Selecting the correct flange bolt materials is critical for flange joint integrity. The right materials and coatings ensure optimal performance. Key factors influence the selection of a Flange Bolt, including strength, corrosion resistance, and temperature tolerance. An incorrect choice of flange face bolts leads to premature failure of the flange. This failure creates costly downtime and significant safety hazards for the flange. A custom fasteners manufacturer often provides custom fasteners from a specialized bolt casting. These bolts, including specific flange face bolts, must meet performance standards. The flange face bolts secure the flange, so these bolts are vital. The flange face bolts and other bolts must not fail.

Comparing Common Flange Bolt Materials

The selection of flange bolt materials directly impacts the safety, reliability, and lifespan of a bolted flange connection. Engineers must evaluate each material’s mechanical properties and chemical resilience against the operational environment. The three primary categories of materials for fasteners are carbon steels, stainless steels, and exotic alloys. Each group offers a distinct balance of strength, temperature resistance, and cost.

A Note on Corrosion: Corrosion is a primary failure mode for fasteners, accounting for around 10% of all failures. It can reduce or eliminate the clamping force in bolts. Bare carbon steel bolts are especially vulnerable in harsh environments. Chloride-induced cracking is a major failure mechanism for low alloy steel bolts, particularly when coatings are poor.

Carbon Steel Fasteners

Carbon steel is the most common and cost-effective material for flange face bolts. It provides excellent strength at a low price point, making it a go-to choice for general industrial applications. However, its primary weakness is poor corrosion resistance. These bolts almost always require a protective coating to prevent rust and degradation, especially when paired with more noble metals like stainless steel. This combination can cause galvanic corrosion, where the carbon steel bolt corrodes rapidly, leading to rust staining and seizure.

ASTM A193 Grade B7

ASTM A193 B7 bolts are the workhorse of the petrochemical industry. These chromium-molybdenum alloy steel bolts are quenched and tempered to develop high tensile strength. They are designed for high-temperature and high-pressure service.

- Pros: High strength, excellent availability, low cost, and well-understood performance characteristics.

- Cons: Requires a coating for corrosion protection. Its performance degrades significantly at temperatures below -20°F (-29°C).

ASTM A320 Grade L7

ASTM A320 L7 bolts are chemically and mechanically similar to B7 bolts. The key difference is that L7 bolts undergo additional impact testing to ensure performance in low-temperature applications. This makes them the standard choice for cryogenic service and refrigeration.

- Pros: Excellent toughness and strength at low temperatures, suitable for cryogenic flange connections.

- Cons: Higher cost than B7 bolts. Still requires a coating for corrosion resistance.

ASTM A307

ASTM A307 specifies low-strength carbon steel bolting. These bolts are often used for low-pressure utility applications like water and plumbing. Their specified minimum yield strength is 30 ksi (206 MPa). This makes them suitable for Class 150 and Class 300 flange joints that use soft gaskets.

- Pros: Very low cost and widely available.

- Cons: Low tensile strength. Not suitable for temperatures above 400°F (200°C) or below -20°F (-29°C).

Stainless Steel Fasteners

Stainless steel offers a significant upgrade in corrosion resistance over carbon steel. The addition of chromium (at least 10.5%) creates a passive oxide layer on the surface of the flange face bolts. This layer protects the steel from environmental attack. These corrosion-resistant materials are ideal for applications with exposure to moisture, chemicals, and corrosive elements.

Austenitic Stainless Steel (304/316)

Austenitic stainless steels are the most widely used stainless grades. They are non-magnetic and offer excellent general corrosion resistance.

- 304 Stainless Steel: A versatile and economical choice for atmospheric and mild chemical exposure.

- 316 Stainless Steel: Contains added molybdenum, which dramatically improves its performance against chlorides. This makes it one of the best flange bolt materials for marine environments.

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Key Element | Chromium, Nickel | Chromium, Nickel, Molybdenum |

| Chloride Resistance | Fair | Excellent |

| Best Use Case | General purpose, food processing | Marine parts, chemical equipment |

Grade 316 stainless steel’s molybdenum content allows it to endure the severe conditions of saltwater exposure far more effectively than other grades.

