A 2 inch 3-bolt exhaust flange is a crucial mechanical connector. It joins two sections of 2-inch diameter exhaust pipe. The 2 inch 3-bolt exhaust flange utilizes a triangular pattern for a strong, serviceable joint. A quality Flange Bolt and bolt casting are essential. Sometimes, a custom fasteners manufacturer provides specialized custom fasteners for unique applications. The core function of the 2 inch 3-bolt exhaust flange is to form a leak-proof seal between components. This ensures the exhaust system properly routes gases.

Did You Know? Faulty exhaust gaskets, which work with the 2 inch 3-bolt exhaust flange, account for 32% of emission test failures in light-duty vehicles and 41% in diesel trucks.

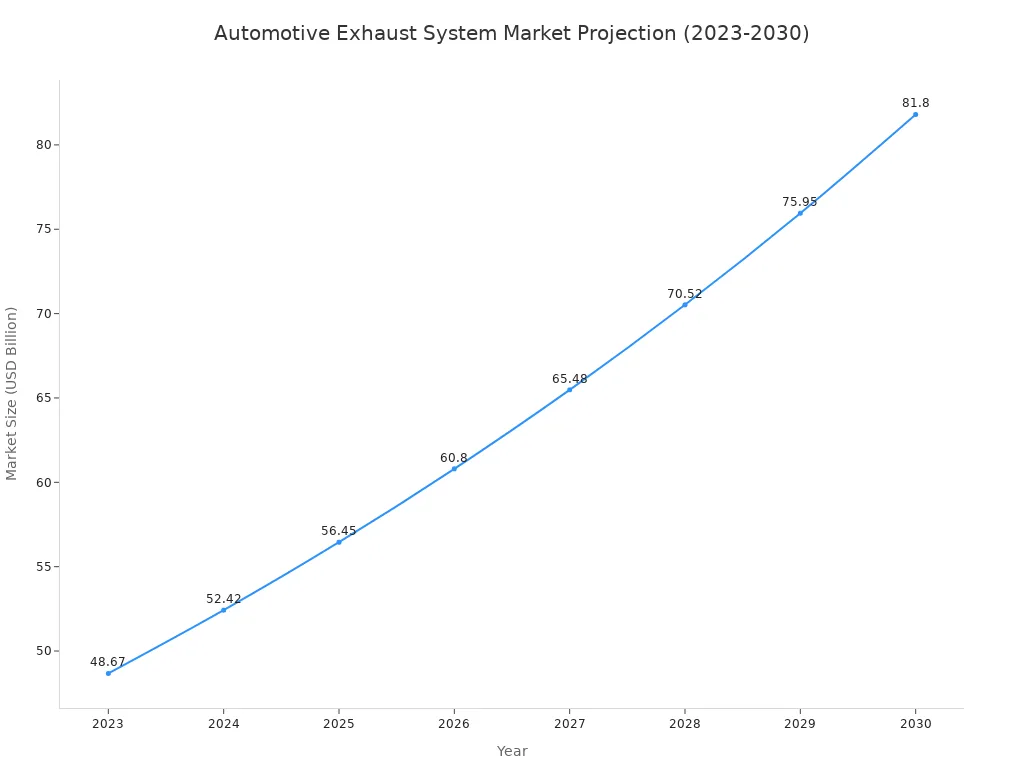

The market for these and other exhaust components is expanding significantly, reflecting their importance in vehicle maintenance and performance. The 2 inch 3-bolt exhaust flange remains a key part of this growing industry.

What is a 2 Inch 3-Bolt Exhaust Flange?

A 2 inch 3-bolt exhaust flange is more than just a piece of metal; it is an engineered component with specific characteristics. Its name directly communicates its primary specifications, while its physical features determine its function and application within an exhaust system. Understanding these details is essential for proper selection and installation.

Deconstructing the Name

The name itself provides the most important details about the component’s size and design. Each part of the name has a distinct meaning.

