Selecting the correct hollow wall anchor is a critical task where mistakes are common. Incorrect installation, often due to a poor anchor choice, accounts for a high rate of failure. A successful project hinges on correctly matching three essential elements. Getting these factors right is the secret to a secure hold that prevents wall damage. A person must choose the right anchor for the job, whether it’s one of the many available hollow wall anchors or specialized Anchor Bolts. Some unique projects may even require custom anchor bolts from a custom fasteners manufacturer.

The Three Pillars of a Secure Hold 🏛️

- The Wall Material

- The Item’s Weight

- The Specific Anchor Type

Step 1: Identify Your Wall Material

Before selecting from the wide array of hollow wall anchors, a person must first determine the type of wall they are working with. The material’s composition, thickness, and internal structure dictate which anchors will provide a secure hold.

Understanding Drywall (Gypsum Board)

Drywall is the most common interior wall material in modern construction. It consists of a gypsum plaster core pressed between two thick sheets of paper.

How to Identify Drywall

A simple “pushpin test” can identify drywall. A thumbtack or pushpin will press into the wall with minimal effort. The wall surface feels smooth and has a papery finish. Knocking on the wall produces a hollow sound between the studs.

Best Drywall Anchors for Standard Walls

Standard drywall is typically 1/2-inch thick. For this material, threaded drywall anchors and plastic expansion anchors are excellent for light-duty tasks. Molly bolts and toggle bolts provide superior strength for medium to heavy loads.

Working with Double-Layer Drywall

Some walls, particularly those needing extra fire resistance or soundproofing, use two layers of drywall (often 5/8-inch thick each). This increased thickness requires anchors with a longer grip range. Snap toggles and longer molly bolts are ideal for this application.

Tackling Plaster and Lath Walls

Found in homes built before the 1950s, plaster walls require a different approach due to their brittle nature.

How to Identify Plaster Walls

Plaster walls feel much harder and more solid than drywall. A pushpin will not penetrate the surface easily. Knocking on a plaster wall produces a dull, less resonant thud. The surface may also have slight waves or imperfections.

Why Plaster is Brittle

Plaster’s brittleness comes from its construction. Installers applied multiple coats of plaster over a framework of thin wooden or metal strips called lath. This created a hard, inflexible surface prone to cracking under pressure.

- Lath Framework: Narrow strips of wood, metal, or gypsum board (rock lath) were nailed to wall studs.

- Plaster Coats: A base coat was pushed through the lath gaps, creating “keys” that held it in place. A sandy brown coat and a smooth finish coat followed.

- Reinforcement: Older lime-based plaster often contained horsehair to add tensile strength and prevent the plaster keys from breaking.

Pro Tip: When drilling into plaster, use a sharp bit and apply steady, gentle pressure to prevent cracking the surrounding surface.

Recommended Anchors for Plaster

Toggle bolts and snap toggles are the best choices for plaster. They distribute the load across a wide area behind the lath, reducing stress on the brittle plaster itself. Avoid expansion-style anchors, which can crack the wall.

