Drop in anchors provide strong, secure fastening solutions in solid concrete. The global mechanical anchor industry, generating USD 1,949.5 million in 2024, is projected to reach USD 2,567.8 million by 2033, highlighting the importance of components like drop-in anchors. A custom fasteners manufacturer produces many types of Anchor Bolts, including custom anchor bolts and concrete drop-in anchors for specific project needs. These fasteners are essential for medium to heavy-duty applications.

A drop-in anchor is a female-threaded mechanical expansion anchor. It creates a secure, flush-mounted anchor point. This design allows for the easy insertion and removal of a threaded bolt or rod.

How Do Drop-In Anchors Work?

The effectiveness of drop in anchors lies in a simple yet powerful mechanical principle: controlled expansion. This process creates immense friction inside a concrete hole, providing a secure anchor point. Understanding the components and their interaction reveals how this strength is achieved.

The Expansion Mechanism Explained

The anchor’s design consists of two primary parts that work together with a specialized tool to create a secure fit. The magic happens when these components interact under force.

The Anchor Body

The anchor body is a cylindrical steel sleeve with internal threads at the top. These threads are what accept a bolt or threaded rod. The bottom half of the body is slotted or scored. These slots allow the anchor’s diameter to expand when force is applied from within.

The Internal Expander Plug

Inside the bottom of the anchor body rests a small, solid metal cone known as an expander plug. The anchor’s function relies on a process called displacement-controlled expansion. When driven downward, this plug forces the slotted sides of the anchor body to flare outwards.

The Role of the Setting Tool

A drop in anchor setting tool is essential for proper installation. This tool is a steel pin designed to fit perfectly inside the anchor body and rest directly on top of the expander plug. When struck with a hammer, the drop in anchor setting tool drives the plug a specific distance toward the bottom of the hole. This action expands the sleeve correctly, locking the anchor in place.

Creating a Secure Friction Hold

The expansion of the anchor body generates the holding power. This creates a tight grip against the surrounding concrete, making drop-in anchors reliable for heavy loads.

Force Distribution in Concrete

The expander plug’s movement increases the volume of material within the pre-drilled hole. This expansion pushes the anchor’s walls firmly against the interior surface of the concrete. The immense outward pressure generates significant friction. This friction is the primary mechanism that resists pull-out forces, distributing the load securely into the base material.

Why a Clean Hole is Critical

Important Note: A clean hole is non-negotiable for a secure installation. Any dust or debris left from drilling can prevent the anchor from expanding fully.

- Debris can cushion the expansion, reducing friction.

- It can also stop the anchor from being inserted to the correct depth.

Always use a wire brush and compressed air to thoroughly clean the hole before inserting any drop in anchors.

Key Features and Benefits of Drop In Anchors

Drop in anchors are a popular choice in construction and industrial settings due to their distinct advantages. Their design delivers a combination of strength, versatility, and durability that makes them suitable for a wide range of demanding applications. Understanding these key features helps professionals select the right fastener for their project.

High Load Capacity

The primary benefit of drop-in anchors is their ability to support significant weight. Their expansion mechanism creates a powerful connection with the concrete, providing reliable performance under stress.

Shear and Tensile Strength

These anchors exhibit excellent resistance to two types of forces. Tensile strength resists pull-out forces, while shear strength resists side-to-side pressure. The anchor’s holding power is directly related to its size and the concrete’s compressive strength. For example, zinc-plated anchors demonstrate substantial pull-out values in standard concrete.

| Anchor Size | Pull-Out (lbs.) in 2000 PSI Concrete |

|---|---|

| 3/8″ Drop-In Anchor Zinc Plated | 1170 |

| 1/2″ Drop-In Anchor Zinc Plated | 2328 |

| 5/8″ Drop-In Anchor Zinc Plated | 2492 |

Safety First: These figures represent ultimate load values. Professionals typically apply a 4:1 safety factor to determine a safe working load. This means the intended load should not exceed 25% of the ultimate value.

