Selecting the best drop in anchors is crucial for project safety and efficiency. The market for these essential fasteners, including custom anchor bolts, continues to expand, reflecting their importance in modern construction. A custom fasteners manufacturer often provides a range of options to meet specific project needs.

| Metric | Value |

|---|---|

| Projected Market Size (2033) | USD 5.67 Billion |

| Compound Annual Growth Rate (CAGR) (2026-2033) | 5.4% |

| Estimated Market Size (2024) | USD 3.56 Billion |

For 2026, the Hilti HDI-P stands out for its superior load capacity in cracked concrete. The Red Head Multi-Set II offers a reliable, budget-conscious alternative for various applications. For projects prioritizing speed, the Simpson Strong-Tie Drop-In Anchor provides exceptional ease of installation, making it a top choice for repetitive tasks involving Anchor Bolts.

The best drop in anchors: 2026 Detailed Reviews

This section provides an in-depth analysis of the top-performing drop-in anchors for 2026. Each review examines the critical factors that professionals consider, from material composition to real-world performance data.

1. Hilti HDI-P – Best Overall

The Hilti HDI-P earns its top spot through exceptional engineering and robust performance, making it the go-to choice for critical structural applications.

Material and Build Quality

Hilti manufactures the HDI-P anchor from high-quality, zinc-plated carbon steel. The anchor body features a smooth, uniform finish, indicating precise manufacturing tolerances. A key design element is its pre-assembled expansion plug, which is engineered to ensure consistent and reliable setting every time. The material quality directly contributes to its long-term durability in dry, interior environments.

Load Capacity and Performance Data

This anchor truly excels in its performance metrics. The HDI-P boasts impressive tensile and shear load capacities. Its most significant advantage is its extensive list of approvals, including ICC-ES reports for use in both cracked and uncracked concrete. This certification makes it one of the few drop-in anchors qualified for seismic applications, a critical requirement for projects in earthquake-prone regions.

Professional Tip: Always consult the manufacturer’s technical data sheets for specific load values corresponding to the concrete strength (psi) and embedment depth of your project.

Installation Process and Tools

Installation of the HDI-P requires standard tools: a rotary hammer, a correctly sized carbide drill bit, compressed air, a wire brush, and the corresponding Hilti manual setting tool (HDI-ST). The process is straightforward, but cleaning the drilled hole is critical for achieving maximum load capacity. The Hilti setting tool is designed to provide clear tactile feedback, confirming when the anchor is fully and correctly expanded.

Ideal Applications

The HDI-P is ideal for heavy-duty and safety-critical fastening.

- Structural steel connections

- Overhead pipe and sprinkler systems

- Seismic bracing and retrofitting

- Machinery and equipment anchoring

Pros and Cons

- Pros:

- ✅ Superior load values in cracked and uncracked concrete

- ✅ ICC-ES approved for seismic conditions

- ✅ Highly reliable and consistent expansion

- ✅ Excellent build quality

- Cons:

- ❌ Premium price point compared to competitors

- ❌ Requires meticulous hole cleaning for optimal performance

2. Red Head Multi-Set II – Best Value

The Red Head Multi-Set II anchor provides a fantastic balance of reliable performance and cost-effectiveness, making it a staple for general-purpose construction projects.

Material and Build Quality

This anchor is constructed from zinc-plated carbon steel, offering good corrosion resistance for indoor use. The build quality is consistent and dependable for non-critical applications. While it may not have the refined finish of a premium anchor, its functionality is solid. The internal plug is designed for effective expansion in solid concrete base materials.

Load Capacity and Performance Data

The Multi-Set II offers respectable load capacities in uncracked concrete. It serves as a dependable choice for static loads where seismic or cracked concrete ratings are not a project requirement. The anchor’s value proposition is strong; it delivers reliable holding power at an accessible price point, making it an economical choice for large-scale projects with standard fastening needs.

Installation Process and Tools

Installation follows the standard drop-in procedure. It requires a carbide drill bit, a setting tool, and a hammer. The Red Head setting tool is readily available and works effectively to expand the anchor. The process is simple, making it suitable for crews of all experience levels. For best results, cleaning the hole of debris remains a recommended practice.

Ideal Applications

This anchor is a versatile workhorse for a wide range of medium-duty tasks.