The “2 Inch” Pipe Diameter Specification

The “2 inch” measurement refers to the nominal inner diameter of the exhaust pipe the flange is designed to connect. This specification guides technicians and DIYers in matching the flange to the correct pipe size. A proper fit is the first step toward creating a secure, leak-free exhaust system. Using a 2 inch 3-bolt exhaust flange with a different pipe size will result in a poor connection and likely lead to performance issues.

The “3-Bolt” Triangular Configuration

The “3-bolt” designation describes the fastening method. This exhaust flange features three holes arranged in a triangular pattern. This design is not arbitrary; it allows for even distribution of clamping pressure across the sealing surface when the flange bolts are tightened. This balanced force is critical for compressing the gasket evenly and preventing exhaust gas leaks. The triangular layout provides a strong, stable joint that can withstand engine vibration.

Key Anatomical Features

Beyond its name, the physical anatomy of a 2 inch 3-bolt exhaust flange dictates how it performs. Several key features define its role and compatibility.

The Flange Face and Sealing Surface

The flange face is the flat, machined surface that makes contact with another flange or exhaust component. This is the primary sealing surface. For a gas-tight seal, this face must be perfectly flat, smooth, and clean. Any warping, corrosion, or debris on the flange face can compromise the gasket’s ability to seal, resulting in a leak.

Bolt Holes and Bolt Circle Diameter (BCD)

The three bolt holes must align perfectly with the corresponding component. The spacing of these holes is standardized by a measurement known as the Bolt Circle Diameter (BCD).

Tech Tip: 🔧 The BCD is the diameter of an imaginary circle that runs through the center of all the bolt holes. When sourcing a replacement 2 inch 3-bolt exhaust flange, verifying the BCD is just as important as confirming the pipe diameter to ensure a direct fit.

Pipe Connection Style (Weld-on vs. Slip-fit)

An exhaust flange connects to a pipe in one of two primary ways: by welding or by slipping over the pipe. Each style has distinct advantages and is chosen based on performance needs, cost, and ease of installation.

- Weld-on (or Weld-Neck) Flanges: These are welded directly to the end of the exhaust pipe, creating a permanent and very strong bond.

- Slip-fit (or Slip-on) Flanges: These flanges slide over the outside of the pipe and are typically welded in place around the perimeter.

The choice between these styles impacts the system’s durability and flow characteristics.

| Feature | Slip-fit Flanges | Weld-on Flanges |

|---|---|---|

| Structural Integrity | Lower; relies on fillet welds which can concentrate stress. | Higher; features a tapered hub for better stress distribution. |

| Installation | Faster and easier fit-up; less sensitive to pipe length. | Slower; requires precise pipe preparation and alignment. |

| Initial Cost | Generally lower due to simpler manufacturing and faster labor. | Higher due to more complex forging and skilled welding needs. |

| Vibration Resistance | More prone to fatigue cracking under heavy vibration. | Superior resistance to vibration and thermal cycling. |

| Flow Dynamics | Can create some turbulence at the connection point. | Provides a smoother internal transition, reducing turbulence. |

Weld-on flanges offer superior structural robustness and better fatigue resistance, making them ideal for high-performance or heavy-duty applications where vibration and heat are extreme. The continuous stress transfer through their tapered hub makes them the preferred flange for critical systems. In contrast, slip-fit flanges offer a faster installation and lower upfront cost. This makes them a popular choice for standard repairs and systems where cyclic stress is less of a concern. The decision between them involves a trade-off between installation speed and long-term structural durability.

Core Functions of an Exhaust Flange

An exhaust flange is a small but mighty component in a vehicle’s exhaust system. Its design allows it to perform three critical functions: sealing harmful gases, providing structural support, and simplifying maintenance. A 2 inch 3 bolt exhaust flange executes these roles with a specific geometry tailored for 2-inch piping, ensuring the entire exhaust system operates safely and efficiently.

Ensuring a Gas-Tight Seal

The primary and most critical function of any exhaust flange is to create a perfect seal between two connecting parts of the exhaust system. This seal is vital for both safety and engine performance.

