Selecting the correct fasteners is critical for secure concrete and brick applications. The global market for concrete fasteners reflects this importance, with projections showing it will reach USD 8.1 Billion by 2033. Quality expansion bolts provide immense holding power through their unique expansion mechanism inside the base material. The market offers a wide array of anchors, from standard Anchor Bolts to solutions from a custom fasteners manufacturer for unique needs like custom anchor bolts.

A Quick Look at Top Performers for 2026:

- Hilti Kwik Bolt 3: Top-tier for structural concrete loads.

- Simpson Strong-Bolt 2: Best overall for cracked concrete.

- CONFAST Sleeve Anchor: An all-around choice for brick and block.

- Hillman Group Sleeve Anchor: Ideal for medium-duty brick work.

- ITW Dynabolt: Versatile for mixed materials, including brick and brick.

Detailed Reviews of the Top 10 Expansion Bolts

Choosing the right fastener is the most critical decision for ensuring a safe and durable installation. This section provides an in-depth look at the top-performing expansion bolts for 2026. We analyze their strengths, specifications, and ideal use cases to help you select the perfect anchor for your project.

1. Hilti Kwik Bolt 3

Best For

Heavy-duty structural applications in uncracked concrete, such as securing steel columns, heavy machinery, and racking systems.

Key Specifications

- Material: High-strength carbon steel and stainless steel options

- Approvals: ICC-ESR for uncracked concrete, ACI 318 compliance

- Mechanism: Torque-controlled wedge anchor

- Head Style: Threaded stud

Pros

- Unmatched Load Capacity: The Kwik Bolt 3 offers some of the highest tensile and shear load values in its class, making it the go-to for critical connections.

- Extreme Reliability: Hilti’s manufacturing and quality control are legendary. Professionals trust this anchor for projects where failure is not an option.

- Optimized Clip Design: The anchor features a proprietary clip design that ensures uniform expansion and superior holding power.

Cons

- Premium Price: Hilti products command a high price, placing them at the top end of the market.

- Not for Masonry: This anchor is engineered specifically for concrete and is not suitable for brick or block applications.

2. Simpson Strong-Tie Strong-Bolt 2

Best For

Overall performance in both cracked and uncracked concrete, making it a versatile choice for structural and non-structural fastening.

Key Specifications

- Material: Carbon Steel (Zinc Plated), 304 & 316 Stainless Steel

- Approvals:

- ICC-ES ESR-3037 for cracked and uncracked concrete

- Compliant with IBC, IRC, and ACI 318 codes

- City of L.A. approved (RR 25700)

- Size Availability: Offers a broad range of diameters and lengths, from smaller 1/4″ x 1-3/4″ anchors to large 1/2″ x 7″ options.

- Performance Data: The Strong-Bolt 2 is extensively tested for reliable performance in demanding conditions.

