An excellent flange connection requires careful attention to detail. Selecting the correct flange bolt size and quantity is critical for ensuring a secure, leak-free seal. Improperly assembled bolted flange connections contribute to a significant portion of industrial fugitive emissions. The process to select flange bolt size involves three key factors: the flange standard (like ASME B16.5), its nominal pipe size (NPS), and its pressure class.

For a quick and reliable answer, a standard flange bolt chart is the most efficient tool. Engineers and technicians cross-reference the flange’s size and class on the chart. This action quickly identifies the required bolt quantity and the correct size of the bolt. This initial step prevents errors from the start, avoiding issues related to incorrect bolt casting or the need for custom fasteners from a custom fasteners manufacturer. A proper Flange Bolt selection is foundational to system integrity.

Step 1: Identify Your Flange Specifications

Before selecting any hardware, a technician must accurately identify the specifications of the flange in question. These details are the foundation for all subsequent calculations and selections. The three primary specifications are the Nominal Pipe Size (NPS), the pressure class, and the governing standard.

Finding the Nominal Pipe Size (NPS)

The Nominal Pipe Size dictates the bore dimension of the flange. It is a North American set of standard sizes for pipes used for high or low pressures and temperatures.

Locating Markings on the Flange Rim

Most manufacturers stamp or cast identifying marks directly onto the outer rim of the flange. An engineer can typically find the NPS indicated in one of the following formats:

NPS 4orNPS 4"4"(directly indicating a 4-inch size)

How to Measure an Unmarked Flange

If a flange is unmarked or the markings are illegible, a technician can determine the NPS by measuring the inner bore diameter.

Pro Tip 📏: Use a caliper to measure the inside diameter of the flange opening. This measurement will be slightly larger than the NPS. Round the measurement down to the nearest standard pipe size (e.g., a measurement of 4.5 inches corresponds to an NPS 4 flange).

Determining the Pressure Class

The pressure class rating defines the maximum pressure a flange can withstand at increasing temperatures.

Understanding Class Ratings (150, 300, 600, etc.)

ASME B16.5 specifies a set of pressure classes. A higher class number signifies a stronger flange capable of handling greater pressures. The standard classes are:

- Class 150

- Class 300

- Class 400

- Class 600

- Class 900

- Class 1500

- Class 2500

As operating temperature increases, the pressure capacity of any given flange decreases. For example, at 600°F, a Class 150 carbon steel flange can handle 140 psi, while a stronger Class 300 flange handles 570 psi. This demonstrates the importance of matching the class to both system pressure and temperature.

Where to Find the Class Stamp on the Flange

The pressure class is usually stamped on the flange rim, often appearing as “CL 150,” “150#,” or simply “150.” It is typically located near the NPS marking.

Identifying the Governing Flange Standard

Different international standards dictate flange dimensions, so identifying the correct one is crucial for compatibility.

The Role of ASME B16.5 in the US

In the United States, ASME B16.5 is the predominant standard for pipe flanges and flanged fittings. ANSI adopts this same standard, making ASME and ANSI flanges interchangeable.

Recognizing International Standards (DIN, EN 1092-1, JIS)

Global projects often involve different standards. JIS (Japanese), DIN (German/European), and ASME (American) flanges are not interchangeable due to differences in dimensions and pressure rating systems. A project manager must verify the correct standard to avoid procurement errors.

| Feature | JIS (Japanese) | ANSI/ASME (American) | DIN (German/European) |

|---|---|---|---|

| Pressure Rating | ‘K’ System (e.g., 10K) | ‘Class’ System (e.g., CL150) | ‘PN’ System (e.g., PN16) |

| Measurement Units | Metric (mm) | Imperial (inches) | Metric (mm) |

| Compatibility | Not interchangeable | Not interchangeable | Not interchangeable |