Preventing Toxic Exhaust Gas Leaks

An engine’s combustion process produces hazardous gases, including carbon monoxide (CO) and nitrogen oxides (NOx). The exhaust system directs these gases away from the vehicle cabin and through the catalytic converter for treatment. A 2 inch 3 bolt exhaust flange, when properly installed with a gasket, creates a tight seal that prevents these toxic fumes from leaking.

Safety First! ⚠️ Even small exhaust leaks can allow dangerous gases to enter the passenger compartment, posing a serious health risk. The EPA sets strict limits on vehicle emissions to protect air quality. For instance, under Tier 3 standards, a common passenger car might be certified to a bin that limits CO emissions to 1.7 grams per mile. A leak bypasses the entire emission control system, releasing untreated pollutants.

A secure 2 inch 3 bolt exhaust flange ensures the vehicle complies with these standards and protects its occupants.

Maintaining Backpressure and Performance

A leak-proof exhaust system is essential for optimal engine performance. The 2 inch 3 bolt exhaust flange helps maintain the engineered backpressure and exhaust flow velocity. While excessive backpressure harms an engine, a well-designed exhaust system uses exhaust flow dynamics to help scavenge, or pull, spent gases from the cylinders.

Exhaust leaks disrupt this delicate balance. A leak changes the pressure within the system, which can reduce exhaust flow velocity and hurt the scavenging effect. This leads to reduced engine efficiency, lower horsepower, and poor fuel economy. Maintaining a tight seal with a quality exhaust flange ensures the exhaust flow remains consistent, allowing the engine to breathe efficiently and deliver its intended power.

Providing a Strong Structural Connection

The exhaust system endures constant stress from engine vibration and road impacts. The exhaust flange provides a robust connection point that can withstand these forces.

Resisting Engine Vibration and Road Stress

An engine produces significant vibrations, with frequencies often occurring at multiples of the ignition frequency (e.g., 11.33 Hz, 22.66 Hz, and 34 Hz at idle). These vibrations travel down the entire length of the exhaust system. The 2 inch 3 bolt exhaust flange, with its triangular bolt pattern, distributes clamping force evenly. This creates a rigid joint that resists loosening and fatigue from constant shaking and jarring from uneven road surfaces.

Securely Joining Exhaust Components

From the manifold to the muffler, an exhaust system is a series of connected pipes and components. The 2 inch 3 bolt exhaust flange serves as a key structural link, securely fastening these parts together. Whether connecting a catalytic converter to a mid-pipe or a resonator to an axle-back section, the flange ensures the components remain aligned and fixed. This structural integrity prevents sagging, rattling, and premature failure of hangers and other mounting hardware.

Facilitating Maintenance and Upgrades

While creating a strong, permanent-feeling connection, the exhaust flange also makes the exhaust system modular. This design greatly simplifies repairs and modifications.

Allowing for Easy Component Removal

When an exhaust component like a catalytic converter or muffler fails, it needs to be replaced. A bolted exhaust flange connection allows a technician to simply unbolt the failed part and remove it without cutting any pipes. This modularity saves significant time and labor costs compared to a fully welded exhaust system. The 2 inch 3 bolt exhaust flange makes servicing the exhaust system far more manageable.

Simplifying Aftermarket Part Installation

For enthusiasts seeking a performance improvement, the 2 inch 3 bolt exhaust flange is a gateway to upgrades. Most aftermarket exhaust systems, such as cat-back or axle-back kits, are designed to be direct bolt-on replacements. They use flanges that match the factory locations and specifications. This simplifies the installation process, often allowing a DIYer with basic tools to upgrade their vehicle’s sound and flow in their own garage. This ease of installation is a major reason for the popularity of aftermarket exhaust modifications.

Common Styles of the 3-Bolt Exhaust Flange

Not all 3-bolt exhaust flanges are created equal. Manufacturers produce several distinct styles to meet various performance, durability, and installation requirements. Understanding these common designs helps technicians and enthusiasts select the correct 2 inch 3 bolt exhaust flange for a specific application. Each style uses a unique method to achieve a reliable connection.