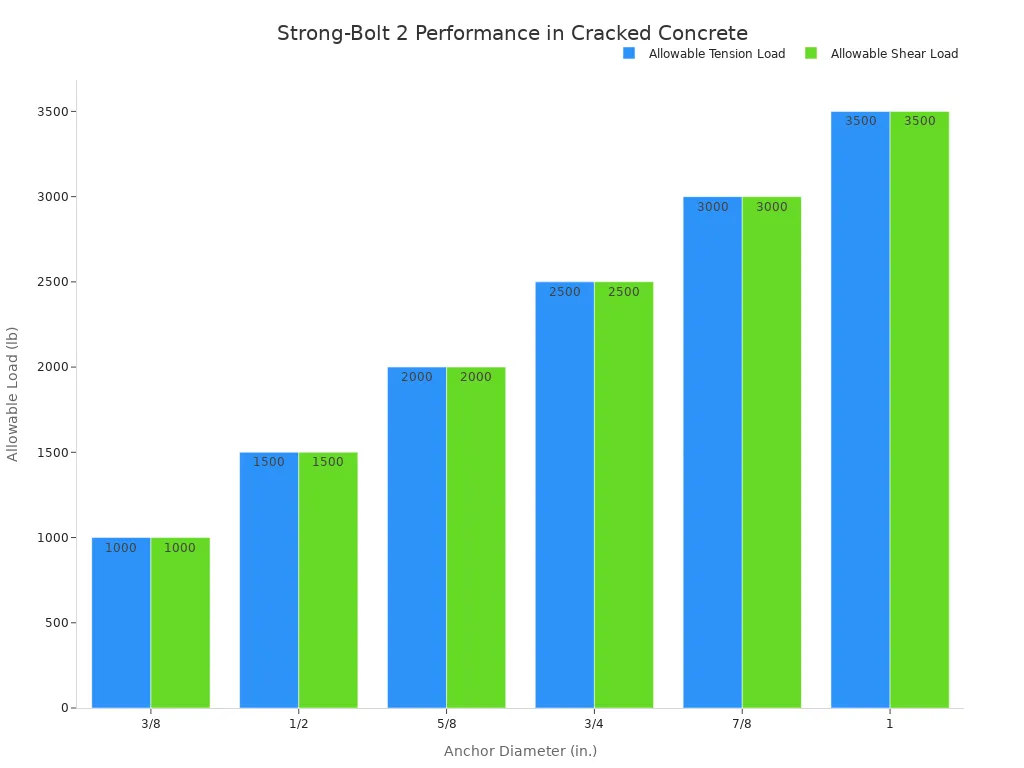

Allowable Loads in 4,000 psi Cracked Concrete The following table outlines the manufacturer’s certified load data, demonstrating the anchor’s consistent performance across various diameters.

Anchor Diameter (in.) Allowable Tension Load (lb) Allowable Shear Load (lb) 3/8 1,000 1,000 1/2 1,500 1,500 5/8 2,000 2,000 3/4 2,500 2,500 7/8 3,000 3,000 1 3,500 3,500

Pros

- Cracked Concrete Approved: Its primary advantage is its excellent, code-compliant performance in cracked concrete, a critical safety feature for modern construction.

- Versatility: One of the few anchors that excels in nearly any concrete application, simplifying inventory for contractors.

- Tri-Segmented Clip: Each anchor has a three-part clip that engages the concrete more effectively for maximum breakout resistance.

Cons

- Higher Cost than Basic Anchors: Its advanced engineering and certifications come at a higher price point than general-purpose wedge anchors.