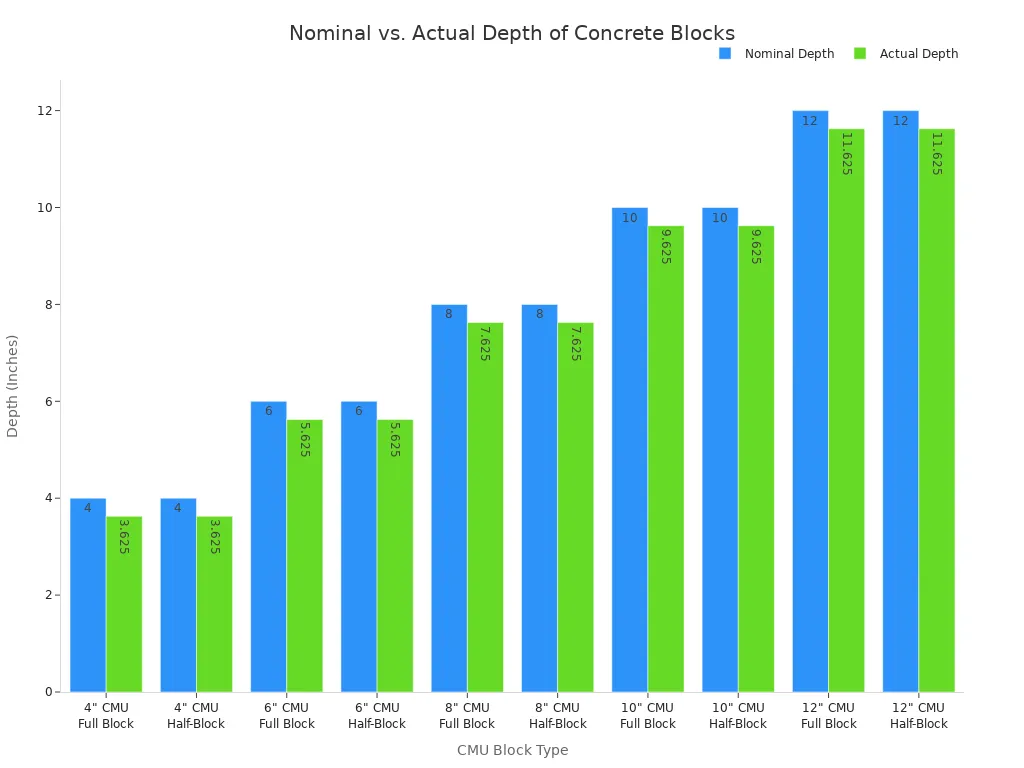

Mounting on Hollow Masonry

Basements, garages, and commercial buildings often feature walls made of hollow concrete block or brick.

Identifying Hollow Block or Brick

These materials are easily identified by their appearance. Hollow concrete masonry units (CMUs) have a distinct gray, porous texture. A quick knock reveals a deep, hollow sound. The most common configuration is a two-cell, three-web unit, though many regional variations exist.

| CMU SIZE | NOMINAL DIMENSIONS D X H X L (INCHES) |

|---|---|

| 6″ CMU Full Block | 6″ x 8″ x 16″ |

| 8″ CMU Full Block | 8″ x 8″ x 16″ |

| 12″ CMU Full Block | 12″ x 8″ x 16″ |

Anchors for Hollow Concrete Block

For hollow block, sleeve anchors are a robust choice. When tightened, the sleeve expands against the inside walls of the block’s cavity, creating a very strong hold suitable for heavy loads.

Anchors for Hollow Brick

Hollow brick has thinner interior walls than concrete block. For this reason, specialized anchors like lag shields or plastic expansion anchors designed for masonry are recommended. They provide a secure grip without risking damage to the brick’s internal structure.

Step 2: Determine Your Item’s Weight

After identifying the wall material, the next critical step is to determine the weight of the object being mounted. An anchor’s holding power must exceed the item’s weight to ensure a safe and lasting installation. Manufacturers categorize anchors by their load capacity, which simplifies the selection process.

Light-Duty Projects (Under 25 lbs / 11 kg)

Light-duty projects involve items that exert minimal force on the wall. These are the most common household hanging tasks. Always check the anchor’s packaging for its specific weight rating, as it can vary by brand.

Common Light-Duty Items

Most decorative items fall into this category. A person can confidently hang objects like small clocks, smoke detectors, and framed art. For example, a 16×20-sized mirror typically weighs around 7 lbs, placing it firmly in the light-duty range. Other common items include:

- Small picture frames

- Thermostats

- Lightweight coat hooks (for single jackets)

- Small decorative wall hangings

Best Anchors for Light Loads

For light-duty applications in drywall, plastic expansion anchors and self-drilling threaded anchors are excellent choices. They are simple to install and provide sufficient holding power. For plaster walls, it is better to use a small toggle bolt to avoid cracking the brittle surface.

Medium-Duty Projects (25-50 lbs / 11-23 kg)

Medium-duty projects require anchors with significantly more strength. These items place a greater load on the wall, demanding a more robust solution to prevent failure.