Flat-Faced Flanges

The flat-faced flange is the most straightforward and common design for a 2 inch 3 bolt exhaust flange. Its simplicity makes it a cost-effective and widely used solution.

Design and Sealing Mechanism

This exhaust flange features a completely flat sealing surface. It creates a connection by compressing a gasket between its face and the face of a mating flange. The effectiveness of this design depends heavily on the surface finish. An ideal flange face is not perfectly smooth; it has a controlled roughness that helps the gasket grip and prevent slippage.

| Sealing Face Type | Typical Roughness (Ra, μm) | Application & Characteristics |

|---|---|---|

| Flat Face (FF) | 3.2 – 6.3 | Common in general exhaust piping; slightly rough surfaces increase gasket grip. |

| Ring Joint (RJ) | 1.6 – 3.2 | High-pressure services; requires precise flatness for metallic ring gaskets. |

Typical Applications and Gasket Needs

Flat-faced flanges are prevalent in both original equipment and aftermarket exhaust systems. They require a full-face gasket that covers the entire surface to function correctly. Many popular American performance vehicles utilize this type of 2 inch 3 bolt exhaust flange.

- LT1 and LS1 exhaust manifold systems

- C5 Corvette LS1 exhaust

- 5.3/6.0L Chevy/GMC truck exhaust

- GM F-Body (Camaro/Firebird) LS1 exhaust

Ring-Style Flanges

A ring-style exhaust flange is an evolution of the flat-faced design. It incorporates a specific feature to improve sealing performance under demanding conditions.

Design Featuring a Raised or Recessed Ring

This flange design includes a machined ring on its sealing face. The ring can be raised from the surface or, in some specialized cases, recessed into the flange. For example, a high-performance 2 inch 3 bolt exhaust flange might feature an integrated recessed “Fire Ring” with a specific outer diameter to ensure a perfect fit and seal. The back of this flange is often tapered to accommodate the exhaust pipe smoothly.

How the Ring Enhances Sealing

The ring is a critical feature for performance. A raised ring concentrates the clamping force from the bolts onto a smaller surface area. This concentration of force significantly increases the sealing pressure on the gasket, creating a more robust and reliable connection that is less prone to leaks.

Ball and Socket Flanges

The ball and socket flange offers a unique solution for systems that require movement. This design consists of two distinct, interlocking parts.

The Male (Ball) and Female (Socket) Design

This 2 inch 3 bolt exhaust flange system uses a convex, ball-shaped “male” flange that fits into a concave, socket-like “female” flange. A gasket, often a donut-style graphite or composite ring, sits between them. When bolted together, the two halves create a strong yet flexible joint.

Allowing for Flex and Misalignment

The primary advantage of this flange is its ability to accommodate movement and imperfect alignment. The ball-and-socket joint allows for a significant degree of angular adjustment, often up to ±10 degrees. This flexibility is essential for absorbing engine vibrations and thermal expansion, preventing stress from cracking welds or other components in the exhaust system.

Understanding Exhaust Flange Materials

The material of a 2 inch 3 bolt exhaust flange directly impacts its durability, cost, and performance. Manufacturers select materials based on a balance of these factors. Choosing the right material is critical for ensuring a long-lasting and effective repair or upgrade for your exhaust system.

Mild Steel

Mild steel is a common and traditional choice for many original equipment and budget-friendly aftermarket exhaust components.

Benefits: Cost-Effectiveness and Malleability

The primary advantage of mild steel is its low cost. This makes it an attractive option for inexpensive repairs. Technicians also find it easy to work with. Its malleability allows for simple shaping and welding, which can reduce labor time during custom fabrications.

Drawbacks: Prone to Rust and Corrosion

Mild steel’s main weakness is its susceptibility to rust. Exposure to moisture, road salt, and heat cycles causes it to corrode quickly. This corrosion weakens the flange, leading to exhaust leaks and eventual failure. While inexpensive upfront, a mild steel flange often has a significantly shorter lifespan and may require replacement much sooner than other options.