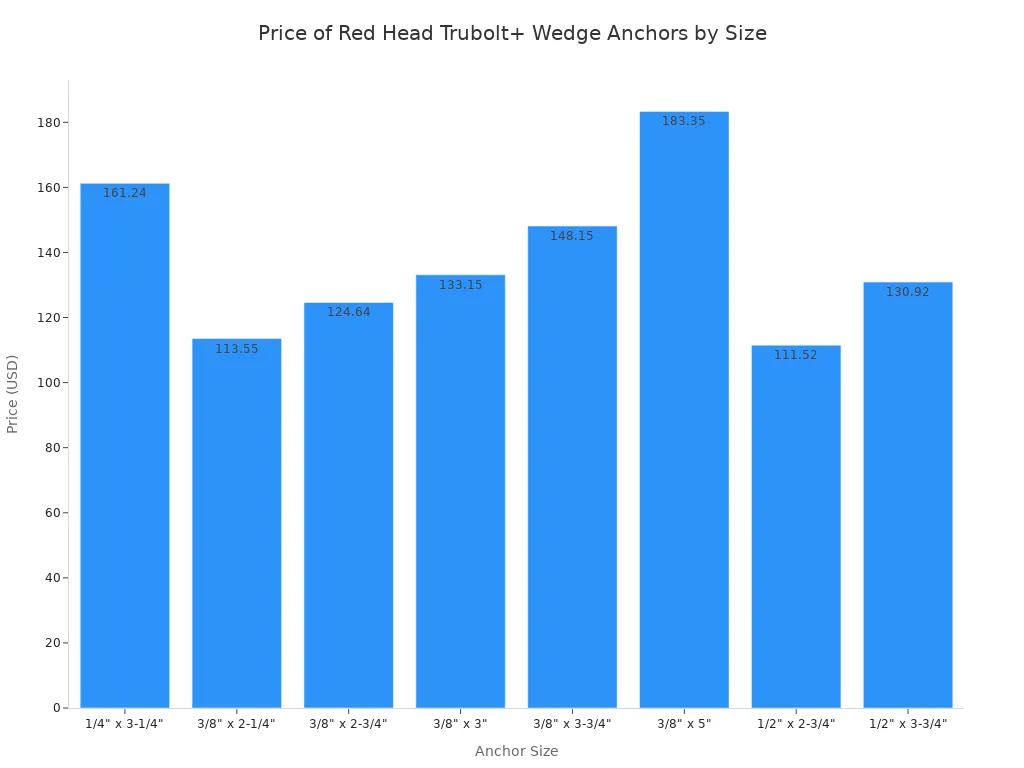

3. Red Head Trubolt+ Wedge Anchor

Best For

General-purpose fastening in solid, uncracked concrete where budget is a key consideration. Ideal for sill plates, support ledgers, and machinery mounting.

Key Specifications

- Material: Zinc-Plated Carbon Steel, 304 Stainless Steel

- Approvals: Meets GSA Specification FFS-325 Group II, Type 4, Class 1

- Strength (5/8″ x 4-1/2″ Anchor):

- Tensile Strength: 10,820 lb (Solid Concrete) / 4,800 lb (Lightweight Concrete)

- Shear Strength: 8,160 lb (Solid Concrete) / 6,440 lb (Lightweight Concrete)

Pros

- Exceptional Value: The Trubolt+ offers reliable performance at a highly competitive price point, especially when purchased in bulk. Boxes of 50 for a common 3/8″ x 3″ size often cost under $45.

- Wide Availability: These anchors are readily available at most hardware stores and construction suppliers.

- Proven Reliability: Red Head is a long-standing, trusted name in the industry, providing dependable holding power for standard applications.

Cons

- Uncracked Concrete Only: It is not rated for use in cracked concrete, limiting its use in certain structural or seismic zones.

- Lower Performance: Load values are generally lower than premium, cracked-concrete-rated options.

4. Powers Fasteners Power-Stud+ SD1

Best For

High-performance structural applications requiring significant shear resistance and seismic qualifications. It is a top choice for anchoring in earthquake-prone regions.

Key Specifications

- Material: Carbon Steel (Zinc Plated), 316 Stainless Steel

- Approvals: ICC-ESR for cracked and uncracked concrete; Seismic Design Categories A-F

- Mechanism: Heavy-duty torque-controlled wedge anchor

- Head Style: Threaded stud

Pros

- Superior Seismic Performance: This anchor is an excellent choice for seismic zones. The Powers Fasteners Power-Stud+ SD1 is approved for seismic design categories A through F, covering both seismic and wind loading applications. This makes it one of the most reliable fasteners for critical connections in demanding environments.

- High Shear and Tension Values: The SD1 is engineered for extreme loads. Its design provides exceptional resistance to both pull-out (tension) and sideways (shear) forces.

- Consistent Installation: The anchor features a fully-threaded design, offering greater flexibility for embedment depth and fixture thickness.

Cons

- Requires Precise Installation: Achieving its maximum load capacity demands strict adherence to installation torque specifications. Over-torquing or under-torquing can compromise its performance.

- Higher Price Point: Its specialized engineering and extensive code approvals place it in a premium price category compared to standard anchors.

5. DEWALT Screw-Bolt+

Best For

Heavy-duty temporary or removable anchoring. It is perfect for formwork, bracing, and equipment mounting where future removal or repositioning is necessary.

