A custom fasteners manufacturer stresses inspecting eye bolts for safety. Riggers must check eye bolts for damage before each lift. Proper eye bolt safety also demands correct installation of the eye bolts. The quality of the bolt casting affects safety during use. A documented periodic inspection for all custom fasteners and eye bolts is mandatory.

Critical Safety Rule: Any failed Eye Bolt requires immediate removal and destruction to prevent accidental reuse.

Fundamentals of Eye Bolts for Safe Lifting

Understanding the fundamentals of eye bolts is the first step toward ensuring operational safety. A rigger’s knowledge of eye bolt types, terminology, and materials directly impacts the security of every lift. Choosing the correct hardware for the job prevents equipment failure and protects personnel.

Types of Lifting Eye Bolts and Their Applications

Different lifting scenarios require specific types of lifting eye bolts. Using the wrong type for a given load can lead to catastrophic failure.

Shoulder Pattern Eye Bolts

Shoulder pattern eye bolts feature a reinforced shoulder between the eye and the shank. This design allows them to handle angular loads, as the shoulder braces the bolt against bending forces. The shoulder must sit flush with the contact surface for proper function.

Plain or Regular Pattern Eye Bolts

Plain, or non-shouldered, eye bolts lack this reinforcing shoulder. Their design makes them suitable only for perfectly vertical, in-line lifts. Any angular or side loading will compromise their integrity and must be avoided.

Machinery Eye Bolts (ASME B18.15)

Machinery eye bolts are high-strength fasteners designed for installation into tapped holes on equipment. When equipped with a shoulder, these eye bolts can manage angular loads.

| Eye Bolt Type | Load-Bearing Capability | Key Feature |

|---|---|---|

| Shoulder Pattern | Withstands angular forces; suitable for rigging and hoisting. | Reinforced shoulder prevents bending under side loads. |

| Plain Pattern | Designed for vertical loads only; integrity compromised by side forces. | Lacks a reinforced shoulder. |

| Machinery Eye Bolt | Can handle angular loads up to 45° when shouldered. | Threaded shank for tapped holes; shoulder allows angular loads. |

Understanding Key Eye Bolt Terminology

Familiarity with key terms helps operators correctly inspect and use lifting eye bolts.

Shank, Threads, and Thread Engagement

The shank is the threaded portion of the bolt. Proper thread engagement is critical for strength. The engagement length should be at least equal to the eye bolt’s diameter. Insufficient engagement creates a weak joint, increasing the risk of threads stripping before the bolt reaches its full tensile strength.

Shoulder, Eye, and Bore

The shoulder is the flange below the eye on shouldered eye bolts. The eye is the loop used for attaching rigging hardware. The bore is the opening within the eye.

Working Load Limit (WLL) vs. Breaking Strength

Note: The Working Load Limit (WLL) is the maximum mass or force a component can safely handle. It is not the same as breaking strength.

Manufacturers determine the WLL by applying a safety factor, often 5-to-1, to the bolt’s ultimate breaking strength. This means an eye bolt with a 10,000 lb breaking strength has a WLL of 2,000 lbs for a straight vertical lift. Angular loading significantly reduces this capacity.

Materials and Manufacturing Impact on Safety

The material and manufacturing process of eye bolts are crucial determinants of their performance and reliability.