Stainless Steel

Stainless steel is the premium material for exhaust components, offering a significant upgrade in longevity and performance. It comes in several grades, with T304 and T409 being the most common.

T304 vs. T409 Grade Differences

The key difference between these grades lies in their chemical composition, specifically their chromium and nickel content. T304 contains more of both elements, giving it superior corrosion resistance.

| Element | T304 Stainless Steel | T409 Stainless Steel |

|---|---|---|

| Chromium | 18% to 20% | 10.50% to 11.75% |

| Nickel | 8% to 10% | 0.50% |

T409 is a ferritic stainless steel that offers good corrosion resistance and is often used by OEMs. T304 is an austenitic, aircraft-quality grade that provides the best protection against rust.

Benefits: Durability and Corrosion Resistance

Stainless steel’s main benefit is its exceptional resistance to rust and corrosion. An exhaust flange made from T409 stainless steel can last for nearly a decade. A high-quality T304 stainless steel component will likely outlast the vehicle itself, even in harsh climates with road salt. This durability makes it a wise long-term investment for any exhaust system.

Aluminum

Aluminum is a specialty material typically reserved for specific high-performance applications where every ounce matters.

Benefits: Lightweight for Performance Builds

The most significant advantage of aluminum is its light weight. In racing and performance builds, reducing vehicle mass is a top priority for improving handling and acceleration. An aluminum flange can offer substantial weight savings compared to steel.

Drawbacks: Lower Melting Point and Cost

Aluminum has two major drawbacks for exhaust use: a lower melting point and higher cost. It cannot withstand the extreme temperatures found near the engine.

Tech Tip: 🌡️ Aluminum’s melting point is significantly lower than steel’s, making it unsuitable for components like headers or downpipes. It is best used further down the exhaust path where temperatures are lower.

| Material | Melting Onset (°C) | Melting Completion (°C) |

|---|---|---|

| 6061 Aluminum | 580 | 650 |

| AISI 304 Stainless Steel | 1400 | 1450 |

This limitation, combined with its higher material cost, restricts its use to specialized, weight-sensitive projects.

How to Select the Right 2 Inch 3-Bolt Exhaust Flange

Selecting the correct 2 inch 3 bolt exhaust flange is a process that demands precision. A mistake in measurement or material choice can lead to installation problems, exhaust leaks, and premature component failure. Following a systematic, three-step approach ensures a perfect fit and a durable, long-lasting repair.

Step 1: Confirm Your Exhaust Pipe Diameter

The first and most fundamental step is to verify the diameter of the exhaust pipe. The “2 inch” designation on an exhaust flange refers to the pipe it is designed to fit, making this measurement non-negotiable for a proper connection.

Using Digital Calipers for Precision

For the most accurate measurement, technicians use digital calipers. This tool provides a precise reading of the pipe’s outer diameter (OD).

- Ensure the pipe end is clean and free of rust or burrs.

- Open the jaws of the calipers and place them around the outside of the pipe.

- Close the jaws until they make firm contact with the pipe’s surface.

- Read the measurement displayed on the digital screen.

A pipe intended for a 2 inch 3 bolt exhaust flange should have an OD that corresponds to that nominal size.

Checking OEM or Aftermarket Part Specs

If direct measurement is not feasible, one can find the pipe diameter by consulting the vehicle’s service manual or the specifications for the existing aftermarket exhaust system. Manufacturers list these details in their product documentation. This method is reliable for stock systems or for identifying the specifications of a previously installed aftermarket kit.

Step 2: Verify the Bolt Pattern and Spacing

Simply finding a flange with three holes is not enough. The spacing of these holes must match the mating component perfectly. This is a common point of error for many DIY repairs.

Measuring Center-to-Center Bolt Hole Distance

The most reliable way to confirm the bolt pattern is to measure the distance from the center of one bolt hole to the center of another. On a triangular 2 inch 3 bolt exhaust flange, all three of these measurements should be identical.

Tech Tip: 📏 Use a ruler or calipers to measure from the center of one hole to the center of an adjacent hole. Record this dimension and compare it to the technical specifications of the new flange you intend to purchase.

