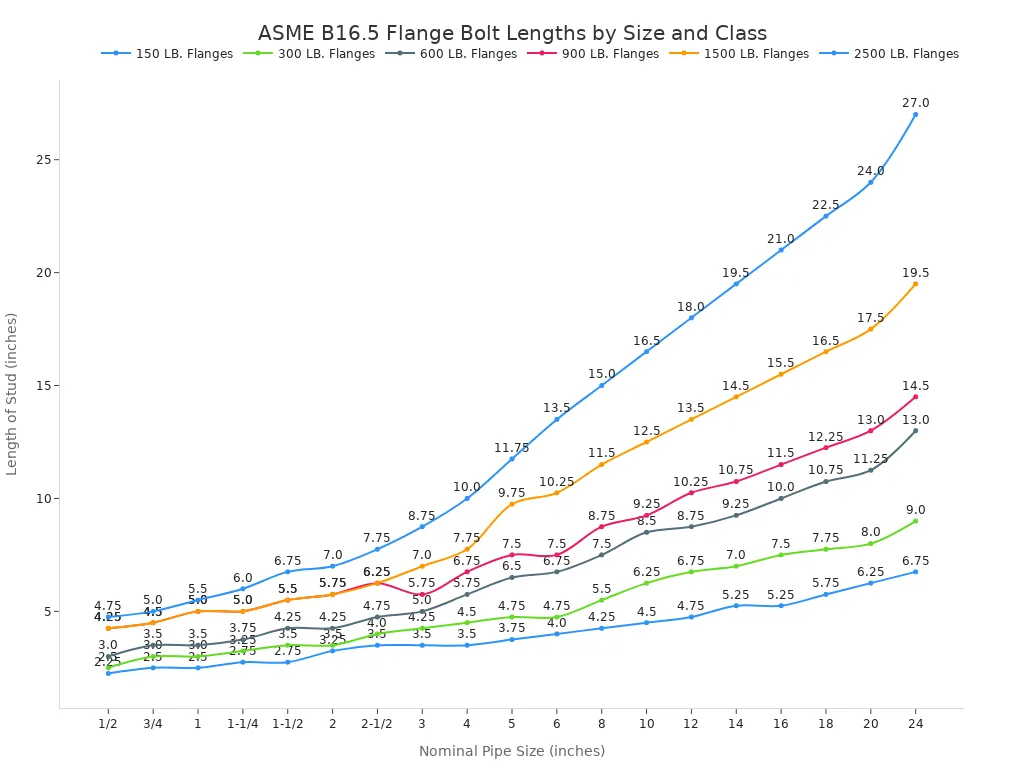

ASME B16.5: Pipe Flanges from NPS ½ to 24

This is the most prevalent standard for process piping. It covers flanges from NPS ½ inch up to 24 inches and defines dimensions, tolerances, materials, and testing for various flange classes.

ASME B16.47: Large Diameter Flanges from NPS 26 to 60

For larger pipelines, engineers turn to ASME B16.47. This standard is split into two distinct series:

- Series A: Specifies thicker, heavier flanges with fewer but larger bolts.

- Series B: Specifies thinner, lighter flanges with more, smaller bolts.

| Feature | ASME B16.5 | ASME B16.47 Series A | ASME B16.47 Series B |

|---|---|---|---|

| NPS | 1/2″ to 24″ | 26″ to 60″ | 26″ to 60″ |

| Pressure Classes | 150-2500 | 150-900 | 75-900 |

| Bolting | Standard | Fewer, larger bolts | More, smaller bolts |

| Weight | Standard | Heavier | Lighter |

API 6A: Flanges for Wellhead and Christmas Tree Equipment

The American Petroleum Institute (API) governs standards for the high-pressure oil and gas industry. API 6A flanges are designed for extreme service, with pressure ratings specified in pounds per square inch (psi), such as 5000 or 10000. They are not interchangeable with ASME flanges.

Understanding Flange Pressure Rating Designations

The pressure rating of a flange is not a single, fixed value. It represents a pressure-temperature curve.

Class 150, 300, 600 for General Service

These are the most common flange ratings found in general industrial applications like water treatment, chemical processing, and power generation. A higher class number indicates a higher pressure capacity.

Class 900, 1500, 2500 for High-Pressure Service

Engineers specify these higher flange classes for severe service conditions involving high pressures and temperatures, common in oil refining and steam generation.