Performance in Solid Concrete

Drop in anchors are engineered specifically for use in solid concrete. The anchor expands to create strong holding points, pressing firmly against the dense base material. This secure grip ensures stability for heavy-duty fastening, from structural supports to overhead equipment. Their performance is less effective in softer materials like brick or block.

Versatility and Removability

The design of concrete drop-in anchors offers unique functional advantages, particularly regarding installation and fixture management.

Flush-Mount Installation

An anchor sits flush with or just below the concrete surface after proper setting. This feature is crucial for applications requiring a smooth finish. It eliminates trip hazards and allows machinery or equipment to be placed directly over the anchor point without obstruction.

Allowing Bolt Removal

A key feature is the ability to remove the bolt or threaded rod after installation. The anchor itself remains permanently set in the concrete. This allows for temporary installations, equipment maintenance, or fixture replacement without the need to drill a new hole or damage the concrete.

Durability and Material Options

Manufacturers produce drop-in anchors from different materials to suit various environmental conditions, ensuring long-term reliability.

Zinc-Plated Carbon Steel

The most common material is zinc-plated carbon steel. This option provides good strength and is ideal for dry, indoor environments where moisture is not a concern. These anchors often comply with rigorous standards like ASTM E488-22, which outlines testing for tensile and shear performance to ensure reliability.

Stainless Steel for Corrosion Resistance

For outdoor applications or indoor areas exposed to moisture and corrosive chemicals, stainless steel is the superior choice. Stainless steel drop in anchors offer excellent protection against rust and degradation, preserving their structural integrity and holding power over time.

Types of Concrete Drop-in Anchors

Professionals select from different types of concrete drop-in anchors based on the specific requirements of an application. While all operate on the same expansion principle, subtle design variations make each type suitable for different scenarios, from shallow flush mounting to specialized forming work.

Lipped Drop-In Anchors

A lipped drop-in anchor is easily identified by the small flange, or lip, that extends around the top of the anchor body. This design feature serves a critical and practical purpose during installation.

Design and Function

The lip acts as a built-in stop. When an installer hammers the anchor into the pre-drilled hole, the lip catches on the surface of the concrete. This prevents the anchor from being driven too deep. The setting tool then drives the internal plug to expand the anchor securely just below the surface.

When to Use a Lipped Anchor

Lipped drop in anchors are ideal for applications where a consistent, shallow embedment depth is required. The lip guarantees uniformity across multiple anchor points.

Key advantages include:

- The lip ensures the anchor is set perfectly flush with the concrete surface.

- This design feature makes drilling precise hole depths less critical.

- It provides consistent embedment, which leads to uniform holding values.

- Installers can use threaded rods of the same length for all anchor points.

Non-Lipped (Straight Wall) Drop-In Anchors

Unlike its lipped counterpart, the non-lipped or straight-wall anchor features a smooth, uniform cylindrical body from top to bottom. This simple design offers greater installation flexibility.

Design and Function

Without a lip to stop it, a non-lipped anchor can be set at any depth within the drilled hole. Installers can position it flush with the surface or drive it deeper into the concrete before using the setting tool to expand it. This makes it a versatile choice for various situations.

Advantages of Deeper Setting

A non-lipped drop-in anchor can be installed at a depth greater than its body length. This deeper embedment provides an opportunity to achieve higher holding values. Setting the anchor further into stronger, more competent concrete can significantly increase its pull-out resistance, making it suitable for more demanding loads.

Coil-Thread Drop-In Anchors

Coil-thread drop in anchors are highly specialized fasteners designed for a niche but critical construction task: concrete formwork. They are essential components in many temporary bracing systems.

Specialized Threading for Concrete Formwork

These concrete drop-in anchors feature special internal threads compatible with coil threaded rods. CONFAST® Coil Threaded Drop-In Anchors are specifically designed for use in concrete forms, with a notable application being in bridge building. The unique threading ensures a secure connection with the forming hardware.

