Expansion bolts are heavy-duty fasteners designed to create a secure anchor in concrete. The core mechanism involves tightening a nut, which pulls a cone-shaped plug through a sleeve. This action forces the sleeve to expand, creating a strong, friction-based hold within the pre-drilled hole. These expansion type concrete fasteners are a vital part of the construction industry. For unique applications, a custom fasteners manufacturer can supply custom anchor bolts. The market for Anchor Bolts and other concrete fasteners shows significant growth, as projected below.

| Metric | Value |

|---|---|

| Market Size (2021) | USD 3120.67 Million |

| Market Size (2025) | USD 3636.02 Million |

| Market Size (2033) | USD 5014.55 Million |

| CAGR (2025–2033) | 4.1% |

A Detailed Guide to Types of Expansion Bolts

Choosing the right fastener is critical for project safety and longevity. Different expansion bolts are engineered for specific loads, materials, and environments. Understanding the primary types of anchors ensures that professionals select the most appropriate hardware for the job. This guide explores the design and function of three common anchors: wedge, sleeve, and drop-in.

Wedge Anchors

Wedge anchors are the workhorses of heavy-duty fastening in solid concrete. Their design provides unparalleled holding power for the most demanding projects.

Anatomy and Design

A wedge anchor consists of four main parts:

- A threaded stud body.

- An expansion clip or sleeve at the bottom.

- A nut.

- A washer.

Installation involves inserting the anchor into a pre-drilled hole. Tightening the nut pulls the stud upward. This action forces the expansion clip over a cone-shaped wedge at the base of the stud. The clip expands outward, pressing firmly against the walls of the concrete hole and creating immense friction.

Best for High-Load Applications

Wedge anchors excel in high-load scenarios due to their exceptional tensile (pull-out) and shear (side) strength. They are the go-to choice for securing structural steel, heavy machinery, and support columns. Their reliable performance under heavy loads makes them essential for critical construction and industrial projects.

The following table compares the general characteristics of different anchor types.

| Feature | Wedge Anchors | Sleeve Anchors |

|---|---|---|

| Load Capacity | Higher load capacity, heavy-duty | Lighter to medium-duty, reliable support |

| Applications | Securing structural steel, heavy machinery | Hanging shelves, fixing decking joists, radiators |

| Base Material | Solid concrete, hard base materials | Softer base materials like brick, hollow block |

| Strength | Stronger, better for heavy-duty applications | Generally not as strong as wedge anchors |

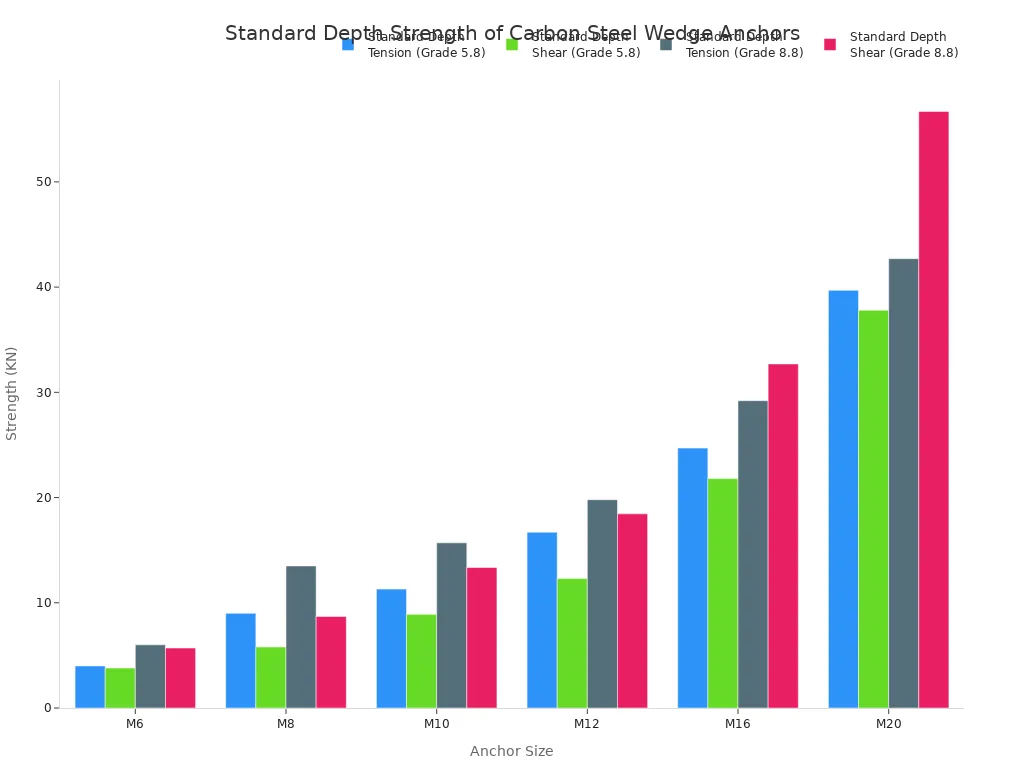

The strength of a wedge anchor is directly related to its grade and diameter. Higher-grade steel and larger diameters provide significantly greater load-bearing capacity, as shown in the data below.