Key Specifications

- Material: Zinc-plated carbon steel, mechanically galvanized options

- Approvals: ICC-ES ESR-4098 for cracked and uncracked concrete

- Mechanism: Thread-forming screw anchor (one-piece design)

- Head Style: Hex Head, Flat Head

Pros

- Removable and Reusable: This anchor’s standout feature is its reusability. It offers a unique advantage for many projects.

- The DEWALT Screw-Bolt+ (both Hex Head and Flat Head versions) is fully removable.

- Users can reinstall it in the same hole, a feature not possible with traditional expansion bolts.

- Fast Installation: The one-piece design installs quickly with an impact wrench or standard socket. It requires no secondary tightening or assembly.

- Close-to-Edge Placement: The screw-style mechanism produces lower expansion forces, allowing for installation closer to concrete edges without risking a blowout.

Cons

- Requires a Clean Hole: Performance is highly dependent on a properly cleaned hole. Any remaining dust or debris can prevent the threads from engaging correctly.

- Lower Ultimate Loads: While strong, its ultimate load values are generally lower than high-capacity wedge anchors of the same diameter.

6. CONFAST Sleeve Anchor

Best For

Versatile light to medium-duty fastening in a variety of masonry materials, including solid concrete, brick, and block.

Key Specifications

- Material: Zinc-plated carbon steel, stainless steel

- Mechanism: Friction-based sleeve expansion anchor

- Head Style: Acorn, Hex, Flat, Round

- Size Range: Available in a wide variety of diameters and lengths for different applications.

Note on Versatility The CONFAST Sleeve Anchor is a true multi-purpose fastener. Its design makes it suitable for installation in solid concrete, brick, and block base materials. This adaptability makes it a valuable item for any toolkit.

Pros

- Excellent for Brick and Block: The sleeve design provides a large bearing surface against the base material. This feature distributes the load effectively, making it ideal for softer or hollow materials like brick and concrete masonry units (CMU).

- Wide Variety of Head Styles: The availability of different head types (Acorn, Hex, etc.) provides a finished look for various aesthetic and functional needs.

- Cost-Effective: These anchors offer reliable performance for many common jobs at a very affordable price, making them a go-to for budget-conscious projects.

Cons

- Lower Load Capacity: Sleeve anchors do not offer the same high-strength holding power as wedge anchors in solid concrete. They are not suitable for heavy structural loads.

- Larger Hole Requirement: They require a larger drill bit diameter relative to the bolt size compared to wedge or screw anchors.

7. Hillman Group Sleeve Anchor

Best For

Light to medium-duty fastening in brick and block. It is an excellent, accessible choice for homeowners and DIYers mounting items like handrails, window guards, and shelving.

Key Specifications

The Hillman Sleeve Anchor is a straightforward fastener designed for reliability in common household and light commercial jobs. Its specifications reflect its focus on accessibility and ease of use.

| Attribute | Value |

|---|---|

| Weight Capacity | 385 lb |

| Diameter | 3/8 in |

| Length | 3 in |

| Material | Steel |

| Finish | Zinc-Plated |

| Head Style | Hex Head |

Pros

- User-Friendly: This anchor is incredibly easy to install, making it a favorite for those who are not professional contractors. Its simple design works well in various masonry materials.

- Wide Availability: You can find Hillman Group products in nearly every major hardware and home improvement store, ensuring you can get them when you need them.

- Good for Softer Materials: The sleeve design creates a wide contact area inside the hole. This feature helps distribute the load, reducing the risk of cracking or damaging softer base materials like old brick or CMU.

Cons

- Limited Load Capacity: With a weight capacity of around 385 lbs for a common size, these anchors are strictly for light to medium-duty tasks. They are not suitable for structural support or heavy machinery.

- Not for Cracked Concrete: This anchor is not engineered or rated for use in cracked concrete, limiting its application in modern structural settings.

8. ITW Ramset/Red Head Dynabolt

Best For

Maximum versatility across a wide range of base materials. It is the ultimate “one-size-fits-most” solution for contractors who work with concrete, block, and brick.