Step 2: Use a Flange Bolt Chart to Find Bolt Quantity and Diameter

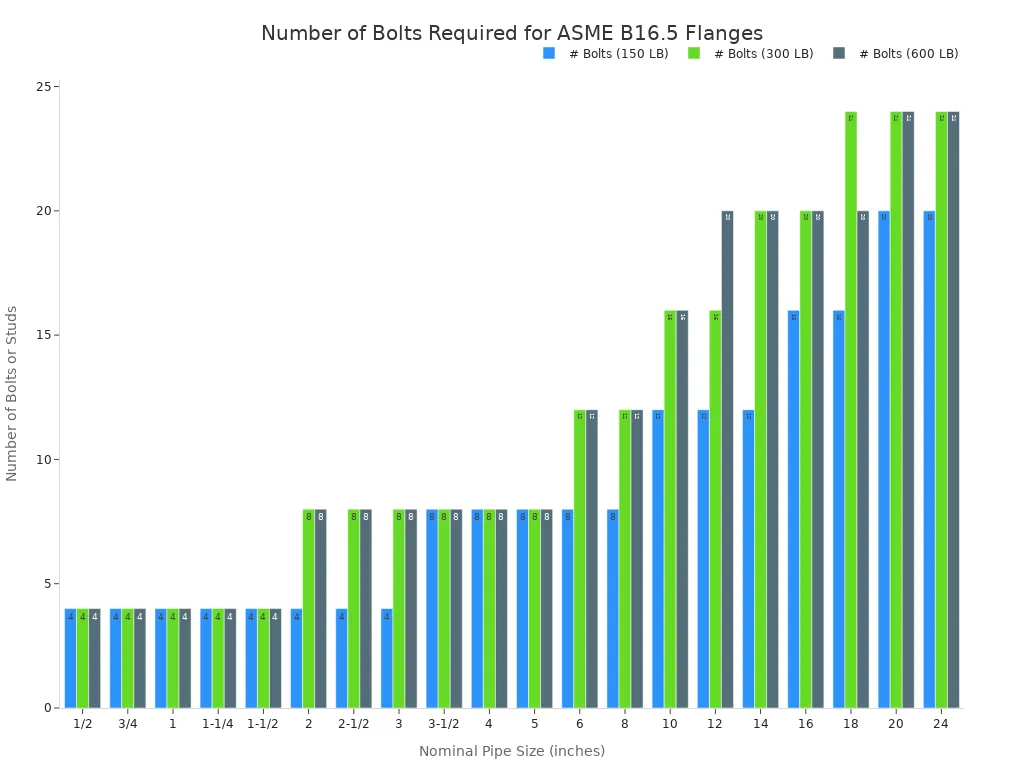

Once a technician identifies the flange specifications, the next step is to consult a standard flange bolt chart. These charts are indispensable engineering tools that consolidate critical data from standards like ASME B16.5. They eliminate guesswork and provide the definitive requirements for bolt quantity and diameter.

How to Read a Standard Flange Bolt Chart

A flange bolt chart organizes data to make finding information quick and efficient. Users read the chart by locating the intersection of their flange’s size and pressure class. Comprehensive charts, like those from suppliers such as Lightning Bolt and Supply, provide all the necessary data in one place.

Below is a partial ASME B16.5 flange bolt chart for common sizes.

| Nominal Pipe Size | 150 LB. Flanges (# Bolts) | 150 LB. Flanges (Dia of Bolts) | 300 LB. Flanges (# Bolts) | 300 LB. Flanges (Dia of Bolts) | 600 LB. Flanges (# Bolts) | 600 LB. Flanges (Dia of Bolts) |

|---|---|---|---|---|---|---|

| 1/2 | 4 | 0.50″ | 4 | 0.50″ | 4 | 0.50″ |

| 1 | 4 | 0.50″ | 4 | 0.63″ | 4 | 0.63″ |

| 2 | 4 | 0.63″ | 8 | 0.63″ | 8 | 0.63″ |

| 3 | 4 | 0.63″ | 8 | 0.75″ | 8 | 0.75″ |

| 4 | 8 | 0.63″ | 8 | 0.75″ | 8 | 0.88″ |

| 6 | 8 | 0.75″ | 12 | 0.75″ | 12 | 1.00″ |

| 8 | 8 | 0.75″ | 12 | 0.88″ | 12 | 1.13″ |

| 10 | 12 | 0.88″ | 16 | 1.00″ | 16 | 1.25″ |

| 12 | 12 | 0.88″ | 16 | 1.13″ | 20 | 1.25″ |

Cross-Referencing NPS and Pressure Class

The primary action involves two simple steps. First, locate the Nominal Pipe Size (NPS) for the target flange in the first column. Second, move horizontally across that row to the columns corresponding to the correct pressure class (e.g., 150 LB, 300 LB). The data in this intersecting section contains the required bolt specifications.