Material Options and Coatings

Material selection depends on the service environment.

- Zinc-Plated Carbon Steel: This is the standard for dry, indoor applications. The zinc coating offers basic corrosion resistance.

- Hot-Dip Galvanized Steel: A thick zinc coating provides superior corrosion protection, making these anchors suitable for outdoor and damp environments.

- Stainless Steel (Type 304 & 316): This material offers the highest level of corrosion resistance. It is ideal for coastal areas, chemical plants, and wastewater treatment facilities.

Sleeve Anchors

Sleeve anchors are versatile concrete fasteners known for their adaptability to various base materials, including concrete, brick, and block.

Anatomy and Variations

A sleeve anchor is a pre-assembled unit containing a threaded bolt or stud, an expansion sleeve, and a cone-shaped expander nut. When an installer tightens the bolt head, the cone-shaped expander is pulled into the sleeve. This action forces the sleeve to expand and grip the surrounding base material. Their design makes them suitable for light to medium-duty fastening in both solid and hollow materials.

Head Styles and Their Uses

Sleeve anchors come in several head styles, each designed for a specific purpose. Choosing the correct head ensures a secure and functional installation.

| Head Style | Specific Use/Benefit in Construction |

|---|---|

| Hex Head | Allows for easy tightening with a standard wrench. It is suitable for situations requiring future removal or adjustment. |

| Acorn Head | Provides a smooth, finished look. It protects against snagging on exposed threads, making it ideal for visible areas like handrails. |

| Flat Head | Sits flush with the surface after installation. This design prevents tripping hazards and is used for door frames and metal plates. |

Best for Medium-Duty Fastening

Sleeve anchors provide adequate support for a wide range of medium-duty tasks. Their holding values, often up to 200 pounds for both shear and pullout, are sufficient for many residential and commercial jobs. Common uses include:

- Securing shelving and radiators to walls.

- Fastening decking joists to a foundation.

- Mounting cabinets and heavy-duty wall hooks.

Drop-In Anchors

Drop-in anchors are female anchors designed for flush-mount installation in solid concrete. They are ideal for overhead work where threaded rods are used.

Anatomy and Flush-Mount Design

A drop-in anchor is a cylindrical metal shell with internal threads on one end and a pre-inserted expander plug on the other. The top of the anchor often has a lip. This lip ensures the anchor sits perfectly flush with the concrete surface after installation. This flush-mount design is excellent for overhead hangers, as it creates a clean and unobtrusive anchor point for threaded rods.

Pro Tip: The flush-mount design simplifies installation by providing a consistent embedment depth and making it easier to align threaded rods vertically.

The Role of the Setting Tool

Proper installation of a drop-in anchor is impossible without a dedicated setting tool. This tool is essential for achieving the anchor’s specified load capacity.

- An installer first places the anchor into the pre-drilled hole with the threaded end up.

- Next, they insert the setting tool into the anchor.

- The installer then hammers the setting tool. This drives the internal expander plug deep into the anchor body.

- Hammering continues until the shoulder of the setting tool touches the top of the anchor, which indicates the plug is fully set.

Warning: Failure to use the setting tool correctly will prevent the anchor from expanding, resulting in a drastic reduction of its holding power.

Ideal for Overhead Applications

The combination of a female thread and a flush-mount design makes drop-in anchors the preferred choice for many overhead applications. After setting the anchor, an installer can easily screw a threaded rod into it to suspend items from a concrete ceiling. Common uses include hanging:

- Pipes and conduits

- HVAC ductwork

- Cable trays

- Light fixtures

Strike Anchors (Hammer-Drive Anchors)

Strike anchors are simple, effective concrete fasteners designed for quick, permanent, light-duty installations. These types of expansion bolts are valued for their ease of use and tamper-resistant properties.

Anatomy and Installation Method

A strike anchor has a straightforward two-piece design:

- A hollow anchor body formed from a corrosion-resistant alloy.

- A steel pin that acts as the expansion nail.

Installation is exceptionally fast. An installer drills a hole to the specified diameter and depth. They then clean the hole of all dust and debris. The installer places the anchor through the fixture and into the hole. A few strikes with a hammer drive the pin flush with the head of the anchor body. This action forces the sides of the anchor to expand, locking it securely into the concrete.

Best for Light-Duty, Tamper-Resistant Needs

Strike anchors achieve tamper resistance through their design. Once an installer drives the pin and the anchor expands, it becomes extremely difficult to remove. Any attempt to extract the anchor typically damages the fixture or the surrounding concrete surface. This permanent quality makes these anchors ideal for public or industrial settings where security is a priority.

Note: The tamper-resistant nature of these anchors is a key advantage in specific environments.