- Fastening electrical conduit and cable trays

- Suspending ductwork and strut channels

- Anchoring handrails and wall partitions

- General-purpose fixtures in solid concrete

Pros and Cons

- Pros:

- ✅ Excellent price point and overall value

- ✅ Reliable performance for static loads

- ✅ Widely available and easy to source

- ✅ Simple installation process

- Cons:

- ❌ Not rated for cracked concrete or seismic use

- ❌ Lower load capacities than premium options

3. Simpson Strong-Tie Drop-In – Easiest to Install

For projects where speed and repetition are paramount, the Simpson Strong-Tie Drop-In Anchor (DIA) is a standout performer, designed specifically to streamline the installation process.

Material and Build Quality

The DIA is available in zinc-plated carbon steel and two grades of stainless steel (Type 304 and 316), offering options for various corrosive environments. A key feature contributing to its ease of use is its flush-mount design. The anchor body is engineered to sit perfectly flush with the concrete surface, creating a clean and professional finish without any secondary adjustments.

Load Capacity and Performance Data

Simpson provides clear performance data for the DIA in solid concrete. While its load values are suitable for many light to medium-duty applications, its primary selling point is not raw strength but installation efficiency. The anchor provides secure holding power for common tasks, and its reliable performance makes it a trusted name on the job site. It is one of the best drop in anchors for projects that demand both speed and dependability.

Installation Process and Tools

This is where the Simpson DIA shines. The anchor is designed for rapid setting.

- Drill the hole to the specified depth.

- Drop the anchor in.

- Use the correct Simpson setting tool to expand it.

The anchor’s design ensures it can be installed quickly and correctly, which is a major benefit for repetitive tasks like suspending thousands of feet of conduit. This focus on installation speed and reliability minimizes labor costs and project timelines.

Ideal Applications

The DIA is the top choice for high-volume, repetitive anchoring tasks.

- Overhead lighting and fixture installation

- Suspending fire protection systems

- Securing strut and channel supports

- Any application where installation speed is a critical factor

Pros and Cons

- Pros:

- ✅ Exceptionally fast and easy installation

- ✅ Flush-mount design provides a neat, finished appearance

- ✅ Available in stainless steel for corrosive environments

- ✅ Reduces labor time on repetitive tasks

- Cons:

- ❌ Not intended for heavy structural loads

- ❌ Setting tool is required for proper expansion

4. Powers Vertigo+ – Best for Overhead Applications

The Powers Vertigo+ anchor system is an innovative solution engineered specifically to improve safety and efficiency for overhead fastening. Its unique design sets it apart from traditional drop-in anchors.

Material and Build Quality

Powers constructs the Vertigo+ from zinc-plated carbon steel, suitable for dry, non-corrosive indoor environments. The anchor’s standout feature is its integrated design, which combines the anchor body with a threaded rod coupling. This single-piece construction eliminates the need for separate components, ensuring a secure and consistent connection for suspended systems. The build quality is robust, reflecting its purpose for secure overhead installations.

Load Capacity and Performance Data

The Vertigo+ provides reliable performance for static overhead loads. Its load values are specified for use in solid concrete. While it may not compete with the raw strength of heavy-duty structural anchors, its primary advantage lies in its safe and efficient installation method for suspended applications. The system is designed to provide confidence when hanging threaded rods for electrical, mechanical, and plumbing systems.

Installation Process and Tools

Installation of the Vertigo+ is a specialized process that delivers significant time savings.

- Drill a hole into the concrete ceiling using a standard rotary hammer.

- Attach the Vertigo+ anchor to a special drive tool, which fits onto an extension pole.

- Insert the anchor and tool into the hole from the ground, eliminating the need for ladders or lifts.

- Use the drill to drive the anchor, which simultaneously sets the anchor and cleans the hole.

This method dramatically increases safety and reduces labor time for large-scale overhead projects.

Safety Note: Always use the manufacturer-specified drive tool and follow the installation instructions precisely. This ensures the anchor is set correctly and can support its intended load.

Ideal Applications

The Vertigo+ is purpose-built for suspending threaded rods in overhead concrete.