Comparing with Technical Diagrams

Exhaust flanges are not standardized across the automotive industry in the same way as other industrial components. Manufacturers often use proprietary designs. For example, companies like Caterpillar and Detroit Diesel utilize their own unique bolt layouts for their engines. For this reason, a technician must always cross-reference the bolt pattern with the Automotive/OEM specification for the specific vehicle model to ensure the new exhaust flange will fit.

For exact drilling dimensions, consulting technical resources is the best practice. Detailed CAD drawings and specification tables, such as those available from suppliers like API International, provide the precise measurements needed to confirm a flange is correct before purchase. This step prevents the costly mistake of ordering an incompatible part.

Step 3: Choose the Appropriate Material

The final decision involves selecting the material for the new 2 inch 3 bolt exhaust flange. This choice affects the part’s lifespan, corrosion resistance, and overall cost.

Matching Material to Your Exhaust System

The best practice is to match the flange material to the material of the connecting exhaust pipe. Using a flange material different from the pipe material can lead to a serious issue known as galvanic corrosion. This electrochemical process is most severe at the weld connecting the two dissimilar metals, such as a stainless steel flange on a carbon steel pipe. The presence of a conducting medium like road salt dissolved in water significantly accelerates this corrosion. While a gasket can protect the flange faces, the critical weld area remains vulnerable. Therefore, welding a stainless steel flange to a stainless steel pipe is the ideal scenario for maximum longevity.

Balancing Budget Against Longevity Needs

The choice of material often comes down to a trade-off between initial cost and long-term durability.

- Mild Steel: A mild steel flange offers the lowest upfront cost, making it a popular choice for budget-conscious repairs. However, its poor corrosion resistance means it will likely fail much sooner, especially in regions with harsh winters.

- Stainless Steel: A stainless steel exhaust flange costs more initially but provides superior resistance to rust and heat. This makes it a smart investment, as it will outlast its mild steel counterpart by many years, saving money on future labor and parts.

Ultimately, a technician or vehicle owner must weigh the immediate savings of a cheaper flange against the long-term value and reliability of a more durable one.

A Guide to Upgrading to a 2 Inch 3 Bolt Exhaust Flange

Properly upgrading to a 2 inch 3 bolt exhaust flange requires careful preparation and execution. This process ensures a secure, leak-free connection for the exhaust system. Following a structured guide for the installation is essential for success. The task of upgrading to a 2 inch 3 bolt exhaust flange involves removing the old component and correctly fitting the new one.

Tools and Safety Equipment

A technician gathers specific tools and safety gear before beginning the installation. This preparation makes the job of upgrading to a 2 inch 3 bolt exhaust flange safer and more efficient.

Essential Hand Tools and PPE

Technicians need a basic set of tools for this job. Personal Protective Equipment (PPE) is also mandatory.

- Hand Tools: A socket set, combination wrenches, a wire brush, and a torque wrench are fundamental.

- PPE: Safety glasses protect the eyes from rust and debris. Mechanic’s gloves protect the hands from cuts and heat.

Penetrating Oil and Anti-Seize Compound

These two chemical aids are critical for a professional installation.

Pro Tip: 🛠️ A technician applies penetrating oil to rusted flange bolts several hours before attempting removal. This action helps break the bond of corrosion. They then apply anti-seize compound to the threads of the new flange bolts during installation to prevent future seizing and simplify later repairs.

Removal of the Old Flange

Removing the old flange can be the most challenging part of upgrading to a 2 inch 3 bolt exhaust flange. Corrosion often complicates this step.

Safely Removing Rusted Bolts

Rusted bolts are a common problem. A technician uses a six-point socket for the best grip to avoid stripping the bolt heads. If a bolt is stubborn, applying controlled heat with a torch can help expand the metal and break it free. In worst-case scenarios, a bolt extractor kit may be necessary to remove a broken stud.