Common Medium-Duty Items

This category includes functional and decorative items that have more substantial weight. Examples include large mirrors, curtain rods supporting heavy drapes, and some types of shelving. The Kitchen Cabinet Manufacturers Association (KCMA) certifies that standard wall cabinets must hold 15 pounds per square foot of shelf space, often placing them in this weight class.

| Item Type | Typical Weight Range |

|---|---|

| Large Mirrors | 25-45 lbs |

| Wall Cabinets (unloaded) | 30-50 lbs per linear foot |

| Substantial Floating Shelves | 20-50 lbs |

Recommended Anchors for Medium Loads

Molly bolts are a superior choice for medium-duty tasks in both drywall and plaster. Their metal legs expand behind the wall, creating a wide footprint that distributes the load effectively. For heavier items near the top of this range, snap toggles and traditional toggle bolts offer an even greater margin of safety.

Heavy-Duty Projects (Over 50 lbs / 23 kg)

Heavy-duty projects demand the strongest available anchors. For these applications, there is no room for error. The anchor’s strength is paramount to preventing property damage or personal injury.

Safety First! ⚠️ For any item over 50 pounds, especially dynamic loads like TV mounts, always choose an anchor rated for at least four times the item’s weight. Whenever possible, securing directly into a wall stud is the safest method.

Common Heavy-Duty Items

These items represent the most significant loads a hollow wall will support. They include:

- Large flat-screen televisions

- Heavy-duty shelving units

- Small wall-mounted cabinets

- Grab bars (which must support dynamic loads)

Essential Anchors for Heavy Loads

Snap toggles and toggle bolts are the go-to solutions for heavy-duty applications. Their design provides the largest load-bearing surface area behind the wall, maximizing holding power. For mounting in hollow block, sleeve anchors are the professional standard. Using robust heavy-duty anchors is non-negotiable for these critical installations.

Step 3: A Deep Dive into Hollow Wall Anchor Types

Understanding the mechanics of different hollow wall anchors helps a person select the perfect one for the job. Each type has a unique design that provides holding power in different ways.

Plastic Expansion Anchors

These are some of the most common anchors, often included in kits with shelves or pictures. They are simple, inexpensive, and effective for very light loads.

How They Work

A plastic expansion anchor works through friction. An installer first drills a pilot hole and taps the plastic sleeve into the wall until it is flush. As a screw is driven into the sleeve, the plastic body expands, pressing firmly against the inside of the drywall.

Best Uses and Limitations

Plastic anchors are strictly for light-duty applications. Their pull-out strength can be as low as 10 lbs in 1/2-inch drywall. While some are rated to support between 25 to 35 lbs, they are best reserved for items under 20 pounds, like small picture frames and smoke detectors. They are not suitable for plaster or for holding anything valuable or heavy.

Installation Tips

Note: The key to success is a correctly sized pilot hole. If the hole is too large, the anchor will spin. If it is too small, the anchor may deform or damage the wall during insertion. Always use the drill bit size specified on the anchor’s packaging.

Self-Drilling Threaded Anchors

These anchors offer a step up in strength and convenience, eliminating the need for a separate pilot hole in most cases.

How They Work

A self-drilling anchor features a sharp, aggressive point and wide threads. An installer drives the anchor directly into the drywall using a screwdriver or drill. The point pierces the wall, and the wide threads cut into the gypsum, creating a secure hold. A screw is then inserted into the anchor to hang the item.

When to Choose Them

These anchors are an excellent choice for light to medium-duty tasks. Certain zinc models can hold up to a 50 lbs maximum shear load in 1/2″ drywall, making them suitable for larger pictures and shelves. Some heavy-duty versions even exceed their claimed ratings in tests.

| Anchor Type | Claimed Weight Rating | Tested Weight Rating |

|---|---|---|

| E-Z Ancor Twist-N-Lock Medium Duty | 75 LBS | 100 LBS |

Installation Guide

- Mark the desired location on the wall.

- Place the tip of the anchor on the mark and apply firm pressure.

- Using a screwdriver, turn the anchor clockwise until the head is flush with the wall.

- Drive the screw into the anchor to mount your item.

Molly Bolts (Metal Hollow Wall Anchors)

Also known as mollys, this metal hollow wall anchor provides excellent holding power for medium-duty applications in drywall and plaster.