- They are suitable for public areas where fixtures must be secured against vandalism.

- They are also useful in industrial settings to prevent unauthorized removal of equipment or signage.

Common Use Cases

The speed and security of strike anchors make them a popular choice for repetitive, light-duty fastening tasks. Common applications include securing:

- Electrical boxes and conduit straps

- Roof flashing and termination bars

- Lightweight signage

- Furring strips

Lag Shield Anchors

Lag shield anchors are two-part expansion anchors designed to be used with lag screws. They are versatile and can be used in a variety of base materials, including concrete, brick, and mortar joints.

Anatomy and How They Work

A lag shield anchor is a cylindrical sleeve, typically made of a zinc alloy. The exterior of the sleeve features ribs that help it grip the inside of the drilled hole. The interior is tapered. When an installer drives a lag screw into the anchor, the screw’s threads engage the sleeve. As the screw advances toward the tapered end, it forces the two halves of the shield to expand outward, creating a strong compressive force against the base material. These anchors provide a reliable hold for medium-duty loads.

Pairing with Lag Screws

Selecting the correct lag screw is critical for the proper function of lag shield anchors. An installer must match both the diameter and length to achieve the specified holding power.

- Diameter Matching: The size of the lag shield anchor corresponds directly to the diameter of the lag screw it requires. For example, a 3/8″ lag shield needs a 3/8″ diameter lag screw.

- Shield Length: The choice between a short or long shield depends on the base material. Short shields work well in hard, dense concrete. Long shields are better for softer materials like brick or block because they distribute the load over a larger surface area.

- Screw Length Calculation: The lag screw must be long enough to expand the shield fully. To find the minimum screw length, an installer should add the thickness of the fixture to the length of the anchor, plus an extra half-inch. This ensures the tip of the screw passes beyond the bottom of the shield for complete expansion.

Applications in Brick and Concrete

The design of lag shield anchors makes them one of the more versatile types of fasteners. They perform well in both solid concrete and softer masonry materials where other anchors might fail. Their ability to distribute expansion forces makes them a safe choice for fastening into older brick or block. Installers commonly use them for mounting heavy signs, benches, and handrails.

How to Select the Right Expansion Bolt for Your Project

Selecting the correct expansion bolts is a critical decision that directly impacts the safety and integrity of a structure. A professional must analyze several factors to ensure the chosen fastener can handle the demands of the specific applications. This process involves evaluating load requirements, the condition of the base material, and proper placement.

Step 1: Assess Load Requirements

The first step is to determine the forces the anchor will need to resist. Industry standards, such as the American Concrete Institute’s ACI 318, provide the framework for calculating anchor capacities.

Understanding Tensile Load (Pull-Out)

Tensile load is the force that tries to pull an anchor straight out of the concrete. This is a primary consideration for overhead fixtures or items suspended from a wall. An installer must choose anchors with a pull-out strength that far exceeds the anticipated tensile forces.

Understanding Shear Load (Side)

Shear load is the force that acts perpendicular to the anchor, trying to cut or snap it off. This force is common when mounting items to a vertical wall, such as a heavy sign or a handrail. Design calculations must account for potential failure modes like concrete breakout and anchor pryout under shear loads.

Static vs. Dynamic Loads

- Static Loads: These are constant, unchanging forces, such as the weight of a stationary piece of equipment.

- Dynamic Loads: These forces change over time and include vibrations, shocks, or seismic activity. Anchors in dynamic load environments require higher safety factors and are often subject to more stringent design codes.

Step 2: Evaluate the Concrete Base Material

The strength and condition of the concrete are just as important as the anchor itself. A strong anchor in weak concrete will inevitably fail.