Martensitic Stainless Steel (410)

Martensitic stainless steels like Grade 410 can be heat-treated to achieve high strength and hardness, similar to carbon steels. They offer moderate corrosion resistance, better than carbon steel but less than austenitic grades. These flange face bolts are often chosen when strength is a higher priority than maximum corrosion resistance.

- Pros: High strength and hardness, wear-resistant.

- Cons: Less corrosion resistant than 300-series stainless steel.

Duplex Stainless Steel (2205)

Duplex stainless steels have a mixed microstructure of austenite and ferrite. This structure gives them unique properties, including very high strength and exceptional resistance to chloride stress corrosion cracking (SCC). While austenitic grades like 316L can be susceptible to SCC at temperatures above 130°F (55°C), duplex materials provide superior reliability in harsh marine and chemical processing environments. Their higher chromium, molybdenum, and nitrogen content creates a robust passive layer that resists pitting in high-chloride solutions.

- Pros: Superior strength, excellent resistance to pitting, crevice corrosion, and SCC.

- Cons: Higher cost and less common than austenitic grades.

Alloy and Superalloy Fasteners

For the most demanding applications involving extreme temperatures, high pressures, and aggressive chemicals, engineers turn to alloy and superalloy fasteners. These materials deliver performance where carbon and stainless steels would fail.

High-Temperature Alloys (B16, B8M)

Certain ASTM grades are specifically designed for high-temperature service.

- ASTM A193 B16: A chromium-molybdenum-vanadium steel bolt used for high-pressure, high-temperature service up to 1100°F (593°C).

- ASTM A193 B8M: A 316 stainless steel bolt that is carbide solution treated for optimal performance in high-temperature or corrosive flange applications.

Nickel Alloys (Inconel, Monel)

Nickel-based superalloys are renowned for their strength and stability at extreme temperatures.

- Inconel: These alloys maintain excellent mechanical strength and resist oxidation at temperatures exceeding 1832°F (1000°C). Inconel 718 bolts, for example, show outstanding creep strength up to 1300°F (700°C). They are preferred for high-temperature strength.

- Monel: This nickel-copper alloy excels in marine and chemical environments. It is particularly resistant to seawater and hydrofluoric acid, making it a top choice for specific flange applications in the naval and chemical sectors.

Exotic Alloys (Hastelloy)

Hastelloy is a nickel-molybdenum-chromium superalloy family known for its outstanding resistance to a wide range of severe chemicals. Hastelloy flange face bolts are essential in chemical processing plants to ensure equipment integrity. They are specified for reactors, piping, and pressure vessels that handle highly corrosive media.

These flange face bolts are critical in environments with:

- Sulfuric, hydrochloric, and hydrofluoric acids

- Chloride, acid, and oxidizing conditions

- Seawater and brine solutions

The use of these advanced materials prevents catastrophic leaks and failures in the most challenging industrial settings.

Evaluating Protective Coatings for Flange Bolts

While the base material provides the foundational strength, protective coatings are essential for enhancing the lifespan and reliability of flange bolts. These coatings shield the bolts from environmental attack, reduce friction during installation, and prevent premature failure. The selection of a coating depends on the service environment, temperature, and the mechanical demands on the flange connection. The right coatings can elevate the performance of standard bolts, while advanced coatings and better materials are required for the most extreme conditions.

Sacrificial Coatings

Sacrificial coatings protect the underlying steel by corroding preferentially. They are made from a metal, typically zinc, that is more electrochemically active than steel. This ensures the base metal of the flange face bolts remains intact even if the coating is scratched.

Hot-Dip Galvanizing (HDG)

Hot-dip galvanizing involves immersing steel bolts in a bath of molten zinc. This process creates a thick, durable, and metallurgically bonded coating. HDG offers a multi-layered defense against corrosion.

- Barrier Protection: The zinc coating forms a robust physical shield that blocks corrosive elements from reaching the steel.

- Cathodic Protection: Zinc acts as a sacrificial anode. If the coating is scratched, the zinc corrodes first, protecting the exposed steel of the flange face bolts.

- Zinc Patina: Over time, the zinc develops a tough, stable patina that further slows the corrosion process and provides a self-healing effect.