Key Specifications

The Dynabolt is a true multi-purpose fastener, tested to perform reliably in numerous substrates. Its specifications highlight its robust and adaptable design.

| Specification | Detail |

|---|---|

| Material | Carbon Steel, 304 Stainless Steel |

| Approved Materials | Concrete, Grout-Filled Block, Hollow Block, Brick |

| Head Configurations | Hex, Flat, Round |

| Testing Standard | Meets ASTM E488 criteria |

| Drill Bit Size | Requires a drill bit of the same diameter as the anchor |

Pros

- Unmatched Versatility: The Dynabolt’s key strength is its certified performance in a variety of materials. A contractor can carry one type of anchor and confidently fasten into solid concrete, hollow block, or brick.

- Finished Appearance: The availability of multiple head styles (Hex, Flat, Round) allows users to choose an option that provides a clean, professional finish for exposed applications.

- Reliable Expansion: The sleeve compresses during installation to create a secure, 360-degree contact patch inside the hole, providing dependable holding power.

Cons

- Lower Strength in Concrete: While versatile, its ultimate load values in solid concrete do not match those of high-performance wedge anchors of the same diameter.

- Hole Size is Critical: Performance depends on drilling a hole that matches the anchor’s diameter precisely. An oversized hole will significantly compromise its holding power.

9. Wej-It Ankr-TITE CCAT Wedge Anchor

Best For

Demanding applications in corrosive and outdoor environments. It is the premier choice for coastal construction, chemical facilities, and any project exposed to moisture or harsh elements.

Key Specifications

- Material: Hot-Dip Galvanized (HDG) Steel, Type 316 Stainless Steel

- Approvals: ICC-ESR for cracked and uncracked concrete

- Mechanism: Torque-controlled wedge anchor

- Special Feature: Chamfered top with a three-segment clip for reliable expansion.

Pro Tip: Choosing the Right Material 💡

- Use Hot-Dip Galvanized (HDG) for most outdoor applications where moisture is a concern.

- Choose Type 316 Stainless Steel for extreme conditions, such as saltwater exposure or contact with corrosive chemicals.

Pros

- Superior Corrosion Resistance: This is the anchor’s defining feature. The HDG and 316 stainless steel options provide maximum protection against rust and degradation, ensuring long-term safety and stability.

- High Load Performance: As a premium wedge anchor, the Ankr-TITE CCAT offers exceptional tensile and shear load values, making it suitable for heavy structural connections.

- Cracked Concrete Rated: Its ICC-ESR approval for cracked concrete makes it a code-compliant solution for modern construction in challenging environments. These expansion bolts provide peace of mind.

Cons

- Significant Cost: The specialized materials and coatings make these anchors much more expensive than standard zinc-plated versions. Their cost is only justified when corrosion resistance is a critical requirement.

- Overkill for Indoor Use: Using these high-performance anchors for dry, indoor applications is unnecessary and not cost-effective.

10. Fischer FAZ II Bolt Anchor

Best For

Advanced applications involving dynamic, shock, or seismic loads in cracked concrete. This anchor excels at securing heavy equipment that produces vibrations, such as lifting platforms, conveyor belts, and industrial pumps.

Key Specifications

The Fischer FAZ II is a product of extensive German engineering, backed by numerous international approvals. Its specifications demonstrate its suitability for the most demanding jobs.

- Material: Zinc-Plated Steel, Hot-Dip Galvanized Steel, A4 Stainless Steel

- Mechanism: Torque-controlled expansion anchor with an optimized expansion clip.

- Key Approvals: The FAZ II holds a wide range of European Technical Assessments (ETA) and other certifications, including:

- ETA-19/0520

- ETA-05/0069

- ESR-2948 (ICC-ES)

- DoP No. 0186 & 0334

- Base Materials: Approved for cracked and uncracked concrete.

Pros

- Exceptional Dynamic Performance: The FAZ II is specifically engineered to handle movement and vibration. It has been assessed and approved for influences subject to fatigue, impact (collisions, explosions), and seismic activity. This makes it one of the safest expansion bolts for critical, non-static loads.