- Hanging pipe supports and fire sprinkler lines

- Suspending HVAC ductwork and equipment

- Installing overhead electrical conduit and cable trays

- Securing strut channel systems to ceilings

Pros and Cons

- Pros:

- ✅ Drastically improves safety by allowing installation from the floor

- ✅ Significantly faster installation than traditional methods

- ✅ Reduces labor costs and the need for lifts or scaffolding

- ✅ Reliable for static overhead loads

- Cons:

- ❌ Requires a proprietary installation tool

- ❌ Limited to overhead threaded rod applications

- ❌ Not intended for structural or seismic loads

5. CONFAST 316 Stainless Steel – Top Corrosion-Resistant Option

When a project demands maximum protection against rust and corrosion, the CONFAST 316 Stainless Steel Drop-In Anchor is the premier choice. Its material composition makes it ideal for the most severe environments.

Material and Build Quality

This anchor’s primary feature is its Type 316 stainless steel construction. This material contains molybdenum, which provides superior resistance to chlorides and other harsh chemicals compared to Type 304 stainless steel. The build quality is excellent, with clean threads and a uniform body designed for reliable expansion. This anchor is built to last in environments where standard zinc-plated anchors would quickly fail.

Load Capacity and Performance Data

CONFAST provides clear load data for its anchors in solid concrete. While stainless steel anchors generally have slightly lower tensile and shear strengths than their high-strength carbon steel counterparts, their value is not in pure strength. Their performance is measured by longevity and reliability in corrosive settings. They provide secure, long-term fastening without the risk of degradation, making them the best drop in anchors for asset preservation in harsh conditions.

Installation Process and Tools

The installation process for the CONFAST 316 anchor is identical to that of standard drop-in anchors. It requires a rotary hammer, a carbide bit, a wire brush, compressed air for hole cleaning, and a matching setting tool. The anchor is tapped into the pre-drilled hole and expanded by driving the internal plug with the setting tool. This familiar process ensures that crews can install it correctly without special training.

Ideal Applications

This anchor is essential for applications with exposure to moisture, salt, and chemicals. Its robust material composition makes it suitable for submerged and chemical-heavy environments.

- Marine construction, including docks, piers, and seawalls

- Wastewater treatment plants and chemical facilities

- Coastal buildings and structures exposed to salt spray

- Food processing plants and breweries with frequent washdowns

Pros and Cons

- Pros:

- ✅ Maximum corrosion resistance from Type 316 stainless steel

- ✅ Ideal for marine, chemical, and coastal applications

- ✅ Provides a long-term, reliable fastening solution

- ✅ Standard installation procedure

- Cons:

- ❌ Significantly higher cost than carbon steel anchors

- ❌ Lower ultimate load values compared to some carbon steel options

How to Choose the Right Drop-In Anchor

Choosing the correct drop-in anchor involves more than just picking a size. A professional assessment requires matching the anchor’s material, load capacity, and base material compatibility to the specific demands of the project. This ensures a secure, durable, and code-compliant installation.

Matching Anchor Material to Your Environment

The anchor’s material is the first line of defense against environmental degradation. Selecting the right material prevents premature failure and ensures long-term performance.

Zinc-Plated Carbon Steel

Most drop-in anchors are made from zinc-plated carbon steel. This material offers good strength and is cost-effective. The zinc coating provides a basic level of corrosion resistance, making these anchors suitable for dry, indoor environments where exposure to moisture is minimal.

304 Stainless Steel

For applications with moderate moisture exposure, such as damp basements or covered outdoor areas, Type 304 stainless steel is a better choice. It offers significantly more corrosion resistance than zinc-plated steel, protecting the anchor from rust in less severe conditions.

316 Stainless Steel

Type 316 stainless steel provides the highest level of corrosion protection. It contains molybdenum, which makes it exceptionally resistant to chlorides and harsh chemicals. This material is essential for:

- Marine environments with salt spray

- Wastewater treatment plants

- Chemical facilities

- Food processing areas with frequent washdowns

Understanding Critical Load Requirements

An anchor’s primary job is to resist forces. Understanding these forces is critical for safety. The holding power of an anchor depends on its size, embedment depth, and the concrete’s strength (PSI).

Defining Tensile Load (Pull-Out)

Tensile load is the force that tries to pull the anchor straight out of the concrete. This is a critical consideration for overhead applications, like suspending pipes or light fixtures, where gravity is the primary force.

Defining Shear Load (Side-Force)

Shear load is the force that acts perpendicular to the anchor, trying to slice it off at the surface. This occurs when anchoring items to a wall, such as handrails or heavy equipment, where the weight pulls downward against the anchor.