How Temperature Affects a Flange’s Pressure Rating

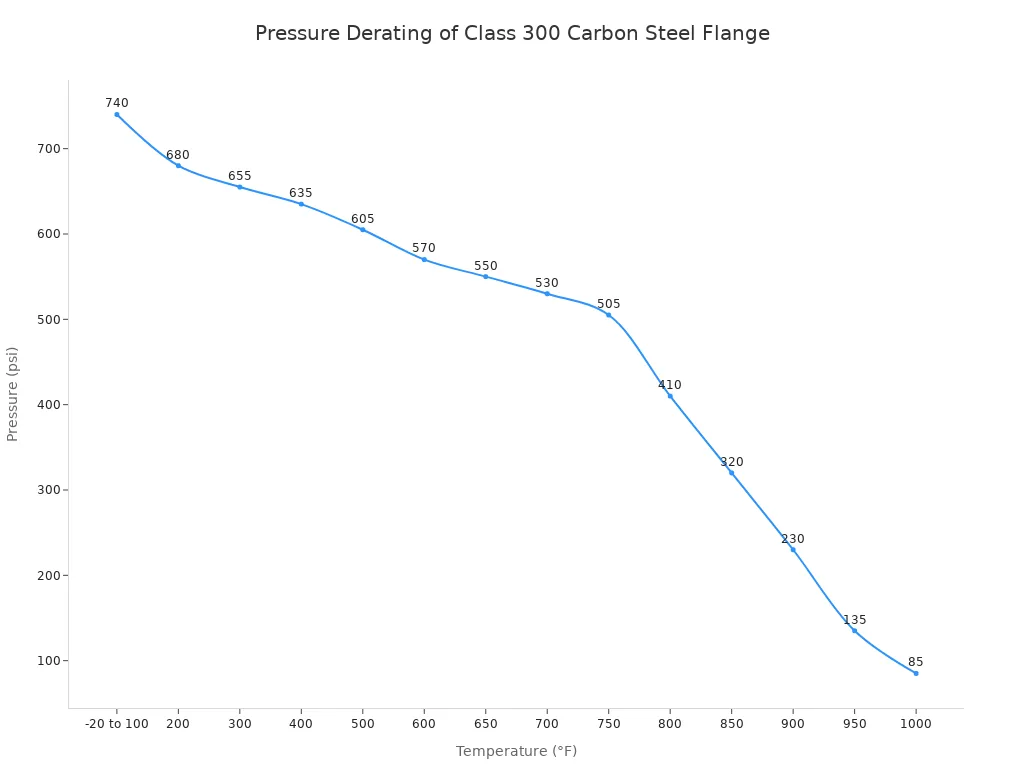

Important Note: A flange’s pressure rating decreases as its operating temperature increases. The “Class” number is a nominal identifier, not a direct pressure value in psi.

For example, an ASME Class 300 carbon steel flange has a maximum working pressure rating of 740 psi at ambient temperatures. However, as the service temperature rises, its pressure-holding capacity is derated significantly. At 800°F, that same flange can only handle 410 psi. Always consult the pressure-temperature tables in the relevant ASME standard to confirm a flange’s capability at its design temperature.

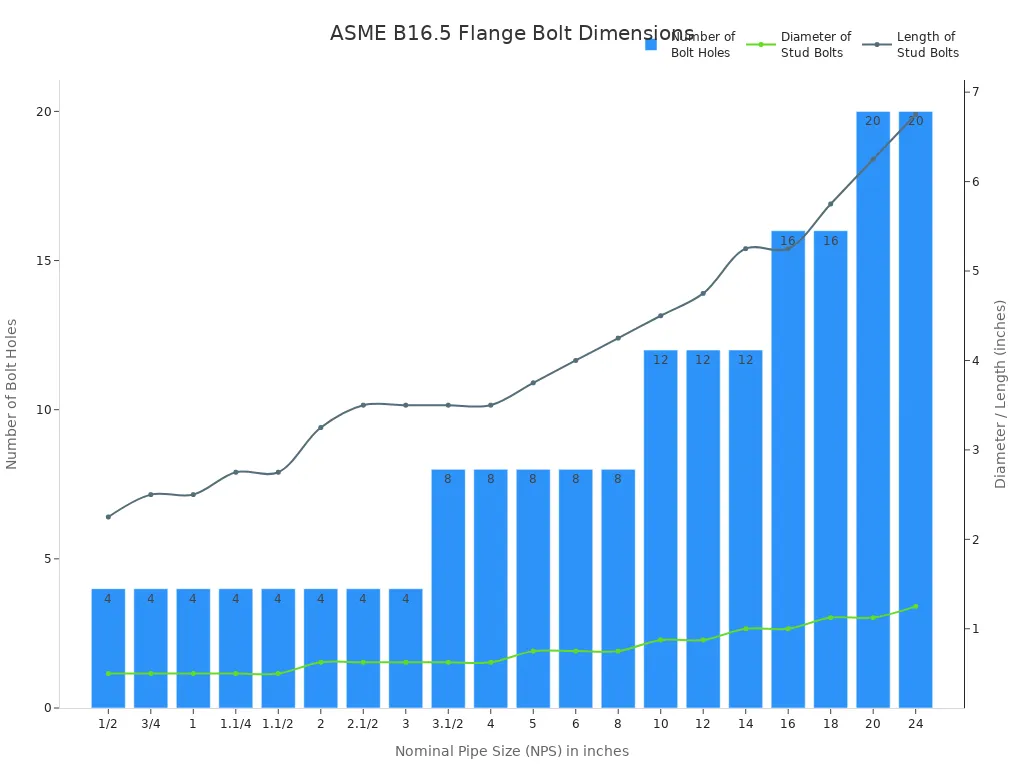

Step 2: Determine Bolt Quantity and Diameter from Standard Charts

Once an engineer identifies the flange’s standard and pressure rating, the next step is to consult the official dimensional charts. These tables are the definitive source for determining the correct number and size of bolts required for a specific flange connection. The ASME B16.5 standard provides comprehensive data that removes guesswork and ensures the joint is designed according to proven engineering principles.

Navigating ASME B16.5 Dimensional Tables

The ASME B16.5 standard contains a series of tables that detail every dimension of a flange for each pressure class. Knowing how to navigate these tables is essential for accurate bolt selection. The official dimensional tables for flanges, which include all necessary bolt information, are found throughout the ASME B16.5 2020 document. Key tables include:

- Table 8, 8C

- Table 11, 11C

- Table 14, 14C

- Table 16, 16C

- Table 18, 18C

- Table 20, 20C

- Table 22, 22C

Finding Your NPS and Pressure Class

The tables are organized primarily by pressure class. Within each class-specific table, data is listed by Nominal Pipe Size (NPS). The first action is to locate the correct table for the flange’s class (e.g., Class 150, Class 300). Then, find the row corresponding to the flange’s NPS. This cross-reference pinpoints the exact specifications for that particular flange.

Locating Number of Bolts and Bolt Hole Diameter

After finding the correct row for the NPS and pressure class, the engineer can read across the columns to find critical bolting information. The tables clearly specify:

- Number of Bolts: The total quantity of bolts required to assemble the joint.

- Diameter of Bolt Holes: The diameter of the holes drilled into the flange.

Note: The required bolt diameter is slightly smaller than the bolt hole diameter to allow for easy installation. For example, a 1-inch diameter bolt hole typically accommodates a 7/8-inch diameter bolt. The charts specify the correct bolt diameter to use.