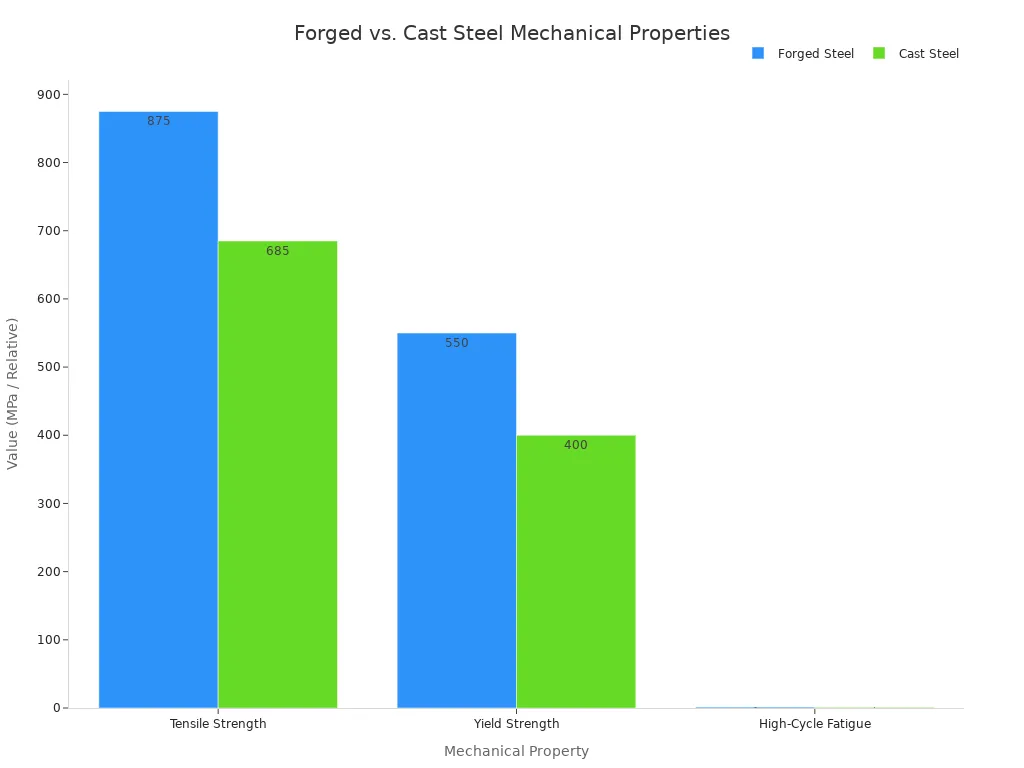

Forged vs. Cast Eye Bolts

Forged steel eye bolts offer superior mechanical properties compared to cast alternatives. The forging process creates a refined, aligned grain structure that enhances tensile strength and resistance to fatigue and impact. This process minimizes internal defects like porosity, making forged eye bolts the safer, more reliable choice for critical lifting applications.

Carbon Steel vs. Stainless Steel Options

Carbon steel is a common material for eye bolts, offering high strength for general use. Stainless steel provides excellent corrosion resistance, making it ideal for marine, chemical, or food processing environments where rust is a concern.

The Pre-Use Check: Your First Line of Defense in Eye Bolt Safety

A diligent pre-use check is the most critical, hands-on activity for ensuring operational safety. Before every lift, riggers must perform a thorough tactile and visual inspection. This routine habit is the primary defense against equipment failure, protecting both personnel and property. It ensures the hardware is fit for service at the exact moment of use.

Visual Inspection: What to Look For

A careful visual scan can identify the most common and dangerous forms of damage. An inspector should remove any eye bolt from service if it displays any of the following defects.

Bending, Stretching, or Elongation

Overloading or improper angular loading can cause the steel to deform permanently. This damage compromises the component’s structural integrity. An inspector must look for clear shape distortions.

- Bent, twisted, or elongated eyes or shanks.

- Stretched or cracked load-bearing components.

- Any visible bulging or deformation of the bolt’s original shape.

Cracks, Nicks, and Gouges

Surface discontinuities act as stress risers, creating weak points where a fracture can begin under load. Safety standards mandate that eye bolts must be removed from service if an inspector finds ‘Excessive nicks or gouges‘. These components can only return to service after a qualified person performs a detailed evaluation and grants approval. Even seemingly minor damage can lead to catastrophic failure.

Thread Damage or Stripping

The threads transfer the entire load from the eye bolt to the receiving structure. Damaged threads significantly reduce the bolt’s capacity. A rigger must inspect threads for any signs of stripping, crossing, or flattening. This type of damage prevents full engagement and creates a severe risk of the bolt pulling out under load.

Signs of Corrosion or Heat Damage

Environmental factors can degrade eye bolts over time. Corrosion, such as rust or pitting, eats away at the material and reduces its cross-sectional area, weakening it. Additionally, exposure to high heat can alter the steel’s temper, making it brittle. An inspector should look for any discoloration, particularly a bluish tint, which indicates the bolt’s strength has been compromised.