- High Load-Bearing Capacity: This anchor provides a significantly higher tensile load-bearing capacity compared to previous models. Its robust material strength ensures it can handle extreme forces in demanding concrete applications.

- Reliable Installation: The anchor’s expansion clip is designed to prevent rotation during tightening. This feature provides a secure setting and gives the installer tangible feedback when the correct torque is achieved. These anchors offer a high degree of safety.

Cons

- Premium Price Point: The advanced engineering and extensive international testing place the Fischer FAZ II in a high-end price category. Its cost is typically justified only for critical structural or dynamic load applications.

- Requires Professional Installation: To achieve its certified load values, this anchor demands precise installation according to the manufacturer’s specifications. Incorrect hole cleaning or torque application can compromise its elite performance.

How to Choose the Right Concrete Fasteners

Selecting the correct concrete fasteners is a process that balances the base material, load demands, and environmental exposure. A methodical approach ensures a secure and durable installation for all types of applications.

Assess Your Base Material

The foundation of any successful anchoring project is a thorough understanding of the base material. The strength and composition of concrete, brick, or block dictate which fasteners are appropriate.

Solid Concrete

Solid concrete provides a strong, dense base for anchoring. Its compressive strength is a critical factor, often determined through standardized tests. Destructive methods involve crushing concrete cubes or cylinders, while non-destructive methods like the rebound hammer test estimate strength on-site. High-strength concrete allows for the use of powerful wedge anchors.

Cracked vs. Uncracked Concrete

Designers must consider whether the concrete may crack under load or tension. Cracked concrete has significantly reduced holding capacity. Many modern building codes require anchors specifically rated for cracked concrete in structural applications to ensure safety.

Solid Brick

Solid brick is a common masonry material but is generally softer and more prone to crumbling than concrete. The compressive strength of brick is verified by testing representative samples until failure. This property makes sleeve-style masonry anchors a better choice than aggressive wedge anchors, as they distribute the load over a wider area.

Hollow Brick or Block

Hollow brick or block presents a unique challenge due to its internal voids. An anchor has less material to grip, making standard fasteners ineffective. The performance of different anchors varies significantly across materials.

| Anchor Type | Solid Concrete | Hollow Block | Solid Brick |

|---|---|---|---|

| Wedge Anchors | Reliable | Not suitable | Not specified |

| Sleeve Anchors | Versatile | Versatile | Versatile |

| Lag Shield Anchors | Effective | Effective | Effective |

Determine Load Capacity Needs

After identifying the base material, a user must determine the forces the anchor will need to resist. These forces are categorized as tensile, shear, static, or dynamic.

Understanding Tensile and Shear Loads

An anchor must handle two primary forces.

- Tensile Load: A pulling force that tries to extract the anchor from the hole.

- Shear Load: A sideways force that runs parallel to the material’s surface.

Industry standards like AISC 360-16 provide complex formulas for calculating the shear and tensile strength of bolted connections.

Static vs. Dynamic Loads

Static loads are constant, like the weight of a stationary cabinet. Dynamic loads fluctuate due to vibration, wind, or seismic activity. Anchors for dynamic loads require special designs to resist loosening over time.

Calculating Load Requirements

For any project, calculating the maximum expected load is essential. Professionals apply a safety factor to this calculation, often multiplying the expected load by four for critical connections. This ensures the chosen concrete fasteners can handle unforeseen stresses.

Consider Environmental Conditions

The environment where the anchors will be installed plays a huge role in their long-term performance and safety.

Indoor and Dry Environments

For indoor applications with no moisture, basic fasteners with a simple zinc plating are often sufficient. This coating provides minimal corrosion resistance but is adequate when rust is not a concern.

Outdoor and Wet Environments

Pro Tip: For outdoor projects exposed to rain and humidity, hot-dip galvanized fasteners offer superior corrosion protection compared to zinc plating. This thicker coating ensures longevity.