Understanding Bolt Circle Diameter

Another key dimension listed is the Bolt Circle Diameter (BCD). This is the diameter of the imaginary circle that runs through the center of all the bolt holes. The BCD ensures that the clamping force is applied evenly around the gasket, which is crucial for achieving a reliable seal. It also confirms that the flange and its mating component will align correctly.

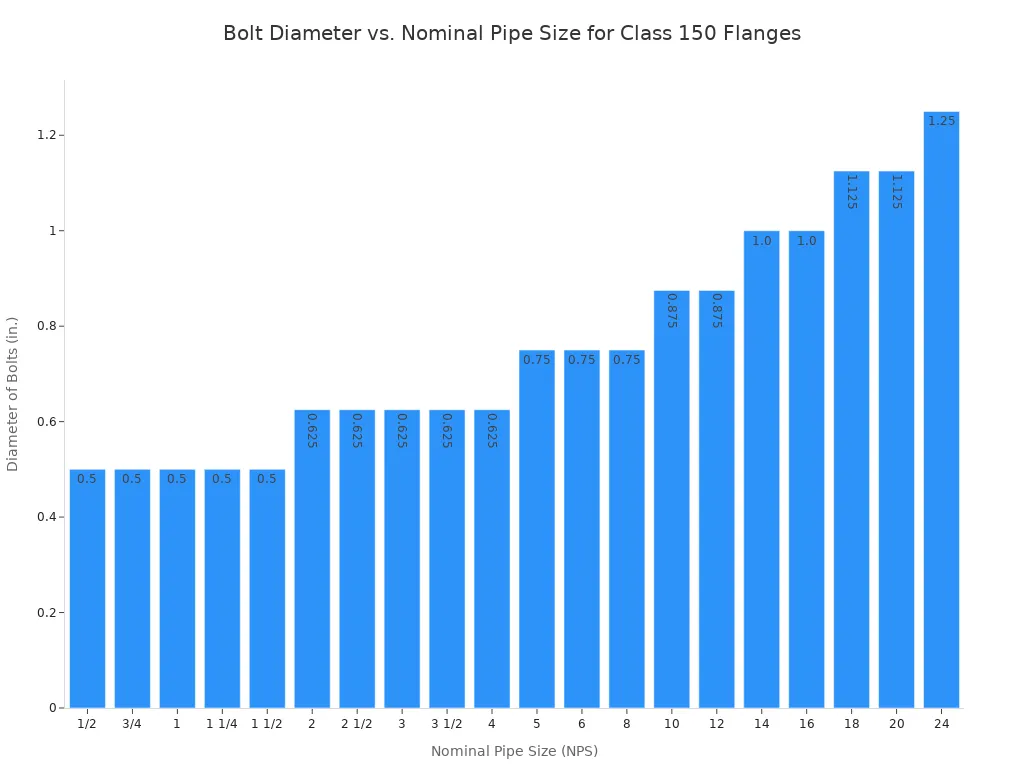

Bolt Chart Data for Class 150 Flanges

Class 150 flanges are common in low-pressure, general-purpose applications. The bolting requirements for this rating vary significantly with pipe size, reflecting the different forces at play.

Requirements for Small Bore (NPS ½ – 2)

For small bore piping, from NPS ½ inch to 2 inches, Class 150 flanges consistently require four bolts. The bolt diameter starts at ½ inch for sizes up to 1 ½ inches and increases to ⅝ inch for a 2-inch flange. This configuration provides sufficient clamping force for the relatively small surface area and lower pressures seen in these lines.

Requirements for Large Bore (NPS 2 ½ – 24)

As the pipe size increases, so does the force acting on the flange. To counteract this, the number and diameter of the bolts must also increase. For a 2 ½-inch flange, the requirement is still four bolts. However, a 4-inch flange requires eight bolts, and a 12-inch flange needs twelve bolts. The bolt diameter also scales up, reaching 1 ¼ inches for a 24-inch Class 150 flange. This progressive increase ensures the joint can safely contain the pressure over a much larger area.

The following chart illustrates how bolt diameter increases with pipe size for Class 150 flanges.

Bolt Chart Data for Class 300 Flanges

Class 300 flanges are designed for more demanding service with higher pressures and temperatures. Consequently, their bolting requirements are more robust than those for Class 150. A flange pressure rating chart will show that a Class 300 flange can handle significantly more pressure than a Class 150 flange of the same size.

Requirements for Small Bore (NPS ½ – 2)

Even in small bore sizes, the increased pressure rating of Class 300 flanges necessitates stronger bolting. While an NPS ½ inch flange still uses four bolts, the quantity quickly increases. A 2-inch Class 300 flange requires eight ⅝-inch bolts, which is double the quantity needed for its Class 150 counterpart. This doubling of fasteners provides the extra clamping force needed to maintain seal integrity under higher operational pressures.

Requirements for Large Bore (NPS 2 ½ – 24)

The trend of increased bolting continues for large bore Class 300 flanges. The number of bolts and their diameters are consistently greater than for Class 150. For example, a 12-inch Class 300 flange uses twelve 1 ⅛-inch bolts, whereas the Class 150 version uses twelve ⅞-inch bolts. This larger diameter provides a substantial increase in the bolt’s cross-sectional area and tensile strength, enabling it to generate and maintain the higher preload required for this service class.