Concrete Strength (PSI) and Condition

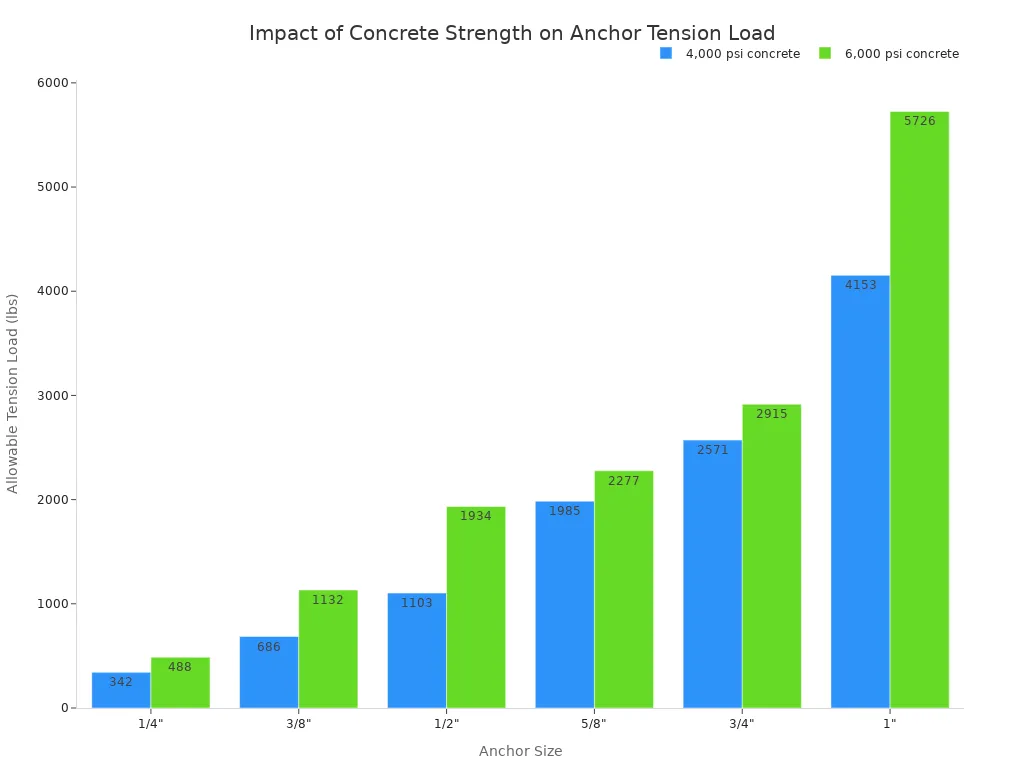

Concrete strength is measured in pounds per square inch (PSI). Higher PSI concrete provides a denser, stronger base, which significantly increases an anchor’s holding power. As shown below, an anchor’s allowable load capacity increases substantially in higher-strength concrete.

| Anchor Size | Embedment Depth (in.) | Allowable Tension Load (4,000 psi concrete) | Allowable Tension Load (6,000 psi concrete) |

|---|---|---|---|

| 1/4″ | 1-1/8″ | 342 lbs | 488 lbs |

| 3/8″ | 1-5/8″ | 686 lbs | 1,132 lbs |

| 1/2″ | 2-1/4″ | 1,103 lbs | 1,934 lbs |

| 5/8″ | 2-3/4″ | 1,985 lbs | 2,277 lbs |

| 3/4″ | 3-3/8″ | 2,571 lbs | 2,915 lbs |

| 1″ | 4-1/2″ | 4,153 lbs | 5,726 lbs |

Minimum Concrete Thickness

The concrete slab or wall must be thick enough to accommodate the full embedment depth of the anchor. A general rule is that the concrete thickness should be at least 1.5 times the anchor embedment depth.

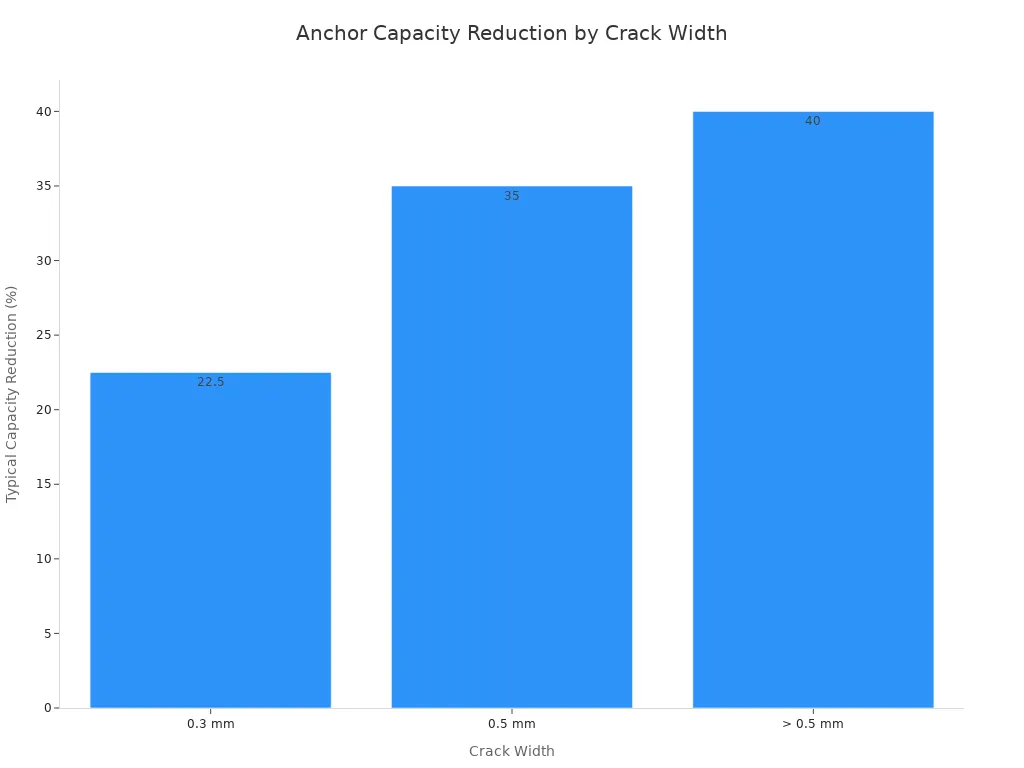

Cracked vs. Uncracked Concrete

Design professionals must determine if the anchor will be in a region prone to cracking. According to ACI 318, a designer must assume cracked concrete if:

- The structure is in a high-risk seismic zone (Categories C, D, E, or F).