Applications in Temporary Construction Bracing

Coil-thread anchors are categorized under ‘Concrete Forming Systems & Accessories‘. They play a vital role in securing temporary structures needed to pour concrete. Common applications include:

- Bridge Deck Forming

- Heavy Duty Forming Products

- Steel/Plywood Form Accessories

- Miscellaneous Forming Hardware

How to Install Drop In Anchors: A Step-by-Step Guide

Proper installation is the most critical factor for achieving the full holding power of drop in anchors. Following a precise, methodical process ensures a safe and secure connection. This guide outlines the essential steps to correctly install drop in anchors in solid concrete.

Step 1: Gather Your Tools and Materials

Before beginning the installation, an installer must assemble all necessary equipment. Having the right tools on hand streamlines the process and prevents errors. The tools needed to install drop in anchors are specific to working with concrete and mechanical fasteners.

Required Tools

A successful installation requires a few key pieces of equipment. Each tool plays a specific role in creating a secure anchor point.

- Hammer Drill: This provides the necessary impact and rotation to drill into dense concrete.

- Carbide-Tipped Drill Bit: The bit must match the anchor size. Carbide tips are essential for durability and precision in concrete.

- Hammer: A standard hammer is used to tap the anchor into place and strike the setting tool.

- Drop in anchor setting tool: This specialized pin is crucial for expanding the anchor correctly.

Safety Equipment

Working with concrete and power tools presents potential hazards. Using appropriate personal protective equipment (PPE) is non-negotiable for safety.

Safety First! 👷 Always wear the following safety gear:

- Safety Glasses: Protects eyes from flying concrete dust and debris.

- Gloves: Protects hands during drilling and handling of materials.

- Hearing Protection: A hammer drill produces significant noise that can damage hearing over time.

Step 2: Drill the Hole

Drilling a precise hole is the foundation of a strong anchor point. The hole’s diameter and depth must meet the manufacturer’s specifications for the specific anchor being used. This step is fundamental when you install drop in anchors.