The table below provides a sample of the bolting data found in ASME B16.5 for a specific pressure class.

| NPS | Number of Bolt Holes | Diameter of Stud Bolts | Length of Stud Bolts |

|---|---|---|---|

| 1/2 | 4 | 1/2 | 2.25 |

| 3/4 | 4 | 1/2 | 2.5 |

| 1 | 4 | 1/2 | 2.5 |

| 1.1/4 | 4 | 1/2 | 2.75 |

| 1.1/2 | 4 | 1/2 | 2.75 |

| 2 | 4 | 5/8 | 3.25 |

| 2.1/2 | 4 | 5/8 | 3.5 |

| 3 | 4 | 5/8 | 3.5 |

| 3.1/2 | 8 | 5/8 | 3.5 |

| 4 | 8 | 5/8 | 3.5 |

| 5 | 8 | 3/4 | 3.75 |

| 6 | 8 | 3/4 | 4 |

| 8 | 8 | 3/4 | 4.25 |

| 10 | 12 | 7/8 | 4.5 |

| 12 | 12 | 7/8 | 4.75 |

| 14 | 12 | 1 | 5.25 |

| 16 | 16 | 1 | 5.25 |

| 18 | 16 | 1.1/8 | 5.75 |

| 20 | 20 | 1.1/8 | 6.25 |

| 24 | 20 | 1.1/4 | 6.75 |

Note: Dimensions are in inches unless otherwise indicated. The length of the Stud Bolt does not include the height of the chamfers (points) and accounts for a compressed spiral wound gasket.

This data can also be visualized to show the relationship between pipe size and the required bolting specifications.

Bolt Chart Data for Class 600 Flanges

Class 600 flanges mark a transition into more demanding, high-pressure service. Their design requires significantly more robust bolting to manage the increased forces. The bolting specifications reflect this jump in performance requirements, with notable increases in both bolt quantity and diameter compared to lower classes.

Requirements for Small Bore (NPS ½ – 2)

In small bore piping, the bolting for Class 600 flanges is substantially heavier than for Class 300. A 2-inch Class 600 flange, for instance, still uses eight bolts, but the standard increases the required bolt diameter from ⅝ inch to ⅞ inch. This larger diameter provides a greater cross-sectional area, enabling the bolts to generate and sustain the much higher clamping force needed for this pressure service.

Requirements for Large Bore (NPS 2 ½ – 24)

For large bore Class 600 flanges, the bolting requirements escalate dramatically. The design must safely contain immense pressure over a large surface area.

- Increased Bolt Quantity: The number of bolts increases significantly. A 6-inch Class 600 flange requires 12 bolts, compared to the 8 bolts needed for a Class 300 flange of the same size.

- Increased Bolt Diameter: The bolt diameters are also consistently larger. A 12-inch Class 600 flange uses 20 bolts with a 1 ⅜-inch diameter, a major increase from the 12 bolts at 1 ⅛-inch diameter for a Class 300 flange.

This combination of more and larger bolts is essential to distribute the clamping load evenly and prevent joint failure under high-pressure conditions.

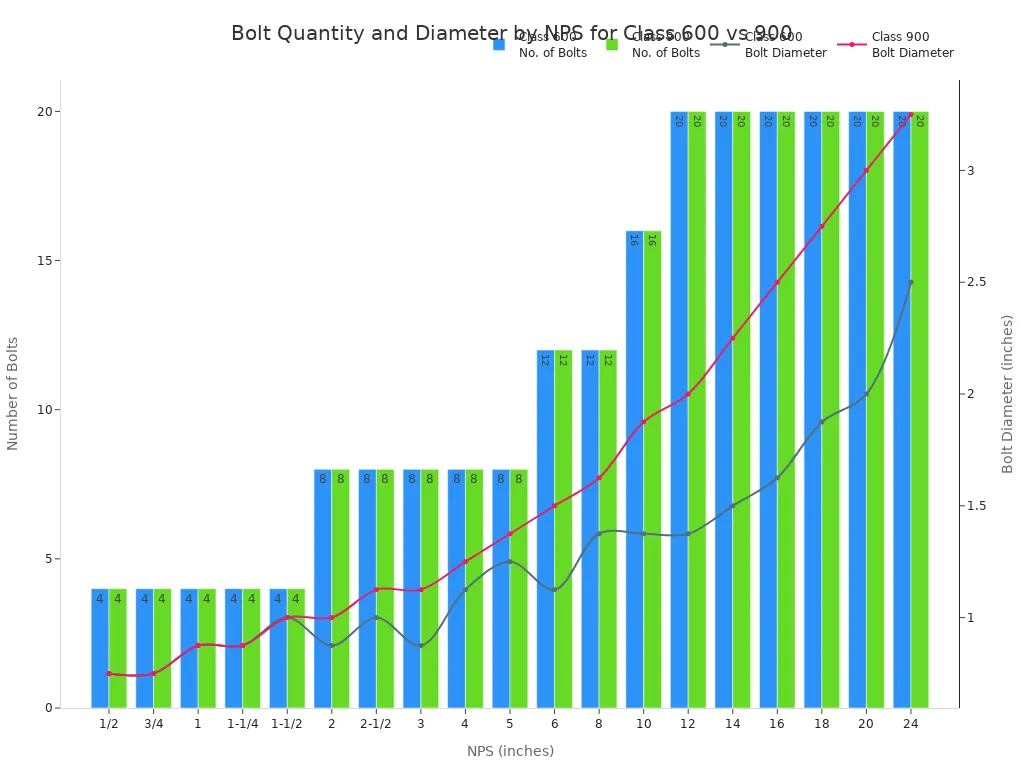

Bolt Requirements for High-Pressure Classes (900, 1500, 2500)

Engineers specify Class 900, 1500, and 2500 flanges for severe and critical service applications, such as high-pressure steam lines, hydrocarbon processing, and wellhead equipment. The bolting for these classes is the most robust defined by ASME B16.5, reflecting the extreme internal pressures they must contain.

Increased Bolt Quantity and Diameter

As the pressure rating increases from Class 600 to Class 900 and higher, the primary method for strengthening the joint is to increase the bolt diameter. This provides a greater tensile strength capacity for each fastener. While the number of bolts often stays the same between Class 600 and Class 900 for a given pipe size, the higher pressure rating of a Class 900 flange demands larger, stronger bolts to achieve the necessary preload.