Corrosive or Chemical Exposure

In the most demanding environments, such as coastal areas with salt spray or industrial facilities with chemical exposure, stainless steel is the only suitable choice. These premium anchors provide the ultimate defense against degradation.

Installation Guide for Expansion Bolts

Proper installation is just as critical as selecting the right fastener. A high-quality bolt can fail if installed incorrectly. This guide provides a professional process for ensuring a secure and reliable connection every time.

Essential Tools and Safety Gear

Assembling the correct equipment beforehand streamlines the installation process and ensures safety.

Required Tools

- Hammer Drill or Rotary Hammer

- Carbide-Tipped Drill Bit (matching the anchor diameter)

- Wire Brush and Compressed Air/Blower Bulb (for hole cleaning)

- Hammer

- Torque Wrench with appropriate socket

- Tape Measure

Personal Protective Equipment (PPE)

- Safety Glasses: Protect eyes from concrete dust and debris.

- Gloves: Guard hands against abrasion.

- Dust Mask or Respirator: Prevent inhalation of harmful silica dust.

Step-by-Step Installation Process

Following these four steps methodically guarantees that anchors achieve their specified load capacity.

Step 1: Drill the Hole

An installer must drill a hole to the correct diameter and depth specified by the manufacturer. Using a hammer drill makes this process efficient. For masonry, knowing how to drill into brick without causing cracking is essential; a rotary hammer on the drill-only setting is often best. The hole must be perpendicular to the surface.

Step 2: Clean the Hole

This step is critical for proper expansion and grip. An installer should use a wire brush to scrub the inside of the hole, loosening all dust and debris. Afterward, they must use compressed air or a blower bulb to completely clear the hole of all loose particles. Repeat this process until the hole is clean.

Step 3: Install the Anchor

The user should lightly tap the anchor through the fixture and into the pre-drilled hole. The nut and washer should be in place. The anchor must be driven to the required embedment depth, ensuring the washer is snug against the fixture’s surface.

Step 4: Tighten to Torque Specs

Using a calibrated torque wrench is the only way to ensure correct tension. The installer tightens the nut to the manufacturer’s specified torque value. This action pulls the cone-shaped end into the sleeve, creating the expansion force that secures the fastener.

Typical Torque Specifications for Wedge Anchors Adhering to torque values is non-negotiable for a safe installation. The table below provides general guidelines.

Size Torque (ft./lbs.) 1/4” 2 – 6 3/8” 15 – 18 1/2” 18 – 26 5/8” 30 – 40 3/4” 60 – 90

Common Installation Mistakes to Avoid

Installation errors are a primary cause of fastener failure. The Construction Fixings Association (CFA) has documented cases where improper anchor spacing and positioning led to refractory lining failures, causing plant shutdowns and significant financial losses.

Incorrect Hole Depth or Diameter

A hole that is too shallow prevents the anchor from reaching its required embedment. A hole that is too wide will prevent the anchor from gripping the base material effectively.

Insufficient Hole Cleaning

Debris left in the hole acts as a barrier. It prevents the anchor from making full contact with the concrete or brick, drastically reducing its holding power.

Over-Torquing the Anchor

Applying too much torque can be as bad as applying too little. It can strip the threads, break the bolt, or even crack the concrete around the anchor, leading to a complete failure of the connection.

Quick Comparison of Top Expansion Bolts

Navigating the options requires a clear overview. This section provides a quick-reference matrix and a focused guide for choosing fasteners for masonry applications.

Performance and Feature Matrix

This table summarizes the key features of our top-rated anchors, helping users make a quick and informed decision.