Functional Check: Seating and Alignment

After the visual check, a functional check confirms the eye bolt can be installed correctly for a specific lift. This step in inspecting eye bolts verifies the mechanical interface between the hardware and the load.

Confirming Full Thread Engagement

Proper thread engagement is essential for achieving the rated WLL. The shank must be long enough to engage the receiving hole fully.

- An inspector must verify that the eye bolt threads match the receiving hole’s threads in size, pitch, and standard (inch/inch or metric/metric).

- Both the bolt and the tapped hole threads must be clean and free of debris.

- The inspector should check all tapped receiving holes for signs of wear or deterioration.

Ensuring a Flush Shoulder Contact

For shoulder pattern eye bolts, the shoulder must make firm, flush contact with the load surface. This contact is necessary to support angular loads properly.

Important: A rigger must never undercut an eye bolt’s shank to make the shoulder seat. Instead, they should use properly sized hardened washers or countersink the hole to achieve a flush fit. The bolt must be screwed down completely for proper seating.

Verifying Load Angle Alignment

The plane of the eye must be aligned with the direction of the sling pull. Misalignment introduces dangerous side-loading forces, which can bend or break the bolt. This alignment is a non-negotiable aspect of eye bolt safety, especially when using plain pattern eye bolts that have no capacity for angular loads.

Checking Markings and Identification

Legible markings provide critical information about the eye bolt’s capacity and origin, helping to prevent the use of incorrect or counterfeit hardware.

Legible Manufacturer Markings

Inspectors should look for stamped letters or symbols that identify the manufacturer. These unique marks allow for traceability in the event of a product recall or quality issue. Eye bolts with missing or ground-off manufacturer markings are immediately suspect and must be removed from service.

Clear Working Load Limit (WLL)

The WLL rating must be clearly stamped and legible on the eye bolt. If the marking is unreadable, the bolt must be discarded. Riggers should also be aware of signs that may indicate counterfeit eye bolts, which often have fraudulent markings.

- Conflicting ratings or codes on the bolt versus its documentation.

- Documentation or markings that show obsolete manufacturer information or incorrect trademarks.

- Unusual packaging or inconsistent marking quality.

- Prices that seem unusually low or “too good to be true.”

A Guide to Formal Periodic Eye Bolt Inspection

While pre-use checks are vital, a formal periodic eye bolt inspection program provides a deeper, documented assessment of hardware condition over time. This scheduled process goes beyond a simple visual scan. It involves removing eye bolts from service for a meticulous evaluation to catch gradual wear, hidden damage, and other safety risks before they lead to failure.

Establishing an Inspection Frequency

A qualified person must determine the inspection frequency for all rigging hardware. This decision depends on factors like the frequency of use, the severity of environmental conditions, and the nature of the lifting activities. Rigging safety standards categorize service conditions to guide this schedule.

| Service Type | Inspection Frequency | Description |

|---|---|---|

| Normal Service | Yearly | Involves lifts with uniform loads and use in non-corrosive environments. |

| Severe Service | Monthly to Quarterly | Includes use in corrosive or high-temperature environments or with frequent, heavy load cycles. |

| Special Service | As Recommended | Involves lifting critical or hazardous loads, requiring inspection before and after each use. |

Normal Service: Annual Inspections

Eye bolts used in ideal conditions with infrequent load cycles require a documented inspection at least once a year. This annual review ensures the hardware remains fit for service and maintains a baseline of safety.

Severe Service: Monthly to Quarterly Inspections

When eye bolts operate in harsh environments—such as marine settings, chemical plants, or areas with extreme temperatures—they degrade faster. Frequent or heavy loading also increases wear. For these severe service conditions, inspections must occur more often, typically on a monthly to quarterly basis.

Special Service: Before and After Each Use

Special service applies to the most critical lifts, such as hoisting personnel, valuable equipment, or hazardous materials. For these applications, a qualified person must perform a complete inspection before and after every single lift to ensure maximum safety.

The Step-by-Step Periodic Inspection Process

A formal inspection is a structured, hands-on process that must be documented. Following these steps ensures a consistent and thorough evaluation of all eye bolts.