The following table directly compares the bolting requirements for Class 600 and Class 900 flanges, illustrating the consistent increase in bolt diameter.

| NPS (inches) | Class 600 No. of Bolts | Class 600 Bolt Diameter (inches) | Class 900 No. of Bolts | Class 900 Bolt Diameter (inches) |

|---|---|---|---|---|

| 2 | 8 | 7/8 | 8 | 1 |

| 4 | 8 | 1-1/8 | 8 | 1-1/4 |

| 6 | 12 | 1-1/8 | 12 | 1-1/2 |

| 8 | 12 | 1-3/8 | 12 | 1-5/8 |

| 12 | 20 | 1-3/8 | 20 | 2 |

| 24 | 20 | 2-1/2 | 20 | 3-1/4 |

This trend is clearly visible when the data is plotted, showing how bolt diameter scales up to meet the demands of the higher pressure class.

For the most extreme flange classes, the rules become even more stringent to ensure maximum safety and reliability.

Critical Service Note: For Class 1500 and Class 2500 flanges, standards permit only high-strength stud bolts. The use of machine bolts or any low-strength bolting materials is strictly prohibited. This ensures that the joint has the maximum possible clamping force and resistance to failure under the most severe operating pressures.

Step 3: The Complete Guide to Flange Bolt Selection by Material

Selecting the correct bolt size and quantity is only half the battle. The material of the bolt is equally critical. The right material ensures the joint can withstand the service temperature, pressure, and any corrosive media. An incorrect material choice can lead to premature failure, leaks, and significant safety hazards. This step guides engineers through the process of material selection for various service conditions.

Matching Bolt Material to Flange and Service Conditions

The bolt, flange, and gasket form an interconnected system. The material of each component must be compatible with the others and suitable for the operational environment. This holistic approach to bolt selection prevents many common causes of joint failure.

Ensuring Material Compatibility

Material compatibility extends beyond just the flange and bolt. It also involves the gasket and the process fluid. For example, a system handling corrosive chemicals requires bolts and gaskets that resist chemical attack.

System-Wide Compatibility Check:

- Temperature Tolerance: The bolt material must retain its strength at the system’s operating temperature.

- Chemical Resistance: The bolt must not corrode or degrade when exposed to the process fluid.

- Mechanical Strength: The bolt’s tensile strength must be sufficient to achieve the required preload for the chosen gasket type. For instance, soft gaskets require less bolt load than spiral wound or ring-type joint (RTJ) gaskets.

The following table shows how different industries select gasket materials based on application, which in turn influences bolting requirements.

| Industry | Preferred Gasket Materials | Application Rationale |

|---|---|---|

| Oil and Gas | Spiral wound, RTJ | Handles high pressure, temperature, and exposure to hydrocarbons |

| Pharmaceutical and Food Processing | PTFE, Silicone | Ensures contamination-free sealing and meets FDA hygiene standards |

| Water and Wastewater | EPDM, CNAF | Resists moisture, chlorinated compounds, and standard treatment chemicals |

| Power Generation | Graphite, Metallic | Withstands extreme heat and pressure cycling in turbine and boiler systems |

How to Prevent Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals are in contact in the presence of an electrolyte, like moisture. One metal becomes the anode and corrodes rapidly, while the other becomes the cathode and is protected. Since bolts have a small surface area, they can fail very quickly if they act as the anode.

This phenomenon has caused catastrophic failures in major structures. The Statue of Liberty, for example, suffered severe galvanic corrosion where its copper skin (cathode) touched its cast-iron frame (anode), leading to extremely costly repairs. To prevent this:

- Select bolt and nut materials that are close to the flange material on the galvanic series.

- Use coated bolts or insulating washers and sleeves to break the electrical circuit.

- Ensure the bolt material is more noble (cathodic) than the flange material if a mismatch is unavoidable.

Carbon Steel Flanges in Standard Service

For the vast majority of industrial applications involving carbon steel flanges, a standard, high-strength bolting combination is used. This pairing is specified across numerous piping codes for its reliability and proven performance.

ASTM A193 Grade B7: The Industry Standard Bolt

ASTM A193 Grade B7 is the most specified material for flange bolts in process piping. It is a chromium-molybdenum (chrome-moly) alloy steel that is quenched and tempered to develop high tensile strength and good performance at elevated temperatures.

Key Feature: B7 studs are reliable for applications with service temperatures up to 750°F (400°C). Above this temperature, their strength begins to decrease significantly.

The mechanical properties of B7 bolts make them ideal for generating the high clamping force needed to seal flanged joints effectively.

| Property (for sizes up to 2.5 inches) | Value |

|---|---|

| Minimum Tensile Strength | 125,000 psi |

| Minimum Yield Strength | 105,000 psi |

| Maximum Hardness | 321 HBW or 35 HRC |

| Minimum Tempering Temperature | 1100°F |

ASTM A194 Grade 2H: The Required Heavy Hex Nut

A high-strength bolt is only as good as its nut. The standard specifies ASTM A194 Grade 2H heavy hex nuts for pairing with A193 B7 bolts. These nuts are also quenched and tempered carbon steel, designed to match the strength of the B7 bolt. Using a lower-grade nut (like ASTM A563 Grade A) with a B7 bolt is a dangerous practice, as the nut can strip its threads long before the bolt reaches its required preload.

Stainless Steel and High-Temperature Service

When service conditions involve corrosive environments or temperatures beyond the limits of carbon steel, engineers turn to stainless steel and other specialized alloys.

ASTM A193 Grade B8/B8M for Stainless Steel Flanges

For stainless steel piping systems, the corresponding bolt materials are ASTM A193 Grade B8 and B8M. These bolts are typically paired with ASTM A194 Grade 8 or 8M nuts.

- Grade B8: Made from AISI 304 stainless steel. It offers good corrosion resistance in most environments.

- Grade B8M: Made from AISI 316 stainless steel. The addition of molybdenum gives B8M superior corrosion resistance, especially against chlorides.

Application Tip: Always specify Grade B8M bolts for marine environments, coastal facilities, or systems handling chloride-rich chemicals to prevent pitting and crevice corrosion.

Both B8 and B8M have a minimum tensile strength of 75,000 psi, which is lower than B7. This must be accounted for in torque calculations.