How to Calculate Your Project’s Needs

Calculating precise load requirements is a complex engineering task. Professionals often use standards like ACI 318-19 to determine anchor capacity. However, a fundamental principle is applying a safety factor. For non-engineered applications, a common safety factor is 4:1. This means the safe working load is 25% of the anchor’s ultimate published load value.

Important Note: For critical applications like fall protection, OSHA requires anchor points to support at least 5,000 pounds per worker or be designed by a qualified person with a safety factor of at least two. Always consult an engineer for safety-critical designs.

Base Material Compatibility

Drop-in anchors are designed for specific base materials. Using them in unapproved materials can lead to catastrophic failure.

Performance in Solid Concrete

Drop-in anchors perform best in solid, normal-weight concrete. The compressive strength of the concrete, measured in PSI, directly impacts the anchor’s holding power. Higher PSI concrete generally yields greater load capacities. The best drop in anchors have performance data tested across a range of concrete strengths.

Considerations for Brick and Block

Drop-in anchors are not recommended for use in hollow block (CMU) or soft brick. The expansion mechanism requires a solid, dense material to create friction. In hollow or brittle materials, the anchor can break out the base material, resulting in a complete loss of holding power. For these applications, sleeve anchors or adhesive anchors are the appropriate choice.

A Closer Look at Anchor Dimensions

Selecting the correct anchor dimensions is as critical as choosing the right material. The diameter and embedment depth of a drop-in anchor directly determine its holding power and overall performance. A miscalculation in either area can compromise the integrity of the entire fastening.

Choosing the Right Anchor Diameter

The diameter of the anchor is the first dimensional decision a professional makes. This choice influences both the hardware used and the anchor’s ultimate strength.

Matching Diameter to Bolt Size

A drop-in anchor’s designated size corresponds to the diameter of the bolt it accepts. The anchor’s internal threads must match the external threads of the bolt or threaded rod. This relationship also dictates the size of the hole drilled into the concrete.

- The drill bit diameter must match the anchor’s outer diameter.

- For example, a 1/2-inch anchor requires a 1/2-inch hole and accepts a 1/2-inch bolt.

- Some installers prefer a slightly oversized bit, like a 5/8-inch bit for a 1/2-inch anchor, to ease installation and improve alignment, though one should always consult manufacturer guidance.

