This installation guide details the professional framework for hex bolt installation. Proper selection and installation prevent bolt failure, a common issue stemming from incorrect preloading or material choice. A technician first selects the correct hex bolt and nut; a custom fasteners manufacturer can supply custom fasteners or unique bolt casting for specific needs. They insert the bolt, hand-thread the hex nut, and then tighten the hex nut to the specified torque.

A final inspection of the completed hex bolt and nut connection confirms the joint is secure, ensuring the hex hex hex assembly meets all safety and performance standards.

Pre-Installation Essentials: Tools and Components

A successful hex bolt installation begins long before a technician tightens the first fastener. Proper preparation involves assembling the right tools and selecting the correct components. This foundational step ensures the final connection is both strong and reliable.

Gathering Your Essential Toolkit

A well-organized toolkit is critical for efficiency and safety. Technicians should gather all necessary items before starting work to avoid interruptions.

Wrenches and Socket Sets

The primary tools for any hex bolt and nut job are wrenches and sockets. A standard kit should include a variety of sizes to handle different hex head dimensions.

- Allen Keys: 5/32″, 4mm, 3/16″, 5/16″

- Sockets: 1/2″, 7/16″, 5/16″

- Torx: T30

- Other: Flathead Screwdriver

Using high-quality tools from brands like Bondhus or Wiha is highly recommended. These tools provide a better fit, which helps prevent stripping the hex head of the bolt, especially when dealing with fasteners secured with a thread-locking compound.

The Critical Role of the Torque Wrench

A calibrated torque wrench is non-negotiable for achieving the correct preload. This tool allows a technician to apply a precise amount of rotational force, ensuring the hex bolt and nut assembly is tight enough to resist loosening but not so tight that it damages the bolt or the joint materials.

Cleaning Supplies and Safety Gear

Safety and cleanliness are paramount. A technician needs wire brushes, clean cloths, and appropriate solvents to prepare joint surfaces. Personal Protective Equipment (PPE), including safety glasses and gloves, must be worn to protect against debris and chemicals.

How to Select the Right Hex Bolt

Choosing the correct hex bolt is crucial for the integrity of the joint. A technician must consider material, strength, dimensions, and thread type.

Decoding Bolt Materials (Steel, Stainless, etc.)

The bolt material determines its resistance to corrosion and its overall performance. Steel is common for general use, while stainless steel is ideal for environments exposed to moisture. Other materials like brass or bronze offer unique properties for specific applications.

Understanding Bolt Grades and Strength Markings

Bolt grades indicate the fastener’s strength. Markings on the hex head of a bolt, such as radial lines (for SAE) or numbers (for metric), identify its tensile strength. A higher grade or number signifies a stronger bolt.

Measuring for Correct Diameter, Length, and Grip

A technician must measure for the correct bolt diameter and length. The grip length—the unthreaded portion of the bolt shank—should be long enough to span the full thickness of the materials being joined to maximize shear strength.

Choosing Between Coarse (UNC) and Fine (UNF) Threads

The choice between coarse (UNC) and fine (UNF) threads depends on the application. UNC threads are more common and install faster, while UNF threads offer greater precision and resistance to loosening from vibration.

| Feature | UNC Threads (Coarse) | UNF Threads (Fine) |

|---|---|---|

| Pitch | Threads are spaced farther apart | Threads are spaced closer together |

| Application | General construction, heavy-duty use | Aerospace, electronics, high-precision |

| Strength | Superior strength, handles greater loads | Less effective with heavy loads |

| Installation | Easier and quicker to install | More time-consuming to install |

Selecting the Correct Hex Bolt and Nut Combination

A hex bolt is only as strong as its accompanying nut. The hex bolt and nut must be compatible in grade, material, and size.