This robust protection gives HDG an exceptional service life. In many industrial environments, it can protect a flange for decades. However, the thick coating requires that the corresponding nuts be tapped oversized to ensure proper thread engagement.

| Coating Type | Coating Thickness (micrometers) | Estimated Service Life (years in an industrial atmosphere) |

|---|---|---|

| Zinc Plating | 10 | ~5-10 |

| Hot-Dip Galvanizing | 100 | ~50-100 |

Zinc Electroplating

Zinc electroplating applies a thin layer of zinc to the bolts using an electrical current. This process produces a bright, uniform finish, making it a popular and low-cost option for mild environments. The resulting coating is much thinner than HDG, offering limited protection. It performs adequately in industrial atmospheres but is not recommended for salty or highly corrosive environments. The thin layer provides minimal sacrificial protection and is easily damaged, making it unsuitable for a critical flange.

Cadmium Plating

Cadmium plating once offered excellent corrosion resistance, a low friction coefficient, and reliable performance, especially in salt-laden air and marine settings. However, cadmium is highly toxic and a known carcinogen.

⚠️ Health and Environmental Alert: Due to its toxicity, environmental regulations have severely restricted the use of cadmium. It is now rarely specified for new flange applications and has been replaced by safer, high-performance alternatives.

Barrier and Lubricant Coatings

This category of coatings works by creating an impermeable physical barrier between the bolt and its environment. Many also contain lubricants to reduce friction, which helps achieve consistent and accurate preload during the tightening of a flange.

Phosphate Coatings (Zinc/Manganese)

Phosphate coatings are conversion coatings, meaning they chemically react with the steel surface to form a microcrystalline layer. They are not standalone corrosion inhibitors. Instead, they serve two primary functions:

- Pre-treatment: They create an excellent adhesion base for paints or other topcoats.

- Lubricant Retention: The porous structure absorbs and holds oils, waxes, and rust-preventative liquids. This feature is crucial for providing temporary corrosion protection and ensuring smooth threading for bolts.

Heavy zinc phosphate coatings are particularly effective at retaining oils, improving the overall rust resistance of flange face bolts. However, these coatings have limitations. They are not environmentally friendly and are unsuitable for parts that will undergo further heat treatment.

Ceramic-Filled Fluoropolymer

Ceramic-filled fluoropolymer coatings, often known by the generic term PTFE (polytetrafluoroethylene), are a top choice for critical applications. These coatings combine the chemical resistance and low friction of fluoropolymers with the hardness of ceramic fillers. This combination dramatically reduces the torque needed to tighten bolts by lowering the friction coefficient (K factor). A lower and more predictable K factor ensures that more of the installer’s energy translates into clamping force on the flange, rather than being lost to friction. This leads to highly consistent and reliable bolt preloads.

Electroless Nickel Plating (ENP)

Electroless nickel plating is an autocatalytic process that deposits a nickel-phosphorus alloy onto the bolt without using an electrical current. This method creates an exceptionally uniform coating, even on complex shapes and internal threads. ENP is prized for its high hardness, excellent wear resistance, and good corrosion protection, making it a significant upgrade over standard electroplating for demanding flange applications.

Advanced Proprietary Coatings

For the most severe service conditions, engineers turn to advanced proprietary coatings. These multi-component systems are engineered to provide superior performance that commodity coatings cannot match.

SermaGard Coatings

SermaGard is a family of ceramic-metallic coatings that offer outstanding protection against corrosion, abrasion, and high temperatures. These coatings are particularly valuable for high-strength bolts that are susceptible to hydrogen embrittlement from traditional plating processes. A SermaGard system often includes a basecoat and a topcoat, providing multi-layered defense.

| Feature | SermaGard 1105/1280 | Hot Dip Galvanizing |

|---|---|---|

| Corrosion Resistance (Salt Spray) | 3000-4000 hours | Very effective |

| Hydrogen Embrittlement Risk | No risk | High risk for high-strength bolts |

| Torque Consistency | Consistent | Can be uneven due to thickness variation |

| High-Temperature Use | Effective up to 750°F+ | Not recommended |

The data shows SermaGard provides exceptional corrosion resistance without the risks associated with galvanizing high-strength flange face bolts.

Geomet and Dacromet Coatings

Geomet and Dacromet are non-electrolytic, zinc-aluminum flake coatings. They are applied as a liquid and then thermally cured, a process that completely avoids the risk of hydrogen embrittlement. This makes them an ideal choice for protecting high-tensile flange face bolts (Grade 10.9 and higher). These thin coatings provide excellent sacrificial protection and maintain dimensional tolerance on threads, eliminating the need for oversized nuts. Their primary advantage is ensuring the mechanical integrity of high-strength bolts in corrosive environments.