How They Work

A molly bolt consists of a screw inside a metal sleeve. After drilling a pilot hole, the installer inserts the entire unit into the wall. As the screw is tightened, the metal sleeve behind the wall compresses and expands, forming four legs that grip the back of the wall surface.

Advantages of Molly Bolts

The primary advantage of a molly is its strength and reliability. The metal construction provides a more secure hold than plastic. Once installed, the screw can be removed and reinserted without the anchor losing its grip, which is ideal for items that may need to be taken down periodically.

How to Install and Remove Them

Installation: Insert the molly into a pilot hole and tap it flush. Turn the screw clockwise until you feel significant resistance. This indicates the legs have fully expanded. Removal: To remove a molly, an installer must back the screw out partially, tap it to collapse the legs, and then pull the anchor out. Alternatively, one can drive the anchor completely into the wall cavity and patch the small hole.

Toggle Bolts (Spring Toggles)

Toggle bolts are a classic heavy-duty hollow wall anchor. They provide exceptional strength in drywall, plaster, and hollow block.

How They Work

A toggle bolt has two parts: a machine bolt and a spring-loaded wing mechanism (the “toggle”). An installer drills a hole large enough for the folded toggle to pass through. Once inside the wall cavity, the wings spring open. Tightening the bolt pulls the wings flat against the back of the wall, distributing the load over a wide surface area.

Pros and Cons

Installers must weigh the benefits and drawbacks of this anchor type.

- Pros:

- Excellent tensile strength for heavy loads.

- Works well in various wall materials and thicknesses.

- Cons:

- Requires a large pilot hole.

- The toggle falls into the wall cavity if the bolt is ever fully removed.

Step-by-Step Installation

- Drill a pilot hole large enough for the folded toggle to pass through.

- Disassemble the bolt from the toggle. Pass the bolt through your fixture’s mounting hole.

- Re-thread the toggle onto the bolt by a few turns.

- Pinch the wings closed and push the toggle through the hole into the wall cavity.

- Pull the bolt outward to seat the opened wings against the back of the wall.

- Tighten the bolt until the fixture is secure.

The holding power is significant. A 1/4-inch anchor can support a substantial load, with its capacity influenced by the bolt’s diameter and the wall’s thickness.