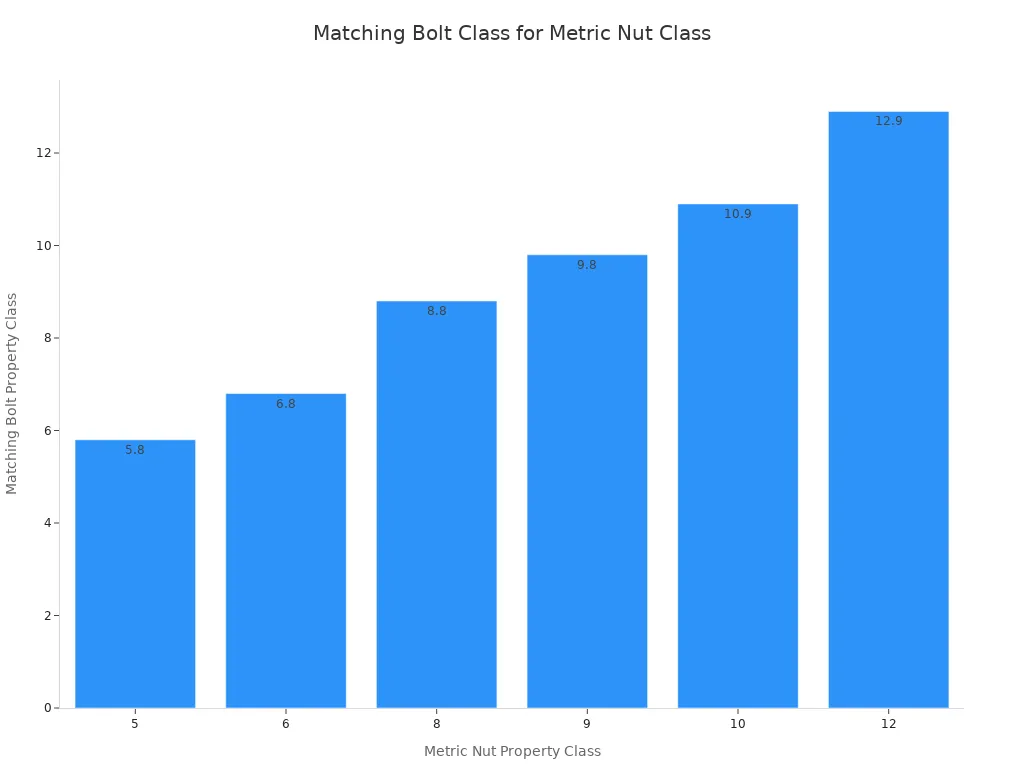

Matching Nut Grade and Material to the Bolt

A nut must meet or exceed the strength grade of its corresponding bolt. Using a lower-grade nut with a high-strength hex bolt will compromise the entire assembly, as the nut threads may strip before the bolt reaches its required tension. The hex nut should also be made of a compatible material to prevent galvanic corrosion.

Pro Tip: Always match the nut grade to the bolt grade. A Grade 8 hex bolt requires a Grade 8 hex nut to achieve its full strength potential.

| SAE Nut Grade | Markings | Matching Bolt Grade |

|---|---|---|

| Grade 2 | No markings | Grade 2 |

| Grade 5 | 3 radial lines | Grade 5 |

| Grade 8 | 6 radial lines | Grade 8 |

The Function of Washers: Plain, Spring, and Locking

Washers play a key role in a hex bolt and nut connection. A plain washer distributes the load from the bolt head and nut over a wider surface area. A spring or locking washer provides resistance against vibration-induced loosening, ensuring the nut remains secure over time.

Preparing for a Flawless Hex Bolt Installation

Proper preparation is a non-negotiable phase of professional fastener work. Before the first turn of a wrench, a technician must ensure that all joint components are clean, correctly aligned, and properly lubricated. This meticulous groundwork is the key to a secure and durable connection.

Surface and Hole Preparation

The condition of the mating surfaces directly impacts the performance and longevity of a bolted joint. Cleanliness and correct alignment are foundational to achieving an even distribution of the load.

Cleaning Debris, Rust, and Old Lubricants

A technician must prepare surfaces by making them clean and free of debris. Any rust, dirt, or old lubricants can prevent the hex head and hex nut from seating correctly. This contamination can lead to inaccurate torque readings and uneven load distribution. For painted connections, it is critical to clean fasteners of any surface contamination. If using galvanized nuts, the factory lubricant must be sufficiently removed to avoid compromising the adhesion of a new coating. Clean surfaces are essential for a reliable joint.