Step 1: Remove from Service and Clean

An inspector begins by taking the eye bolts out of active service. He or she then thoroughly cleans each component to remove all dirt, grease, and debris. A clean surface is essential for an accurate visual examination, as contaminants can easily hide dangerous cracks or corrosion.

Step 2: Perform Detailed Visual Examination

The inspector conducts a close-up visual assessment, looking for the same defects as a pre-use check but with greater scrutiny. This includes searching for any bending, elongation, cracks, nicks, gouges, thread damage, or signs of heat damage. Even minor surface flaws can indicate a serious problem.

Step 3: Measure for Deformation and Wear

Pro Tip: Use digital calipers to compare the eye bolt’s current dimensions against its original manufacturing specifications. Any deviation is a sign of potential overloading.

Overloading can stretch or deform an eye bolt in ways not immediately obvious to the eye. An inspector should measure the shank and eye for any signs of elongation or bending. He or she can also use a wrench to check for any looseness, or tap the bolt with a hammer to listen for a dull thud, which may indicate internal cracks.

Step 4: Document All Findings in a Log

Every formal inspection must be recorded in a dedicated logbook. The inspector documents the date, the unique identifier of the eye bolt, the findings of the evaluation (pass/fail), and any actions taken. This log provides a complete service history and demonstrates regulatory compliance.

Step 5: Remove and Destroy Failed Eye Bolts

Any eye bolt that fails inspection must be removed from service immediately. Critically, the failed component must be physically destroyed to make it unusable. An inspector should cut it in half or crush the threads. This decisive action prevents a damaged bolt from being accidentally put back into circulation.

Advanced Techniques for Inspecting Eye Bolts

For high-stakes applications or when a standard visual check is insufficient, advanced methods provide a deeper look into the component’s structural integrity. These techniques require specialized equipment and trained operators.

Non-Destructive Testing (NDT) Methods

Non-Destructive Testing (NDT) includes several methods for inspecting eye bolts without damaging them. One common technique is Ultrasonic Testing, where high-frequency sound waves are sent through the bolt. An operator analyzes the returning echoes to detect internal defects like cracks or corrosion that are impossible to see from the surface.

Magnetic Particle Inspection for Cracks

Magnetic Particle Inspection (MPI) is a highly effective NDT method for finding surface and near-surface flaws in ferromagnetic materials like carbon steel.

- An inspector first magnetizes the eye bolt.

- Next, he or she applies fine iron particles (either dry or in a liquid suspension) to the surface.

- If a crack or flaw is present, it will disrupt the magnetic field, causing the particles to gather at the defect and create a visible indication.

MPI is valued for its high sensitivity to very fine surface-breaking cracks, its speed, and its relative cost-effectiveness. However, its primary limitation is that it only works on magnetic materials and is not suitable for detecting deep internal flaws.

Essential Maintenance for Eye Bolt Longevity

Proper maintenance extends the service life of eye bolts and is a cornerstone of a comprehensive safety program. Diligent cleaning, correct storage, and appropriate protective measures ensure that rigging hardware remains in optimal condition, ready for safe use. These practices prevent premature degradation and support accurate inspections.

Proper Cleaning Procedures

Regular cleaning is essential for effective visual inspection. Contaminants can easily hide dangerous flaws.

Removing Dirt, Grease, and Debris

A technician should clean eye bolts using simple and safe methods. The most recommended cleaning agent is warm, soapy water. This solution effectively removes grease and grime from both carbon steel and stainless steel components without causing material degradation. Aggressive chemicals should be avoided as they can harm the steel.

Thoroughly Drying to Prevent Moisture

After washing, it is critical to dry each component completely. Any remaining moisture can lead to rust and corrosion, which weakens the hardware over time. A thorough drying process is a simple but vital step in preventing this type of damage.

Correct Storage Practices

How eye bolts are stored when not in use directly impacts their condition and readiness.

Storing in a Dry, Controlled Environment

Operators must store hardware in a clean, dry, and well-ventilated area. This practice protects the components from corrosive elements and extreme temperature fluctuations. A controlled environment minimizes the risk of rust and other environmental degradation.