| Toggle Bolt Type (1/4-inch) | Load Limit (pounds) |

|---|---|

| Plastic Toggle | ~50 |

| Standard Metal Toggle | 85+ |

| Large Metal Toggle | 120 – 265 |

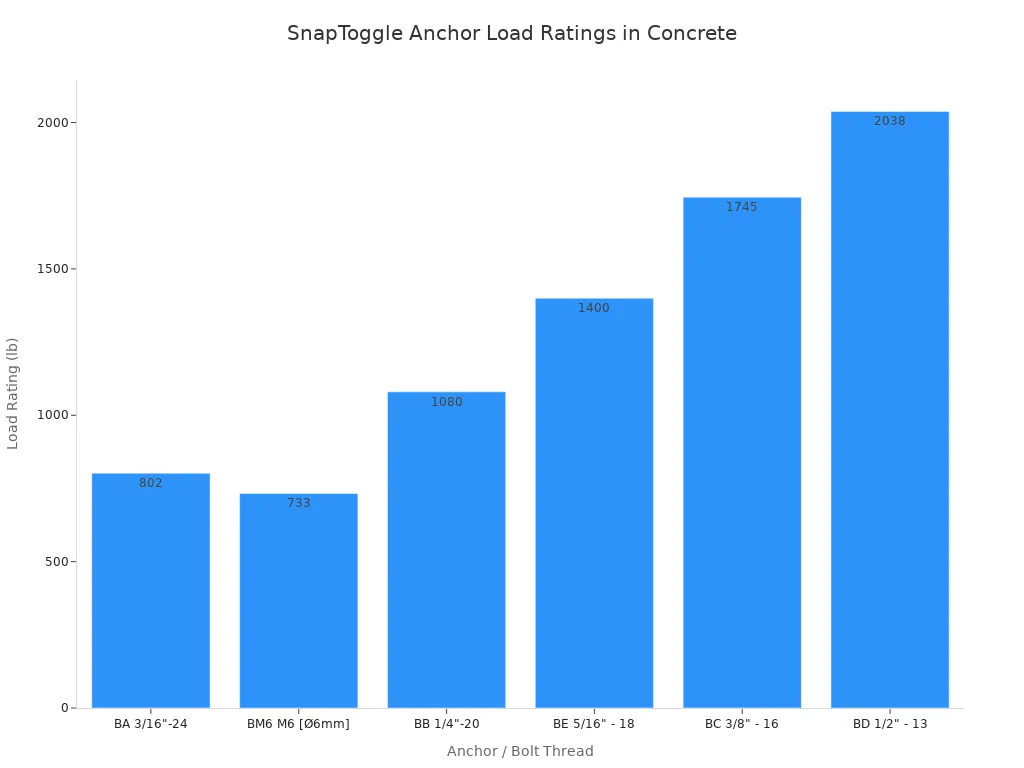

Snap Toggles (Strap Toggles)

Snap toggles are a modern evolution of the traditional toggle bolt. They offer superior strength and a more user-friendly installation process, making them a top choice for professionals.

How They Work

A snap toggle consists of a metal channel connected to two plastic straps. An installer drills a hole, inserts the metal channel, and pulls the straps until the channel rests flush against the back of the wall. The installer then slides a plastic cap down the straps to lock the channel in place and snaps the straps off. This leaves a threaded receiver ready for a machine bolt.

Why They Are a Top Choice

Snap toggles are among the strongest hollow wall anchors available. Unlike spring toggles, the anchor channel remains in place if the bolt is removed, allowing for fixture changes. They also require a smaller pilot hole than a comparable spring toggle. Their strength is remarkable; for example, the ultimate tensile load for a TOGGLER BB 1/4″-20 anchor is rated at 1,080 lbs. in concrete block.

Installation Made Easy

Installation Tip: Ensure the metal channel is oriented correctly inside the wall before tightening the cap. It should sit vertically for maximum contact.

- Drill a 1/2-inch pilot hole.

- Fold the metal channel and insert it through the hole.

- Pull the straps until the channel is snug against the inside of the wall.

- Slide the plastic cap down the straps until it is flush with the outer wall.

- Snap the straps off level with the cap’s flange.

- Place your item over the hole and secure it with the provided machine bolt.

Putting It All Together: How to Choose the Right Anchor

The previous steps provided the foundational knowledge of wall materials, weight classes, and anchor mechanics. This section synthesizes that information into practical, actionable advice. An installer can use these guidelines to confidently select the perfect anchor for any common household project.

Quick Reference Chart

For a quick decision, an installer can consult a simple comparison table. This chart matches the wall material and project weight to the most suitable anchor types, streamlining the selection process.

Anchor Comparison Table (Wall Type, Weight, Anchor)

| Wall Material | Light-Duty (< 25 lbs) | Medium-Duty (25-50 lbs) | Heavy-Duty (> 50 lbs) |

|---|---|---|---|

| Drywall | Plastic Expansion, Self-Drilling | Molly Bolts, Self-Drilling (Zinc) | Snap Toggles, Toggle Bolts |

| Plaster | Small Toggle Bolts | Molly Bolts, Toggle Bolts | Snap Toggles, Toggle Bolts |

| Hollow Block | Masonry Sleeve Anchors | Masonry Sleeve Anchors | Masonry Sleeve Anchors |

| Hollow Brick | Lag Shields, Masonry Screws | Lag Shields, Masonry Screws | N/A (Seek professional advice) |

Project-Specific Recommendations

Different projects exert different forces on a wall. Understanding these nuances is key to a successful installation. Here are specific recommendations for some of the most common mounting tasks.

Best Anchor for a TV Mount

Mounting a television is a high-stakes task that demands maximum security. A failure can result in property damage and safety hazards. An installer must always prioritize strength over convenience.

Critical Factors for TV Mounts 📺 Before choosing an anchor, a professional considers several key factors:

- The wall material (drywall is most common).

- The total weight of the television and the mount itself.

- The type of stress, especially the tension from an articulating mount.

- The accessibility for a clean installation.