Verifying Hole Alignment and Diameter

Proper alignment of the joined parts is crucial for a smooth installation. A technician should verify that holes line up perfectly to allow the hex bolt to pass through without force. Misalignment can damage threads and place unintended stress on the fastener. The hole diameter should also be checked to ensure a correct fit for the selected hex bolt, preventing excessive movement that could compromise the joint’s integrity over time.

The Lubrication Factor

The decision to use a lubricant can significantly alter the dynamics of tightening a hex fastener. It is a critical factor that influences both the required torque and the final clamping force.

To Lubricate or Not to Lubricate?

Applying a lubricant to a bolt is often a best practice for achieving consistent results. While dry installations are possible, lubrication offers several distinct advantages for the hex assembly.

- Creates a barrier: A quality lubricant facilitates easier disassembly in the future.

- Removes debris: The application of a lubricant can help clear particulate matter from threads.

- Protects against corrosion: Certain lubricants provide a protective layer that reduces the risk of rust.

- Ensures consistent loading: Lubricated hex studs lead to more consistent and accurate stress application.

Note: Using a lubricant with a known K-factor (Nut Factor) is the most reliable way to prevent issues like bolt yielding or insufficient clamping force.

How Lubricants Affect Torque Values

Lubricants directly influence the required tightening torque by reducing friction. This friction exists between the hex nut and bolt threads and between the nut and the joint surface. A lubricant ensures these frictional properties are consistent, which is essential for determining the correct torque value. A non-lubricated hex fastener has an unpredictable friction level, making it impossible to achieve an accurate preload. For this reason, a technician should apply lubricant generously to the threads and under the hex head to achieve the target clamping force with significantly less variation.

The Core Installation Guide: A 5-Step Process

With all components selected and surfaces prepared, a technician can begin the core installation. This professional installation guide outlines a precise, five-step method. Following these steps ensures that every hex bolt and nut assembly achieves its designed clamping force and structural integrity. The first three steps establish the foundation for a secure joint.

Step 1: Insert the Bolt and Position Components

The initial placement of the hex bolt sets the stage for the entire assembly. Correct orientation and full insertion are critical for distributing loads evenly and preventing component damage.

Correct Bolt Orientation and Alignment

Proper alignment is essential for a stress-free connection. A technician ensures all parts line up correctly before inserting the first hex bolt. A systematic approach guarantees precision.

- Inspect Components: A technician first examines the hex bolt, nut, and washers for any defects like cracks or damaged threads.

- Verify Hole Alignment: They confirm that the holes in the mating parts are perfectly aligned and correctly sized for the bolt.

- Mark Alignment Points: For complex joints, a technician can use a marker to indicate the correct orientation.

- Insert the First Bolt: They insert the first hex bolt to act as a guide, threading its nut on slightly to hold it in place.

- Position Remaining Bolts: Using the first bolt as a reference, they insert the remaining fasteners, ensuring all are parallel before proceeding.

Ensuring Full Insertion Through the Joint

The bolt must pass completely through all layers of the joint. The shank of the hex bolt, not the threads, should bear the shear load. A technician verifies that the bolt is long enough for the nut to engage fully without bottoming out on the shank. This full insertion is a non-negotiable checkpoint for a secure connection.

Step 2: Add Washers and Thread the Nut

Once the hex bolt is in position, the technician adds the washers and nut. This sequence must be performed correctly to distribute pressure and prevent loosening.

Proper Washer Placement and Order

Washers are not optional accessories; they are integral components of a high-strength hex connection. A technician follows a specific order for maximum effectiveness.

- A flat washer goes under the component being turned, which is typically the nut. This placement distributes the turning pressure over a wider surface area, protecting the joint material.

- If a spring or locking washer is used, it is placed directly against the hex nut. This allows it to apply counter-pressure and resist loosening from vibration.

Starting the Nut by Hand to Prevent Cross-Threading

A technician must always start threading the hex nut by hand. Using a wrench from the beginning risks cross-threading, a situation where the threads of the nut and bolt misalign and cut into each other. This damages both components and compromises the strength of the connection. Hand-tightening for the first few turns ensures the threads are properly engaged.

Step 3: Achieve a Snug-Tight Connection

Before applying final torque, the joint must be brought to a “snug-tight” condition. This crucial intermediate step eliminates gaps and prepares the assembly for final tensioning.