- Analysis shows that cracking is likely under service loads.

Note: In the absence of a detailed analysis, the safest approach is to assume the concrete is cracked and select anchors specifically rated for that condition.

Step 3: Consider Edge and Spacing Distances

Improper placement can cause the concrete to fail even if the anchor is correctly sized and installed.

Minimum Distance from Edges

Placing an anchor too close to an unsupported edge can cause a “blowout,” where the side of the concrete breaks away. While manufacturer specifications vary, ACI 318 suggests a minimum edge distance of 8 anchor diameters if no other data is available.

Minimum Spacing Between Anchors

When multiple anchors are installed close together, their stress cones can overlap. This overlap reduces the total holding capacity of the group. Installers must follow manufacturer guidelines for minimum spacing to ensure each anchor can develop its full strength.

How to Avoid Concrete Failure

Concrete cone failure occurs when the load exceeds the tensile strength of the concrete, pulling out a cone-shaped piece of material. This risk increases significantly when anchors are placed too close together or near an edge. Furthermore, cracks in the concrete severely reduce anchor capacity by disrupting stress transfer.

Step 4: Choose the Correct Material and Finish

The service environment dictates the necessary material and finish for an anchor. Choosing the wrong material can lead to premature corrosion and catastrophic failure, compromising the safety of the entire installation. A professional must match the anchor’s material to its intended environment to ensure long-term durability.

Indoor/Dry: Zinc-Plated Steel

For indoor applications with no exposure to moisture, zinc-plated carbon steel is the standard and most economical choice. The zinc plating provides a minimal barrier against corrosion in dry, climate-controlled settings. Installers commonly use these expansion bolts for projects inside homes, offices, and warehouses where humidity is not a concern. However, this thin coating offers insufficient protection for outdoor or damp conditions.

Outdoor/Wet: Hot-Dip Galvanized Steel

Hot-dip galvanized steel provides a significant upgrade in corrosion resistance for outdoor and wet environments. This process involves dipping the steel anchor into molten zinc, creating a thick, protective layer. This coating offers good protection against water and can withstand general outdoor exposure. If the zinc layer gets scratched, it acts as a sacrificial anode, corroding itself to protect the underlying steel. While galvanized steel can handle water exposure, it is not suitable for saltwater or marine environments where the zinc coating will degrade more rapidly.

| Factor | Stainless Steel | Hot-Dip Galvanized |

|---|---|---|

| Corrosion Resistance | Excellent – long-term durability | Good – moderate protection |

| Environment Suitability | Harsh, humid, coastal, industrial | Dry, mild, inland |

Corrosive Environments: Stainless Steel

Stainless steel offers the ultimate protection against corrosion and is essential for harsh or critical applications. Its corrosion resistance comes from chromium blended into the alloy, which forms a passive, self-healing layer. This protective quality does not wear down like a coating. Two common grades are Type 304 and Type 316. Type 304 works well in many environments but can degrade with exposure to chlorides and salt.

For the most demanding conditions, Type 316 stainless steel is the superior choice. Its added molybdenum content provides enhanced resistance to salt and chlorides. A professional should select Type 316 stainless steel for anchors in a concrete structure when:

- The installation is in a coastal or marine location.

- The environment has high levels of environmental sulphate.

- The anchor will be exposed to de-icing salts or other corrosive chemicals.

Note: The price difference between 304 and 316 stainless steel is often minimal. Using 316 provides an extra margin of safety against corrosion in nearly all outdoor applications.

Essential Tools and Safety Gear for Installation

A successful expansion bolt installation depends on using the correct tools and prioritizing safety. Proper preparation prevents installation errors and protects the installer from potential injury. Assembling all necessary equipment before starting work ensures a smooth, efficient, and secure fastening process.

Required Tool Checklist

A professional’s toolkit contains specific items for each phase of the installation, from drilling the hole to tightening the anchor. Having these tools ready minimizes downtime and ensures each step is completed to specification.

Drilling and Measuring Tools

An installer first needs the right equipment to create a precise hole. The accuracy of the hole’s dimensions is fundamental to the anchor’s performance.

- Rotary Hammer Drill: This tool provides the necessary power and impact to drill efficiently into dense concrete.

- Carbide-Tipped Masonry Bit: The bit must match the exact diameter specified by the anchor manufacturer.

- Tape Measure: An installer uses a tape measure to mark the correct drilling depth on the bit.

Cleaning Equipment

Debris left in the hole can reduce an anchor’s holding power by over 50%. Thorough cleaning is a critical, non-negotiable step.