Locating the “Number of Bolts” Column

Within each pressure class grouping, a technician will find specific columns for each attribute. The column labeled “Number of Bolts” or “# of Studs” explicitly states the required bolt quantity for the connection. A standard chart typically includes columns for:

- Nominal Pipe Size

- Number of Studs

- Diameter of Studs (inches)

- Length of Stud – RF (inches)

- Wrench Size (inches)

Finding the “Diameter of Bolts” Column

Adjacent to the quantity column, an engineer will find the “Diameter of Bolts” or “Dia of Bolts” column. This specifies the required nominal bolt diameter. It is crucial to pay attention to the units.

Note on Units 📝: ASME charts primarily use the Imperial system (inches), while DIN or JIS charts use the Metric system (millimeters).

- Imperial (UNC/UNF): Diameter is in inches, often as a fraction (e.g., 5/8″). Thread is defined by Threads Per Inch (TPI).

- Metric (ISO): Diameter is in millimeters (e.g., M16). Thread is defined by pitch, the distance between threads.

Practical Example: A Class 150, NPS 4 Flange

Let’s apply this process to a common scenario: selecting bolts for a Class 150, NPS 4 flange.

Step-by-Step Chart Lookup Process

- Find the NPS Row: An engineer scans the first column of the flange bolt chart and locates the row for NPS

4. - Find the Pressure Class Columns: They then look across the top headers for the “150 LB. Flanges” section.

- Identify the Bolt Quantity: Following the NPS 4 row across to the “150 LB. Flanges (# Bolts)” column, they find the value

8. - Identify the Bolt Diameter: Moving to the next column, “150 LB. Flanges (Dia of Bolts),” they find the value

0.63". This decimal is the equivalent of 5/8 inch.

Interpreting the Results: 8 Bolts, 5/8″ Diameter

The chart lookup confirms that a Class 150, NPS 4 flange requires 8 bolts, each with a nominal bolt diameter of 5/8 inch. This result is non-negotiable for meeting the ASME B16.5 standard. The number of bolts required for a flange increases with both pipe size and pressure class to ensure a safe and robust seal under operational loads.

This chart lookup provides the first two critical pieces of information: the total number of bolts needed and the correct bolt diameter for each bolt hole. The next step is to calculate the proper length for each bolt.

Step 3: How to Calculate the Required Bolt Length

After determining the quantity and diameter, the next critical task is calculating the correct bolt length. A bolt that is too short will not achieve proper thread engagement, compromising the joint’s integrity. A bolt that is excessively long can create a safety hazard and interfere with nearby equipment. A precise calculation is essential for a secure and professional installation.

The Bolt Length Calculation Formula

Industry practice relies on a standardized formula to determine the required bolt length. This formula accounts for every component stacked between the two nuts.

Presenting the Formula: L = 2(T) + G + 2(N) + A

The standard formula for calculating the required stud bolt length (L) is as follows:

L = 2(T) + G + 2(N) + A

This calculation ensures the bolt is long enough to pass through both flanges and the gasket, with sufficient length for full nut engagement and a small protrusion.

Defining Each Variable (Flange Thickness, Gasket, Nut, Allowance)

Each variable in the formula represents a critical physical dimension of the flange assembly:

- L: The final calculated stud bolt length.

- T: The thickness of a single flange. The formula multiplies this by two to account for both flanges in the connection.

- G: The compressed thickness of the gasket used between the two flanges.

- N: The height of a single heavy hex nut. The formula multiplies this by two for the nuts on each end of the bolt.

- A: The protrusion allowance, which is the extra length needed for threads to extend beyond the nut face.