ASTM A193 Grade B16 for High-Temperature Chrome-Moly Flanges

For service temperatures above 750°F (400°C), the strength of B7 bolts begins to diminish. In these high-temperature applications, such as steam lines and refinery furnaces, engineers specify ASTM A193 Grade B16 bolts. B16 is a chromium-molybdenum-vanadium alloy steel designed to retain its strength and resist creep at elevated temperatures, making it a safer choice for critical, high-heat service.

Low-Temperature and Cryogenic Service

Standard carbon steel bolts, like ASTM A193 B7, become brittle and can fracture at low temperatures. Engineers must select specialized materials for applications involving refrigeration, LNG processing, or piping in cold climates. These materials undergo rigorous testing to guarantee they remain ductile and tough when temperatures drop.

ASTM A320 Grade L7 for Low-Temperature Carbon Steel

The industry standard for low-temperature carbon steel bolting is ASTM A320 Grade L7. This material is a chromium-molybdenum alloy steel, chemically similar to A193 B7. However, Grade L7 undergoes a specific heat treatment process and, most importantly, must pass a Charpy V-notch impact test. This test proves the material’s ability to absorb impact energy without fracturing at a specified low temperature.

What is a Charpy Impact Test? ⚙️ This test involves striking a small, notched sample of the material with a weighted pendulum. The amount of energy the sample absorbs before breaking indicates its toughness. For L7 bolts, this test is performed at very low temperatures to simulate service conditions.

The ASTM A320 standard specifies the minimum temperature at which L7 bolts are proven to perform safely.

| Grade | Charpy Impact 20-ft-lbf @ temp |

|---|---|

| L7 | -150° F |

This impact testing ensures the bolts will not fail in a brittle manner. While the Charpy test is performed at -150°F, the material is generally considered suitable for a minimum service temperature of -100°F, providing a reliable safety margin.

| Material | Minimum Temperature °C (°F) |

|---|---|

| B7, L7 | -73 (-100) |

Nut Pairings for A320 Bolts

A low-temperature bolt requires a nut that can perform under the same conditions. The standard pairing for ASTM A320 L7 bolts is an ASTM A194 Grade 4 or Grade 7 nut. These nuts are also manufactured and tested for low-temperature service to ensure they retain their strength and do not become brittle. Using a standard A194 Grade 2H nut with an L7 bolt is a critical error, as the nut would not have the required low-temperature toughness and could fail.

Special Service: Sour Environments (H2S)

Sour service refers to applications where hydrogen sulfide (H2S) is present. H2S is a highly corrosive and dangerous gas commonly found in oil and gas production. It can cause a catastrophic failure mechanism in high-strength steels known as sulfide stress cracking (SSC). Selecting the correct bolt material is a matter of critical safety in these environments.

Understanding NACE MR0175/ISO 15156

The primary standard governing material selection for sour service is NACE MR0175 (also known as ISO 15156). This document provides strict requirements for materials used in H2S-containing environments to prevent cracking failures. The core principle of the standard is controlling the material’s hardness. Harder, higher-strength steels are more susceptible to SSC. Therefore, NACE sets maximum hardness limits for all components, including bolts and nuts.

Specifying ASTM A193 Grade B7M Bolts

For sour service applications, engineers specify ASTM A193 Grade B7M bolts. These bolts are chemically identical to standard B7 bolts but undergo a different heat treatment process. This modified treatment results in lower tensile strength and, crucially, a lower hardness.

Hardness Control is Key: For NACE MR0175 sour service applications, all carbon and low-alloy steel bolting materials must adhere to a maximum hardness of 22 HRC (Rockwell Hardness C).

This controlled, lower hardness makes the B7M material significantly more resistant to sulfide stress cracking. While NACE MR0175 lists numerous acceptable materials, B7M (UNS G41400) is the most common choice for bolted flange connections in sour service.

Specifying ASTM A194 Grade 2HM Nuts

Just as B7M bolts are required, a corresponding nut with controlled hardness is also mandatory. The correct pairing for a B7M bolt is an ASTM A194 Grade 2HM nut. The “M” designation signifies that the nut has also been specially heat-treated to meet the NACE hardness requirement of 22 HRC maximum. Using a standard A194 Grade 2H nut would violate the NACE standard, as its higher hardness would make it the weak link in the system and highly susceptible to cracking and failure in a sour environment.

Step 4: How to Calculate the Correct Length for Flange Bolts

After determining the diameter and material, the final critical step is calculating the correct length for the flange bolts. A bolt that is too short will not achieve proper thread engagement, creating a weak and dangerous joint. A bolt that is too long can pose a safety hazard and interfere with nearby equipment. Precise length calculation is essential for a secure connection.

The Standard Bolt Length Calculation Formula

Engineers use a straightforward formula to determine the required length of a stud bolt. This calculation accounts for every component in the bolted flange connection.

Length = (2 x Flange Thickness) + Gasket Thickness + (2 x Nut Height) + Allowance

The formula is a simple addition of the key dimensions:

- 2 x Flange Thickness: The thickness of both flanges being joined.

- Gasket Thickness: The compressed thickness of the gasket.

- 2 x Nut Height: The height of two heavy hex nuts.

- Allowance: A small extra length for thread protrusion.

The Rule for Thread Protrusion Allowance (2-3 Threads)

Safety Standard: A properly installed stud bolt should have at least two to three threads showing past the outer face of the nut. This protrusion provides a quick visual confirmation that full thread engagement has been achieved within the nut, guaranteeing the connection can develop its full strength.

Variables That Impact Required Bolt Length

Several factors can alter the final length calculation. An engineer must consider these variables to ensure accuracy.

Flange Face Type: Raised Face (RF) vs. Ring-Type Joint (RTJ)

The type of flange face directly influences bolt length. A flange bolt chart shows that Ring-Type Joint (RTJ) flanges often require different stud bolt lengths compared to standard Raised Face (RF) flanges of the same size and class. This is because RTJ flanges have deeper grooves for metallic ring gaskets, which can alter the effective distance between the outer flange faces.