Organizing by Size, Type, and Capacity

A well-organized storage system prevents confusion and misuse. Technicians should keep eye bolts sorted by their size, type (shoulder vs. plain), and Working Load Limit (WLL). Clear labeling helps riggers quickly select the correct hardware for a specific lift.

Protecting Threads from Impact Damage

The threads are a critical part of the eye bolt. During storage, they must be protected from impacts that could cause nicks or stripping. Storing them in designated bins or on racks, rather than in a loose pile, helps preserve thread integrity.

Lubrication and Protective Measures

Applying the right treatments can prevent common issues like thread galling and corrosion.

Applying Lubricant to Threads

Proper lubrication reduces friction and prevents threads from seizing, especially with stainless steel. Several specialized anti-seize compounds offer excellent protection.

- Nickel-Based Anti-Seize: This is often considered the best option for stainless steel. It provides superior resistance to high temperatures and corrosion.

- Lanotec or Prolan: These sheep-wool-oil-based lubricants are effective and improve saltwater corrosion resistance.

- Tef Gel: This product is excellent for preventing galvanic corrosion when using eye bolts with dissimilar metals, such as aluminum.

Why You Must Never Paint Eye Bolts

Safety Alert: Painting an eye bolt is a dangerous practice that must be strictly avoided.

Paint and other coatings can conceal serious defects like cracks, gouges, and signs of heat exposure. This makes the crucial task of inspecting eye bolts nearly impossible and can lead to a damaged component remaining in service, creating a severe safety hazard.

Safe Installation and Load Application for Lifting Eye Bolts

A secure lift begins long before the load leaves the ground. Correct installation and a clear understanding of load forces are fundamental to safety. A rigger’s diligence in preparing the receiving hole and applying the load properly prevents hardware failure and protects personnel.

Preparing the Receiving Hole

The integrity of the tapped hole is just as important as the bolt itself. A compromised receiving hole will undermine the strength of the entire connection.

Checking Hole Depth and Thread Condition

A rigger must first verify that the receiving hole has the correct depth and clean threads. For machinery eye bolts, the minimum tapped depth should be the shank length plus one-half of the nominal bolt diameter. For other screw eye bolts, the tapped hole must have a minimum depth of one-and-a-half times the bolt diameter. This ensures sufficient thread engagement to handle the rated load. The threads in the hole must also be free of damage or excessive wear.

Cleaning Threads in the Tapped Hole

Debris, rust, or old lubricant can prevent full thread engagement. A technician should use a wire brush or a thread tap to clean the internal threads of the receiving hole before installing the bolt. A clean connection is essential for achieving proper torque and seating.

Correct Installation Techniques

The method of installation directly affects the performance and safety of lifting eye bolts. Each step requires careful attention to detail.

Hand-Tightening and Proper Seating

A rigger should always start threading eye bolts by hand. This practice prevents cross-threading, which can permanently damage both the bolt and the receiving hole. For shouldered types, the operator must continue tightening until the shoulder makes firm, flush contact with the load surface.

Correct Use of Washers and Shims

If a gap exists under the shoulder after full thread engagement, a rigger can use hardened, flat washers or shims. These components fill the gap, ensuring the shoulder seats correctly and can properly support angular loads. Never use more shims than necessary.

Avoiding Over-Torquing and Under-Torquing

Caution: Improper torque creates a significant safety risk.

Under-torquing a shouldered bolt leaves a gap, which negates its ability to handle angular loads. Over-torquing can stretch the bolt shank and damage the threads, permanently reducing its load capacity and leading to potential failure.

Understanding Load Dynamics and Forces

The forces acting on lifting eye bolts are not always straightforward. A rigger must account for angles and dynamic movements.

How Angular Loading Reduces Capacity

Applying a load at an angle to a shouldered eye bolt introduces bending forces and significantly reduces its Working Load Limit (WLL). Plain pattern bolts must never be used for angular lifts. The plane of the eye must always be aligned with the direction of the pull.