Gathering Your Measurements for the Formula

An engineer must gather accurate measurements for each variable to ensure a correct bolt length calculation.

Measuring Flange Thickness (T)

A technician can measure the flange thickness (T) using a caliper. The measurement is taken from the face of the flange (the surface that contacts the gasket) to its back face. This value is specified in standards like ASME B16.5, but physical verification is always a good practice.

Determining Gasket Thickness (G)

The gasket thickness (G) used in the formula is its compressed thickness, not its nominal (uninstalled) thickness. Gasket materials compress under load. For example, a spiral wound gasket with a nominal thickness of 4.45 mm might have a compressed thickness between 3.17 mm and 3.43 mm. A technician should consult the manufacturer’s data sheet for this specific value.

| Nominal Gasket Thickness | Typical Compressed Thickness |

|---|---|

| 3.20 mm (1/8″) | 2.40 – 2.60 mm |

| 4.45 mm (3/16″) | 3.17 – 3.43 mm |

| 6.35 mm (1/4″) | 4.60 – 4.80 mm |

Design Note 📝: For some non-asbestos sheet gaskets, designers may use a 3.2mm thickness in calculations as a conservative standard, even if a thinner 1.6mm gasket is ultimately installed.

Finding Standard Nut Height (N)

The nut height (N) corresponds to the bolt diameter. Heavy hex nuts, specified by ASME B18.2.2, are standard for flange bolting. An engineer can find the nut height on a standard dimensional chart. For example, a 3/4″ heavy hex nut has a nominal height of 47/64″ (approximately 0.73″).

Understanding Protrusion Allowance (A)

The protrusion allowance (A) ensures the bolt threads fully engage the nut. Industry best practice, guided by standards like ASME PCC-1, calls for the bolt to extend slightly beyond the outer face of the nut.

- General Rule: A good practice is to use the shortest standard length fastener that provides a minimum of one to three full threads protruding past the nut.

- ASME Standards: Standards like ASME B31.1 and B31.3 mandate that the bolt must extend completely through the nut. A lack of engagement by more than one thread is generally considered unacceptable.

- Tensioning Requirement: For applications using hydraulic bolt tensioning, the bolt should extend at least one bolt diameter beyond the nut on the tensioner side to accommodate the tool.

A common allowance is approximately 1/4″ (6 mm), which typically provides the necessary two to three threads of protrusion.

Calculation Example in Action

Let’s calculate the required bolt length for a Class 300, NPS 6 raised face flange. From the bolt chart, we know this connection requires 12 bolts with a 3/4″ diameter.

Assigning Values to Each Variable

An engineer gathers the following specifications for the calculation:

- Flange Thickness (T): A Class 300, NPS 6 flange has a thickness of 1.44 inches.

- Gasket Thickness (G): A standard 1/16″ raised face uses a spiral wound gasket with a compressed thickness of approximately 0.13 inches.

- Nut Height (N): A standard 3/4″ heavy hex nut has a height of 0.73 inches.

- Protrusion Allowance (A): A standard allowance of 0.25 inches is selected for adequate thread engagement.

Executing the Step-by-Step Calculation

The technician now inputs these values into the bolt length formula:

- Formula:

L = 2(T) + G + 2(N) + A - Substitute Values:

L = 2(1.44") + 0.13" + 2(0.73") + 0.25" - Calculate Each Part:

2 * 1.44" = 2.88"2 * 0.73" = 1.46"

- Sum the Values:

L = 2.88" + 0.13" + 1.46" + 0.25" - Final Calculated Length:

L = 4.72 inches

The calculated bolt length is 4.72 inches. The next step involves rounding this value up to the nearest standard bolt length, which would be 4.75 inches (4 3/4″). This confirms the standard bolt length often listed in reference charts for this specific application.

Step 4: How to Select Flange Bolt Size and Finalize Length

After calculating the theoretical bolt length, a technician must finalize the specifications for procurement. This step involves converting the calculated dimension into a standard, available product and verifying its compatibility with the flange. The process to select flange bolt size correctly includes rounding the length and confirming hole clearance.