Gasket Thickness Variations

Gaskets come in various materials and thicknesses. A thin, non-asbestos sheet gasket has a different compressed thickness than a thick, spiral wound gasket. The calculation must use the gasket’s final compressed thickness, not its uncompressed state.

The Role of Hardened Washers

If the design specification requires hardened washers (ASTM F436), their thickness must be added to the total length. Using washers on both sides of the joint will increase the required bolt length accordingly.

Using Pre-Calculated Charts for Common Configurations

To streamline the process, engineers often rely on pre-calculated charts. These resources provide standard bolt lengths for common flange sizes and classes, saving time and reducing the risk of manual calculation errors.

Finding Lengths for RF Flanges

Many suppliers provide comprehensive resources for their customers. For example, Lightning Bolt and Supply offers an ASME B16.5 Stud Bolt Flange Chart on their website. These charts list required stud lengths for various flange classes, including those with 1/16″ and 1/4″ raised faces.

Finding Lengths for RTJ Flanges

The same charts typically include data for RTJ flanges. The table below shows a sample of pre-calculated stud lengths for different flange classes and sizes, demonstrating how length increases with both pipe size and pressure rating.

| Nominal Pipe Size | 150 LB. Flanges (Length of Stud 1/16 RF) | 300 LB. Flanges (Length of Stud 1/16 RF) | 600 LB. Flanges (Length of Stud 1/4 RF) |

|---|---|---|---|

| 1/2 | 2-1/4 | 2-1/2 | 3 |

| 1 | 2-1/2 | 3 | 3-1/2 |

| 2 | 3-1/4 | 3-1/2 | 4-1/4 |

| 4 | 3-1/2 | 4-1/2 | 5-3/4 |

| 6 | 4 | 4-3/4 | 6-3/4 |

| 12 | 4-3/4 | 6-3/4 | 8-3/4 |

Note: All dimensions are in inches.

This data can also be visualized to quickly compare requirements across different flange classes.

Common Errors in Bolt Length Sizing

Accurate bolt length calculation is a fundamental requirement for a safe and reliable flanged joint. Deviating from the correct length, even slightly, introduces significant risks. Both undersized and oversized bolts create distinct problems that can compromise the integrity of the entire piping system. Technicians must recognize and avoid these common sizing errors.

Risk of Insufficient Thread Engagement (Too Short)

A bolt that is too short is one of the most dangerous errors in flange assembly. This condition prevents the nut from fully engaging with the bolt’s threads. The connection cannot develop its required strength when only a few threads are carrying the entire load. During tightening, these few threads are subjected to immense stress. This overload often leads to thread stripping, where the threads inside the nut shear off long before the bolt reaches its target preload.

A joint with stripped threads cannot generate the necessary clamping force on the gasket. This results in an unreliable seal that is prone to leaking under operational pressure. In a worst-case scenario, the weakened connection can fail completely, leading to a catastrophic blowout.

The Visual Check: A properly installed stud bolt must show at least two to three threads protruding past the nut. The absence of this protrusion is a clear and immediate sign of insufficient thread engagement, and the joint must be disassembled and corrected.

Safety Hazards of Excessive Protrusion (Too Long)

While less likely to cause an immediate joint failure, a bolt that is too long creates numerous safety and maintenance issues. The excessive length protruding from the nut presents a significant hazard in any industrial environment. These long, exposed studs can easily interfere with operations and create unsafe conditions.

Engineers and maintenance personnel must consider several risks associated with overly long bolts:

- Snag Hazard: The protruding ends can catch on workers’ clothing, tool belts, or nearby hoses. This creates a serious trip and fall hazard, especially in confined spaces or on elevated platforms.

- Equipment Interference: Long bolts may collide with adjacent piping, structural steel, or insulation. This can prevent proper installation or cause damage from vibration over time.

- Corrosion and Damage: The extra exposed threads are vulnerable to atmospheric corrosion and mechanical damage. This corrosion can make it extremely difficult or impossible to remove the nuts during future maintenance, often forcing technicians to cut the bolts off.

Properly sized bolts ensure a safe working environment and simplify future maintenance activities.

Best Practices for Flange Bolt Installation and Management

Properly selecting flange bolts is only the first step; correct installation and management are essential for ensuring joint integrity. Following established best practices prevents leaks, enhances safety, and extends the service life of the connection. The interaction between the gasket, lubricant, and washers directly influences the performance of the bolts.

The Critical Impact of Gaskets on Bolt Performance

The gasket type is the most significant variable determining the required bolt load. Each gasket material has a specific seating stress range needed to create an effective seal. Applying too little load results in a leak, while too much can crush the gasket and cause it to fail.

Bolt Load for Soft Gaskets (e.g., Non-Asbestos)

Soft gaskets, such as compressed non-asbestos fiber (CNAF) or rubber, are designed for low-pressure applications. They require a relatively low bolt load to conform to flange imperfections and create a seal. Over-tightening can easily crush or extrude these materials from the joint.

Bolt Load for Spiral Wound Gaskets

Spiral wound gaskets are composite seals made of a metal winding and a soft filler material. They require a significantly higher bolt load to compress the metal windings, which act as a spring to maintain a seal during pressure and temperature fluctuations.

Bolt Load for Ring-Type Joint (RTJ) Gaskets

RTJ gaskets are solid metal rings used in high-pressure, high-temperature service. They demand the highest bolt load of all gasket types. The immense force from the bolts causes the softer gasket material to deform and flow into the flange grooves, creating a highly reliable metal-to-metal seal.

Bolt Lubrication and Torque Management

Achieving the correct bolt preload is impossible without managing friction. Proper lubrication is a non-negotiable step in achieving accurate and consistent clamping force.

The Importance of a Quality Bolt Lubricant

A quality lubricant reduces friction between the nut face and the flange, as well as between the bolt and nut threads. This ensures that a greater percentage of the applied torque is converted into useful bolt stretch (preload) rather than being wasted overcoming friction.