🧹 Pro Tip: A clean hole ensures maximum friction between the anchor and the concrete, which is essential for achieving the specified load capacity.

Common cleaning tools include a stiff wire brush to loosen debris and compressed air or a hand-held blower to remove all dust from the hole. A shop vacuum with a narrow attachment is also highly effective.

Tightening and Setting Tools

The final step requires specific tools to set the anchor and apply the correct clamping force.

- Hammer: A hammer is used to gently tap the anchor into the pre-drilled hole to the correct embedment depth.

- Setting Tool: Drop-in anchors require a dedicated setting tool. An installer uses this tool to drive the internal plug and expand the anchor.

- Torque Wrench: A calibrated torque wrench is the only tool that can accurately tighten the anchor to the manufacturer’s required torque value.

Personal Protective Equipment (PPE)

Drilling concrete creates significant hazards from flying debris, loud noise, and harmful dust. Wearing the proper Personal Protective Equipment (PPE) is mandatory for ensuring an installer’s safety on the job site.

Eye and Face Protection

Flying concrete chips and dust pose a serious risk to an installer’s eyes. ANSI-rated safety glasses are the absolute minimum requirement for any drilling task. For added safety, a full-face shield provides superior protection against high-velocity particles.

Hearing Protection

Rotary hammer drills operate at noise levels that can cause permanent hearing damage with prolonged exposure. Professionals must protect their hearing during operation.

| Protection Type | Benefit |

|---|---|

| Earplugs | Disposable and convenient for short-term use. |

| Earmuffs | Offer higher noise reduction ratings for extended work. |

Respiratory and Hand Protection

Concrete dust contains crystalline silica, a hazardous substance that can cause serious lung disease if inhaled. An installer must wear an N95-rated respirator to filter out these harmful particles. Additionally, heavy-duty work gloves protect hands from cuts and abrasions while improving grip on tools.

Step-by-Step Installation Guide with Pro Tips

Proper installation is just as important as selecting the right hardware. Following a precise, step-by-step process ensures that expansion bolts achieve their maximum holding power and provide a secure, reliable connection. These professional installation tips will help prevent common errors and guarantee a successful outcome.

Step 1: Drill the Hole

The foundation of a secure anchor is a perfectly drilled hole. An installer must pay close attention to diameter, depth, and angle.

Choosing the Correct Drill Bit Size

An installer must use a carbide-tipped masonry bit that matches the diameter specified by the anchor manufacturer. The accuracy of the drill bit’s size is paramount.

- A hole that is too small can damage the anchor’s expansion mechanism during insertion or torquing.

- A hole that is too large prevents the anchor from making full contact with the concrete. This mistake can reduce the holding power of some anchors by up to 60%.

Drilling to the Correct Depth

The hole must be drilled deeper than the anchor’s required embedment depth. This extra space allows room for dust and debris to settle without obstructing the anchor. An installer can mark the correct depth on the drill bit with a piece of tape for a clear visual guide.

Technique for a Perpendicular Hole

An installer should hold the rotary hammer drill as straight as possible. Drilling at an angle can create an oval-shaped hole, which compromises the performance of the anchors. Maintaining a perpendicular angle ensures the expansion forces are distributed evenly against the concrete.

Step 2: Clean the Hole Thoroughly

A clean hole is non-negotiable for a strong connection. Debris acts as a barrier, preventing the anchor from fully engaging with the base material.

The Critical Importance of Cleaning

Dust and concrete particles left inside the hole can severely reduce friction. This lack of grip prevents the anchor from reaching its specified load capacity. Installers must clean every hole meticulously to ensure safety and performance.

The Brush-and-Blow Method

The industry-standard cleaning procedure is a multi-step process.

- An installer first blows compressed air or uses a hand pump to force loose particles out of the hole.

- Next, they use a stiff wire brush with a diameter matching the hole to scrub the interior walls.

- Finally, they blow the hole out one more time to remove any remaining dust.

Note: For maximum effectiveness, many manufacturers recommend a “2x2x2” cycle: blow, brush, blow, and repeat.

Using a Vacuum for Dust Removal

While a shop vacuum seems convenient, many official anchor approvals specify the use of a blow-out pump or compressed air. An installer should always follow the manufacturer’s instructions, as using unapproved methods could void guarantees and create liability issues.

Step 3: Install the Anchor

With a clean hole, the installer can now set the anchor. This step requires care to avoid damaging the hardware or the concrete.

Setting the Anchor to Embedment Depth

An installer should place the anchor into the hole. For some anchors, like wedge anchors, the nut and washer should be attached. The anchor is then ready for the next step.

Through-Fastening vs. Pre-Setting Methods

- Through-Fastening: The installer drills through the fixture directly into the concrete, then places the anchor through the fixture and into the hole. This method is common for wedge and sleeve anchors.

- Pre-Setting: The installer drills the hole and sets the anchor first. The fixture is then placed over the anchor and secured. This method is necessary for drop-in anchors.