Rounding to the Nearest Standard Length

Manufacturers produce bolts in standard, incremental lengths. A calculated length like 4.72 inches is not an off-the-shelf item. The technician must round this value to a practical, standard size.

Why Rounding Up is Standard Practice

Rounding the calculated bolt length up to the next standard size is a critical safety practice.

- Ensures Full Engagement: Rounding up guarantees the bolt is long enough for the nut to achieve full thread engagement, a primary requirement for joint strength.

- Avoids Short Bolts: A bolt that is too short is unusable and compromises the integrity of the connection.

- Procurement Efficiency: Specifying standard lengths simplifies purchasing and ensures parts are readily available.

Safety First ⚠️: Always round the calculated bolt length up, never down. A slightly longer bolt is acceptable; a bolt that is too short is a failure point.

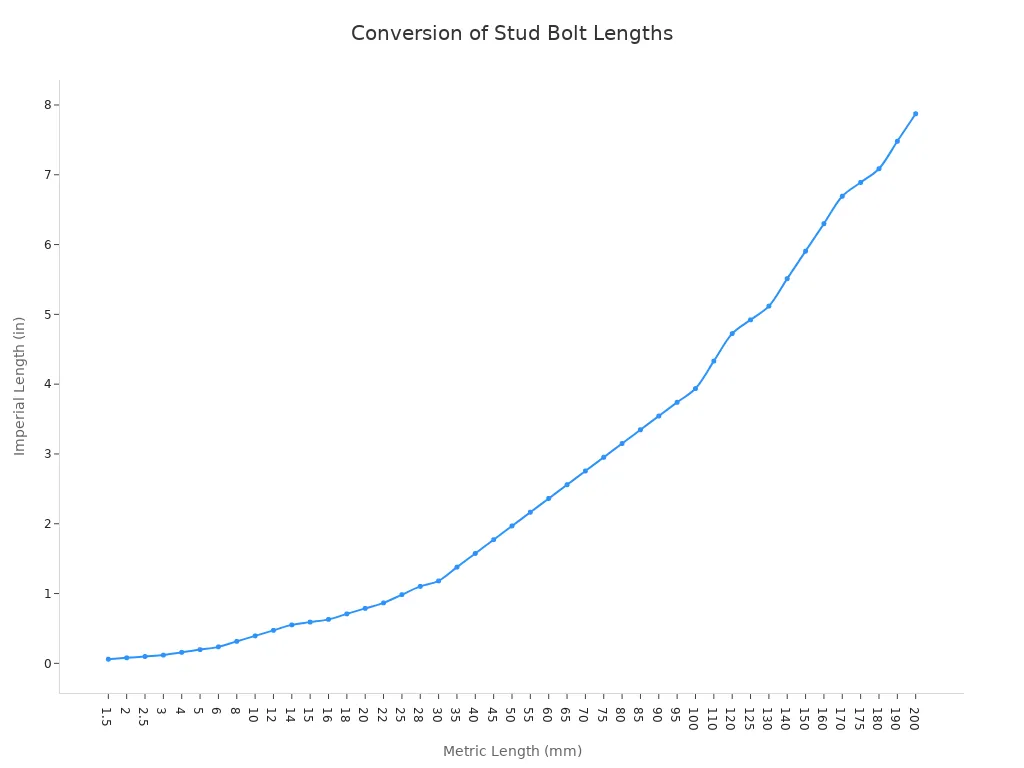

Common Imperial and Metric Standard Bolt Lengths

Standard bolt lengths typically increase in 1/4-inch increments for Imperial sizes and 5 mm or 10 mm increments for metric sizes. The following table shows common standard lengths and their metric equivalents.

| Metric (mm) | Inches (in.) | Closest Fraction* |

|---|---|---|

| 70 mm | 2.7559 in. | 2-3/4″ |

| 75 mm | 2.9528 in. | 2-15/16″ |

| 80 mm | 3.1496 in. | 3-1/8″ |

| 90 mm | 3.5433 in. | 3-1/2″ |

| 100 mm | 3.9370 in. | 3-15/16″ |

| 110 mm | 4.3307 in. | 4-5/16″ |

| 120 mm | 4.7244 in. | 4-3/4″ |

| 125 mm | 4.9213 in. | 5″ |

| 130 mm | 5.1181 in. | 5-1/8″ |

| 140 mm | 5.5118 in. | 5-1/2″ |

| 150 mm | 5.9055 in. | 6″ |

*Fractions are approximations—rounded for common tool and fastener use.