For mounting a TV on drywall, heavy-duty toggle bolts are the industry standard. Professionals recommend products like TOGGLER’s SNAPTOGGLE® Heavy-Duty Toggle Bolts. These anchors can hold up to twice the load of traditional wing anchors, providing an essential margin of safety. Always use an anchor rated for at least four times the combined weight of the TV and mount.

Best Anchor for Floating Shelves

Floating shelves create significant shear stress, as the weight pulls downward, parallel to the wall. The anchor must resist this force without sagging. The choice of anchor often involves a balance between strength and cost.

For lighter decorative shelves, Molly bolts provide excellent shear strength and a secure hold. For shelves intended to hold books or heavy kitchenware, an installer should upgrade to toggle bolts or snap toggles. While snap toggles may cost more than general toggle bolts, they are often rated for higher loads and offer superior quality control.

Best Anchor for a Heavy Mirror

A heavy mirror exerts a static, high-tension load on the wall. The primary goal is to prevent the anchor from pulling out. The value of the mirror and the risk of shattered glass make a robust hollow wall anchor a necessity.

Molly bolts are a reliable choice for mirrors in the medium-duty weight range (up to 50 lbs). Their metal construction provides a dependable hold in both drywall and plaster. For exceptionally large or ornate mirrors weighing over 50 pounds, an installer should use toggle bolts or snap toggles. These anchors distribute the weight across the largest possible area behind the wall, offering the ultimate peace of mind.

Best Anchor for Curtain Rods

Curtain rods present a unique challenge because they endure dynamic loads. The repeated action of opening and closing curtains can gradually loosen an anchor over time. The anchor must resist both shear force from the rod’s weight and tension force from being pulled.

- Lightweight Curtains: For sheer or light fabric curtains, heavy-duty self-drilling threaded anchors or Molly bolts are sufficient. They provide a secure grip that resists the minor forces of daily use.

- Heavy Drapes: For blackout curtains or heavy decorative drapes, an installer should use toggle bolts. The wide bracing of a toggle prevents it from wiggling loose within the drywall, ensuring the rod remains firmly attached to the wall for years.

Essential Tools and Techniques for Installation

Selecting the right anchor is only half the battle. Proper installation technique ensures the anchor performs to its maximum capacity. An installer’s attention to detail during this stage prevents wall damage and guarantees a secure hold.

Choosing the Right Drill Bit

The pilot hole is the foundation of a successful anchor installation. A hole that is too large will cause the anchor to spin, while a hole that is too small can damage the wall or the anchor itself.

Reading the Anchor Packaging

The most reliable source of information is the anchor’s packaging. Manufacturers specify the exact drill bit size required for their product. An installer should always follow this recommendation for optimal results. This simple step eliminates guesswork and prevents common installation failures.

What if You Don’t Have the Right Size?

An installer without the specified bit should not proceed with a close guess. A simple trick can help. A person can hold the drill bit in front of the anchor. The bit should be the same diameter as the anchor’s shaft, not including the threads or flange. If the bit hides the shaft completely, it is too large.

General Guide for Common Anchors 🛠️ While the packaging is the best guide, this table provides a general reference for common anchor types.

Anchor Type Drill Bit Size Range Toggle Bolt 1/8 inch to 1/4 inch Threaded 3/16 inch to 5/16 inch Self-Drill No drill bit needed Expansion 1/8 inch to 1/4 inch

Proper Drilling Technique

The wall material dictates the correct drilling method. Each surface requires a specific approach to create a clean hole without causing damage.

Drilling into Drywall

Drilling into drywall is straightforward. An installer can use a standard drill bit. A person should apply steady, light pressure to let the drill do the work. This prevents tearing the paper surface and creating a messy hole.

Drilling into Plaster

Plaster is hard and brittle, demanding a more careful technique to avoid cracks. An installer should use a sharp masonry or carbide-tipped bit.

- Place a piece of masking tape over the drilling location to help prevent the plaster from chipping.

- Start with a small pilot hole to guide the larger bit.

- Use a slow, steady drill speed with gentle pressure. Avoid using the drill’s hammer function.

Setting the Anchor Correctly

The final step is seating the anchor properly in the wall. This ensures it can engage correctly and support the intended load.