Correct Hammering Technique

An installer should use a hammer to gently tap the anchor into the hole until it reaches the required embedment depth. They must use controlled strikes to avoid damaging the anchor’s threads or body.

Step 4: Tighten to Secure the Anchor

The final step in the installation process is tightening the fastener. This action engages the expansion mechanism and creates the clamping force that secures the fixture. Proper tightening is a critical skill that directly determines the anchor’s performance and safety.

Using a Torque Wrench for Accuracy

An installer must use a calibrated torque wrench to tighten expansion bolts. This tool is not optional; it is essential for structural integrity. A torque wrench allows for the precise measurement of applied pressure, ensuring nuts and bolts are set to the manufacturer’s recommended torques. Using the correct torque value prevents common installation failures.

- Over-torquing can strip the threads, break the bolt, or damage the concrete base material.

- Under-torquing results in a loose connection, which can lead to fixture movement and eventual anchor failure.

Using a calibrated torque wrench helps find the perfect “Goldilocks” value for clamping force. This significantly reduces the chance of failure and ensures the connection can support its designed load. Following these installation tips is also vital because manufacturers’ performance data and warranties are only valid when their guidance is strictly followed.

Finding Manufacturer Torque Specs

The required torque value is specific to each anchor’s type, diameter, and embedment depth. An installer must locate this information before tightening. These specifications are typically found in several places:

- On the product packaging.

- In the installation instructions included with the anchors.

- Within the Technical Data Sheet (TDS) available on the manufacturer’s website.

Warning: Never guess the torque value. Always refer to the official manufacturer documentation to ensure a safe and compliant installation.

Visual Signs of a Secure Anchor

In addition to using a torque wrench, an installer can look for visual cues that indicate a successful installation. These signs confirm that the anchor has been set correctly and the fixture is secure.

| Anchor Type | Visual Confirmation |

|---|---|

| Wedge Anchor | The nut is tight against the washer and fixture, with at least three threads showing past the nut. |

| Sleeve Anchor | The head of the anchor is drawn down flush and tight against the surface of the fixture. |

| Drop-In Anchor | The shoulder of the setting tool bottomed out on the anchor’s lip during the setting process. |

A properly installed fixture will feel completely solid. An installer should apply firm hand pressure to the fixture after tightening. There should be no wobble, movement, or gaps between the fixture and the concrete surface. These checks provide the final confirmation of a secure connection for all types of anchors.

Common Mistakes to Avoid for Secure Fastening

Even the highest-quality expansion bolts can fail if installed incorrectly. Professionals can prevent catastrophic failures by avoiding common errors during installation, placement, and selection. Understanding these pitfalls is essential for ensuring a safe and durable connection.

Critical Installation Errors

The installation process itself is where many problems originate. A small mistake at this stage can compromise the entire fastening.

Incorrect Hole Diameter or Depth

An installer must drill a hole with the exact diameter and sufficient depth specified by the manufacturer. A hole that is too wide prevents the anchor from gripping the concrete. A hole that is too shallow stops the anchor from reaching its required embedment depth, severely reducing its holding power.

Inadequate Hole Cleaning

Debris left in the drilled hole acts as a lubricant. It prevents the anchor from creating the necessary friction against the concrete walls. This single oversight can cut an anchor’s load capacity in half.

Over-Torquing or Under-Torquing

Applying the correct torque is non-negotiable. An installer must use a calibrated torque wrench to avoid these critical failures:

- Under-torquing creates insufficient friction. This leads to anchor slippage and a loose fixture.

- Over-torquing causes severe damage. It can break the anchor, crack the base material, or cause the anchor’s moving parts to seize, leading to complete failure.

Common Placement Errors

Where an anchor is placed is just as important as how it is installed. The location determines how forces are distributed into the base material.

Ignoring Edge Distance Rules

Placing anchors too close to an unsupported edge can cause the side of the concrete to break away, a failure known as “blowout.” Installers must always respect the minimum edge distances provided by the manufacturer.

Ignoring Anchor Spacing Rules

When multiple concrete fasteners are installed too close together, their stress zones overlap. This overlap significantly reduces the load capacity of the entire group. Following minimum spacing guidelines ensures each anchor can perform as designed.

What to Do If You Hit Rebar

Encountering rebar while drilling is a common problem. An installer should follow a clear procedure:

- The best solution is to abandon the hole and relocate the fastening point.

- If moving the anchor is not possible, the Engineer of Record (EOR) must approve any plan to cut the rebar.

- Drilling through rebar requires specialized bits and techniques to avoid damaging the hole or the structural steel.

- The EOR will likely require onsite testing after installation to verify the anchor’s performance.

Key Selection Errors

The selection process is the first line of defense against failure. Choosing the wrong hardware for the job guarantees a weak connection.