Verifying Bolt Hole Diameter vs. Bolt Diameter

The final check before procurement is to confirm the selected bolt diameter is correct for the bolt holes in the flange. This ensures a proper fit during assembly.

Understanding Clearance Requirements

Bolt holes are intentionally drilled larger than the bolt diameter. This clearance is essential for several reasons:

- It allows the bolt to be inserted easily without binding.

- It accommodates minor misalignments between the two flanges.

- It helps maintain sufficient material thickness in the flange, preventing bolt pull-through under high pressure.

Checking Chart Specifications for Hole Size

ASME B16.5 tables specify both the required bolt diameter and the corresponding hole diameter. A quick review of these specifications confirms compatibility. As a general rule, the bolt hole is typically 1/8 inch (3 mm) larger than the nominal bolt diameter. For example, a flange requiring a 3/4″ diameter bolt will have a bolt hole diameter of 7/8″. This clearance is a non-negotiable design feature. Any flange with a bolt hole smaller than the specified bolt would be rejected, as assembly would be impossible. This final verification helps an engineer confidently select flange bolt size and length.

Step 5: How to Select the Right Type of Bolt for Your Application

Beyond diameter and length, an engineer must select the right type of bolt for the job. The two primary options for flange connections are stud bolts and machine (hex) bolts. The choice depends on the application’s pressure, temperature, and flange type. This decision is a key part of the overall process to select flange bolt size and hardware.

Stud Bolts vs. Machine (Hex) Bolts

Stud bolts and machine bolts serve different purposes. A stud bolt is a fully threaded rod with two nuts, while a machine bolt has a pre-formed head and uses one nut.

When to Use Fully-Threaded Stud Bolts

Technicians prefer fully-threaded stud bolts for most critical piping applications, especially in high-pressure and high-temperature services. Their design offers significant mechanical advantages.

- Superior Strength: A stud bolt provides better load distribution across the flange joint compared to a headed bolt.

- Even Clamping: The use of two nuts allows for more precise and even tensioning, which is crucial for achieving a reliable seal.

- High-Stress Applications: Engineers specify stud bolts for demanding environments where joint integrity is paramount.

Pro Tip ⚙️: Stud bolts are the standard choice for raised face flanges in process industries like oil and gas, chemical processing, and power generation.

Common Applications for Machine (Hex) Bolts

Machine bolts, or hex bolts, are more common in general-purpose structural applications and low-pressure utility services. While a strong fastener, this type of bolt is less ideal for the high stresses found in many industrial flange connections. Their single-headed design provides less effective load distribution. A technician might use a machine bolt on low-pressure, flat-faced water lines but would avoid it for high-pressure steam systems.

Raised Face (RF) vs. Flat Face (FF) Flange Considerations

The design of the flange face directly impacts bolting requirements. The two most common types are Raised Face (RF) and Flat Face (FF).

Bolting Requirements for Raised Face Flanges

A Raised Face (RF) flange concentrates the clamping force onto a smaller gasket area, creating a higher-stress seal. This design requires a robust bolt that can handle the significant tension. High-strength stud bolts (like ASTM A193 B7) are the standard pairing for RF flanges to ensure the joint can withstand the high gasket seating stress without failure.

Bolting Requirements for Flat Face Flanges

A Flat Face (FF) flange has a gasket surface that is level with the bolting circle face. These are used in lower-pressure applications, often with brittle gaskets (like cast iron). The threading requirement for bolts in this setup is less demanding. The primary concern is to apply even pressure without cracking the flange. The overall threading must be clean and undamaged to ensure smooth nut rotation and accurate torque application. The procedure to select flange bolt size for an FF flange must prevent over-stressing the joint.