Deep Dive into PTFE-Coated Bolts

PTFE-coated bolts offer a unique combination of properties that make them a superior choice for many critical flange applications. The PTFE coating acts as a robust barrier, enhancing the performance of the underlying steel. However, engineers must also consider the potential drawbacks to make an informed decision.

The Advantages of PTFE-Coated Fasteners

The advantages of PTFE-coated fasteners are significant, especially in corrosive or high-friction environments. These benefits directly improve the integrity and reliability of a bolted flange.

Superior Corrosion and Chemical Resistance

A primary benefit of PTFE is its exceptional corrosion resistance. The PTFE coating creates a chemically inert barrier that seals the flange face bolts from moisture and aggressive chemicals. This protection is vital for any flange operating in harsh industrial or marine settings. The coating’s excellent chemical resistance ensures the bolts withstand exposure to a wide range of substances, preventing degradation and extending the service life of the flange.

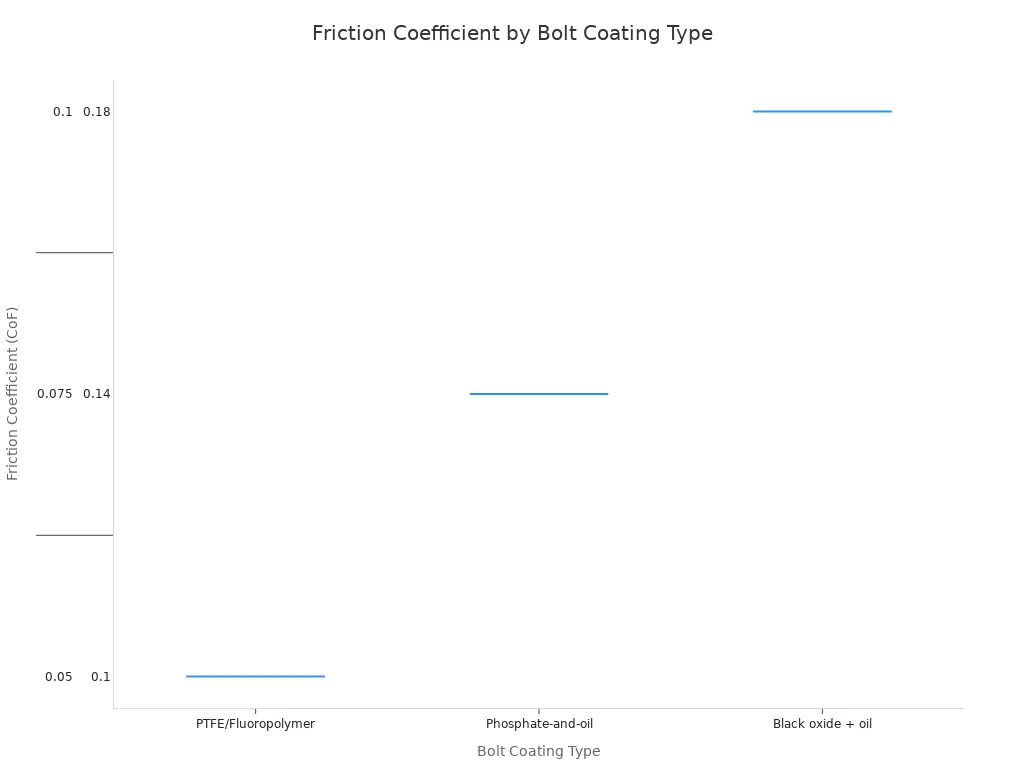

Low Friction for Consistent Torque

PTFE coatings dramatically lower the friction coefficient of a fastener. This low friction ensures that more of the installer’s torque translates into clamping force (preload) on the flange, rather than being lost to overcoming friction. The result is a more accurate and consistent preload across all bolts in a flange connection.

| Bolt Coating Type | Friction Coefficient (CoF) Range |

|---|---|

| PTFE/Fluoropolymer | 0.05 – 0.10 |

| Plain, dry uncoated steel | 0.2 or higher |

| Lightly oiled plain steel | ~0.15 |

| Zinc electroplating (unlubricated) | 0.18 – 0.25 |

| Hot-dip galvanized (unlubricated) | > 0.25 |

| Phosphate-and-oil | 0.10 – 0.18 |

| Black oxide + oil | 0.12 – 0.20 |

This consistency is critical for achieving a leak-free seal on a gasketed flange.