Preparing the Pipe for the New Flange

Once the old flange is off, the pipe end and mating surface need thorough cleaning. A technician uses a wire brush or abrasive pad to remove all old gasket material, carbon buildup, and rust. A clean, smooth surface is vital for the new 2 inch 3 bolt exhaust flange to seal correctly. This preparation is a key step in the installation process.

Installation of the New Flange

The final stage of upgrading to a 2 inch 3 bolt exhaust flange is the new part installation. Precision is key to preventing leaks.

Aligning the Flange and Gasket

A technician carefully aligns the new gasket between the two flange faces. They ensure the bolt holes of the gasket and each 2 inch 3 bolt exhaust flange line up perfectly. Misalignment is a primary cause of exhaust leaks after an installation. The new flange must sit flush against the gasket and mating flange.

Proper Bolt Tightening Sequence and Torque Specs

Properly tightening the flange bolts ensures even pressure on the gasket.

- A technician first hand-tightens all three bolts.

- They then use a torque wrench to tighten the bolts in a star or triangular pattern.

- This sequence is repeated in stages, gradually increasing torque until the manufacturer’s specification is met.

This methodical installation approach prevents the flange from warping and guarantees a durable seal for the new exhaust flange.

Post-Installation Checks

A successful installation of a 2 inch 3 bolt exhaust flange concludes with a thorough verification process. A technician performs these final checks to confirm the connection is completely sealed and secure. Skipping this crucial step can negate all the hard work of the repair, leading to performance issues and safety hazards. These checks are simple yet effective methods for validating the integrity of the new joint.

Performing a Leak Test with Soapy Water

The soapy water test is a reliable and time-tested visual method for pinpointing even the smallest exhaust leaks. A technician can perform this check with basic household items, making it an accessible and effective diagnostic tool. The process is straightforward and provides immediate feedback on the quality of the seal.

- Prepare the Solution: A technician mixes a simple solution of dish soap and water in a spray bottle. The ideal mixture is bubbly but still fluid enough to spray easily.

- Start the Engine: The vehicle’s engine must be running for this test. This creates the necessary pressure within the exhaust system to reveal any leaks.

- Apply the Solution: The technician sprays the soapy water generously around the entire perimeter of the newly installed flange. They focus on the seam where the two flange faces meet.

- Observe for Bubbles: A perfect seal will show no change. If a leak is present, the escaping exhaust gas will create bubbles in the soap solution. The size and frequency of the bubbles indicate the severity of the leak.

Success Indicator: ✅ No bubbles forming around the new 2 inch 3 bolt exhaust flange means the gasket and hardware have created a perfect, gas-tight seal.

Listening for Audible Hissing or Ticking

An auditory check complements the visual soapy water test. Certain types of leaks produce distinct sounds that a trained ear can easily identify. This test is most effective when the engine is cold, as the metal components have not yet expanded with heat.

A technician starts the engine and listens carefully around the new exhaust flange.

- Hissing: A steady hissing sound often points to a continuous, small leak where gas is escaping under pressure.

- Ticking: A rhythmic ticking or puffing sound that matches the engine’s RPM is a classic sign of a gasket leak. The sound is the result of individual exhaust pulses escaping through a gap in the seal.

A professional often uses a mechanic’s stethoscope or a simple length of rubber hose held to their ear. This tool helps isolate the sound and pinpoint its exact origin around the exhaust connection. Detecting no unusual sounds provides another layer of confidence that the installation was successful.

Troubleshooting Common Exhaust Flange Issues

Even a well-installed exhaust flange can develop problems over time. A technician must know how to diagnose and address these issues to maintain vehicle safety and performance. Identifying the root cause of a failure is the first step toward an effective and lasting repair.

Identifying an Exhaust Leak

Detecting exhaust leaks early prevents more significant problems. Technicians rely on both auditory and visual cues to pinpoint the source of a leak around an exhaust flange.

Audible Signs of a Leak

The most common indicator of a leak is a change in the exhaust sound.

- A rhythmic ticking or puffing noise that increases with engine RPM often signals a failed gasket.

- A constant hissing sound may indicate a smaller, continuous leak from the flange connection.