Product Name

Best For

Material

Load Rating

Price Range

| Product Name | Best For | Material(s) | Load Rating | Price Range |

|---|---|---|---|---|

| Simpson Strong-Bolt 2 | Cracked Concrete | Carbon & Stainless Steel | High | $$ – $$$ |

| Red Head Trubolt+ | General Purpose Concrete | Carbon & Stainless Steel | Medium | $ – $$ |

| CONFAST Sleeve Anchor | Brick and Block | Carbon & Stainless Steel | Light-Medium | $ |

| Wej-It Ankr-TITE CCAT | Corrosive Environments | HDG & 316 Stainless Steel | High | $$$ – $$$$ |

Finding the Best Anchors for Brick

Anchoring into brick presents unique challenges. Brick is a brittle material compared to concrete. The wrong anchor can easily crack the brick, compromising the entire installation. Selecting the right fasteners is crucial for a secure hold in any masonry wall.

Sleeve Anchors

Sleeve-style masonry anchors are often considered one of the best anchors for brick. Their design is ideal for this material. The sleeve expands along the length of the anchor, distributing the expansion force over a larger surface area. This action significantly reduces the stress on a single point within the brick. It minimizes the risk of cracking the brick during installation. This makes them a reliable choice for both solid and hollow brick.

Hammer Drive Anchors

Hammer drive anchors offer a simple solution for very light-duty applications in solid brick. These anchors consist of a pin and an expanding body. An installer simply drills a hole and hammers the pin flush. This action flares the end of the anchor, securing it inside the brick. They are suitable for attaching electrical conduit or signage to a brick surface.

Masonry Screws (Tapcon)

Masonry screws, like the popular Tapcon brand, are another excellent choice. These hardened screws cut their own threads directly into the brick. They provide a secure hold without any expansion force, making them one of the best anchors for brick, especially when fastening close to an edge. Their removability is a key advantage for temporary installations on a brick facade. The best anchors for brick ultimately depend on the specific load and the condition of the masonry itself.

Selecting the correct concrete fasteners ensures success for various applications. A few products stand out for specific needs:

- Top Overall: The Simpson Strong-Tie Strong-Bolt 2 excels in a wide range of applications.

- Best Value: The Red Head Trubolt+ provides dependable strength for general-purpose applications.

- Best Heavy-Duty: Hilti’s Kwik Bolt 3 is the professional choice for maximum load capacity.

A project’s success depends on matching these concrete fasteners to specific load requirements. Users must always verify manufacturer data before installing these types of fasteners.

FAQ

What is the main difference between a wedge anchor and a sleeve anchor?

A wedge anchor provides superior strength in solid concrete through a small, powerful expansion clip at its base. A sleeve anchor uses a larger sleeve that expands along its body. This design distributes pressure, making it better for softer materials like brick and block.

Can users reuse expansion bolts after removal?

Most expansion bolts are permanent, single-use fasteners. The removal process damages the expansion mechanism, rendering it unsafe for reinstallation. Screw-style anchors are the exception, as manufacturers design them specifically for removal and reuse in temporary applications.

Why is cleaning the drilled hole so important?

Debris in the hole prevents the anchor from making full contact with the base material. This severely reduces its holding power. A clean hole ensures the anchor’s expansion mechanism can properly grip the concrete or brick, achieving its full, specified load capacity.

What happens if an installer over-torques an anchor?

Over-torquing is a critical installation error. It can strip the anchor’s threads, break the bolt, or even fracture the concrete around the anchor. Any of these outcomes will cause a complete failure of the connection. Always use a calibrated torque wrench.

What does “cracked concrete rated” mean?

“Cracked concrete rated” signifies that an anchor has passed rigorous testing for safe use in concrete that may crack under tension. Modern building codes often require these certified anchors for structural connections to ensure safety and prevent failure.

How close to a concrete edge can an anchor be installed?

The minimum edge distance varies by anchor type and size. Aggressive wedge anchors require more distance than screw-style anchors.

Always consult the manufacturer’s technical data sheet. Installing an anchor too close to an edge can cause the concrete to break out, leading to connection failure.

Which anchor is best for hollow block? 🤔

Sleeve anchors are an excellent choice for hollow block or CMU. Their long expansion sleeve provides a large contact area inside the block’s voids. This feature distributes the load effectively and prevents the anchor from pulling through the thin material walls.