Calculating Reduced WLL for Angular Lifts

The reduction in WLL is substantial as the sling angle increases. Riggers must consult manufacturer charts to determine the reduced capacity.

| Sling Angle (from vertical) | WLL Reduction |

|---|---|

| 0° (Vertical Lift) | 100% of Rated WLL |

| 45° | 30% of Rated WLL |

| 90° (Horizontal) | 25% of Rated WLL |

The Dangers of Shock Loading

Shock loading occurs when a load is suddenly accelerated or decelerated. This action can generate forces many times greater than the static weight of the object being lifted. Such dynamic forces can easily exceed the bolt’s WLL, causing immediate and catastrophic failure. Riggers must always lift, move, and lower loads smoothly.

Common Mistakes in Eye Bolt Use and How to Avoid Them

Even with high-quality hardware, human error remains a significant risk factor in lifting operations. Understanding and avoiding common mistakes is essential for maintaining a safe work environment. These errors often fall into three categories: installation, inspection, and rigging.

Critical Installation Errors

Proper installation is the foundation of a safe lift. Errors made at this stage can compromise the entire operation.

Incomplete Thread Engagement

A rigger must ensure the eye bolt’s shank is fully threaded into the receiving hole. Insufficient engagement creates a weak connection, concentrating stress on only a few threads. This can cause the threads to strip long before the bolt reaches its rated capacity.

Misalignment with Load Direction

The plane of the eye must always align with the direction of the sling pull. Installing an eye bolt so the pull is across the eye introduces dangerous bending forces. This misalignment significantly weakens the component and can lead to sudden failure.

Using Plain Eye Bolts for Angular Lifts

A plain pattern eye bolt lacks a reinforced shoulder at its base. This design makes it extremely susceptible to bending under any angular load. Using these eye bolts for anything other than a straight vertical lift is a critical mistake. Even shouldered lifting eye bolts experience a sharp reduction in strength when loaded at an angle.

- An angle of 15° from vertical can reduce capacity to 63%.

- An angle of 30° can reduce capacity to 40%.

- An angle of 45° can reduce capacity to just 25%.

Common Inspection Oversights

Diligent inspection catches wear and damage before it leads to an accident. Overlooking key warning signs is a frequent and dangerous error.

Ignoring “Minor” Nicks or Gouges

An inspector might dismiss small nicks or gouges as insignificant wear. However, these surface flaws act as stress risers, creating weak points where a crack can begin under load. Any visible damage requires a thorough evaluation by a qualified person.

Failing to Check Thread Condition

Inspectors sometimes focus only on the eye and shank, neglecting the threads. Damaged, corroded, or stripped threads prevent proper seating and load transfer. This oversight can lead to the bolt pulling out of its mounting hole during a lift.

Skipping Mandatory Pre-Use Checks

The pre-use check is a non-negotiable safety step. Rushing a job and skipping this quick visual and functional inspection means potentially using damaged eye bolts. This oversight eliminates the most effective defense against equipment failure.

Improper Rigging Practices

Correct rigging technique ensures that forces are applied to lifting eye bolts as intended by the manufacturer.

Exceeding the Rated Working Load Limit

A rigger must never subject an eye bolt to a load greater than its stamped WLL. This includes accounting for angular load reductions and avoiding shock loading, which can create forces far exceeding the static weight of the load.

Using Incompatible or Damaged Hardware

Connecting shackles or hooks that are too large or small for the eye can create unsafe point loading. A rigger must always use correctly sized, compatible hardware. Furthermore, rigging with any damaged component compromises the entire system’s safety.

Side Loading a Plain Pattern Eye Bolt

Critical Error: Applying a side load to a plain pattern eye bolt is one of the most dangerous mistakes a rigger can make. These components have no capacity for angular forces and will likely bend or break.

Documentation, Compliance, and Regulatory Standards

Thorough documentation is the backbone of any effective rigging safety program. Maintaining detailed records, understanding compliance obligations, and adhering to established standards transform safety from a guideline into an enforceable practice. This process provides accountability and a clear history of equipment integrity.

The Importance of an Eye Bolt Inspection Log

An inspection log is more than a simple record; it is a critical tool for managing the lifecycle and safety of rigging hardware. It provides a centralized source of truth for every component in service.

Tracking Asset Service History

A dedicated log creates a complete service history for each individual eye bolt. This record tracks every inspection, any observed wear, and all maintenance actions performed. Over time, this data helps safety managers identify trends, predict component lifespan, and make informed decisions about retirement schedules.