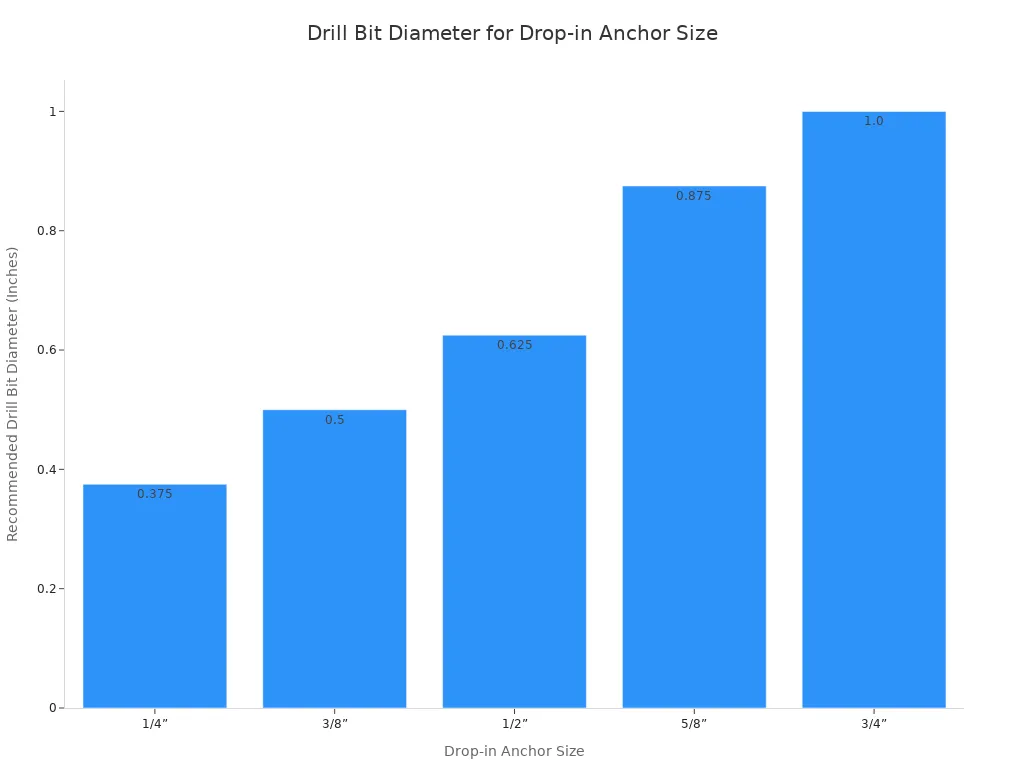

Selecting the Correct Drill Bit

Using the correct drill bit diameter is crucial for the anchor’s performance. A hole that is too small will prevent insertion, while a hole that is too large will prevent the anchor from expanding properly, severely compromising its load capacity. The bit diameter must be larger than the anchor’s thread size. For example, a 1/2-inch anchor typically requires a 5/8-inch drill bit.

The following table provides a general guide for matching drop-in anchors to the correct carbide bit diameter.

| Drop-in Anchor Size | Recommended Drill Bit Diameter |

|---|---|

| 1/4” | 3/8” |

| 3/8” | 1/2” |

| 1/2” | 5/8” |

| 5/8” | 7/8” |

| 3/4” | 1” |

Drilling to the Proper Depth

The hole must be drilled to a depth that is at least the minimum embedment depth required for the anchor. This depth is typically equal to the anchor’s length. For a standard 1/2-inch anchor, the minimum embedment depth and anchor length are both 2 inches. Drilling the hole slightly deeper than the minimum requirement ensures that any remaining fine dust will not obstruct the anchor from being fully seated.

Step 3: Clean the Hole

A clean hole is absolutely essential for a secure installation. Concrete dust and debris left in the hole can prevent the anchor from expanding fully, creating a weak connection that could fail under load. This is a vital part of installing drop in anchors.

Using a Wire Brush

After drilling, an installer should use a stiff wire brush to scrub the inside of the hole. The brush should have a diameter that matches the hole size. This action dislodges dust and particles that are compacted against the interior walls of the hole.

Using Compressed Air or a Blower

After brushing, the loosened debris must be removed. The industry-standard cleaning procedure is often called “Blow, Brush, Blow.” Professionals use compressed air at a minimum of 90 psi to forcefully blow all dust out of the hole.

Pro Tip: For maximum effectiveness, follow the 2x2x2 cleaning method. This involves blowing out the hole, brushing it thoroughly, and then blowing it out a second time. Repeating this cycle ensures the hole is completely free of debris before you use the drop in anchor setting tool in the next step.

Step 4: Insert and Set the Anchor

With a clean hole prepared, the next phase focuses on correctly setting the anchor. This two-part action creates the expansion that gives drop in anchors their formidable holding power. Proper execution here is essential for a secure and reliable fastening.

Inserting the Anchor

An installer begins by taking the anchor and placing it into the drilled hole. The open, threaded end should face upward, toward the surface. The anchor should slide into the hole easily. A light tap with a hammer may be necessary to seat it until its top is flush with or just below the concrete surface. This step prepares the anchor for expansion.

Using the Setting Tool and Hammer

Setting the anchor is the most crucial action when you install drop in anchors. The installer inserts the correct drop in anchor setting tool into the anchor body. The tool’s pin rests directly on the internal expander plug.

The installer then strikes the top of the setting tool firmly with a hammer. Several hard, sharp blows drive the plug downward, forcing the anchor’s slotted base to expand and grip the concrete. An installer can verify a correct set by observing the tool.

Verification Checklist ✅

- Insert the

drop in anchor setting toolinto the anchor.- Strike the tool with a hammer until it stops moving forward.

- A proper set is confirmed when the shoulder of the setting tool makes contact with the top of the anchor. This indicates the plug has traveled its full, required distance.

Step 5: Install the Fixture

Once the anchor is permanently set, the final step is to mount the desired object. This stage involves positioning the fixture and securing it with the appropriate threaded fastener. The process of installing drop in anchors concludes with a strong, load-bearing connection.