Preventing Galling in Stainless Steel

Galling, or cold welding, is a common problem when tightening stainless steel bolts. The threads can seize, damaging the flange face bolts and preventing proper tightening. A PTFE coating acts as a solid lubricant, creating a barrier between the mating threads. This barrier effectively prevents galling, allowing for smooth installation and easy removal of bolts during maintenance.

Color Coding for Identification

Manufacturers offer PTFE coatings in a wide variety of colors. This feature provides a simple yet effective method for visual identification.

Tip: Teams can use different colors to distinguish between material grades, sizes, or specific applications on-site. For example, blue PTFE bolts might be designated for a specific flange service, while green PTFE bolts are used for another. This system helps prevent installation errors.

The Disadvantages of PTFE-Coated Fasteners

Despite their benefits, there are disadvantages of PTFE-coated fasteners that require careful consideration during selection and installation.

Susceptibility to Installation Damage

The PTFE coating, while durable, is not indestructible. Improper handling or installation techniques can compromise its integrity.

- The coating on flange face bolts can be scratched or scraped by tools.

- Over-tightening is a significant risk. Using torque values intended for plain bolts on low-friction PTFE-coated bolts can lead to excessive force, potentially damaging the coating or even the bolt itself.

- Abrasion on contact surfaces can wear away the PTFE layer.

Any damage that exposes the base metal creates a site for corrosion to begin, negating the coating’s primary benefit.

Higher Initial Cost

PTFE-coated bolts have a higher upfront cost compared to standard zinc-plated or galvanized bolts. This initial investment can be a significant factor in project budgeting. However, for critical flange systems, this cost is often justified by improved reliability, reduced maintenance, and a longer service life.

Performance Variation by Manufacturer

Not all PTFE coatings are created equal. The quality of the application process, coating thickness, and curing method can vary significantly between manufacturers. These inconsistencies can affect the performance and durability of the flange face bolts. This is one of the key disadvantages of PTFE-coated fasteners. It is crucial to source these specialized bolts from reputable suppliers to ensure consistent quality and reliable performance.

How Material and Coating Choices Impact Flange Performance

The material and coating of a flange bolt are not just components; they are critical variables that dictate the safety, durability, and performance of the entire flange assembly. The impact of flange face bolt features extends from mechanical load-bearing to long-term environmental resistance. Making the right choice prevents joint failure and ensures operational reliability.

Mechanical Strength and Integrity

The primary function of a bolt is to provide clamping force. The material’s inherent mechanical properties determine its ability to perform this role effectively under stress.

Tensile and Yield Strength

Engineers determine the preload in a bolted joint as a percentage of the bolt material’s tensile yield strength. This preload is essential for keeping the clamped parts of a flange under compression. A higher preload maximizes the bolt’s utility. The material’s ductility determines how close this preload can be to the yield strength, with a common guideline being two-thirds of yield. Different materials also behave differently under stress; for instance, carbon steels have a shear-to-tensile strength ratio of 0.60, while stainless steels have a ratio of 0.55. This high tensile strength is fundamental to the performance of the flange.

Hardness and Ductility

Hardness directly affects a material’s susceptibility to hydrogen embrittlement (HE). As the strength and hardness of steel increase, the material becomes less ductile and more vulnerable to HE.

This loss of fracture strength begins at a hardness of approximately 35 HRC. The critical hardness, below which materials remain largely unaffected, is 39 HRC. This factor is crucial for the durability of high-strength flange face bolts.

Fatigue and Vibration Resistance

Bolted joints in dynamic systems face fatigue from vibration and cyclic loading. A properly and consistently preloaded bolt resists these forces more effectively. Coatings like PTFE, with their low friction, ensure that applied torque translates into consistent clamping force across all bolts. This uniformity is key to preventing loosening and enhancing the fatigue life of the flange connection.

Corrosion Resistance in Different Environments

Corrosion is a primary enemy of bolted joints. The choice of materials and coatings is the first line of defense.