What is a Snug-Tight Fit?

A snug-tight connection is the point where all parts of a joint are in firm contact. The technician tightens the hex nut until any looseness is gone and the components can no longer be moved by hand.

A snug-tight fit is formally defined as the full effort an individual can apply with a standard spud wrench. It means the connection is firm enough that the nut cannot be removed without a tool. This state ensures all plies are drawn together before final tensioning begins.

The Importance of Hand-Tightening First

Achieving a snug-tight fit is a prerequisite for accurate final tightening. This initial step removes all slack from the joint. Methods like the ‘Calibrated Wrench Method’ and the ‘Turn-of-the-Nut Method’ depend on this baseline. Applying torque without first snugging the connection would waste energy on closing gaps rather than stretching the bolt to achieve the correct clamping force. This can lead to an improperly tensioned hex bolt and nut, creating a risk of loosening under stress.

Step 4: Wrench Tightening to Final Specification

With the joint snug-tight, the technician proceeds to the most critical phase: applying the final, specified torque. This step stretches the bolt to create the precise clamping force required for a secure and lasting connection.

Using a Wrench for Initial Run-Down

A technician uses a standard spud or socket wrench for the initial run-down of the hex nut. This process quickly brings the nut from a hand-tight position to the snug-tight condition. Using a standard wrench for this task is more efficient. It also preserves the calibrated mechanism of the torque wrench for the final, precise application of force. The goal is to eliminate all gaps before the final torque is applied.

How to Set and Use Your Torque Wrench Correctly

Achieving an accurate preload is entirely dependent on the correct use of a calibrated torque wrench. A technician’s technique is as important as the tool’s calibration. The following steps ensure precision:

- Set the Wrench Carefully: The technician adjusts the torque wrench to the value specified in the project’s engineering documents. He or she visually confirms the correct setting on the dial or digital display to prevent misreading errors.

- Operate Slowly and Steadily: The technician pulls the wrench in a smooth, continuous motion. Rapid or jerky movements can lead to over-tightening. The pull continues until the wrench indicates the target torque has been reached, often with an audible “click.”

- Apply Force Only to the Handle: A technician must apply force exclusively to the designated handle area. The wrench is calibrated to measure torque accurately only when pressure is applied at this specific point. Pushing on the wrench body or using an extension can produce an inaccurate reading.

Professional Insight: A torque wrench measures rotational force, not the clamping load itself. The final clamping load depends on conditions assumed by the manufacturer. Factors like surface coatings, temperature, and lubrication introduce friction variations. For example, using a torque specification for a dry hex bolt on a greasy hex bolt can lead to severe over-tightening. The grease reduces friction, so the bolt stretches more for the same amount of torque, creating a dangerously high clamping load.

Applying Final Torque in a Smooth, Continuous Motion

The final application of torque must be a deliberate and fluid action. A technician applies force to the torque wrench handle in a single, uninterrupted pull until the tool signals that the target value is met. Stopping and starting during the final pull can lead to a false reading, as it takes more force to overcome static friction than to maintain motion. This smooth motion ensures the energy from the wrench is consistently used to stretch the bolt, not to overcome intermittent friction, resulting in an accurate and reliable hex connection.

Step 5: The Final Quality and Safety Check

The final step in this installation guide is a thorough quality and safety inspection. A technician visually and physically examines the completed hex bolt and nut assembly to confirm its integrity. This check ensures the installation meets all performance and safety standards.

Verifying Proper Bolt Head and Nut Seating

A technician first performs a visual check to ensure the hex head and the hex nut are firmly seated against the joint surfaces. There should be no visible gap between the fastener’s bearing surface and the material or washer. The components must sit flat and square. Any tilting of the hex head or nut indicates a problem, such as hole misalignment or debris trapped in the joint, which compromises the connection’s strength.

Inspecting for Gaps or Misalignment

The technician carefully inspects the entire joint for any signs of gaps between the plies or plates being fastened. A properly tightened connection draws all components into firm, uniform contact. The presence of gaps suggests that the clamping force is insufficient or unevenly distributed. This could be due to an incorrect snugging procedure or an obstruction within the joint. This final visual sweep is a simple yet effective way to spot a potential failure point before the structure is put into service.