Visual Indicators like Soot Trails

A visual inspection can confirm the location of a leak. A technician looks for black, powdery soot trails around the flange. This soot is unburned carbon that escapes with the exhaust gas, leaving a clear visual marker of the leak’s origin.

Common Causes of Failure

Several factors can cause an exhaust flange connection to fail. Understanding these common causes helps in performing the correct repair.

Gasket Blowout or Degradation

The gasket is the most common failure point. Over time, heat and pressure can cause the gasket material to degrade, crack, or “blow out,” creating a path for exhaust gases to escape.

Flange Warping from Heat Cycles

An exhaust flange endures constant thermal cycling. The flange can experience temperature swings from ambient (20°C) up to 315°C or higher, especially in turbocharged systems. This repeated heating and cooling causes the metal to expand and contract. This process can lead to flange warping and a loss of clamping pressure from the flange bolts, creating gaps that result in exhaust leaks.

Severe Corrosion or Cracking

Corrosion is a major enemy of any exhaust component. Rust can eat away at the sealing surface of the flange, creating an uneven face that the gasket cannot seal. In severe cases, the exhaust flange itself can crack from stress and corrosion, requiring a complete replacement.

Effective Repair Strategies

Once a technician identifies the problem, they can choose the appropriate repair strategy. The choice depends on the condition of the flange itself.

Replacing the Gasket and Hardware

If the exhaust flange faces are still flat and in good condition, the repair is straightforward. A technician can often solve the problem by simply replacing the old gasket and flange bolts.

Pro Tip: 🔧 Always use a new gasket and new hardware for this repair. Reusing old, stretched bolts or a compressed gasket is a common cause of repeat failures.

When to Replace the Entire Flange Section

A technician must replace the entire flange section if the inspection reveals significant damage.

- The flange is visibly warped or bent.

- The sealing surface is heavily pitted by corrosion.

- The flange has physical cracks.

In these situations, a new gasket alone will not fix the exhaust leak. Welding on a new 2 inch 3 bolt exhaust flange is the only way to restore a reliable, long-lasting seal for the exhaust system.

The 2 inch 3 bolt exhaust flange is a critical connector defined by its specific dimensions. This component plays an essential role in the integrity of the entire exhaust system. It creates a durable seal, provides structural support, and ensures vehicle performance. Correctly selecting and performing the installation of this flange is crucial for any exhaust repair. A proper understanding of this exhaust flange empowers technicians and owners to make informed maintenance decisions for their vehicles.

FAQ

Can a technician reuse an old exhaust gasket?

No, a technician should never reuse an old exhaust gasket. Gaskets compress to create a seal and lose their effectiveness. A new gasket is essential for a reliable, leak-free repair. Reusing an old one almost always results in a leak.

Why is bolt torque so important for a flange?

Proper bolt torque applies even clamping pressure across the gasket. This action prevents the flange from warping and guarantees a gas-tight seal. Incorrect torque is a primary cause of connection failure and exhaust leaks.

Is a stainless steel flange always the best choice? ⚙️

Stainless steel offers the best durability and corrosion resistance, making it a wise long-term investment. Mild steel is a cost-effective alternative for budget repairs, though it has a much shorter lifespan, especially in harsh climates.

What is the easiest way to check for a flange leak?

A technician can perform two simple checks.

- Listen for a rhythmic ticking or hissing sound with the engine running.

- Spray soapy water on the flange; bubbles will appear at the leak source.

Which is better: a weld-on or slip-fit flange?

The choice depends on the application.

- Weld-on flanges offer superior structural strength for high-performance systems.

- Slip-fit flanges allow for faster, easier installation, making them great for standard repairs.

How does one measure the bolt pattern correctly?

A technician measures the distance from the center of one bolt hole to the center of an adjacent hole. This center-to-center dimension is critical. It must match the technical diagram of the replacement flange to ensure a direct fit.

Can a warped flange be repaired?

Repairing a warped flange is not recommended. The uneven surface will prevent any gasket from sealing properly. The most effective and permanent solution is to cut off the old flange and weld on a new, perfectly flat replacement.