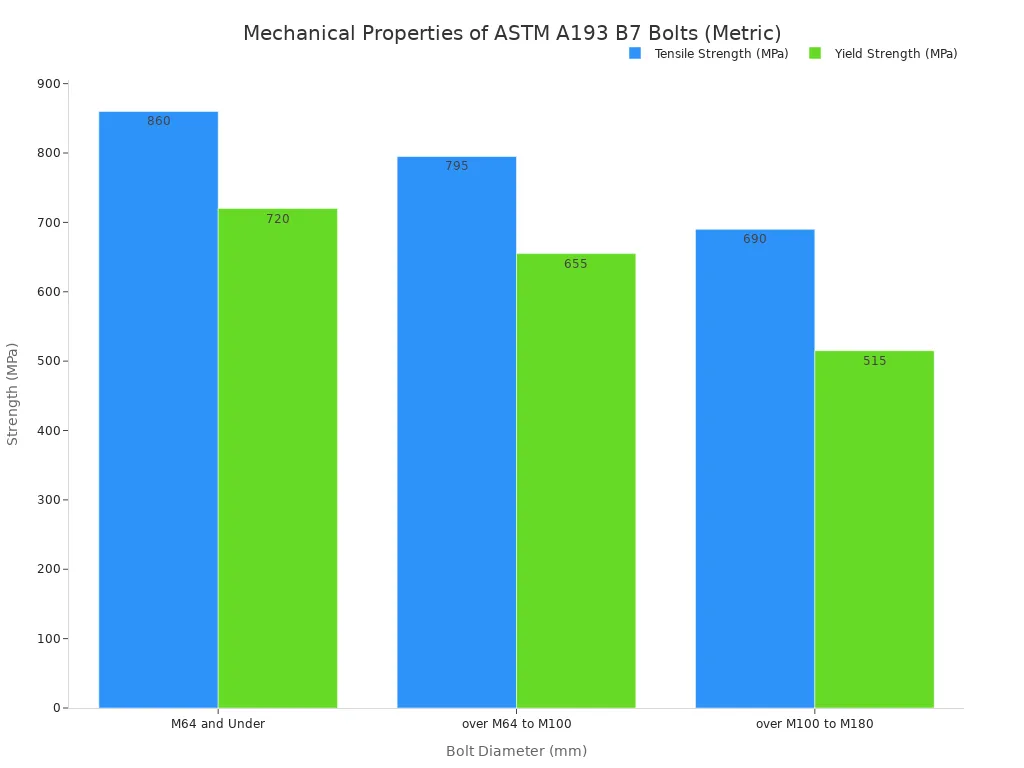

Step 6: Select the Correct Bolt and Nut Material

Selecting the correct material is the final, crucial step in the specification process. The material determines a bolt’s strength, corrosion resistance, and temperature limits. ASTM standards provide clear recommendations for various service conditions, ensuring reliability and safety.

Common Bolt Material Grades (ASTM)

ASTM International provides specifications for a wide range of fastener materials. An engineer selects a grade based on the application’s pressure, temperature, and chemical exposure.

Carbon Steel: ASTM A193 B7

ASTM A193 B7 is the most common specification for heavy hex bolts and studs in the oil and gas industry. This heat-treated chromium-molybdenum steel offers high strength and good performance in moderate-temperature applications. A B7 bolt maintains its integrity in conditions typically below 750°F (400°C). It has a minimum tensile strength of 125 ksi and a minimum yield strength of 105 ksi for diameters up to 2.5 inches.

Stainless Steel: ASTM A193 B8/B8M

For applications requiring corrosion resistance, stainless steel is the preferred choice. The primary distinction between Grade B8 and B8M lies in their material composition and performance.

| Feature | ASTM A193 B8 Bolts | ASTM A193 B8M Bolts |

|---|---|---|

| Material | AISI 304 Stainless Steel | AISI 316 Stainless Steel |

| Key Additive | None | Molybdenum |

| Corrosion Resistance | General | Superior, especially against pitting |

| Environment | Outdoor, damp | Seawater, chemical processing |

The molybdenum in B8M provides superior protection against chlorides and other corrosive agents, making it ideal for marine and chemical plant environments.