How to Avoid Over-Tightening

Over-tightening is a common mistake. It can strip a threaded anchor, break a plastic anchor, or damage the drywall itself. An installer should tighten the screw until it feels snug. For molly bolts, a person should stop turning once they feel significant resistance, which indicates the legs have fully expanded.

Ensuring the Anchor is Flush

The head or flange of the anchor must sit flush against the wall surface. An anchor that protrudes will prevent the mounted item from sitting flat. An anchor that is recessed too far into the wall loses holding power. A person can gently tap the anchor with a hammer or mallet to seat it perfectly before driving the screw.

Advanced Considerations for Your Hollow Wall Anchor

Beyond the basics of wall type and item weight, a professional installer considers the specific forces at play and the exact dimensions of the wall. Understanding these advanced concepts ensures that every installation is not just secure, but optimized for long-term performance.

Shear vs. Tension Strength

Every anchor has two primary strength ratings that describe how it resists different types of force. An installer must know the difference to choose the most effective hardware for a project.

What is Shear Strength?

Shear strength measures an anchor’s ability to resist a force that runs parallel to the wall surface. It is essentially the load an anchor can support before the fastener breaks or tears through the wall material. Think of it as a downward-pulling or slicing force.

The Physics of Shear 🔬 The Industrial Fastener Institute states that a fastener’s shear strength is approximately 60% of its minimum tensile strength. This force is calculated by dividing the applied force (F) by the cross-sectional area of the fastener (A).

Common projects involving shear force include hanging heavy shelves or wall cabinets.

What is Tension Strength?

Tension strength, or pull-out strength, measures the force required to pull an anchor directly out from the wall. This force acts perpendicular to the wall surface. Bolts and screws are often weaker against this type of axial pull compared to shear forces. This rating is critical for items that pull away from the wall.

Which Matters for Your Project?

The type of force an object exerts determines which rating is more important.

- Shear-Dominant Projects: A floating shelf primarily exerts shear force, as its weight pulls directly downward.

- Tension-Dominant Projects: An object hung from a ceiling exerts pure tension force.

- Combined Forces: Many items, like an articulating TV mount, create both shear and tension. The tension increases significantly as the TV is pulled away from the wall. For these dynamic loads, an installer must consider both ratings.

Understanding Wall Thickness

The thickness of your wall material directly impacts an anchor’s performance. A hollow wall anchor designed for a standard wall may fail in a thicker or thinner one.

Standard Drywall Thickness (1/2″ vs. 5/8″)

Most residential interior walls use 1/2-inch drywall. However, installers will often encounter 5/8-inch drywall in certain areas. Building codes, such as the International Residential Code (IRC), often mandate 5/8-inch Type X fire-rated drywall for garages and utility rooms to slow the spread of a potential fire. An installer must identify the thickness before choosing an anchor.

How Thickness Affects Anchor Choice

Wall thickness is a critical factor for anchors that function behind the wall, like toggle bolts. The anchor’s grip range must match the wall’s thickness.

- Insufficient Thickness: A toggle bolt’s wings may not have enough space to deploy fully inside a thin wall, drastically reducing its holding power.

- Excessive Thickness: An anchor with a short grip range will not be able to expand properly behind a thick wall, like double-layered drywall.

Pro Tip: Always check the anchor’s packaging. It specifies the compatible wall thickness range. Selecting an anchor with the correct length and grip range is essential for proper engagement and maximum strength.

Troubleshooting Common Anchor Problems

Even with careful planning, an installer can encounter issues during installation. Knowing how to troubleshoot common problems saves time and prevents wall damage. This section covers the most frequent challenges and their professional solutions.

What to Do if You Hit a Stud

Drilling a pilot hole and hitting solid wood is not a problem; it is an opportunity. A wall stud provides the most secure mounting point possible, far superior to any hollow wall anchor.

Switching to a Wood Screw

When an installer hits a stud, they should abandon the anchor and use a wood screw instead. A screw driven directly into the stud creates an exceptionally strong hold. The installer must ensure the screw is long enough to penetrate at least one inch into the wood for a secure grip.

Repositioning Your Item

Sometimes, the stud’s location is not ideal for the item’s placement. An installer must then find a new spot in a hollow section of the wall. Using a stud finder helps locate the edges of the stud, allowing for precise repositioning.