Impact on Load Capacity

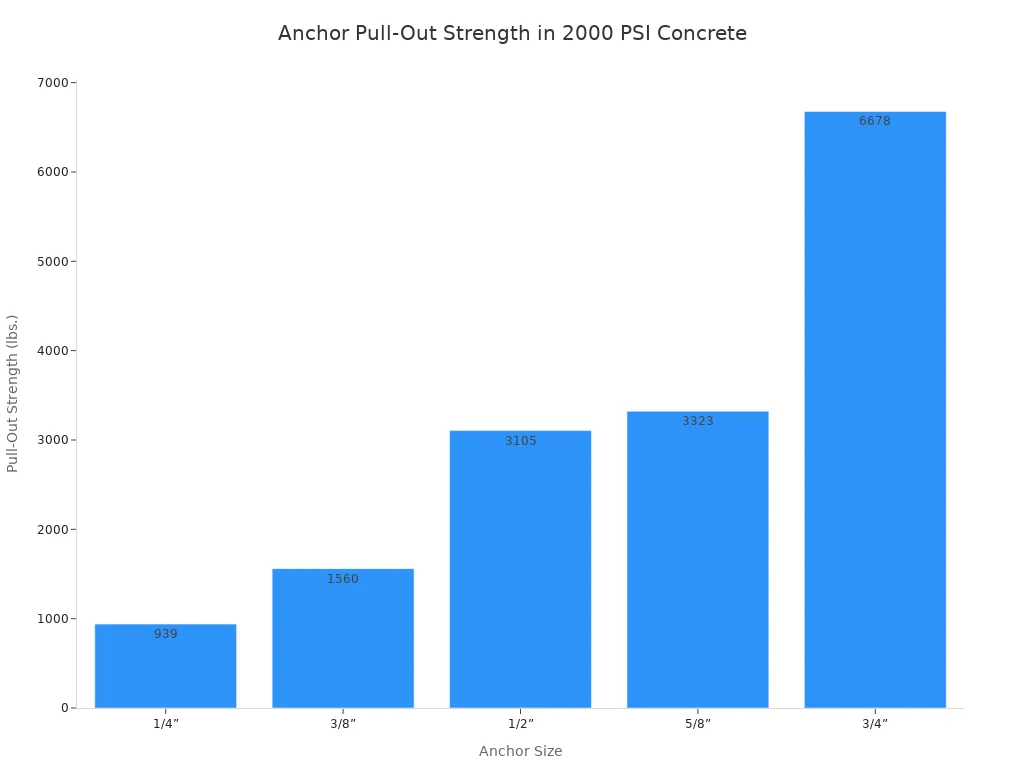

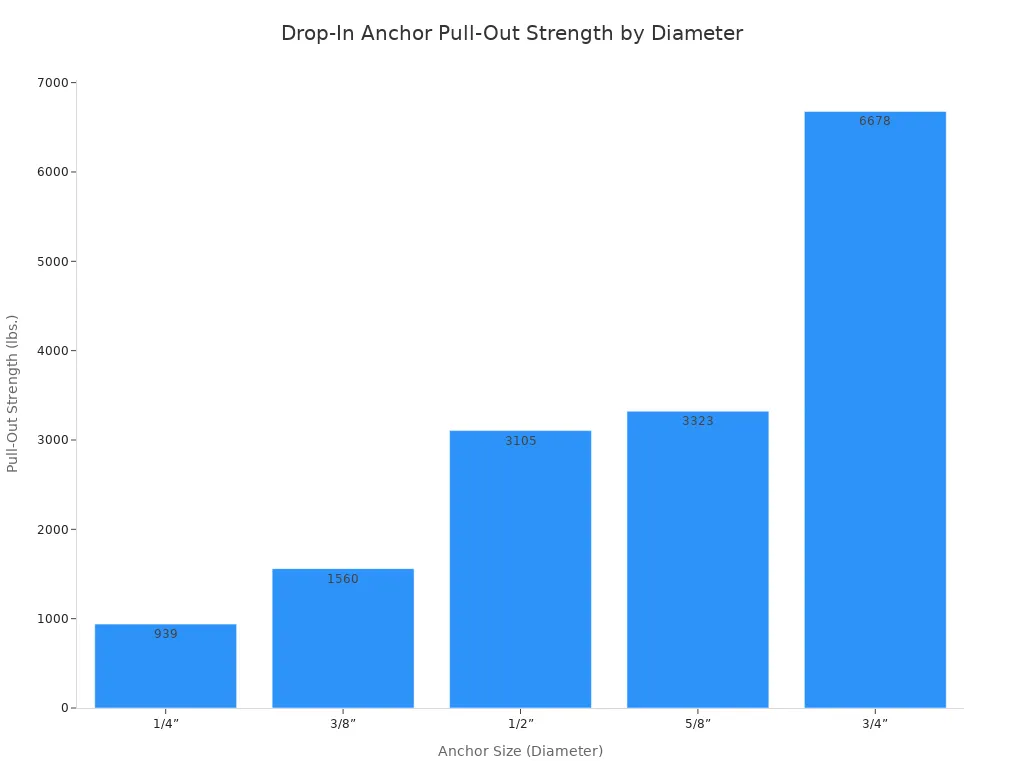

An anchor’s diameter has a significant impact on its load capacity. A larger diameter anchor creates more surface area for friction against the concrete, resulting in greater resistance to both pull-out (tensile) and side-force (shear) loads. The relationship is clear: increasing the diameter dramatically increases the anchor’s strength.

The table below shows the ultimate pull-out strength for different anchor sizes in 2000 PSI concrete.