Mismatching Anchor Type to Load

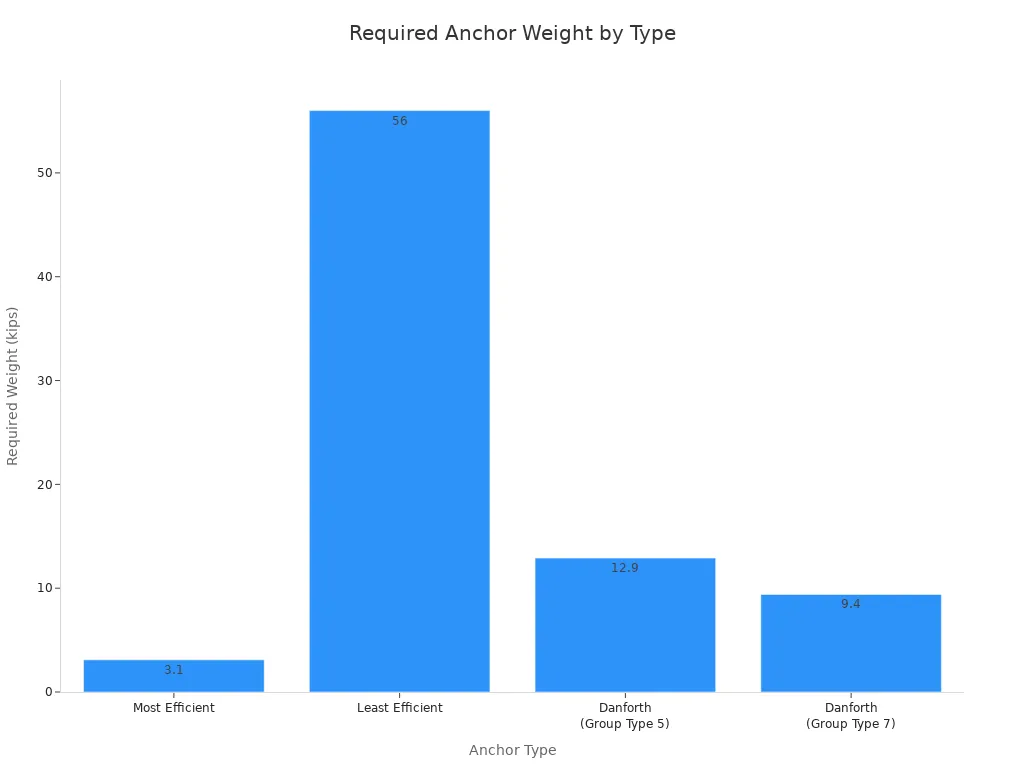

Different anchor designs have vastly different holding capacities. Selecting an anchor based on size alone without considering its design efficiency can lead to failure. For certain applications, the most efficient anchor may be many times lighter than the least efficient one for the same load requirement.

Choosing the Wrong Material

The anchor’s material must match its service environment. Using a simple zinc-plated anchor in a wet or corrosive environment will lead to premature rust and failure. Stainless steel is often required for outdoor or chemical exposure.

Misreading Load Capacity Charts

Manufacturers provide detailed technical data sheets. An installer must read these charts carefully, paying close attention to factors like concrete strength, embedment depth, and cracked vs. uncracked conditions. Misinterpreting this data can lead to selecting an undersized anchor.

A professional ensures a safe and durable connection by selecting the correct expansion bolts for the specific load and concrete condition. The most critical installation steps involve drilling a precise hole and cleaning it meticulously. Finally, an installer must always adhere to manufacturer specifications for torque, embedment depth, and spacing. This diligence guarantees maximum holding power and prevents failure in the concrete.

FAQ

Can I reuse an expansion bolt?

No. An installer should never reuse an expansion bolt. The expansion mechanism deforms during the first installation. Reusing it compromises its holding power and creates a significant safety risk, as the anchor will not achieve its specified load capacity.

What happens if I drill the hole too big?

A hole that is too large prevents the anchor from expanding correctly. The anchor cannot create the necessary friction against the concrete walls. This mistake drastically reduces the anchor’s load capacity and can lead to complete failure under load.

How long should concrete cure before installing anchors?

A professional must wait for the concrete to reach its full design strength. This process typically takes at least 28 days. Installing an anchor in uncured, or “green,” concrete will result in a weak connection and potential failure.

Why is a torque wrench so important?

A torque wrench ensures the correct clamping force is applied. It prevents two critical errors:

- Under-tightening, which causes looseness.

- Over-tightening, which can break the anchor or crack the concrete. Proper torque is essential for safety and performance.

Can I use expansion bolts in brick or block?

Some anchors, like sleeve anchors and lag shields, work well in brick or block. Wedge anchors, however, require solid concrete. An installer must always match the anchor type to the specific base material to ensure a secure hold.

How do I remove an expansion bolt?

Most expansion bolts are designed for permanent installation. Removing them often damages the surrounding concrete. An installer can sometimes cut the bolt flush with the surface or drill it out, but this is a difficult and destructive process.