Demonstrating Regulatory Compliance

Best Practice: A well-maintained log is the strongest evidence of a company’s commitment to safety and due diligence.

Regulatory bodies require employers to ensure equipment is safe. While a standard like ASME B30.26 may not explicitly mandate a written record for every type of inspection, a detailed log is the universally accepted method for proving compliance. It demonstrates that a company has a structured inspection program in place and follows it consistently.

What to Record in Your Inspection Log

A useful inspection log must be clear, concise, and contain specific information. Each entry should provide a complete snapshot of the component’s status at the time of inspection. Key data points include:

Unique Eye Bolt Identifier

Each of the lifting eye bolts needs a unique serial number or identifier. This code links the physical component to its record in the log, eliminating any confusion and ensuring accurate tracking throughout its service life.

Inspection Date and Inspector Name

The log must clearly state the date of the inspection and the name or initials of the qualified person who performed it. This information establishes a clear timeline and assigns accountability for the assessment.

Detailed Pass/Fail Results

A simple checkmark is insufficient. The log should have a clear field indicating a “Pass” or “Fail” result. This definitive outcome dictates the immediate action required for the component.

Notes on Condition and Actions Taken

This section provides crucial context. The inspector should note any specific findings, such as minor corrosion or thread wear. If an eye bolt fails inspection, the log must record the action taken, for example, “Removed from service and destroyed.”

Key Regulatory Standards for Eye Bolts

Compliance requires a working knowledge of the primary standards governing rigging hardware. These documents provide the technical requirements and legal obligations for safe operation.

ASME B30.26: Rigging Hardware

The American Society of Mechanical Engineers (ASME) B30.26 standard is the foundational technical document for rigging hardware. It details the requirements for the construction, installation, testing, and marking of components, including lifting eye bolts. It provides the industry-accepted criteria for inspection and removal from service.

OSHA 1910.184: Slings and Rigging

The Occupational Safety and Health Administration (OSHA) 1910.184 standard is a federal law in the United States. It places a legal responsibility on employers to protect workers by ensuring all rigging equipment is inspected and maintained properly. This regulation makes adherence to industry best practices, like those in ASME standards, a legal requirement for a safe workplace.

Ultimate eye bolt safety relies on a rigger’s consistent diligence. A professional must follow several non-negotiable rules for every lifting operation.

- Perform a pre-use inspection to ensure overall safety.

- Adhere to a documented periodic schedule to find gradual damage.

- Immediately destroy failed eye bolts to prevent accidental reuse.

- Guarantee correct installation with full thread engagement.

- Maintain a detailed log for compliance and lifecycle tracking.

FAQ

What is the single most important eye bolt safety check?

A rigger must perform a pre-use check before every single lift. This quick visual and functional inspection is the most critical defense against equipment failure. It confirms the hardware is safe for use at that exact moment.

Can a damaged eye bolt be repaired and reused?

No. A person must never attempt to repair a damaged eye bolt by welding, grinding, or heating. Such actions compromise its integrity. Any failed component requires immediate removal from service and complete destruction to prevent accidental reuse.

Why is the shoulder on an eye bolt so important?

The shoulder allows an eye bolt to support angular loads. It braces the bolt against bending forces when the lift is not perfectly vertical. The shoulder must sit completely flush with the load surface to work correctly.

Is it safe for a technician to paint an eye bolt?

Warning: A person must never paint an eye bolt. Paint and other coatings hide dangerous defects like cracks, gouges, and heat damage. This makes a proper inspection impossible and creates a severe safety hazard.

How does a rigger choose between carbon and stainless steel?

A rigger selects carbon steel for general-purpose strength in normal environments. He or she chooses stainless steel for its excellent corrosion resistance. Stainless steel is essential for marine, chemical, or food processing applications where rust is a concern.

What is shock loading and why is it dangerous?

Shock loading occurs when a load is suddenly dropped, stopped, or swung. This action creates dynamic forces far greater than the object’s static weight. These forces can easily exceed the eye bolt’s WLL and cause immediate, catastrophic failure.