| Anchor Size | Pull-Out (lbs.) |

|---|---|

| 1/4” | 939 |

| 3/8” | 1560 |

| 1/2” | 3105 |

| 5/8” | 3323 |

| 3/4” | 6678 |

Determining Correct Embedment Depth

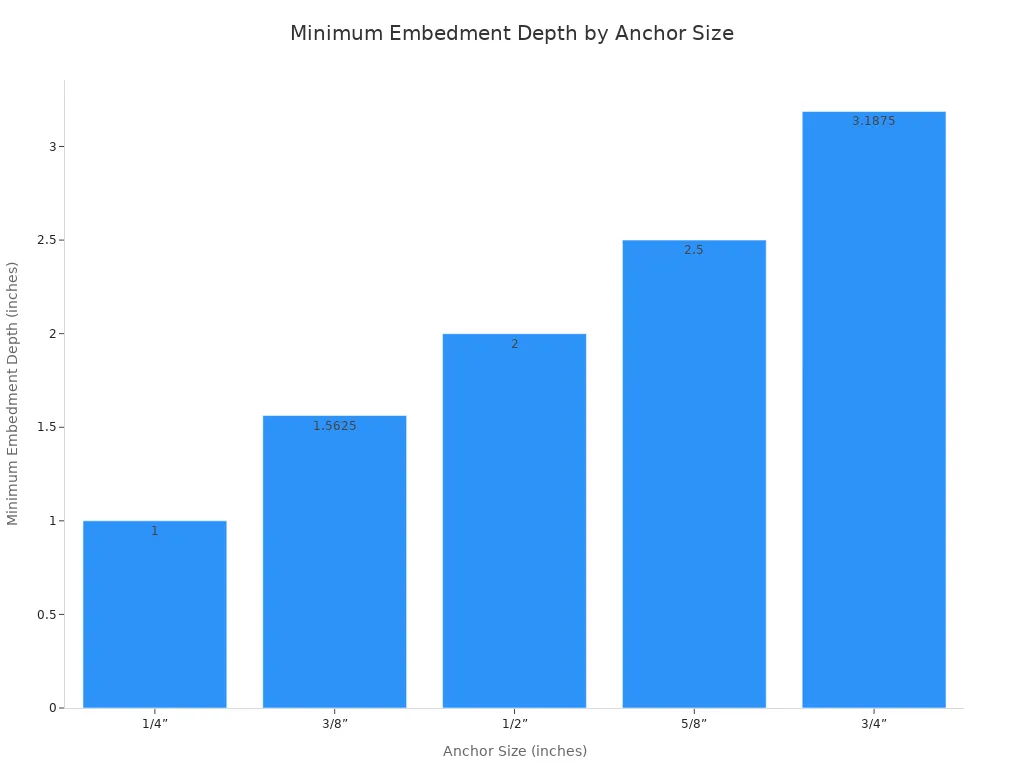

Embedment depth is the distance the anchor is installed into the base material. Proper embedment is essential for the anchor to achieve its published load values.

Manufacturer Specifications

Manufacturers provide a “minimum embedment depth” for each anchor size. This is the shallowest depth at which the anchor can be installed to function safely. Installing an anchor at less than this minimum depth will severely reduce its holding power. As a general rule, deeper embedment yields higher load capacity.

| Size | Minimum Embedment |

|---|---|

| 1/4” | 1” |

| 3/8” | 1-9/16” |

| 1/2” | 2” |

| 5/8” | 2-1/2” |

| 3/4” | 3-3/16” |

Fixture Thickness Considerations

The thickness of the material being fastened (the fixture) must be added to the embedment depth to determine the total required hole depth. A simple formula helps calculate the correct length for the bolt and the minimum depth of the drilled hole.

Pro Tip: Calculating Total Hole Depth ⚙️ Use this formula to ensure your hole is deep enough:

Total Hole Depth = Fixture Thickness + Minimum Anchor Embedment + Bolt Engagement DepthAlways drill the hole slightly deeper than your calculation to allow space for dust and debris.

Step-by-Step Installation Guide for Perfect Setting

Proper installation is not just a recommendation; it is a requirement for achieving an anchor’s full load capacity. Shockingly, studies show up to 80% of drop-in anchors are installed incorrectly, often due to simple but critical mistakes. Following a precise, methodical process ensures every anchor performs safely and effectively.

Step 1: Drill the Hole

The installation begins with creating a precise cavity in the concrete. This foundational step dictates the anchor’s alignment and initial fit.

Select the Correct Carbide Bit Size

Professionals must match the carbide drill bit diameter to the anchor’s outer diameter. For instance, a 1/2-inch anchor requires a 1/2-inch hole. Using a worn or incorrect bit can create an undersized hole. This mistake increases stress on the concrete during expansion and can compromise the anchor’s holding power. Frequent inspection of drill bits is a best practice.

Drill to the Specified Depth

Installers drill the hole to the depth specified by the manufacturer. This depth accounts for the anchor’s minimum embedment and the thickness of the fixture. Drilling slightly deeper than required provides extra space for any remaining dust, ensuring the anchor can be set at the correct depth without obstruction.

Step 2: Clean the Hole

This is the most critical and frequently overlooked step in the installation process. Debris left in the hole can drastically reduce an anchor’s performance.