Marking the Fastener for Future Inspection

For long-term maintenance and safety, a technician often marks the completed installation. The most common method is using a paint pen to draw a straight line from the center of the hex nut across the threads of the bolt and onto the joint surface. This “match-mark” provides an immediate visual reference. If the line on the nut moves out of alignment in the future, it indicates the fastener has loosened.

Some modern fasteners simplify this process with built-in indicators:

- Squirter® DTIs use a patented orange indication media that appears when the correct bolt tension is achieved.

- SmartBolts feature an indicator that changes color to show the fastener’s tension level.

- TurnaSure® and ViewTite® DTIs provide a clear visual cue, either by flattening completely or by displaying a bright neon green color, to confirm a successful hex bolt and nut installation.

Advanced Techniques for the Installation of Hex Bolt and Nut

Beyond the standard procedure, certain applications demand advanced techniques for a successful installation of hex bolt and nut. This installation guide covers specialized fasteners and methods that technicians use to ensure maximum safety and performance in critical joints. Mastering these techniques elevates a standard installation to a professional level.

Understanding Torque-to-Yield (TTY) Bolts

Torque-to-Yield (TTY) bolts, also known as stretch bolts, represent a specialized class of fasteners designed for high-performance applications. They provide a very precise and uniform clamping force.

What Are TTY Bolts and Why Are They Single-Use?

A technician tightens a TTY bolt beyond its elastic limit into its plastic region. This process permanently stretches the bolt. The metallurgical reason for this single-use design is that the stretching irreversibly changes the steel’s internal crystal properties. Once a TTY bolt undergoes this plastic deformation, it cannot return to its original shape. Reusing a stretched bolt is dangerous because it will either fail to provide adequate clamping force or break under load.

Common Applications for TTY Fasteners

Technicians use TTY fasteners in high-frequency, high-load situations where joint integrity is paramount. These bolts excel at resisting fatigue-related failures. A prime example is in automotive engines, where they secure critical components like cylinder heads. The uniform clamping force they provide is essential for maintaining a perfect seal under extreme pressure and temperature changes.

The Turn-of-Nut Tightening Method

The Turn-of-Nut method is a reliable alternative to using a torque wrench. It provides accurate preload by controlling bolt elongation directly.

How the Turn-of-Nut Method Works

This technique is effective because it relies on geometry rather than friction. A technician first brings the connection to a snug-tight condition. Then, they mark the nut, bolt, and joint surface with a straight line. Finally, they rotate the nut a specific fraction of a turn (e.g., 1/2 turn, 2/3 turn) as specified in engineering documents. This prescribed rotation ensures the bolt stretches a precise amount, creating a consistent clamping force that is largely independent of friction variables.

When to Use This Alternative to Torque

A technician should use the Turn-of-Nut method in structural steel connections where achieving a specific minimum tension is more critical than adhering to a torque value. It is favored in field applications where conditions like grit or temperature can make torque readings unreliable. Because it measures elongation, it provides a more accurate preload than a torque wrench, which can have errors as high as ±35% due to friction.

Working with Gaskets and Soft Joints

Installing a hex bolt and nut on a joint with a gasket requires a special approach to prevent leaks and component damage. The goal is to compress the gasket evenly.

Applying Even Tightening Patterns (e.g., Star Pattern)

To achieve uniform pressure, a technician uses a specific tightening sequence. The most common method is the criss-cross or star pattern. This pattern prevents uneven loading on one side of the gasket. The process involves multiple passes:

- Hand-tighten each nut in the correct sequence.

- Tighten each nut to approximately 30-50% of the final torque using the star pattern.

- Repeat the sequence, tightening to 60% of the final torque.

- Perform a final pass, bringing each nut to 100% of the specified torque.

How to Prevent Gasket Damage During Installation

The primary cause of gasket failure is uneven compression. The incremental, multi-pass tightening sequence ensures the gasket is compressed gradually and uniformly. Rushing the process or fully tightening one side before the other can pinch, crush, or extrude the gasket material. Following the star pattern meticulously prevents this “crosstalk,” where tightening one fastener affects the tension of its neighbors, ensuring a durable, leak-free seal.