Understanding the Nut Factor (K-Factor) in Torque Calculations

The “nut factor,” or K-Factor, is a coefficient that accounts for friction in torque calculations. It is an empirical value that changes based on the lubricant, material, and surface finish. The standard formula for calculating torque is:

T = K * D * F- Where:

T= Target TorqueK= Nut Factor (friction coefficient)D= Nominal Bolt DiameterF= Target Bolt Load (preload)

How Lubricant Affects Required Torque

The choice of lubricant directly impacts the K-Factor and, therefore, the required installation torque values. A high-quality lubricant with a low K-Factor requires less torque to achieve the same target preload compared to a poor lubricant or a dry, unlubricated bolt.

The Proper Use of Hardened Washers

Hardened washers are not just spacers; they are critical components that improve the reliability of a bolted joint.

When Are ASTM F436 Washers Required?

Piping specifications often mandate the use of ASTM F436 hardened washers, especially in high-strength bolting applications. They are essential when bolting against a soft flange material or when the bolt hole is oversized or slotted.

Preventing Galling and Distributing Load

Washers serve two primary functions. First, they provide a hard, smooth bearing surface for the nut to turn against, preventing galling (thread seizure), especially with stainless steel fasteners. Second, they distribute the high compressive load from the nut over a larger area on the flange face, reducing stress and preventing damage.

Guidelines on the Reusability of Flange Bolts

The question of whether to reuse flange bolts is a common one in maintenance operations. While reusing fasteners can seem cost-effective, it introduces significant risks if not managed correctly. Technicians must approach this decision with caution, understanding that a bolt’s performance can degrade after its first use.

Why Reusing Yielded Bolts is Unsafe

A flange bolt functions like a very stiff spring. During proper tightening, it stretches within its elastic limit to create clamping force. After disassembly, it should return to its original length. However, if a bolt is over-tightened, it can be stretched beyond this elastic limit into its plastic zone. This permanent stretch is called “yielding.”

A yielded bolt is permanently damaged. It has lost its original mechanical properties and can no longer achieve the required preload reliably. Re-tightening a yielded bolt is dangerous for several reasons:

- It will not provide the correct clamping force, leading to potential leaks.

- It is significantly more likely to fracture under operational stress.

- Torque values become unpredictable, as the relationship between torque and tension is lost.

Critical Safety Rule: A bolt that has been yielded must never be reused. The risk of joint failure is too high. Discard and replace it without exception.

Inspection Criteria for Potential Reuse

In non-critical applications where bolts were not torqued to yield, reuse may be possible. However, this requires a thorough inspection. Following these inspection best practices is essential for ensuring safety. A technician should only consider reusing a bolt if it passes all of the following checks:

- No Visible Corrosion: Inspect the entire bolt for any signs of rust or pitting. Corrosion weakens the bolt and can increase friction, leading to inaccurate torque readings.

- Undamaged Threads: Carefully examine the threads. They must be free of any damage, such as nicks, flat spots, or galling (thread seizure). Damaged threads prevent proper nut engagement and can strip during tightening.

- No Physical Deformation: Check the bolt shank for any signs of bending or reduction in diameter (necking). These are clear indicators that the bolt has yielded.

- Cleanliness: The bolt must be thoroughly cleaned so a proper inspection can be performed. Any dirt or old lubricant can hide defects.

If a bolt shows any of these signs of wear or damage, or if its history is unknown, the safest course of action is to discard it. The small cost of a new bolt is insignificant compared to the cost of a leak or catastrophic failure.

Successful bolt selection follows a methodical approach. Engineers identify the flange standard, pressure rating, and pipe size, then use charts to find the required bolt quantity and diameter. ASTM A193 B7 bolts are standard for most flange ratings. However, service temperature and corrosive conditions demand specific material grades. The rating of the flange is a key factor. Precise length calculation ensures full nut engagement, which is critical for every rating. Engineers must never compromise on safety and should consult official specifications when in doubt.

FAQ

What is the most common type of flange bolt?

ASTM A193 Grade B7 is the industry-standard bolt for carbon steel flanges. Engineers specify this high-strength, chrome-moly steel bolt for its reliability and performance in a wide range of general service applications, making it the default choice for most non-specialized piping systems.

Why are stud bolts preferred over machine bolts?

Engineers prefer stud bolts for through-bolted flanges. They allow for more accurate and even tensioning across the joint. This uniform load distribution ensures a more reliable seal. Machine bolts are typically reserved for tapped holes where a stud cannot pass through completely.

Can technicians reuse old flange bolts?

Warning: Reusing bolts is extremely risky. A bolt stretched beyond its limit (yielded) is permanently damaged and unsafe. Technicians must discard any bolt showing corrosion, thread damage, or deformation. When in doubt, always use new bolts to ensure joint integrity.

What happens if someone uses the wrong nut?

Using a low-strength nut with a high-strength bolt is dangerous. The nut’s threads can strip before the bolt reaches its required tension. This prevents a proper seal and can lead to catastrophic joint failure. Always use the specified nut grade, like A194 2H with A193 B7 bolts.

Why is bolt lubrication so important? ⚙️

Lubricant reduces friction during tightening. This ensures the applied torque correctly translates into bolt stretch (preload). Without it, torque readings are inaccurate, and the joint may not achieve the necessary clamping force for a proper seal, leading to potential leaks.

What does a flange’s “Class” rating mean?

The Class rating (e.g., Class 150, 300) indicates a flange’s pressure-temperature capability. A higher class number signifies a greater ability to withstand pressure. The rating is not a direct psi value; its pressure capacity decreases as the service temperature increases.

What is the difference between B7 and B7M bolts?

B7M bolts are for sour service (H2S). They have the same chemistry as B7 bolts but undergo a special heat treatment. This process lowers their hardness to prevent sulfide stress cracking, a critical failure mode in sour environments.