Critical Safety Alert ⚠️ Failure to clean the hole is a primary cause of anchor failure. Dust and debris prevent the anchor from making solid contact with the concrete, which severely compromises its load-bearing capacity.

Using Compressed Air for Debris Removal

The first cleaning action involves using compressed air or a blow-out pump. Installers direct a powerful stream of air to the bottom of the hole. This action forces the bulk of the drilling dust and debris out. However, this method alone is often insufficient for a perfect setting.

Using a Wire Brush to Scour the Sides

After the initial blowout, a correctly sized wire brush is necessary. Installers scour the interior walls of the hole with the brush. This action dislodges fine dust particles that compressed air leaves behind. A final blast of compressed air removes this loosened debris, leaving a clean surface ready for the anchor. This two-part process is essential for a secure installation and a smooth quick operation.

Step 3: Insert the Anchor

With a clean, properly sized hole, the anchor is ready for placement. This step should be straightforward and require minimal force.

Tapping the Anchor into Place

Installers position the anchor, open end up, into the hole. They use a hammer to gently tap the anchor until its top is level with the concrete surface. The anchor should slide in smoothly. Resistance may indicate the hole is too small or still contains debris.

Ensuring it is Flush or Sub-Flush

The goal is to set the anchor so it sits perfectly flush with the concrete. In some cases, setting it slightly below the surface (sub-flush) is acceptable. This creates a clean, professional appearance and ensures the fixture can be mounted flat against the surface without interference.

Step 4: Set the Anchor

This step transforms the inserted anchor from a simple metal sleeve into a secure fastening point. The installer drives an internal plug downward, forcing the anchor’s walls to expand and grip the concrete.

Using the Correctly Sized Setting Tool

Professionals use a setting tool specifically designed for the anchor’s diameter. Each size, from 1/4-inch to 3/4-inch, has a corresponding tool. This tool features a shoulder, or lip, that stops on the anchor’s edge, preventing the tool from being driven too far. Using the correct tool is not optional; it is essential for achieving proper expansion without damaging the anchor’s internal threads.

How to Confirm Full Internal Expansion

An experienced installer confirms a successful set through both feel and visual cues. They deliver several sharp, solid hammer blows to the setting tool. The anchor is fully expanded when the installer feels a distinct change in resistance, indicating the internal plug has bottomed out.

Confirmation Checklist ✅ A properly set anchor is confirmed when:

- The lip of the setting tool makes solid contact with the lip of the anchor.

- The tool leaves visible marks on the opening of the anchor body.

- The hammer blows produce a solid, ringing sound, signaling the expansion is complete.

These indicators provide confidence that the anchor has achieved its maximum grip within the concrete.

Step 5: Install the Fixture

With the anchor securely set, the final step is to mount the object. This stage involves careful alignment and precise tightening to complete the installation.

Placing the Fixture Over the Anchor

The installer places the fixture, such as a steel bracket or strut channel, over the set anchor. They align the hole in the fixture directly with the anchor’s threaded opening. The flush-mount design of the drop-in anchor ensures the fixture sits flat against the concrete surface, creating a stable and professional-looking connection.

Threading and Tightening the Bolt to Torque Specs

The installer then inserts the correctly sized bolt or threaded rod through the fixture and into the anchor. They hand-tighten the bolt initially to ensure it is not cross-threaded. Finally, they use a calibrated torque wrench to tighten the bolt to the manufacturer’s specified torque value. This critical action applies the correct clamping force, securing the fixture without over-stressing the anchor or the surrounding concrete. Applying the proper torque is the final guarantee of a safe and reliable fastening.

Alternative Anchoring Solutions

While drop-in anchors are versatile, they are not the only solution for every fastening challenge. Professionals often choose between different anchor types based on the specific application, load requirements, and even the environment. Understanding these alternatives helps ensure the selection of the most effective and efficient fastener for the job.

Drop-In Anchors vs. Wedge Anchors

Drop-in anchors and wedge anchors are two of the most common mechanical anchors, yet they function differently and excel in separate applications. Most post-installed mechanical expansion anchors resist loads through friction. This resistance comes from expansion forces between the anchor and the wall of the drilled hole.