Atmospheric and Galvanic Corrosion

When dissimilar metals are in contact, they can form a galvanic cell. Using carbon steel bolts on a stainless steel flange in the presence of an electrolyte (like humid air) creates this exact scenario. The less noble carbon steel acts as the anode and corrodes rapidly, while the more noble stainless steel is protected.

| Metal | Role in Galvanic Corrosion | Electrochemical Potential |

|---|---|---|

| Carbon Steel | Anode (Active) | Less Noble |

| Stainless Steel | Cathode (Noble) | More Noble |

This is why using corrosion-resistant materials or isolating coatings is vital.

Chemical, Pitting, and Crevice Corrosion

In chemical processing plants, flange face bolts face attack from aggressive substances. Pitting is a localized form of corrosion that creates small holes, while crevice corrosion occurs in tight spaces like thread roots. A barrier coating like PTFE seals the bolts from these chemicals, while corrosion-resistant bolting components like Duplex stainless steel offer inherent protection.

Stress Corrosion Cracking (SCC)

SCC is a brittle failure mode caused by the combined action of tensile stress and a corrosive environment.

- Austenitic stainless-steel fasteners (e.g., 316) are susceptible to SCC in chloride-rich environments.

- High-strength bolts are particularly vulnerable to hydrogen sulfide stress cracking (HSSC).

- Medium-high-carbon steels also show greater susceptibility to SCC in certain sulfide solutions.

Temperature and Pressure Tolerance

A flange must maintain its seal across a range of operating temperatures and pressures. The flange bolt materials are central to this capability.

High-Temperature Service

At elevated temperatures, materials can lose strength and “creep,” or slowly deform. The addition of vanadium to ASTM A193 B16 bolts gives them enhanced load bearing capacity and superior creep resistance compared to B7 bolts, making them suitable for higher service temperatures.

| Feature | B7 Stud Bolts | B16 Stud Bolts |

|---|---|---|

| Alloy | Chromium-Molybdenum Steel | Chromium-Molybdenum-Vanadium Steel |

| Designed Service Temperature | Up to ~400°C (750°F) | Up to ~550°C (1000°F) |

| Performance at Higher Temperatures | Strength can decrease | Tougher, with long-term stability |

Cryogenic and Low-Temperature Service

For low-temperature and cryogenic service below -50°F, standard carbon steels become brittle. ASTM A320/A320M is the governing specification for alloy and stainless steel bolting designed to retain its toughness and durability in these extreme cold conditions, ensuring the integrity of the flange.

Pressure-Temperature (P-T) Ratings

The P-T rating of a flange defines its safe operating limits. This rating depends on the entire assembly: the flange itself, the gasket, and the bolts. The strength and thermal stability of the flange face bolts are a limiting factor in this rating, directly influencing the overall system performance.

A Practical Guide to Selecting the Right Fastener

Choosing the right flange face bolts involves a systematic evaluation of the environment, operational stresses, and economic factors. A methodical approach ensures the long-term durability and safety of any bolted flange connection.

Matching Fasteners to Environmental Factors

The service environment is the primary driver for selecting flange bolt materials and coatings.

Marine and Offshore Environments

Offshore platforms present a severe challenge due to saltwater exposure and potential contact with hydrogen sulfide (H2S). For these unique applications of flange face bolts, industry standards provide clear guidance.

NACE MR0175 is the key standard for materials in H2S-containing environments. It specifies materials to prevent sulfide stress cracking and ensure the durability of the flange.

- Bolts: ASTM A193 Grade B7M or ASTM A320 Grade L7M

- Nuts: ASTM A194 Grade 2HM or 7M

- Hardness: A maximum hardness of 32 HRC is required for subsea service.

Chemical Processing Plants

Chemical plants require bolts that can withstand aggressive media. For sulfuric acid service, Alloy 20 offers excellent resistance to corrosion and stress-corrosion cracking. For other unique applications of flange face bolts in extreme chemical environments, engineers turn to exotic materials.

- Hastelloy C276 resists a wide range of acids.

- Tantalum and Zirconium are used for boiling acid conditions.

- Engineered Polymers like PVDF offer solutions for low-temperature acidic services.

High-Humidity or General Industrial Use

For general industrial use where humidity is a concern, cost-effective solutions provide adequate protection. Hot-dip galvanized (HDG) carbon steel bolts offer excellent durability. PTFE-coated flange face bolts are another great option, providing a robust barrier against moisture and simplifying installation for any flange.