Positioning the Fixture

The installer places the fixture over the installed anchor. The mounting hole in the fixture must align perfectly with the threaded opening of the anchor set in the concrete. This ensures the bolt or rod will pass through the fixture and engage the anchor’s threads without obstruction.

Threading the Bolt or Rod

With the fixture in place, the installer inserts a threaded bolt or rod through the fixture’s hole and into the drop-in anchors. The bolt is screwed into the anchor until it feels snug. A wrench can then be used to secure it firmly. This final action completes the process of installing drop in anchors.

Critical Warning: Never apply excessive torque when tightening the bolt. Over-tightening can cause the entire anchor to spin within its hole. This rotation breaks the frictional grip on the concrete, severely compromising the anchor’s holding capacity and potentially leading to failure.

Common Applications and Uses for Drop-In Anchors

The strength and versatility of drop-in anchors make them a staple in numerous construction and industrial environments. Their ability to create a strong, flush, and threaded anchor point in concrete opens up a wide array of applications. The common uses for drop in anchors range from suspending essential building services to securing heavy industrial machinery, highlighting their importance in modern projects.

Industrial and Commercial Construction

In large-scale building projects, contractors rely on drop-in anchors for overhead installations. The anchor’s design allows for threaded rods to be suspended from concrete ceilings, providing secure support for critical infrastructure systems.

Suspending HVAC Ductwork

Installers frequently use these anchors to hang heating, ventilation, and air conditioning (HVAC) systems. Threaded rods are screwed into the anchors to support the heavy ductwork. Building codes, such as ASCE 7-16, provide strict guidelines for this work.

These codes mandate bracing for all suspended ductwork that meets certain criteria:

- It has a cross-sectional area of 6 square feet or greater.

- It weighs 20 pounds per linear foot or more.

The code also requires bracing for any ductwork carrying hazardous gases or used for smoke control. Revisions in ASCE 7-16 slightly increased the allowable design capacity for concrete anchorages, which can permit greater spacing between braces.

Installing Cable Trays and Conduits

Electricians use drop in anchors to mount cable trays and electrical conduits to concrete walls and ceilings. The flush-mount installation creates a clean and unobtrusive anchor point. This allows workers to run organized bundles of wiring throughout a facility, keeping them safely out of the way and compliant with electrical codes.

Securing Fire Sprinkler Systems

Fire sprinkler systems are a life-safety component, and their supports must be exceptionally reliable. Contractors use concrete drop-in anchors to suspend the network of pipes that make up these systems. The high tensile strength of the anchors ensures they can handle the weight of the water-filled pipes, providing a secure installation that can be trusted in an emergency.

Structural and Safety Fastening

Beyond building services, these fasteners play a crucial role in structural applications and safety installations. Their robust holding power is essential for components that protect personnel and support building elements.

Mounting Handrails and Guardrails

Safety is paramount in any commercial or industrial setting. Drop-in anchors provide the strength needed to securely mount handrails and guardrails to concrete stairs and walkways.

According to OSHA, guardrails are mandatory on any walking-working surface that is 4 feet or more above a lower level. These regulations also require a stair rail system for stairways with four or more steps. The anchors create a solid base that can withstand the forces specified in safety standards, preventing falls and enhancing workplace safety.

Anchoring Structural Steel Supports

While not typically used for primary structural connections, drop-in anchors are excellent for securing secondary structural steel elements. This includes anchoring steel support posts, base plates for columns, and bracing elements to concrete foundations or slabs. Their performance in solid concrete ensures a rigid and durable connection.

Heavy Machinery and Equipment

Factories and manufacturing plants use heavy machinery that generates significant vibration and operational forces. Drop-in anchors are well-suited for securing this type of equipment to concrete floors, preventing movement and ensuring operational stability.

Securing Conveyor Belts

Conveyor belt systems are the arteries of many industrial facilities. These anchors are used to bolt the support frames of conveyor systems to the concrete floor. This provides a stable foundation that can withstand the constant dynamic loads and vibrations produced by the moving belt and the materials it transports.