Key Differences in Application

The primary difference lies in their installation and fixture requirements. Drop-in anchors are female anchors, installed flush with the concrete surface. This makes them ideal for applications requiring a removable fixture or a clean, flat surface. Wedge anchors are male anchors that protrude from the concrete, making them a through-fixture fastener.

| Anchor Type | Load-Bearing Mechanism |

|---|---|

| Wedge Anchor | Expands the anchor body by tightening a nut, causing a wedge-shaped mechanism to compress the base material. |

| Drop-in Anchor | A threaded expander bolt and a wedge mechanism are driven down with a setting tool, expanding the anchor within a pre-drilled hole. |

When to Choose One Over the Other

A professional chooses a wedge anchor for heavy-duty structural connections where the fixture can be permanently placed over the anchor bolt. Their design, which actively compresses the base material, often provides higher load capacities.

Pro Tip: Select a drop-in anchor when you need the flexibility to remove a bolt and fixture, such as for temporary bracing or machinery maintenance. They are also perfect for overhead applications where a threaded rod is suspended.

Understanding Specialty Anchors like fishbone tent anchors

The world of anchoring extends far beyond concrete. Specialty anchors are engineered for unique environments where traditional fasteners would be ineffective. The fishbone tent anchors are a prime example of such innovation.

Unique Design and Use Case

These specialty anchors are designed for temporary anchoring in soil, sand, or gravel, often for tents, canopies, or small watercraft. Unlike concrete anchors, fishbone tent anchors use a unique shape to grip soft ground. Their lightweight aluminum construction makes them perfect for remote use. Anglers find them useful as shallow-water anchors when fishing expansive flats, as they can quickly hold position while retying a line.

Comparison to Traditional Concrete Anchors

A direct comparison highlights their specialized nature. Concrete anchors rely on the immense compressive strength of the base material to create friction. In contrast, fishbone tent anchors distribute force over a wider area of soft ground, much like a snowshoe. They offer a clever, portable solution for temporary needs, whereas a drop-in anchor provides a permanent, high-strength fastening point in a solid, man-made material.

For most professional applications in 2026, the Hilti HDI-P remains one of the best drop in anchors. It offers an unmatched balance of strength, reliability, and code approvals. The table below summarizes the top choices for various needs.

| Anchor | Overall Rating | Price | Material | Best Use Case |

|---|---|---|---|---|

| Hilti HDI-P | ⭐⭐⭐⭐⭐ | $$$ | Carbon Steel | Structural & Seismic |

| Red Head Multi-Set II | ⭐⭐⭐⭐ | $ | Carbon Steel | General Purpose |

| Simpson Strong-Tie | ⭐⭐⭐⭐ | $$ | Steel/Stainless | Repetitive Tasks |

Professionals must always select an anchor based on environmental conditions and load requirements. This ensures every installation provides a safe, secure anchor point.

FAQ

Can you reuse a drop-in anchor?

Can you reuse a drop-in anchor?

No, professionals never reuse drop-in anchors. The expansion process permanently deforms the anchor body. Removing it compromises both the anchor and the concrete, preventing a safe and secure re-installation.

What happens if the hole is too big?

What happens if the hole is too big?

An oversized hole prevents proper expansion. The anchor fails to create sufficient friction against the concrete walls. This situation leads to severely reduced load capacity and a high risk of pull-out failure.

Is cleaning the hole really necessary?

Is cleaning the hole really necessary?

Absolutely. Cleaning the hole is a critical step. Concrete dust prevents the anchor from achieving full contact with the base material. This oversight severely compromises load capacity and is a primary cause of anchor failure.

Can drop-in anchors be used in brick or block?

Can drop-in anchors be used in brick or block?

Professionals avoid using drop-in anchors in hollow block or soft brick. The expansion force can crack these brittle base materials. Sleeve anchors or adhesive anchors are the correct fasteners for such applications.

How close can I install two anchors?

How close can I install two anchors?

Manufacturers provide minimum spacing requirements. Placing anchors too close creates overlapping stress zones within the concrete. This condition can cause a large cone-shaped piece of concrete to break out under load. Always consult the technical data sheet.

Why is a special setting tool required?

Why is a special setting tool required?

The setting tool guarantees correct expansion. Its shoulder stops on the anchor’s lip, preventing over-driving and thread damage. Using an incorrect tool, such as a simple punch, often results in an incomplete set.

What does “cracked concrete” mean?

What does “cracked concrete” mean?

Cracked concrete refers to concrete that is under tension and may develop fine cracks over time. Anchors rated for cracked concrete, like the Hilti HDI-P, are designed to maintain their holding power even if a crack forms through the anchor hole.