Low-Temperature Alloys: ASTM A320 L7

For cryogenic and low-temperature services, ASTM A320 L7 is the standard. This alloy steel is specifically designed to remain ductile at temperatures as low as -150°F (-101°C), passing a Charpy impact test at that temperature. This property prevents the bolt from becoming brittle and failing in cold environments.

Matching Materials to Service Conditions

An engineer must match the fastener material directly to the system’s operational demands.

Material Selection for High-Temperature Service

While A193 B7 is suitable for many applications, services exceeding 800°F (427°C) require different material recommendations. ASTM A193 B16, a chromium-molybdenum-vanadium alloy, is frequently used for temperatures up to 1000°F (538°C). Materials not stress-rupture tested for these high temperatures must be permanently marked “NR”.

Material Selection for Corrosive Environments

In highly corrosive environments, such as chemical processing plants, the entire joint system must be considered. An ASTM A193 B8M bolt is an excellent choice. Engineers often pair it with a PTFE (Teflon) gasket, which offers near-universal chemical inertness against strong acids and solvents.

Nut and Washer Material Compatibility

A fastener assembly is only as strong as its weakest component. Proper nut and washer selection is non-negotiable.

The ASTM A194 2H Heavy Hex Nut Standard

Technicians must pair ASTM A193 B7 bolts with ASTM A194 2H heavy hex nuts. These nuts are heat-treated to a strength level that matches or exceeds the bolt. This strength matching ensures that if the joint is over-torqued, the bolt will break before the threading strips, providing a safer failure mode. The heavy hex design also provides a larger bearing surface for better load distribution.

Ensuring Proper Hardened Washer Selection (ASTM F436)

Hardened washers, specified by ASTM F436, are essential for distributing the clamp load and preventing galling, especially during high-torque tightening. When using stainless steel fasteners, it is critical to use washers of a compatible material (e.g., a 316 stainless steel washer with a B8M bolt) to prevent galvanic corrosion and maintain joint integrity.

A technician achieves a secure and leak-free flange joint by following a systematic process. This involves identifying the flange, determining the correct bolt quantity, and selecting the right bolt type and material. Proper installation is non-negotiable for operational safety and system integrity. For a successful installation, an engineer must always verify their work against project specifications and standard installation guidelines.

FAQ

What happens if I use the wrong number of bolts?

Using fewer bolts than specified creates uneven pressure on the gasket. This condition leads to dangerous leaks and potential joint failure. A technician must always use the quantity listed in the standard flange bolt chart to ensure a safe, reliable seal.

Can I reuse old flange bolts?

Best Practice 💡: A technician should not reuse flange bolts in critical service. Used bolts can suffer from thread damage or stretching (yield). This compromises their clamping force and reliability. New fasteners ensure a safe and predictable connection.

What does “torque sequence” mean?

Torque sequence is the star or crisscross pattern a technician uses to tighten nuts. This method applies pressure evenly across the flange face. It ensures a proper gasket seal and prevents flange distortion or damage during assembly.

Why are stud bolts preferred for high-pressure service?

Stud bolts allow for more accurate tensioning and distribute the clamp load more evenly than headed bolts. This design provides a stronger, more reliable joint. Engineers specify them for high-pressure and high-temperature applications where joint integrity is paramount.

Do I need to lubricate flange bolts before installation?

Yes, a technician should apply a proper lubricant to bolt threads and nut faces. Lubrication reduces friction during tightening. This practice ensures the applied torque translates into accurate bolt tension, which is essential for achieving a reliable seal.

What is the difference between a Class 150 and a 150# flange?

There is no difference. The terms “Class 150,” “150#,” and “150 LB” all refer to the same pressure class rating under the ASME/ANSI standard. They are interchangeable terms that a technician will see stamped on a flange rim.

How do I convert a bolt diameter from decimal to a fraction?

A technician can convert a decimal to a fraction by multiplying it by the desired denominator. For example, to convert a 0.75″ diameter to 16ths:

0.75 * 16 = 12- The result is

12/16", which simplifies to3/4".