Bolting Down Manufacturing Equipment

Drop-in anchors are ideal for securing a wide variety of heavy machinery and equipment directly to concrete surfaces. Their ability to handle substantial loads makes them a reliable choice for permanent installations.

Common examples of equipment secured with these anchors include:

- Machine shop equipment like lathes and mills

- Large storage tanks and bulk tanks

- Generators and heavy electrical equipment

This application prevents machinery from “walking” or shifting during operation, which is critical for both safety and production accuracy.

Choosing the Right Drop-In Anchor for Your Project

Selecting the correct fastener is a critical decision that directly impacts the safety and integrity of an installation. Professionals must evaluate several key factors to choose the right drop-in anchors for a specific project. These factors include the type of load, the surrounding environment, and the properties of the base material.

Assessing Load Requirements

The first step is to understand the forces the anchor must resist. Loads are categorized as either static or dynamic, and this distinction is fundamental to proper anchor selection.

Static vs. Dynamic Loads

Different loads demand different anchoring solutions. It is crucial to match the anchor type to the load it will experience.

- Static loads are constant forces without movement. Most mechanical fasteners, including drop in anchors, are designed and tested for these applications.

- Dynamic loads involve constant movement or occasional heavy impacts. Mechanical anchors are generally not recommended for these high-stress situations, which are better suited for other anchoring systems.

Consulting Technical Data Sheets

Manufacturers provide technical data sheets for their products. These documents contain essential performance information, including ultimate tensile and shear strength values. Professionals must consult these sheets to verify that an anchor’s capacity exceeds the project’s calculated load requirements. A standard safety factor is always applied to determine a safe working load.

Environmental Considerations

The anchor’s material composition must be compatible with its service environment. Exposure to moisture and corrosive elements will dictate whether a standard or specialized anchor is necessary.

Interior vs. Exterior Use

The location of the installation is a primary consideration. Zinc-plated carbon steel anchors are a cost-effective and reliable choice for dry, indoor environments with stable humidity. For any outdoor project, stainless steel drop-in anchors are the appropriate choice due to their inherent ability to resist environmental corrosion.

Exposure to Moisture and Chemicals

For projects in wet, coastal, or chemically corrosive environments, stainless steel is the only safe option. Its composition includes chromium, which forms a protective layer that resists rust and degradation. A zinc coating on standard concrete drop-in anchors is sacrificial; it wears away over time, exposing the steel to corrosion and eventual failure.

Base Material Limitations

The performance of drop in anchors is entirely dependent on the quality and type of the base material they are installed into.

Why Solid Concrete is Essential

These anchors function by expanding and exerting immense outward pressure. This mechanism requires a dense, solid base material that can withstand these forces. Solid concrete provides the necessary resistance, allowing the anchor to generate the high friction needed for its holding power.

Unsuitability for Brick or Block

Installers must not use drop-in anchors in softer or hollow base materials like brick or concrete block (CMU). The expansion force can easily crack or shatter these materials, resulting in a complete failure of the anchor point. They are engineered exclusively for use in solid concrete.

Drop-In Anchors vs. Other Concrete Anchors

Choosing the right fastener requires comparing drop-in anchors to other common solutions. Each anchor type has a distinct mechanism, installation process, and ideal application. Understanding these differences helps professionals make the most effective choice for their project.

Drop-In Anchor vs. Wedge Anchor

Wedge anchors and drop-in anchors are both heavy-duty mechanical fasteners, but they function and install differently.

Installation Differences

A wedge anchor is a male-threaded stud that installs through a fixture. An installer drills a hole equal to the anchor’s diameter, inserts the anchor through the object being fastened, and tightens a nut. This tightening action pulls the stud upward, forcing a clip at the bottom to expand and wedge against the concrete. In contrast, concrete drop-in anchors are female-threaded and require a setting tool.

| Feature | Wedge Anchor | Drop-in Anchor |

|---|---|---|

| Installation Depth | Driven into concrete at least 4 inches | Driven into concrete by less than 1.5 inches |

| Ease of Use | Easier to manage for overhead installations | More challenging for overhead installations |

Use Case Comparison

Wedge anchors are ideal for through-bolting applications where the fixture is placed before the anchor is installed. They excel in securing base plates and structural elements. Drop-in anchors are better suited for applications requiring a flush surface or the ability to remove a bolt, such as for temporary bracing or equipment maintenance.