Troubleshooting: Common Mistakes and How to Avoid Them

Even a skilled technician can encounter issues during a hex bolt and nut installation. Understanding common mistakes is the first step toward preventing them. This knowledge ensures every connection is secure, durable, and safe.

The Dangers of Reusing Old or Damaged Bolts

The temptation to reuse fasteners is a significant risk in any assembly. A previously used bolt may appear fine, but it can hide critical weaknesses.

Why Reusing Fasteners is Risky

Reusing fasteners is a dangerous practice because the initial tightening process can permanently alter their properties. A technician should never combine used bolts with a new nut or vice versa. Age and tension create invisible deformities in the threads, leading to unstable joints.

- A bolt tensioned beyond its yield point enters a ‘plastic zone’ and elongates permanently.

- This stretching means it cannot provide the required clamping force upon reuse.

- The risk of breakage or joint failure far outweighs the small cost of a new fastener.

How to Identify a Fatigued or Stretched Bolt

Visually inspecting a used bolt for fatigue is often unreliable. It is nearly impossible to see if a fastener has been stretched into its plastic zone. However, a technician can look for obvious warning signs.

- Deformed Threads: Threads may look flattened, worn, or visibly stretched.

- Necking: The shank of the bolt may have a noticeable reduction in diameter in one area.

- Corrosion: Any sign of rust or corrosion compromises the fastener’s integrity.

Caution: If there is any doubt about a fastener’s condition, a technician must discard it. The potential cost and liability of a failure are too high.

Preventing Thread Damage During Installation

Protecting the threads of the bolt and nut is essential for achieving a strong connection. Two common issues that cause thread damage are cross-threading and galling.

What is Cross-Threading and How to Prevent It

Cross-threading occurs when a nut and bolt misalign during initial engagement, causing the threads to cut into each other. This permanently damages both components. A technician prevents this by always starting the nut by hand for several turns before using a wrench. A smooth, resistance-free start confirms proper alignment.

Understanding and Preventing Galling (Cold Welding)

Galling, or cold welding, happens when pressure and friction cause metal surfaces to fuse. This is common with materials like stainless steel, aluminum, and titanium. The friction during tightening can break down the protective oxide layer, allowing the bare metals to seize.

- Use Lubricants: Apply an anti-seize compound to reduce friction and heat.

- Slow Down: Reduce the speed of power tools to allow heat to dissipate.

- Mix Alloys: Use a nut and bolt of slightly different grades (e.g., a 316 bolt with a 304 nut) to reduce the likelihood of fusion.

Consequences of Improper Tightening

The final torque value is not arbitrary. It is calculated to achieve a specific clamping force. Deviating from this value leads to predictable and dangerous outcomes.

Risks of Under-Tightening: Vibration and Loosening

An under-tightened connection lacks the necessary clamping force to resist external loads. In systems exposed to vibration or thermal cycles, the fastener will inevitably loosen. This can lead to unstable structures, fluid leaks in sealed systems, and uneven stress distribution that causes premature part failure.

Risks of Over-Tightening: Bolt Failure and Material Damage

Applying excessive torque is just as dangerous as under-tightening. It can stretch a fastener beyond its yield strength, causing it to snap during installation or fail later under load. Over-tightening also damages the joint itself.

- It can strip threads, especially in softer materials.

- It may crack brittle components like flanges or plastic housings.

- It can crush gaskets, leading to leaks in sealed assemblies.

Post-Installation Care and Maintenance

A successful installation is only the beginning. The long-term integrity of a bolted joint depends on diligent post-installation care and maintenance. A technician establishes a proactive inspection plan to identify potential issues before they lead to failure, ensuring continued safety and performance.

Establishing a Routine Inspection Schedule

Regular inspections are the cornerstone of reliable joint maintenance. The frequency of these checks depends on the application’s criticality, operating environment, and exposure to loads or vibration.

Visual Inspection Checklist for Fasteners

A technician performs routine visual checks to catch early warning signs. They look for any movement in previously applied match-marks, which indicates loosening. They also inspect the area for signs of weeping or leaks in sealed joints. The overall condition of the fastener and surrounding material provides valuable clues about the joint’s health.