Aligning with Operational Demands

The mechanical function of the flange dictates fastener selection.

High-Pressure and Critical Systems

In high-pressure systems, achieving the correct bolt preload is paramount for joint integrity. Improper installation is a leading cause of failure. Advanced techniques like hydraulic tensioning or using Direct Tension Indicators (DTIs) are essential for these high-performance fastening solutions. Choosing the right flange face bolts with predictable friction characteristics is critical.

Cyclic Loading and Vibration

Systems with vibration or thermal cycles demand consistent clamping force to prevent bolt loosening and fatigue failure. The innovative features of flange face bolts with low-friction coatings ensure that applied torque translates into reliable preload. Proper lubrication can reduce friction by 15-50%, enhancing the durability of the entire flange assembly.

Ease of Maintenance and Reusability

Maintenance often requires the disassembly and reassembly of a flange. Stainless steel bolts are prone to galling, which can make removal impossible.

Anti-galling coatings act as a solid lubricant, preventing thread seizure. This simple feature makes disassembly smooth, reduces downtime, and allows for the reuse of flange face bolts, which improves lifecycle economy. These innovative features of flange face bolts are invaluable.

Balancing Economic and Regulatory Needs

Practical constraints also influence material choices.

Initial Cost vs. Lifecycle Cost

Choosing the right flange face bolts requires looking beyond the initial price. A low-cost coated carbon steel bolt may seem economical, but it could require frequent replacement. In contrast, a solid 316L stainless steel bolt has a higher upfront cost but offers a much longer service life with minimal maintenance, often making it the wiser long-term financial decision.

Material Availability and Lead Times

Project timelines depend on material availability. Standard flange bolt materials like ASTM A193 B7 are widely available. However, exotic alloys may have significant lead times that project managers must incorporate into their schedules.

Environmental and Safety Regulations

Global regulations restrict the use of hazardous materials. The EU’s RoHS directive, for example, limits cadmium in coatings to just 0.01%. These rules have driven the industry toward safer, high-performance alternatives, making compliance a key factor in selecting coatings for flange face bolts.

Selecting the optimal flange face bolts requires balancing environmental conditions, mechanical demands, and budget for any flange. High-quality coatings can significantly enhance the performance of these bolts. The application quality of the coatings is paramount for reliable performance. The right flange face bolts ensure the integrity of the entire flange. These bolts are critical for the flange. The performance of the flange face bolts directly impacts the flange performance.

For any critical flange application, engineers should always consult industry standards (ASME, ASTM) or a materials specialist to guarantee safety and optimal performance of the bolts.

FAQ

Why are ASTM A193 B7 bolts so common?

ASTM A193 B7 bolts are the industry standard for high-pressure applications. They offer high tensile strength and excellent performance at a low cost. Their widespread availability and well-documented characteristics make them a reliable choice for many industrial flange connections.

When should engineers choose stainless steel bolts?

Engineers select stainless steel bolts for their superior corrosion resistance. The material’s passive layer protects against moisture and chemicals. This makes stainless steel ideal for marine, chemical, and food processing environments where carbon steel would quickly degrade.

What is the main advantage of a PTFE coating?

The primary advantage of a PTFE coating is its extremely low friction. This feature ensures that applied torque converts directly into clamping force. The result is a highly accurate and consistent preload across all bolts on a flange.

How does one prevent galling in stainless steel bolts?

Preventing galling requires a barrier between the mating threads. Applying an anti-seize compound or using bolts with a PTFE coating creates a solid lubricant. This lubrication allows for smooth tightening and prevents the threads from seizing during installation or removal.

Can someone use carbon steel bolts on a stainless steel flange?

Using carbon steel bolts on a stainless steel flange is not recommended. This combination creates a galvanic cell in the presence of moisture. The carbon steel bolt will corrode rapidly, compromising the integrity and safety of the flange joint.

What makes a bolt suitable for cryogenic service? (remove emoji)

A bolt for cryogenic service must remain tough at extremely low temperatures. Materials like ASTM A320 Grade L7 undergo special impact testing to ensure they do not become brittle. This guarantees the bolt’s mechanical integrity in applications like refrigeration.