Drop-In Anchor vs. Sleeve Anchor

Sleeve anchors are versatile fasteners, but their mechanism and strength differ significantly from drop in anchors.

Mechanism and Strength

A sleeve anchor consists of a threaded bolt inside an expandable sleeve. As an installer tightens the bolt head or nut, a cone is pulled into the sleeve, causing it to expand and grip the base material. While effective, they generally offer lower holding values compared to the solid expansion of drop-in anchors in solid concrete.

When to Choose One Over the Other

Sleeve anchors are often a better choice for light to medium-duty applications or when working with various base materials like brick or block.

- They offer greater versatility and are simpler for DIY enthusiasts to install.

- Sleeve anchors facilitate immediate fixture installation without special tools.

- Drop-in anchors, while providing a flush mount, require a specialized setting tool.

Drop-In Anchor vs. Epoxy Anchor

Epoxy anchors represent a completely different category of fastening technology that relies on chemical adhesion rather than mechanical expansion.

Mechanical vs. Chemical Anchoring

Mechanical anchors, like drop-ins, create a friction hold by expanding against the concrete. Chemical anchors, including epoxy types, use a two-part adhesive that is injected into the hole. An installer inserts a threaded rod, and the epoxy cures to form an incredibly strong bond with both the rod and the surrounding concrete.

Load Times and Performance

Epoxy anchors generally offer higher tensile capacity than mechanical anchors of the same size. They create a stress-free bond, making them suitable for brittle materials or installations close to an edge. Their performance under vibration is a key advantage.

An expert in vibration control states they never recommend expansion anchors for dynamic loads due to their tendency to loosen. Epoxy anchors are a superior choice for applications involving vibratory loads.

The main trade-off is cure time. Mechanical anchors can be loaded immediately, while epoxy anchors require a specific curing period before they can bear any weight.

Drop in anchors offer a reliable and robust fastening solution for heavy-duty applications in solid concrete. Their primary benefit is creating a strong, flush anchor point that allows for bolt removal. Correct installation is essential for achieving the maximum holding power of drop in anchors. Professionals must avoid common mistakes.

Key installation errors to prevent include:

- Drilling an incorrect hole size.

- Failing to clean debris from the hole.

- Over-tightening the anchor bolt.

Understanding these steps ensures professionals can confidently use concrete drop-in anchors for many projects.

FAQ

Can you reuse a drop-in anchor?

An installer cannot reuse the anchor body itself. The expansion process permanently deforms the metal sleeve. However, a key feature is the ability to remove and replace the threaded bolt or rod as many times as needed.

What happens if the hole is too big?

A hole that is too large is a critical error. The anchor will not expand enough to create the necessary friction against the concrete. This results in a very weak connection that cannot support the specified load and will likely fail.

Are drop-in anchors suitable for overhead use?

Yes, installers frequently use drop-in anchors for overhead applications. They are ideal for suspending items like HVAC ductwork, cable trays, and fire sprinkler pipes from concrete ceilings. Proper installation is absolutely critical for safety in these situations.

Why is a special setting tool required?

The setting tool is engineered to drive the internal plug the exact distance needed for full expansion. Using an improper tool, like a simple punch, can lead to an incomplete set, severely compromising the anchor’s holding power.

Can you install drop-in anchors close to a concrete edge?

Installers must maintain a minimum distance from any unsupported concrete edge. The anchor’s expansion force creates high stress. Placing it too close can crack the concrete, causing the anchor point to fail. Always consult the manufacturer’s technical data for spacing requirements.

How do you remove a drop-in anchor?

Removing the anchor body is not practical as it is designed for permanent installation. An installer can drill it out, but this process damages the surrounding concrete. The main advantage is removing the bolt, leaving the anchor flush within the concrete.