When to Re-Check Torque on Critical Joints

In high-vibration environments or on joints subject to thermal cycling, fasteners can lose preload over time. A technician should re-check the torque on critical connections as part of a scheduled maintenance program. This is especially important after the initial run-in period of new machinery, as components may settle.

Identifying Signs of a Failing Hex Bolt

Recognizing a compromised fastener is a critical skill. A technician must know how to spot the subtle and obvious signs of degradation.

Spotting Corrosion, Rust, and Bending

Visual evidence often provides the first indication of a failing hex fastener. A technician should look for clear signs of distress.

- Brown or reddish stains appearing near connection points.

- Visible metal flaking or pitting on fastener surfaces.

- Physical deformation, such as bent or uneven studs.

- Obvious corrosion, including red rust or white powder on galvanized coatings.

Looking for Signs of Stretching or Necking

Over-tightening or excessive loads can cause a fastener to stretch permanently. This condition, known as “necking,” is a critical sign of impending failure. A technician inspects the shank for any localized reduction in diameter. A necked-down fastener has lost its structural integrity and must be replaced immediately.

Safe Removal and Replacement Procedures

When a fastener must be replaced, a technician follows safe and methodical procedures to avoid damaging the assembly or causing injury.

Best Practices for Removing Old Bolts

Removing a seized or corroded bolt requires patience and the right technique. A technician always starts with the least aggressive method.

First, they apply a quality penetrating oil and allow it to soak. Gently tapping the fastener can help the oil work into the threads. If this fails, they may carefully apply heat to the surrounding material to expand it, helping to break the corrosion bond. As a last resort, a technician may need to drill out the damaged fastener, taking extreme care not to harm the component threads.

Ensuring You Select an Identical Replacement

When replacing a fastener, a technician must select an identical part. This means matching the new hex fastener’s material, grade, diameter, length, and thread pitch to the original. Using an incorrect replacement can compromise the safety and engineering of the entire assembly.

A successful hex bolt installation depends on three pillars: correct component selection, proper tool usage, and precise torque application. This comprehensive installation guide shows technicians how to achieve these goals. By following this step-by-step guide, a technician creates strong, reliable, and safe bolted connections every time.

A technician remembers that long-term joint integrity is maintained through routine inspection and timely maintenance, ensuring continued performance and safety.

FAQ

What happens if a technician uses the wrong size wrench? 🔧

Using an incorrectly sized wrench is a common mistake. It can round off or “strip” the corners of the hex head. This damage makes it difficult to apply the correct torque and can make future removal nearly impossible. A technician always ensures a snug fit.

Can an installer use motor oil instead of a specific bolt lubricant?

A technician should avoid using motor oil as a lubricant. Professional bolt lubricants have a known friction coefficient (K-factor) for accurate torque calculations. Motor oil offers inconsistent friction, which can lead to dangerously inaccurate clamping force and potential bolt failure.

How often should a technician calibrate a torque wrench?

A torque wrench requires regular calibration to ensure accuracy.

- Calibrate the tool at least once a year.

- Recalibrate it immediately if it is dropped.

Note: An uncalibrated wrench delivers unreliable torque values, compromising the safety and integrity of the entire bolted connection.

Is it acceptable to tighten a bolt as much as possible?

No, this is extremely dangerous. A technician tightens a bolt only to its specified torque value. Over-tightening stretches the bolt beyond its design limits, which can cause it to snap during installation or fail unexpectedly under load. Always follow engineering specifications.

Why is hand-tightening the nut first so important?

A technician always starts threading a nut by hand for several turns. This action ensures the threads are properly aligned and engaged. It is the single best method to prevent cross-threading, a type of damage that ruins both the bolt and the nut.

What is the main purpose of a washer in a hex assembly?

A washer performs a critical role in a joint. A plain washer distributes the clamping force over a wider surface, protecting the material from damage. A locking washer adds tension to resist loosening caused by vibration, keeping the connection secure over time.

Can a technician use a Grade 5 nut with a Grade 8 bolt?

No, this creates an unsafe connection. A technician must always match the nut grade to the bolt grade. A lower-grade nut will fail by stripping its threads before the higher-strength bolt can achieve its necessary tension, compromising the entire assembly.