Finding Studs: A Quick Guide 🕵️ An installer can use several methods to locate studs:

- Start at a corner, where a stud is almost always present.

- Measure in 16-inch or 24-inch increments from the corner.

- Use an electronic stud finder to detect changes in wall density.

- Confirm the location by knocking; a hollow sound will turn into a solid thud over a stud.

The Anchor is Spinning in the Hole

A spinning anchor is a sign of a failed installation. The anchor cannot expand correctly because it lacks the initial friction needed to grip the wall.

Causes of a Spinning Anchor

The most common cause of a spinning anchor is a pilot hole that is too large. This happens when an installer uses the wrong drill bit size or wobbles the drill during operation. Reusing an old hole without upsizing the anchor can also lead to this issue.

How to Fix a Spinning Anchor

An installer can sometimes fix a spinning anchor by removing it and using a larger one that fits the oversized hole snugly. If the hole is significantly damaged, the best solution is to switch to a toggle-style anchor. The wings of a toggle bolt will span the damaged area and brace against solid drywall behind it.

Removing Old Anchors

Removing old hollow wall anchors is necessary for a clean wall repair. The removal method depends on the anchor type.

How to Remove a Molly Bolt

An installer has a few options for removing a molly bolt. One method involves using needle-nose pliers to grip the anchor’s flange and bend it back and forth until it breaks off. Another technique is to back the screw out partially, tap it with a hammer to straighten the anchor’s legs inside the wall, and then pull the entire unit out.

How to Remove a Toggle Bolt

A traditional toggle bolt cannot be pulled back through its installation hole. The installer must unscrew the bolt completely, allowing the spring-loaded wings to fall harmlessly inside the wall cavity. The bolt can then be removed from the fixture.

Patching the Leftover Hole

After removing an anchor, a small hole will remain. An installer can easily repair this with a bit of spackling compound. A person should apply the spackle, let it dry completely, sand it smooth, and then prime and paint the area to match the surrounding wall.

An installer ensures a successful project by following a simple process. A person first identifies the wall material and the item’s weight. They then select an anchor that matches these two factors. The manufacturer’s specifications on the packaging provide the most critical data, including weight limits and required drill bit sizes.

A Professional’s Final Check ✅ When a project’s requirements are between two anchor sizes, a professional always chooses the stronger option. This practice creates a 2:1 safety factor, guaranteeing a secure hold and providing long-term peace of mind.

FAQ

Can an installer reuse a wall anchor?

An installer should not reuse most plastic anchors, as they lose integrity upon removal. However, molly bolts and snap toggles allow a person to remove and reinsert the screw. This feature makes them ideal for items requiring periodic takedown.

What if a wall is thicker than standard drywall?

An installer must select an anchor with a grip range matching the wall’s thickness. Toggle bolts and snap toggles are available in various lengths. The product packaging specifies the compatible wall thickness range, ensuring a secure installation in thicker walls.

Why did an anchor pull out of the wall?

Anchor failure typically results from exceeding the anchor’s weight rating. Other common causes include:

- An incorrectly sized pilot hole.

- Using an anchor type unsuitable for the wall material.

- Over-tightening the screw during installation.

Does a person always need to pre-drill a hole?

Most anchors require a pre-drilled pilot hole for proper installation. The main exception is the self-drilling threaded anchor. Its sharp tip pierces drywall directly, eliminating the need for a separate drilling step on light-duty projects.

How much weight can a drywall anchor really hold?

An anchor’s capacity varies significantly by type and wall condition. A person must always consult the manufacturer’s weight rating on the package. For safety, the anchor’s rating should be several times greater than the object’s actual weight.

Is it better to hit a stud or use an anchor?

Expert Advice: Hitting a stud is always the superior choice. A wood screw driven directly into a stud provides a significantly stronger hold than any hollow wall anchor. An installer should prioritize finding a stud for all heavy items.

Can a person use a drywall anchor in a ceiling?

An installer should avoid using standard wall anchors in a ceiling. Ceilings create pure tension force, which most wall anchors are not designed to handle safely. A person must use anchors specifically rated for overhead or ceiling applications.